Unlock High-Quality Graphite Crucible Sourcing for B2B

Introduction: Navigating the Global Market for graphite crucible

Graphite crucibles play a pivotal role in various high-temperature applications, serving as essential tools for melting non-ferrous metals and alloys across diverse industries such as metallurgy, jewelry making, glass production, and semiconductor manufacturing. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the significance of these crucibles is crucial for optimizing production processes and ensuring product quality.

This comprehensive guide delves into the multifaceted world of graphite crucibles, offering insights into various types, such as clay-graphite and high-purity options, along with the materials used in their construction. We will explore the manufacturing processes and quality control measures that ensure durability and performance, as well as provide a detailed overview of leading suppliers in the market.

Additionally, this guide will address cost considerations, market trends, and frequently asked questions to empower buyers in making informed sourcing decisions. Whether you are a manufacturer in Germany, a jeweler in Mexico, or a foundry operator in South Africa, this resource is designed to equip you with the knowledge necessary to navigate the global market for graphite crucibles effectively. By leveraging the insights provided, you can optimize your procurement strategies, enhance operational efficiency, and ultimately drive your business success.

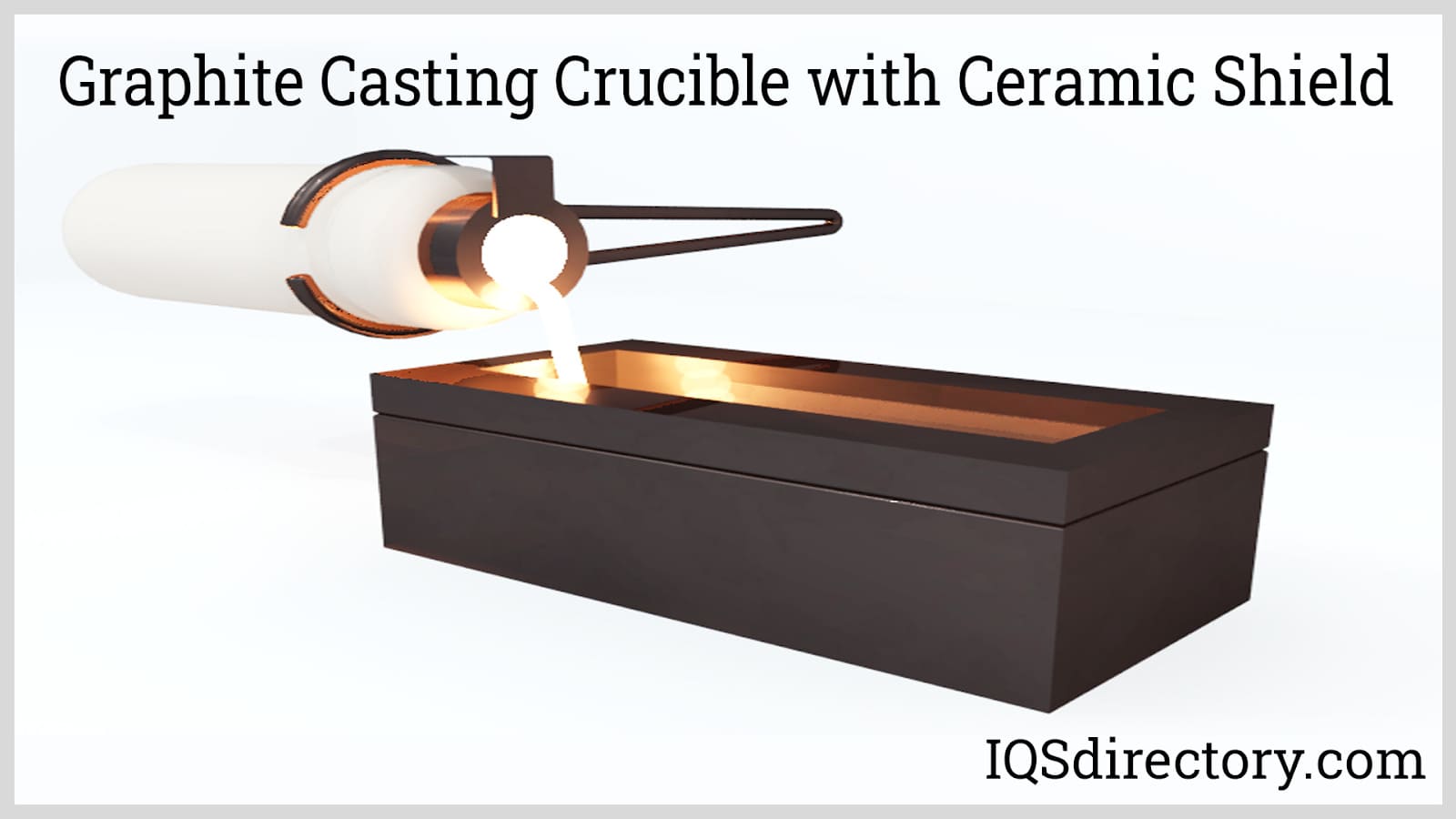

Illustrative Image (Source: Google Search)

Understanding graphite crucible Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clay Graphite Foundry Crucible | High thermal resistance, durable clay-graphite blend | Foundries, metal casting | Pros: Excellent durability, cost-effective; Cons: Limited high-temperature applications. |

| High-Purity Graphite Crucible | Made from fine grain graphite, minimal impurities | Jewelry making, semiconductor production | Pros: Superior thermal conductivity; Cons: Higher cost due to purity. |

| Silicon Carbide Crucible | Enhanced thermal shock resistance, high strength | Glass production, metal fabrication | Pros: Long lifespan, excellent thermal stability; Cons: Heavier than other types. |

| Isostatic Graphite Crucible | Uniform density and structure, low porosity | Research labs, high-precision applications | Pros: Consistent performance, high purity; Cons: Requires longer lead time for production. |

