Unlock Competitive Advantage with Expert Aluminum Trim

Introduction: Navigating the Global Market for aluminum trim

Navigating the global market for aluminum trim is essential for B2B buyers aiming to enhance product quality and meet the increasing demands of diverse industries. Aluminum trim is not just a functional element; it plays a vital role in providing durability, aesthetic appeal, and structural integrity across applications in construction, automotive, furniture, and packaging sectors. As the global landscape evolves, understanding the nuances of aluminum trim is critical for maintaining a competitive edge.

This comprehensive guide covers a wide array of topics to empower decision-makers in their sourcing endeavors. Buyers will find detailed insights into the various types of aluminum trim, the materials used, and essential manufacturing and quality control processes that ensure optimal performance. Additionally, the guide addresses crucial factors like supplier reliability, cost evaluation, and current market trends that could influence purchasing decisions.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—including key markets like Poland and the UK—this guide serves as a valuable resource. By providing actionable insights and data-driven analysis, it aims to facilitate informed sourcing decisions that align with regional market dynamics and specific business objectives. Understanding the complexities of aluminum trim can significantly impact operational success and product quality, making this guide an indispensable tool for savvy buyers in today’s competitive marketplace.

Illustrative Image (Source: Google Search)

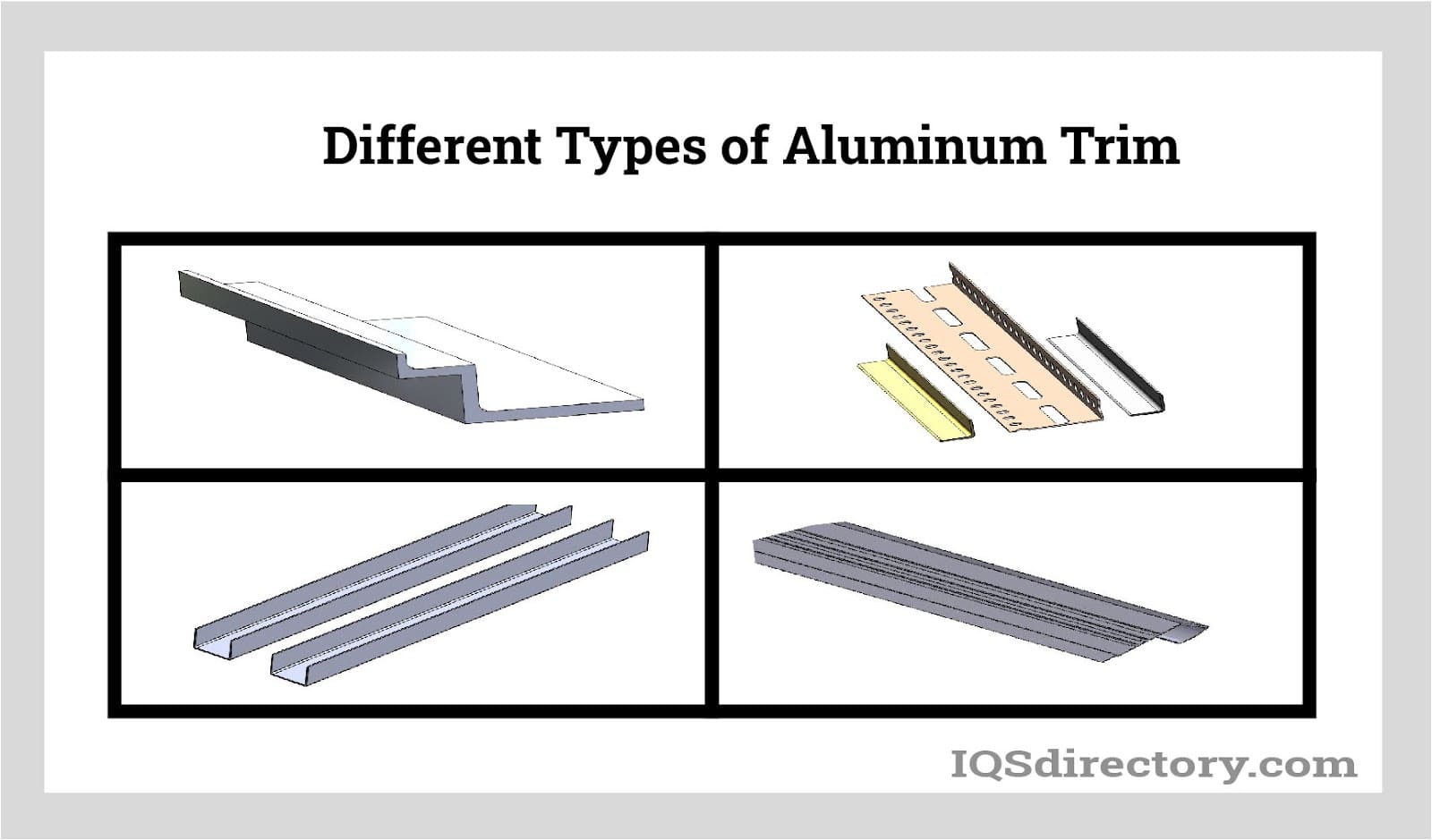

Understanding aluminum trim Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Edging Trim | Simple, flat design; easy to install | Flooring, countertops, signage | Pros: Cost-effective, versatile. Cons: Limited aesthetic appeal. |

