Top 30 Plastic L Channel Manufacturers You Should Know

Are you struggling to find the right plastic L channel supplier for your next project? With so many options out there, it can feel overwhelming. The wrong choice could lead to delays, poor quality, or unnecessary costs—nobody wants that! But fear not! In this article, we’re diving into the top 30 plastic L channel factories and manufacturers that can elevate your production game. Choosing a reputable supplier not only ensures high-quality materials but also streamlines your entire workflow.

Get ready to discover the best in the business, so you can make informed decisions that benefit your projects. Don’t miss out—read on to find the perfect supplier for your needs!

Top 30 Plastic L Channel Manufacturers

McMaster-Carr – Plastic L-Channels and Structural Components

Domain: mcmaster.com

Registered: 1994 ( 31 years )

Introduction: Plastic L-Channels offered by McMaster-Carr are versatile structural components used in various applications.

Jifram – Custom Tooling and Extrusion Solutions

Domain: jifram.com

Registered: 2000 ( 25 years )

Introduction: L Channels for in-house tooling and extrusions.

Lowes – Clear Polycarbonate Plastic Channels

Domain: lowes.com

Registered: 1995 ( 30 years )

Introduction: Plastic Channels available in various sizes and styles, including H and U channels, primarily made from clear polycarbonate.

Boogeylights – LED Lighting Channel Solutions

Domain: boogeylights.com

Registered: 1999 ( 26 years )

Introduction: Plastic L Channel for LED lighting applications.

Displayproducts Online – L-Channel Extrusions Solutions

Domain: displayproductsonline.com

Registered: 2010 ( 15 years )

Introduction: The company offers L-channel extrusions for various display applications.

Petro Packaging – Custom Plastic L Channel Extrusions

Domain: petropackaging.com

Registered: 1998 ( 27 years )

Introduction: Petro Packaging offers custom plastic L channel extrusions made from various polymers, designed to provide smooth and safe edges for a variety of applications.

Richelieu – Functional Molding Solutions

Domain: richelieu.com

Registered: 1996 ( 29 years )

Introduction: L-Channel from Richelieu Hardware is a functional molding designed for various applications in cabinetry and construction.

Plastic Depot – Clear Plastic Solutions

Domain: plastic-depot.com

Registered: 2016 ( 9 years )

Introduction: L Channel Clear is a versatile plastic product designed for various applications, offering durability and clarity.

TP Extrusions – PVC Channels and Fabricated Solutions

Domain: tpextrusions.com

Registered: 2005 ( 20 years )

Introduction: TP Extrusions Ltd offers a variety of plastic PVC channels, including capping channels, clip-on channels, variant channels, double and single sliding tracks, and fabricated channels.

Usplastic – Polyethylene Containers with Screw-On Lids

Domain: usplastic.com

Registered: 1996 ( 29 years )

Introduction: Polyethylene containers with screw-on lids, suitable for various applications.

Mkmplastics – PVC Profiles and Angles Online

Domain: mkmplastics.com

Registered: 1999 ( 26 years )

Introduction: Plastic PVC profiles including Angles available for online purchase.

Home Depot – PVC Moulding Solutions

Domain: homedepot.com

Registered: 1992 ( 33 years )

Introduction: 1/2 in. D x 5/16 in. W x 96 in. L Clear PVC Plastic U-Channel Moulding Fits 1/4 in. Board, (13-Pack)

Forum – Plastic L Channel Solutions

Iqsdirectory – Plastic Channels and Profiles Solutions

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

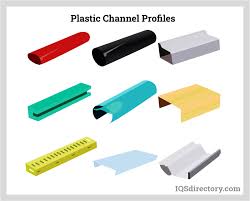

Introduction: Plastic channels are linear, extruded profiles with a uniform cross-section, used for trim edging, connectors, sealants, insulators, panels, guides, and structural elements. They are made from various thermoplastic materials such as PVC, CPVC, ABS, HIPS, Green RoHS Vinyl, and Polyethylene.

Bunnings – PVC Mouldings for Construction

Domain: bunnings.com.au

Registration year: Not available

Introduction: PVC mouldings for various building and construction applications.

Gltileproducts – Tile Transition Trims and Solutions

Domain: gltileproducts.com

Registered: 2001 ( 24 years )

Introduction: L Channels are widely used transition trims primarily designed to transition from tile to carpet, protecting the tile’s edge from chipping. They can also serve as corner guards on vertical wall applications and are available in numerous finishes to coordinate with various tile or stone selections.

Indiamart – PVC L Shape Corner Angles

Domain: indiamart.com

Registered: 1996 ( 29 years )

Introduction: PVC L Shape Corner Angle, Thickness: 3 mm

Extrudedplastics – Custom Linear Plastic Channels

Domain: extrudedplastics.com

Registered: 2000 ( 25 years )

Introduction: Plastic channels are linear extruded profiles that can be extruded to any length for use as trim, insulators, sealants, connectors and gutters.

Grainger – Plastic Angles and Structural Components

Domain: grainger.com

Registered: 1994 ( 31 years )

Introduction: Plastic angles are structural components made from various types of plastic materials, designed for use in a variety of applications.

Barbour Plastics – Flexible Vinyl Channel Profiles

Domain: barbourplastics.com

Registered: 1998 ( 27 years )

Introduction: Barbour Plastics offers a variety of flexible channel profiles produced from high quality flexible vinyl material, suitable for various wall thicknesses between 1/32″ to 1 1/2″.