| Coarse Extruded Graphite Crucible | Economical, good for general melting applications | Industrial melting of non-ferrous metals | Pros: Cost-effective, easy to manufacture; Cons: Less thermal efficiency compared to high-purity variants. |

Clay Graphite Foundry Crucible

The Clay Graphite Foundry Crucible is a popular choice in metallurgy due to its robust construction combining clay and graphite. It excels in foundry applications where high thermal resistance is essential for melting metals like aluminum and bronze. Buyers should consider this type for its durability and cost-effectiveness, especially in environments where extreme temperatures are not the primary concern. However, its performance may be limited in applications requiring higher temperature thresholds.

High-Purity Graphite Crucible

High-Purity Graphite Crucibles are crafted from fine grain graphite, ensuring minimal impurities that could compromise the melting process. This type is particularly favored in jewelry making and semiconductor industries, where precision and purity are paramount. For B2B buyers, the investment in high-purity crucibles pays off in enhanced thermal conductivity and performance. However, the higher cost associated with these crucibles may be a consideration for budget-sensitive operations.

Silicon Carbide Crucible

Silicon Carbide Crucibles are renowned for their exceptional thermal shock resistance and mechanical strength, making them ideal for demanding applications such as glass production and metal fabrication. Their longevity and thermal stability can lead to reduced operational costs over time. Buyers should weigh these benefits against the heavier weight of silicon carbide crucibles, which may affect handling and logistics.

Isostatic Graphite Crucible

Isostatic Graphite Crucibles are characterized by their uniform density and low porosity, making them suitable for high-precision applications in research and development. Their consistent performance and high purity make them a preferred choice for industries that require stringent quality standards. While they offer significant advantages, potential buyers should be aware of longer lead times associated with their production.

Coarse Extruded Graphite Crucible

Coarse Extruded Graphite Crucibles provide a cost-effective solution for general melting applications, particularly in industrial settings. They are easy to manufacture and suitable for melting non-ferrous metals. However, buyers should note that while they are economical, their thermal efficiency is not as high as that of more refined crucible types, which may impact performance in high-temperature scenarios.