| L-Shape Edging Trim | L-shaped profile; provides a clean finish | Wall corners, furniture edges | Pros: Durable, enhances appearance. Cons: Installation complexity. |

| T-Molding Trim | T-shaped profile; ideal for transitions | Flooring transitions, doorways | Pros: Smooth transitions, conceals gaps. Cons: May require precise cutting. |

| Capping Trim | Covers edges; protects from wear and tear | Roof edges, furniture tops | Pros: Protective barrier, aesthetic finish. Cons: Higher cost. |

| Beaded Edging Trim | Decorative beads for enhanced visual appeal | Decorative furniture, displays | Pros: Attractive design, adds texture. Cons: More expensive, niche applications. |

Flat Edging Trim

Flat edging trim is characterized by its straightforward design, making it an economical choice for a variety of applications such as flooring, countertops, and signage. Its ease of installation is a significant advantage for large projects, allowing for quick deployment and minimal labor costs. However, buyers should be mindful of its limited aesthetic appeal, which may not align with high-end design requirements. When sourcing, consider the volume of your project and the potential for bulk purchasing discounts.

L-Shape Edging Trim

The L-shape edging trim is favored for its ability to provide a polished finish at wall corners and furniture edges. This type is particularly durable, enhancing both the functionality and aesthetics of spaces. While it requires skilled labor for installation, making it potentially more expensive, its long-term benefits in terms of durability and visual appeal can justify the initial investment. Buyers should assess their available installation resources and consider the trim’s compatibility with their overall design vision.

