Top 18 Companies for Screw Conveyor Parts & Components

Are you tired of dealing with unreliable screw conveyor parts that slow down your operations? You’re not alone! Many businesses face the frustration of sourcing high-quality components that can withstand the rigors of daily use. Finding the right supplier can transform your workflow, enhance productivity, and save you money in the long run. Imagine having durable, efficient parts that keep your systems running smoothly, day in and day out.

In this article, we’ve compiled a list of the top 30 screw conveyor parts factories and manufacturers. Discover who stands out in quality, reliability, and customer service. Don’t miss out on the chance to elevate your operations—read on to find the perfect partner for your needs!

Top 18 Screw Conveyor Parts Manufacturers

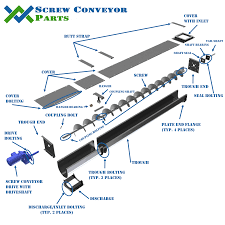

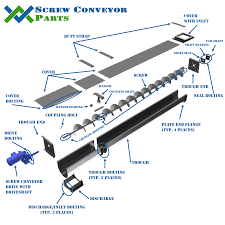

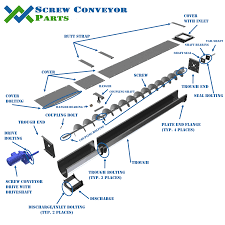

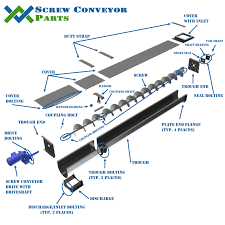

Screw Conveyor Parts – Screw Conveyor Components & Kits

Domain: screwconveyorparts.com

Registered: 2015 ( 10 years )

Introduction: SCP offers a wide range of screw conveyor parts including buttstraps, discharge/inlet bolting, troughs, plate end flanges, seal bolting, trough ends, shaft seals, shaft bearings, and tail shafts. They also provide entire screw conveyor kits for bulk material handling.

KWS Manufacturing – Screw Conveyors and Elevators

Domain: kwsmfg.com

Registered: 1997 ( 28 years )

Introduction: KWS Manufacturing Company specializes in the design and manufacture of screw conveyors, feeders, component parts, and bucket elevators.

Screw Conveyor Corporation – Custom Screw Conveyor Solutions

Domain: screwconveyor.com

Registered: 1996 ( 29 years )

Introduction: Screw Conveyor Corporation offers screw conveyors that are easy to install, simple to maintain, and adaptable for transporting bulk materials. They provide a wide range of designs and materials, including Helicoid and Sectional Flights, as well as options for ribbon, special pitch, or tapered configurations.

Screw Conveyor Bega – Auger Screw Parts & Components

Domain: screwconveyorbega.com

Registered: 2019 ( 6 years )

Introduction: Screw Conveyor and Auger Screw Parts & Components, including ‘U’ troughs, designed for horizontal applications or up to 20 degrees without modifications.

Motion – Screw Conveyor Solutions

Applied – Screw Conveyor Components and Accessories

Domain: applied.com

Registered: 1993 ( 32 years )

Introduction: Screw conveyor components including screws, troughs, and accessories designed for efficient material handling.

Mrosupply – Screw Conveyor Accessories and Components

Domain: mrosupply.com

Registered: 1998 ( 27 years )

Introduction: Screw conveyor accessories including various components designed to enhance the functionality and efficiency of screw conveyors.

Spiroflow – Bulk Handling Equipment Solutions

Domain: spiroflow.com

Registered: 1996 ( 29 years )

Introduction: Spiroflow offers a range of bulk handling equipment including conveyor solutions, bulk bag fillers, bulk bag unloaders, and additional equipment for various industries.

Grainger – Material Handling Conveyors and Components

Domain: grainger.com

Registered: 1994 ( 31 years )

Introduction: Grainger offers a variety of conveyors and components designed for material handling, including belt conveyors, roller conveyors, and conveyor accessories.

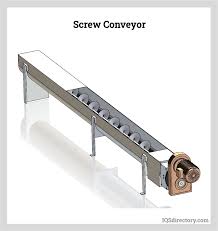

Iqsdirectory – Screw Conveyors and Material Handling Solutions

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

Introduction: Screw conveyors, also known as auger conveyors, are industrial machines designed to efficiently move large quantities of granular materials, semi-solids, liquids, and materials that do not flow easily.

Syntronmh – Screw Conveyor Components and Systems

Domain: syntronmh.com

Registered: 2014 ( 11 years )

Introduction: Syntron Material Handling offers a range of screw conveyor components designed for efficient material handling in various industries. Their products include engineered screw conveyor systems and various components that enhance the performance of screw conveyors.

McMaster-Carr – Conveyor Parts and Material Handling Solutions

Domain: mcmaster.com

Registered: 1994 ( 31 years )

Introduction: McMaster-Carr offers a wide range of conveyor parts including rollers, guides, brackets, and belts, designed to facilitate material handling in various applications.