Related Video: Crucible | How to Make Crucibles?| Rajahmundry | Crucible Industries | To Know Everything | Graphite

Key Industrial Applications of graphite crucible

| Industry/Sector | Specific Application of Graphite Crucible | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Foundry and Casting | Melting non-ferrous metals like aluminum and brass | High thermal resistance and minimal reactivity with metals | Ensure high purity and low porosity to prevent contamination |

| Metal Fabrication and Forging | Shaping and melting metals such as steel and copper | Improved efficiency in metal processing | Look for crucibles with uniform texture for consistent heat distribution |

| Jewelry Making | Refining precious metals like gold and silver | Enhanced purity of refined metals | Sourcing from reputable manufacturers to guarantee quality standards |

| Glass Production | Melting raw materials for glass manufacturing | Consistent quality and thermal stability | Evaluate thermal shock resistance and custom size options |

| Semiconductor Industry | High-temperature processing for semiconductor fabrication | Ability to withstand corrosive environments | Focus on low contamination risk and precise manufacturing tolerances |

In the foundry and casting industry, graphite crucibles are essential for melting non-ferrous metals such as aluminum and brass. They provide high thermal resistance, allowing for efficient melting and pouring processes. International buyers should prioritize sourcing crucibles that exhibit high purity and low porosity to minimize contamination during metal processing.

In metal fabrication and forging, graphite crucibles are utilized to melt and shape metals like steel and copper. The advantages include improved efficiency and consistent results in metal processing. Buyers should seek crucibles with a uniform texture, ensuring even heat distribution to reduce the risk of hot spots, which can lead to defects in the final product.

In jewelry making, graphite crucibles play a crucial role in refining precious metals, including gold and silver. The use of high-quality crucibles enhances the purity of the refined metals, a critical factor for jewelers. When sourcing, it’s vital to choose reputable manufacturers that adhere to stringent quality standards, ensuring that the crucibles meet the necessary specifications for precious metal applications.

The glass production industry relies on graphite crucibles for melting raw materials, which is essential for creating high-quality glass products. These crucibles provide consistent quality and thermal stability, which are vital for producing glass that meets industry standards. Buyers should evaluate the thermal shock resistance of the crucibles and consider custom size options to fit specific production needs.

Lastly, in the semiconductor industry, graphite crucibles are used for high-temperature processing, essential for fabricating semiconductors. Their ability to withstand corrosive materials and high temperatures makes them indispensable in this sector. Buyers need to focus on sourcing crucibles that minimize contamination risk and offer precise manufacturing tolerances to ensure optimal performance in semiconductor applications.

Related Video: Graphite Crucible: The Complete Guide

Strategic Material Selection Guide for graphite crucible

When selecting materials for graphite crucibles, international B2B buyers must consider various factors that influence performance, durability, and cost. Below is an analysis of four common materials used in graphite crucibles, focusing on their properties, advantages, disadvantages, and implications for specific applications.

1. Clay Graphite

Key Properties:

Clay graphite crucibles are composed of a mixture of clay and graphite, providing excellent thermal resistance and mechanical strength. They can typically withstand temperatures up to 1,600°C (2,912°F) and exhibit good resistance to thermal shock.

Pros & Cons:

The primary advantage of clay graphite crucibles is their durability and ability to handle high temperatures, making them suitable for melting metals like aluminum and brass. However, they can be more expensive than other options due to the complexity of manufacturing and the quality of materials used.

Impact on Application:

These crucibles are ideal for foundries and metal casting applications where thermal stability is crucial. Their compatibility with non-ferrous metals makes them a preferred choice in the jewelry and automotive industries.

Considerations for International Buyers:

Buyers should ensure compliance with local and international standards, such as ASTM and DIN, particularly in Europe and the Middle East. Understanding the specific requirements for melting different metals can also guide material selection.

2. High-Purity Graphite

Key Properties:

High-purity graphite crucibles are made from fine-grain graphite, which enhances thermal conductivity and minimizes impurities. They can withstand extreme temperatures and have a low porosity, reducing contamination risks.

Pros & Cons:

The main advantage of high-purity graphite crucibles is their superior performance in precision applications, such as semiconductor manufacturing and precious metal refining. However, they come at a higher cost, which may not be justifiable for all applications.

Impact on Application:

These crucibles are particularly suited for applications requiring high purity, such as in the semiconductor and glass industries. Their ability to maintain material integrity at high temperatures makes them essential for advanced manufacturing processes.

Considerations for International Buyers:

Buyers should be aware of the specific purity levels required for their applications and ensure that suppliers can meet these standards. Additionally, understanding the supply chain and sourcing materials from reputable manufacturers is crucial to avoid contamination.

3. Isostatic Graphite

Key Properties:

Isostatic graphite is produced through a process that applies equal pressure from all directions, resulting in a uniform texture and density. This material can handle temperatures exceeding 3,000°C (5,432°F) and has excellent thermal conductivity.