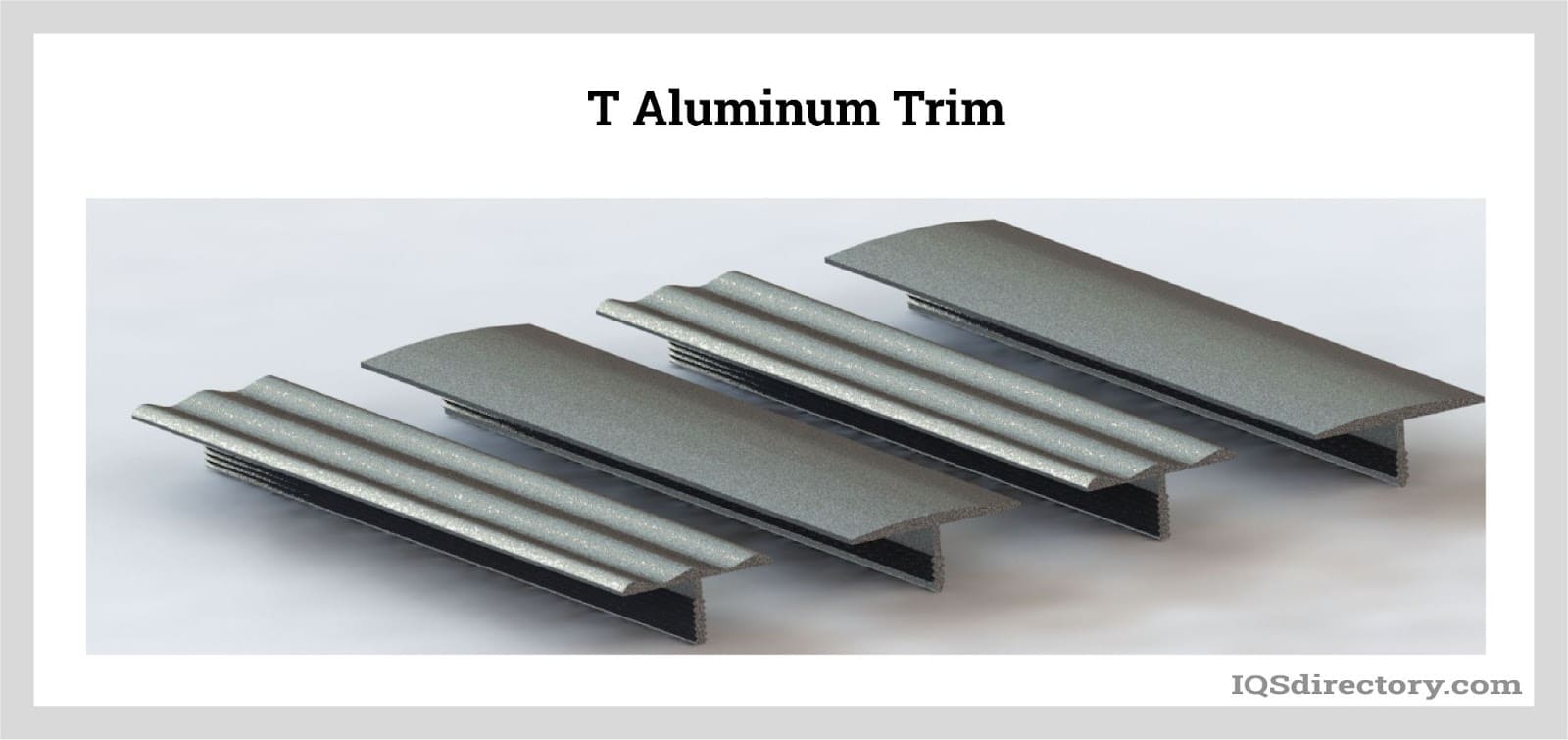

T-Molding Trim

T-molding trim excels in creating seamless transitions between different flooring types or covering gaps at doorways. Its T-shaped profile allows for a snug fit, making it ideal for environments where aesthetics and functionality are critical. However, precise cutting is necessary for optimal installation, which may necessitate additional tools or expertise. B2B buyers should evaluate their installation capabilities and the specific requirements of their projects when considering this trim type.

Capping Trim

Capping trim serves as a protective edge for various surfaces, notably on roofs and furniture tops, guarding against wear and tear. This trim not only enhances the durability of the surfaces it covers but also contributes to the overall aesthetic appeal. While it tends to be more expensive than other trim options, its long-term protective benefits can make it a wise investment. Buyers should weigh their budget against the need for enhanced protection and consider sourcing from suppliers with a strong reputation for quality.

Beaded Edging Trim

Beaded edging trim is designed to add a decorative touch to furniture and displays, featuring textured beads that enhance visual appeal. This type is commonly used in high-end applications where aesthetics play a crucial role. Although it comes at a higher price point and is often limited to niche applications, its attractive design can significantly elevate the overall look of a product. Buyers should consider the balance between aesthetic desires and budget constraints when selecting beaded edging trim for their projects.

Related Video: How to aluminum wrap trim (detailed with tips and tricks)

Key Industrial Applications of aluminum trim

| Industry/Sector | Specific Application of Aluminum Trim | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Edge protection for flooring installations | Enhances safety, reduces maintenance costs | Durability, corrosion resistance, compliance with local standards |

| Automotive | Trim for vehicle interiors | Aesthetic appeal, weight reduction | Lightweight materials, thermal stability, custom shapes available |

| Electronics | Enclosures for electronic devices | Protects components, enhances product lifespan | Precision manufacturing, thermal management, compliance certifications |

| Furniture Manufacturing | Decorative trim for furniture | Enhances aesthetic value, increases marketability | Design flexibility, surface finishes, sustainable sourcing options |

| Packaging | Edge reinforcement for packaging solutions | Increases durability, improves shelf appeal | Material quality, customization options, regulatory compliance |

Construction

In the construction industry, aluminum trim is extensively used for edge protection in flooring installations. By providing a robust barrier against wear and tear, it enhances safety and reduces maintenance costs over time. For international buyers, especially in regions like Africa and South America, sourcing durable and corrosion-resistant aluminum trim is critical. Compliance with local building codes and standards is also essential to ensure the trim meets safety regulations.