Ibtinc – Custom Screw Conveyor Systems

Domain: ibtinc.com

Registered: 1996 ( 29 years )

Introduction: Custom-engineered screw conveyor systems, including a wide selection of parts and accessories such as conveyor screws, shafts, hangers, troughs, seals, covers, and drive reducers.

McClamroch Ag – Screw Conveyor Solutions

Domain: mcclamrochag.com

Registered: 2024 ( 1 years )

Introduction: McClamroch Ag/Perry Equipment offers screw conveyor parts and complete units, providing turnkey solutions including complete drive packages and custom lengths.

Nbe Inc – Flexible Screw Conveyor Solutions

Domain: nbe-inc.com

Registered: 1997 ( 28 years )

Introduction: Flexible screw conveyors designed for efficient bulk material handling.

Fescodirect – Screw Conveyor Parts for Batching Plants

Domain: fescodirect.com

Registered: 2009 ( 16 years )

Introduction: Screw conveyor parts for concrete batching plants, including new, used, and replacement components.

Jmsequipment – Shafted Screw Conveyors and Wear Parts

Domain: jmsequipment.com

Registered: 2008 ( 17 years )

Introduction: Shafted screw conveyors designed for material handling with a focus on wear parts such as head and tail bearings and hanger bearings.

Rexnord – Conveyor Components and Solutions

Domain: rexnord.com

Registered: 1996 ( 29 years )

Introduction: Rexnord offers a range of conveyor components as part of their conveying solutions, including KleanTop conveyor belts, MatTop and TableTop chains, metal conveyor belts, turn and spiral cage belts, and conveyor sprockets.

Category Information

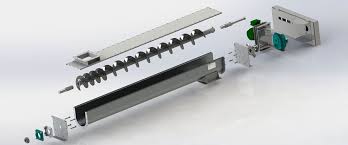

Screw conveyor parts are essential components of screw conveyors, which are mechanical devices used to transport bulk materials in various industries. These systems utilize a helical screw blade, known as a screw flight or auger, that rotates within a tube or trough to move materials efficiently. Key parts include the screw flights, troughs, shafts, bearings, and end plates, each playing a crucial role in the conveyor’s functionality and durability.

The significance of screw conveyor parts lies in their ability to facilitate the movement of granular, powdered, or bulk materials with minimal effort and maximum efficiency. Industries such as agriculture, mining, and manufacturing rely heavily on these systems for their material handling needs, as they offer reliable performance, adaptability to different materials, and ease of maintenance. Understanding the various components is vital for optimizing conveyor design and ensuring smooth operation, thereby enhancing productivity and reducing downtime.

Application Information

Screw conveyor parts are integral to various industries that require efficient material handling. One prominent application area is in the agriculture sector, where screw conveyors are used for transporting grains, seeds, and fertilizers. Their ability to handle bulk materials in a controlled manner makes them ideal for processing plants and farms. Another key application is in the food processing industry, where hygiene and precision are paramount.

Screw conveyors facilitate the movement of ingredients, such as flour, sugar, and other bulk food items, ensuring consistent flow and minimizing contamination risks. Additionally, mining and mineral processing heavily rely on screw conveyors for transporting ores, aggregates, and other materials, owing to their durability and adaptability in rugged environments. Overall, screw conveyor parts play a crucial role in enhancing operational efficiency across these sectors, streamlining processes, and improving productivity.

Production Process Information

The production of screw conveyor parts involves several key stages to ensure high-quality components for material handling systems. First, the design stage is crucial, where engineers create detailed blueprints based on the specific needs of the application, considering factors like capacity and materials to be moved. Next comes the material selection and procurement. Common materials include stainless steel and carbon steel, chosen for their durability and resistance to wear.

Once materials are ready, the manufacturing process begins, which typically involves cutting, shaping, and welding parts like the screw itself, tubes, and flanges. Finally, the assembly and quality control stages ensure that all components fit together correctly and meet safety standards. After thorough testing, the finished screw conveyor parts are packaged and prepared for delivery to customers, ready to efficiently transport bulk materials in various industries.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a screw conveyor parts manufacturer?

When choosing a manufacturer, consider their experience in the industry, quality of materials used, customization options, and production capacity. Look for certifications that demonstrate quality control, and read reviews or testimonials from previous clients to gauge their reliability and service.

How can I ensure the quality of screw conveyor parts?

Request samples or prototypes before placing a large order. Check if the manufacturer adheres to industry standards and has a robust quality assurance process. Certifications like ISO can also indicate a commitment to quality.

What is the typical lead time for screw conveyor parts?

Lead times can vary based on the complexity of the parts and the manufacturer’s workload. Typically, you can expect anywhere from a few weeks to a couple of months. Always ask for an estimated timeline during your initial discussions.

Are custom screw conveyor parts available?

Yes, many manufacturers offer customization options to meet specific requirements. Be sure to communicate your needs clearly, including dimensions, materials, and any special features, to ensure the manufacturer can accommodate your request.

How do I compare prices between different manufacturers?

When comparing prices, ensure you’re looking at similar quality and specifications. Request detailed quotes that break down costs, including materials, labor, and shipping. Remember, the cheapest option isn’t always the best; consider quality and service as well.