Ustrenchdrain – Heavy Duty Trench Drain Solutions

Domain: ustrenchdrain.com

Registered: 2015 ( 10 years )

Introduction: Deep Series 5.4 in. W x 5.4 in. D x 39.4 in. L Channel and Grate – US TRENCH DRAIN – Divert Any Pooling Water With Heavy Duty Trench Drains

Lakeland Plastics – Custom Plastic Extrusions

Domain: lakelandplastics.com

Registered: 1998 ( 27 years )

Introduction: Custom plastic extrusions for designers and engineers, including made-to-order extruded profiles and shapes using available tooling.

Redwood Plastics – Industrial Plastic and Rubber Solutions

Domain: redwoodplastics.com

Registered: 1999 ( 26 years )

Introduction: Redwood Plastics and Rubber offers a wide range of industrial plastic and rubber products, including channel profiles, bushings, bearings, liners, and custom molded solutions.

Evergreen Scale Models – Polystyrene Model Building Materials

Domain: evergreenscalemodels.com

Registered: 2002 ( 23 years )

Introduction: Evergreen Scale Models offers a variety of model building materials primarily made from polystyrene, including strips, rods, tubes, shapes, siding, roofing, sheets, adhesives, displays, and tools.

MSC Direct – Industrial Supply Solutions

Calcresource – Geometric Calculations for Structural Engineering

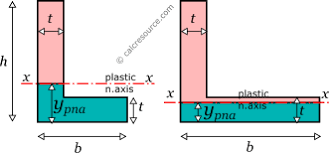

Domain: calcresource.com

Registered: 2016 ( 9 years )

Introduction: The company offers detailed calculations and methodologies for determining geometric properties, moments of inertia, and section moduli of angle cross-sections, particularly focusing on L-sections used in structural engineering.

Paul Murphy Plastics – Custom Plastic Extrusions

Domain: paulmurphyplastics.com

Registered: 1999 ( 26 years )

Introduction: Paul Murphy Plastics specializes in producing high-quality plastic channels tailored to meet the needs of various industries, with custom extrusion capabilities for any shape or dimension.

Ctekleansolutions – L Channel White Solutions

Domain: ctekleansolutions.com

Registered: 2017 ( 8 years )

Introduction: L Channel White 50mm x 75mm T4 Thick 3M

Dkhardware – Mirror Mounting Solutions

Domain: dkhardware.com

Registered: 2006 ( 19 years )

Introduction: L-Bar and other mirror channels for mounting and supporting mirrors in various applications.

Intek Plastics – Extruded Plastic Channels Solutions

Domain: intekplastics.com

Registered: 1997 ( 28 years )

Introduction: Intek Plastics offers a range of extruded plastic channels and display solutions for the Point of Purchase (POP) industry, including C Channels, H Channels, J Channels, L Channels, and U Channels, among others.

Category Information

Plastic L channels are structural components commonly used in various industries, including construction, manufacturing, and DIY projects. These L-shaped profiles are made from durable plastic materials, providing a lightweight yet sturdy option for framing, edging, and support applications. Their design allows for easy installation and versatility in use, making them ideal for both indoor and outdoor settings.

The significance of plastic L channels lies in their ability to resist corrosion and weathering, which makes them suitable for environments where metal alternatives may fail. They are often used in applications such as signage, window framing, and protective barriers. Additionally, their low maintenance requirements and recyclability contribute to sustainable practices in construction and manufacturing, making them an increasingly popular choice among builders and designers.

Application Information

Plastic L channels are versatile components widely used across various industries due to their durability and lightweight properties. One primary application area is in construction and building materials, where they serve as edge protection, framing, and support for structures such as walls and ceilings. Their resistance to moisture and corrosion makes them ideal for environments prone to dampness. Another significant application is in the manufacturing sector, particularly in the production of custom displays and fixtures.

Retail environments often utilize plastic L channels to create attractive product displays and signage. Additionally, these channels are commonly found in the packaging industry, where they are used to create protective barriers and supports for fragile items during shipping. Overall, plastic L channels provide essential solutions in construction, manufacturing, and packaging, demonstrating their broad utility across diverse fields.

Production Process Information

The production of plastic L channels involves several key stages. First, raw materials, primarily plastic pellets, are sourced. These pellets are often made from types of plastic like PVC or polypropylene, chosen for their strength and flexibility. Next, the plastic pellets are heated and melted in an extrusion machine. This machine shapes the molten plastic into a continuous L-shaped channel as it cools and solidifies.

Once formed, the channels are cut to the desired lengths and undergo quality control checks to ensure they meet specifications. Finally, the finished products are packaged and prepared for shipping. Throughout the process, considerations such as material selection, production efficiency, and environmental impact are crucial to ensure high-quality and sustainable products.

Related Video

Frequently Asked Questions (FAQs)

How do I find reliable plastic L channel manufacturers?

Start by researching online directories, trade websites, and industry forums. Look for manufacturers with positive reviews and a solid reputation. Attending trade shows and exhibitions can also help you meet potential suppliers face-to-face and assess their offerings.

What should I consider when choosing a plastic L channel supplier?

Evaluate the supplier’s experience, product quality, and range of services. Check their certifications and compliance with industry standards. Additionally, consider their production capacity, lead times, and customer service to ensure they can meet your needs.

How can I assess the quality of plastic L channels from a manufacturer?

Request samples to evaluate the material and craftsmanship. Look for consistent dimensions, smooth finishes, and durability. You can also ask for test reports or certifications that demonstrate compliance with quality standards.

What are the typical minimum order quantities (MOQs) for plastic L channels?

MOQs can vary significantly between manufacturers. Some may offer low MOQs for custom orders, while others may require larger quantities for cost-effectiveness. Always inquire about MOQs upfront to avoid surprises during the ordering process.

Are there specific certifications I should look for in plastic L channel suppliers?

Yes, look for certifications like ISO 9001 for quality management and any specific industry-related certifications relevant to your application. These certifications indicate that the manufacturer adheres to high standards in production and quality control.