Illustrative Image (Source: Google Search)

Automotive

Aluminum trim is integral to vehicle interiors, offering both aesthetic appeal and weight reduction, which contributes to improved fuel efficiency. The automotive sector demands lightweight materials that maintain thermal stability, making aluminum an ideal choice. Buyers from the Middle East and Europe should focus on suppliers that can provide custom shapes and finishes to meet specific design requirements while ensuring compliance with automotive standards.

Electronics

In the electronics sector, aluminum trim is utilized for enclosures that protect sensitive components. This application not only safeguards devices but also enhances their overall lifespan. International B2B buyers must prioritize precision manufacturing capabilities and thermal management features when sourcing aluminum trim for electronics. Additionally, compliance with industry certifications is crucial to ensure product reliability and safety in various environments.

Furniture Manufacturing

Aluminum trim is increasingly popular in furniture manufacturing, where it serves as decorative trim that enhances the aesthetic value of products. This application is particularly beneficial in high-end markets, where appearance can significantly impact sales. Buyers should consider design flexibility and available surface finishes when sourcing aluminum trim. Sustainable sourcing options are also becoming important, particularly in Europe, where eco-conscious consumers are prevalent.

Packaging

In the packaging industry, aluminum trim is used for edge reinforcement in various packaging solutions, enhancing durability and improving shelf appeal. This application is vital for products that require robust protection during transit and display. B2B buyers should focus on material quality and customization options to meet specific packaging needs. Additionally, understanding regulatory compliance is essential to ensure that the packaging meets industry standards in different markets.

Related Video: Extrusions 101: Aluminum Extrusion Process Explained – INO USA

Strategic Material Selection Guide for aluminum trim

When selecting aluminum trim for various applications, the choice of material is crucial to ensuring optimal performance and longevity. Here, we analyze four common materials used in aluminum trim, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Aluminum Alloy 6063

Aluminum alloy 6063 is widely used in aluminum trim due to its excellent extrudability and surface finish. It offers good corrosion resistance and is suitable for architectural applications. With a temperature rating of up to 150°C, it performs well in moderate thermal environments.

Pros: The alloy is lightweight, has good weldability, and can be easily anodized for enhanced durability.

Cons: While it is durable, it may not withstand extreme mechanical stress as well as some other alloys.

Impact on Application: It is ideal for applications in construction and decorative trim where aesthetics and moderate strength are required.

Considerations for International Buyers: Compliance with standards such as ASTM B221 and EN 573 is essential. Buyers in Europe and the Middle East should ensure suppliers meet local regulations regarding material safety and quality.

2. Aluminum Alloy 6061

Aluminum alloy 6061 is known for its high strength-to-weight ratio and is often used in structural applications. It has a temperature rating of up to 200°C and offers excellent corrosion resistance, making it suitable for outdoor applications.

Pros: This alloy is highly versatile and can be heat-treated for increased strength, making it suitable for demanding environments.

Cons: The manufacturing process is more complex and can lead to higher costs compared to other alloys.

Impact on Application: It is commonly used in automotive and aerospace applications where strength and durability are critical.

Considerations for International Buyers: Buyers should verify compliance with international standards such as ASTM B221 and JIS H 4000. In regions like Africa and South America, understanding local sourcing capabilities and costs is vital.

3. Aluminum Alloy 5005

Aluminum alloy 5005 is often selected for its aesthetic qualities and good corrosion resistance. It is commonly used in applications where appearance is important, such as in decorative trim.

Pros: The alloy provides a smooth surface finish and is available in various colors through anodizing.

Cons: While it is visually appealing, it may not be as strong as other alloys, limiting its use in load-bearing applications.

Impact on Application: This alloy is ideal for decorative applications in furniture and signage, where aesthetics outweigh structural requirements.

Considerations for International Buyers: Compliance with standards such as ASTM B209 is important. Buyers should also consider the availability of color options and finishes that meet local market preferences.

4. Aluminum Alloy 7075

Aluminum alloy 7075 is known for its exceptional strength and is often used in high-stress applications. It has a temperature rating of up to 120°C and offers good corrosion resistance, especially when anodized.

Pros: This alloy is one of the strongest aluminum alloys available, making it suitable for aerospace and military applications.

Cons: The high cost and complex manufacturing process can be prohibitive for some applications.

Impact on Application: It is primarily used in aerospace and defense applications where high strength is paramount.

Considerations for International Buyers: Buyers must ensure compliance with stringent standards such as ASTM B209 and military specifications. Understanding the supply chain for such specialized materials is crucial, especially in regions with limited access to advanced manufacturing capabilities.