Pros & Cons:

The key advantage of isostatic graphite crucibles is their exceptional strength and thermal stability, making them ideal for high-performance applications. However, the manufacturing process is complex and costly, which can lead to higher prices.

Impact on Application:

Isostatic graphite is often used in industries such as aerospace, where high performance and reliability are critical. Its ability to withstand extreme conditions makes it suitable for advanced metallurgical processes.

Considerations for International Buyers:

Buyers from regions with stringent quality controls, such as Germany, should verify that the isostatic graphite meets relevant standards. Additionally, understanding the potential for lead times in manufacturing can help in planning procurement strategies.

4. Molded Graphite

Key Properties:

Molded graphite crucibles are created by compressing graphite powder into molds, allowing for various shapes and sizes. They typically withstand temperatures up to 2,500°C (4,532°F) and offer good thermal shock resistance.

Pros & Cons:

These crucibles are versatile and can be customized for specific applications, making them a cost-effective choice for many manufacturers. However, their performance may not match that of higher-purity options in critical applications.

Impact on Application:

Molded graphite is commonly used in metal casting and glass production, where flexibility in design is advantageous. They are also suitable for applications where cost is a significant concern.

Considerations for International Buyers:

Buyers should assess the specific needs of their applications and consider the trade-offs between cost and performance. Additionally, understanding the local market for molded graphite can help in negotiating better pricing and terms.

Summary Table

| Material | Typical Use Case for graphite crucible | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clay Graphite | Metal casting (aluminum, brass) | Excellent thermal resistance | Higher manufacturing costs | Medium |

| High-Purity Graphite | Semiconductor manufacturing, precious metals | Superior purity and performance | High cost, may not be suitable for all applications | High |

| Isostatic Graphite | Aerospace, advanced metallurgy | Exceptional strength and thermal stability | Complex and costly manufacturing process | High |

| Molded Graphite | General metal casting, glass production | Versatile and customizable | Performance may not match high-purity options | Low to Medium |

This guide provides a comprehensive overview of material options for graphite crucibles, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for graphite crucible

The manufacturing of graphite crucibles involves a series of well-defined processes and stringent quality assurance measures that ensure the final product meets the high standards required in various industries, such as metallurgy, foundry, and semiconductor manufacturing. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes is crucial for making informed purchasing decisions.

Manufacturing Process for Graphite Crucibles

Material Preparation

The first stage in the manufacturing process is the preparation of raw materials. Graphite crucibles are typically made from high-purity graphite combined with other materials like clay to enhance thermal resistance and structural integrity. Suppliers often source raw materials from regions rich in graphite deposits, ensuring the quality and consistency of the input material.

Key techniques in this stage include:

– Material Sourcing: Select high-quality graphite and clay from reputable suppliers.

– Purification: Remove impurities through mechanical and chemical processes to ensure a high purity level, which is critical for thermal conductivity and resistance to thermal shock.

Forming

Once the materials are prepared, they are subjected to forming processes. This is where the crucible takes its shape.

- Molding: The prepared mixture is shaped into crucible forms using techniques such as:

- Die Casting: Using molds to create specific shapes.

-

Isostatic Pressing: Applying uniform pressure to form the crucible, ensuring consistency in density and structure.

-

Drying: After molding, the crucibles are dried to remove moisture, which is crucial to prevent defects during firing.

Assembly

After forming, some crucibles may require additional components or reinforcements, particularly for specialized applications. This stage may include:

– Adding Reinforcements: For certain applications, additional materials may be incorporated to enhance durability.

– Jointing: If the crucible consists of multiple parts, they are assembled using high-temperature adhesives or mechanical fasteners.

Finishing

The final stage involves finishing processes that improve the crucible’s performance characteristics.

-

Firing: Crucibles are fired in kilns at high temperatures to enhance their structural integrity and thermal properties. This step is vital as it determines the crucible’s ability to withstand high temperatures without deformation.

-

Surface Treatment: Some manufacturers apply coatings or treatments to improve wear resistance and reduce porosity, which is essential for applications requiring high purity.

-

Inspection: After finishing, each crucible undergoes a thorough inspection to ensure it meets the specified dimensions and quality standards.