Summary Table

| Material | Typical Use Case for aluminum trim | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy 6063 | Architectural trim, decorative applications | Excellent extrudability, good aesthetics | Limited mechanical strength | Medium |

| Aluminum Alloy 6061 | Structural applications in automotive/aerospace | High strength-to-weight ratio | More complex manufacturing process | High |

| Aluminum Alloy 5005 | Decorative trim in furniture/signage | Attractive finish, good corrosion resistance | Lower strength compared to others | Medium |

| Aluminum Alloy 7075 | Aerospace and military applications | Exceptional strength | High cost, complex manufacturing | High |

This analysis provides international B2B buyers with critical insights into material selection for aluminum trim, ensuring informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum trim

Aluminum trim manufacturing involves several critical stages, each contributing to the final product’s quality and performance. For international B2B buyers, understanding these processes is vital for sourcing high-quality aluminum trim that meets specific project needs. Below, we delve into the manufacturing processes and the associated quality assurance measures that ensure compliance with industry standards.

Manufacturing Processes for Aluminum Trim

1. Material Preparation

The initial step in the manufacturing process involves sourcing high-quality aluminum alloys, typically from the 6000 series, known for their excellent extrudability and weldability. Buyers should ensure that suppliers use aluminum with mechanical properties that align with project requirements.

- Key Techniques:

- Alloy Selection: Identifying the appropriate alloy based on strength, corrosion resistance, and application.

- Quality Inspection: Conducting incoming quality control (IQC) checks on raw materials to verify compliance with specifications.

2. Forming

This stage involves transforming raw aluminum into the desired trim shape through various forming techniques. The most common methods include extrusion, stamping, and bending.

- Extrusion: This method forces heated aluminum through a die to create continuous profiles, ideal for producing uniform shapes like L-shaped or T-molding trims.

- Stamping and Bending: Suitable for creating more intricate designs or custom shapes, these techniques may involve using dies and presses to achieve precise configurations.

3. Assembly

Once the trim pieces are formed, they may need to be assembled with other components, especially in more complex applications.

- Joining Techniques:

- Welding: Commonly used for permanent joints, ensuring structural integrity.

- Mechanical Fastening: Includes screws, rivets, or clips for ease of disassembly or replacement.

4. Finishing

The finishing process enhances the aesthetic appeal and protective qualities of aluminum trim. This stage may include anodizing, powder coating, or applying other surface treatments.

- Anodizing: This electrochemical process improves corrosion resistance and allows for dyeing, which adds color and enhances durability.

- Powder Coating: A technique that applies a dry powder to the aluminum surface, which is then cured to form a hard, protective layer.

Quality Assurance in Aluminum Trim Manufacturing

Quality assurance is paramount in ensuring that the aluminum trim meets both international standards and specific industry requirements. Buyers should be aware of the following key aspects:

International Standards

Adherence to recognized international standards is critical for ensuring product quality. Key certifications include:

- ISO 9001: This standard outlines quality management principles that help organizations ensure they meet customer and regulatory requirements consistently. Buyers should verify if suppliers are ISO 9001 certified, indicating a commitment to quality management.

- CE Marking: For products sold within the European Economic Area, CE marking signifies compliance with safety, health, and environmental protection standards.

Industry-Specific Certifications

Depending on the application, additional certifications may be necessary, such as:

- API (American Petroleum Institute): Relevant for aluminum trims used in the oil and gas sector, ensuring they meet specific safety and performance standards.

- ASTM Standards: These provide specifications for various material properties and testing methods relevant to aluminum products.

Quality Control Checkpoints

Implementing a robust quality control system is essential for maintaining product integrity throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Conducting inspections on raw materials to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process help identify defects early, minimizing waste and ensuring consistent quality.

- Final Quality Control (FQC): This stage involves a thorough inspection of the finished products to ensure they meet all specifications and standards before shipping.

Common Testing Methods

Various testing methods are employed to verify the quality and performance of aluminum trim, including:

- Tensile Testing: Measures the strength and ductility of the aluminum.

- Corrosion Resistance Testing: Ensures that the aluminum can withstand environmental factors, especially in outdoor applications.

- Dimensional Inspection: Checks that the trim dimensions conform to specified tolerances.

Verifying Supplier Quality Control

For international B2B buyers, it is crucial to verify that suppliers adhere to stringent quality control measures. Here are actionable steps to ensure supplier compliance:

- Conduct Audits: Regular audits of supplier facilities can help assess their adherence to quality standards and production processes. Consider using third-party auditing services for impartial evaluations.

- Request Quality Reports: Suppliers should provide documentation demonstrating compliance with relevant standards and testing results. This transparency is essential for building trust.

- Third-Party Inspections: Engaging third-party inspection services before shipment can provide an additional layer of assurance regarding product quality.

Navigating Quality Control for International Buyers

For buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Factors to consider include:

- Cultural and Regulatory Differences: Familiarize yourself with local regulations and quality expectations to ensure compliance with both the supplier’s and your own country’s standards.

- Communication: Establish clear communication channels with suppliers to discuss quality expectations and resolve any potential issues promptly.

- Logistics and Shipping: Consider the impact of transportation on product quality, as improper handling can lead to damage. Ensure that suppliers implement appropriate packaging and shipping protocols.

By comprehensively understanding the manufacturing processes and quality assurance measures for aluminum trim, B2B buyers can make informed decisions that align with their project requirements and quality standards. This knowledge not only enhances product offerings but also strengthens supplier relationships, ultimately contributing to operational success in a competitive market.

Comprehensive Cost and Pricing Analysis for aluminum trim Sourcing

Understanding the cost structure and pricing dynamics of aluminum trim is critical for B2B buyers aiming to optimize their sourcing strategies. The total cost of aluminum trim encompasses several components that influence the final price.

Cost Components

-

Materials: The primary cost driver in aluminum trim sourcing is the raw material itself. Prices can fluctuate based on global demand, availability, and the type of aluminum alloy used. For instance, 6000 series alloys are commonly preferred for their excellent extrudability and strength.

-

Labor: Labor costs vary significantly by region. In countries with higher labor costs, such as those in Europe, the overall pricing may be elevated compared to suppliers in regions with lower wage structures, such as parts of Africa or South America.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can lower overhead costs, thus impacting the price positively.

-

Tooling: Tooling costs are associated with the creation of molds and dies for aluminum extrusion. These costs can be significant for custom profiles but are amortized over larger production runs, making them less impactful on pricing for bulk orders.

-

Quality Control (QC): Ensuring that products meet specific standards is crucial, especially for applications in sensitive industries like automotive or electronics. Increased QC measures can raise costs but may be necessary for compliance with certifications.

-

Logistics: Shipping and transportation costs, including customs duties and tariffs, play a vital role, particularly for international transactions. Factors such as distance, mode of transport, and Incoterms can significantly influence logistics expenses.

-

Margin: Suppliers will add a margin to cover their operational costs and profit. This margin can vary widely based on market competition and supplier reputation.

Price Influencers

-

Volume/MOQ: Pricing often benefits from economies of scale. Larger orders can yield significant discounts, while smaller orders may incur higher per-unit costs due to fixed costs being spread over fewer items.

-

Specifications/Customization: Custom profiles or specific finishes can increase costs. Buyers should clearly define their needs to avoid unexpected price hikes.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO 9001) will increase costs but are essential for ensuring product reliability and performance.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a proven track record may command higher prices but offer better quality assurance.

-

Incoterms: Understanding Incoterms is crucial for managing costs. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can dictate who bears shipping costs and risk, affecting overall pricing.

Buyer Tips

-

Negotiate: Always negotiate prices, especially for larger orders. Suppliers often have room to adjust pricing based on volume and long-term relationships.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just upfront prices. Consider factors like durability, maintenance costs, and potential savings from bulk purchasing.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Africa may offer competitive pricing due to lower labor costs, while European suppliers may emphasize quality and service.

-

Conduct Market Research: Stay informed about market trends and fluctuations in aluminum prices. Being aware of global economic factors can provide leverage during negotiations.

Disclaimer

The prices discussed herein are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always perform due diligence and obtain multiple quotes to ensure the best value for your sourcing needs.

Spotlight on Potential aluminum trim Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘aluminum trim’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for aluminum trim

Key Technical Properties of Aluminum Trim

Understanding the essential technical properties of aluminum trim is crucial for B2B buyers to make informed purchasing decisions. Here are some key specifications:

-

Material Grade

Aluminum trim is often categorized by its alloy grade, such as the 6061 and 6063 series. These grades define the material’s strength, corrosion resistance, and workability. For instance, 6061 is known for its high strength and versatility, making it suitable for structural applications. Buyers should select the grade based on the specific demands of their projects to ensure durability and performance. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of the aluminum trim. Precise tolerances are essential for applications requiring accurate fits and finishes, such as in automotive or electronics manufacturing. Understanding tolerance specifications helps buyers ensure that components will fit correctly in their applications, reducing waste and potential rework costs.

-

Finish Type

The finish applied to aluminum trim, such as anodizing or powder coating, significantly affects its aesthetics and performance. Anodized finishes enhance corrosion resistance and durability, while powder coating offers a broader color range and a smooth surface. Buyers should consider the finish type based on environmental exposure and desired appearance, as it can impact the product’s lifespan and maintenance needs. -

Weight-to-Strength Ratio

Aluminum is favored for its lightweight nature coupled with impressive strength. This ratio is critical for industries such as automotive and aerospace, where reducing weight can lead to improved fuel efficiency and performance. Buyers should evaluate products based on this ratio to achieve optimal performance without compromising structural integrity. -

Corrosion Resistance

Aluminum naturally forms a protective oxide layer that resists corrosion; however, various alloys and finishes can enhance this property. For applications in harsh environments, such as coastal areas or industrial settings, understanding corrosion resistance is vital. Buyers should ensure that the selected aluminum trim meets or exceeds the corrosion resistance requirements of their specific application.

Common Trade Terminology

Familiarity with industry-specific terminology is essential for effective communication and negotiation in the aluminum trim market. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of aluminum trim, buyers often source from OEMs to ensure that components meet specific quality and performance standards required for their products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for buyers to manage inventory costs and ensure that they meet supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers should use RFQs to gather competitive pricing and terms, allowing them to make informed decisions and negotiate better deals. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as delivery points, risk transfer, and shipping costs. Understanding Incoterms is essential for buyers engaging in cross-border transactions, as they can significantly impact total landed costs. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. For B2B buyers, understanding lead times is critical for effective project planning and inventory management. Suppliers with shorter lead times can help buyers meet tight deadlines and stay competitive in their markets.

By grasping these technical properties and trade terms, B2B buyers can navigate the aluminum trim market more effectively, ensuring they select the right products for their needs while optimizing costs and project timelines.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the aluminum trim Sector

Market Overview & Key Trends

The global aluminum trim market is witnessing a robust expansion, driven by increasing demand across various sectors such as construction, automotive, and electronics. The lightweight nature of aluminum, combined with its durability and aesthetic versatility, positions it as a preferred material for manufacturers and builders. Key drivers include urbanization, rising disposable incomes in developing regions, and a growing emphasis on energy-efficient materials.

Emerging B2B tech trends such as digital sourcing platforms and advanced supply chain management tools are reshaping how international buyers engage with suppliers. These technologies enable buyers from Africa, South America, the Middle East, and Europe to streamline procurement processes, allowing for real-time price comparisons and supplier evaluations. Additionally, the integration of data analytics in sourcing decisions is becoming increasingly important, helping buyers anticipate market fluctuations and make informed choices.

Market dynamics are also influenced by geopolitical factors and trade policies, which can affect the availability and pricing of aluminum trim products. For instance, buyers need to stay abreast of tariffs and trade agreements that may impact costs, especially when sourcing from international suppliers. The rising trend of customization in aluminum products is notable, with many suppliers now offering tailored solutions to meet specific buyer needs. This trend is particularly relevant for buyers in Europe, where design aesthetics play a crucial role in product selection.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a focal point in manufacturing, the environmental impact of aluminum production cannot be overlooked. The extraction and processing of aluminum can lead to significant carbon emissions and resource depletion. Therefore, B2B buyers must prioritize ethical sourcing practices by partnering with suppliers committed to sustainable operations.

Seeking suppliers that utilize recycled aluminum is a vital step toward reducing the environmental footprint of aluminum trim products. Certifications such as the Aluminum Stewardship Initiative (ASI) and Leadership in Energy and Environmental Design (LEED) can serve as indicators of a supplier’s commitment to sustainability. Additionally, adopting eco-friendly coatings and surface treatments can further enhance the sustainability profile of aluminum products.

By choosing suppliers that emphasize transparency in their supply chains and adhere to environmental regulations, buyers can not only improve their own sustainability credentials but also contribute to a broader movement towards ethical manufacturing practices. This commitment can resonate well with environmentally conscious consumers and enhance brand reputation in increasingly competitive markets.

Brief Evolution/History

The use of aluminum in trim applications has evolved significantly since its introduction in the early 20th century. Initially valued for its lightweight properties, aluminum gained traction in various industries due to its resistance to corrosion and malleability, allowing for intricate designs. The post-World War II era marked a turning point as advancements in production techniques, such as extrusion and anodization, expanded the range of available aluminum profiles.

Today, the aluminum trim market is not only characterized by enhanced functionality but also by a growing focus on aesthetics and sustainability. The introduction of advanced coatings and finishes has allowed for greater customization, catering to diverse consumer preferences across different regions. As the market continues to evolve, innovation and sustainability will remain central to its future growth.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum trim

-

What criteria should I use to vet suppliers of aluminum trim?

When vetting suppliers, prioritize their industry experience, production capacity, and quality certifications such as ISO 9001. Check their portfolio for previous projects and client testimonials to gauge reliability. Additionally, assess their financial stability and ability to meet your specific requirements, including customization options and adherence to international quality standards. Request samples to evaluate material quality before making larger commitments. -

Can I customize aluminum trim products to meet my specific needs?

Yes, many suppliers offer customization options for aluminum trim products. You can specify dimensions, shapes, and finishes according to your project requirements. Ensure to communicate your needs clearly during the initial discussions and inquire about the supplier’s capabilities to handle custom orders. Be mindful that customization may lead to longer lead times and potentially higher costs, so factor these into your planning. -

What are the typical minimum order quantities (MOQ) and lead times for aluminum trim?

Minimum order quantities can vary significantly between suppliers, often ranging from a few hundred to several thousand units. Lead times typically depend on the complexity of the order and the supplier’s production schedule, generally ranging from 2 to 12 weeks. Always confirm these details upfront, as they can impact your project timelines. Consider potential delays in logistics and customs clearance when planning your procurement. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have robust quality assurance processes in place, including regular inspections during production and final quality checks. They should provide documentation of compliance with relevant standards and certifications. Request detailed information about their quality control practices, including any third-party audits or certifications that verify their commitment to maintaining high standards in production and material quality. -

How can I ensure safe and efficient logistics for my aluminum trim orders?

To ensure safe logistics, work with suppliers who have established relationships with reliable shipping companies. Discuss packaging methods to prevent damage during transit and clarify shipping terms, including Incoterms, to understand who bears the risk at each stage. Consider utilizing freight forwarders familiar with international trade regulations, particularly in your region, to streamline customs processes and avoid delays. -

What steps should I take if a dispute arises with my supplier?

In case of a dispute, start by communicating directly with the supplier to address the issue amicably. Document all correspondence and agreements to have a clear record of the transaction. If a resolution cannot be reached, refer to the contract for any dispute resolution clauses, such as mediation or arbitration procedures. Engaging legal counsel familiar with international trade laws may be necessary to navigate complex situations effectively. -

What payment methods are typically accepted by international suppliers?

Most international suppliers accept various payment methods, including wire transfers, letters of credit, and online payment platforms. Wire transfers are common but may involve bank fees and currency conversion costs. Letters of credit provide added security for both parties, ensuring that payment is made only upon fulfillment of agreed terms. Always clarify payment terms and conditions before placing an order to avoid misunderstandings later. -

How do I assess the sustainability practices of my aluminum trim supplier?

To evaluate a supplier’s sustainability practices, inquire about their sourcing of raw materials, production processes, and waste management strategies. Look for certifications that indicate compliance with environmental standards, such as ISO 14001. Suppliers that utilize recycled materials and energy-efficient technologies demonstrate a commitment to sustainability. Engaging suppliers who prioritize eco-friendly practices can enhance your brand’s reputation and align with global sustainability goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for aluminum trim

In conclusion, strategic sourcing of aluminum trim is crucial for B2B buyers aiming to enhance product quality and operational efficiency. The diverse range of aluminum edging trim types offers unique advantages that cater to various industries, from construction to automotive. By understanding the properties, applications, and cost implications of each trim type, buyers can make informed decisions that align with their project requirements and budget constraints.

Furthermore, prioritizing suppliers who demonstrate strong production capabilities, adherence to quality standards, and a commitment to sustainability can significantly impact long-term success. Buyers should evaluate both domestic and international suppliers to leverage competitive pricing and innovative solutions that meet their specific needs.

As global markets continue to evolve, it is essential for B2B buyers from Africa, South America, the Middle East, and Europe to remain proactive in their sourcing strategies. Embrace the opportunities that come with understanding market trends, building robust supplier relationships, and investing in high-quality materials. By doing so, you can position your business for growth and sustainability in the dynamic landscape of aluminum trim procurement.