Quality Assurance Measures

Quality assurance is paramount in the production of graphite crucibles, particularly due to their applications in high-stakes industries. Buyers should look for suppliers who adhere to recognized international standards.

International Standards

- ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers to ensure consistent quality in their products.

- CE Marking: For products sold in Europe, CE marking indicates compliance with EU safety and environmental requirements.

- API Standards: Relevant for crucibles used in oil and gas applications, ensuring they meet industry-specific requirements.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials before they enter the production process to ensure they meet quality standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages to identify and rectify defects early in the process.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all specifications before shipment.

Common Testing Methods

- Thermal Shock Testing: Evaluates the crucible’s resistance to rapid temperature changes.

- Density and Porosity Testing: Ensures the crucible has the desired density and low porosity, which are critical for maintaining purity during metal melting.

- Dimensional Inspection: Verifying that the crucibles meet specified dimensions and tolerances.

Verifying Supplier Quality Control

For B2B buyers, particularly those operating across international borders, verifying the quality control practices of suppliers is essential. Here are some actionable steps:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and adherence to international standards.

- Request Quality Reports: Ask suppliers for detailed quality assurance reports, including results from recent testing and compliance certificates.

- Third-Party Inspections: Utilize third-party inspection services to evaluate the quality of the products before shipment. This is particularly important for large orders or when sourcing from new suppliers.

- Certifications Verification: Ensure that the supplier’s certifications are current and applicable to the intended market (e.g., EU, North America).

Conclusion

Understanding the manufacturing processes and quality assurance measures for graphite crucibles is essential for B2B buyers to make informed purchasing decisions. By focusing on suppliers who adhere to international standards and demonstrating robust quality control practices, buyers can ensure they receive high-quality products that meet their specific needs. This diligence not only enhances operational efficiency but also mitigates risks associated with material quality and performance in critical applications.

Related Video: Making a Graphite Crucible

Comprehensive Cost and Pricing Analysis for graphite crucible Sourcing

When sourcing graphite crucibles, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. This analysis delves into the key cost components, price influencers, and actionable tips for buyers to optimize their sourcing strategies.

Cost Components

-

Materials: The primary material for graphite crucibles is high-purity graphite, often combined with clay. The cost of these materials can fluctuate based on global market prices, purity levels, and sourcing locations. Buyers should consider the material grade required for their specific applications to avoid overpaying for unnecessary quality.

-

Labor: Labor costs vary significantly by region. In countries with higher labor costs, such as Germany, the overall manufacturing expense may be higher than in regions like Africa or South America. Understanding local labor rates can help buyers gauge the potential impact on pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturers tend to have lower overhead costs, which can translate to more competitive pricing for buyers.

-

Tooling: Custom tooling is often required for specialized crucibles. The cost of tooling can be substantial, particularly for unique designs or high-volume orders. Buyers should factor in these costs when requesting quotes.

-

Quality Control (QC): Ensuring the crucibles meet industry standards involves QC processes that can add to the overall cost. Buyers should inquire about the QC measures in place and consider the implications of quality on their operations.

-

Logistics: Shipping costs can be significant, particularly for international orders. Factors such as distance, shipping method, and import duties can impact overall costs. Buyers should explore various shipping options and consider Incoterms that define responsibilities for transportation and risk.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the supplier’s pricing strategy can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ: Ordering in larger volumes often leads to lower per-unit costs. Buyers should assess their needs and consider consolidating orders to meet minimum order quantities (MOQs) to benefit from pricing breaks.

-

Specifications/Customization: Customization can significantly affect pricing. Buyers should balance the need for specific features against their budget and evaluate whether standard products could suffice.

-

Materials and Quality/Certifications: Higher-quality materials and certifications (e.g., ISO) typically command higher prices. Buyers should weigh the benefits of certified products against their specific application requirements.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Engaging with reputable suppliers may yield better quality and service, which can justify higher costs.

-

Incoterms: Understanding Incoterms is essential for managing costs associated with shipping and insurance. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate the responsibility of costs between buyer and seller, impacting the total cost of ownership.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating terms and prices. Suppliers may be willing to offer discounts for long-term partnerships or larger orders.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the upfront price. Consider factors like durability, maintenance, and potential downtime caused by inferior products.

-

Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Europe may have different pricing structures compared to those in South America or Africa due to varying labor and material costs.

-

Research Suppliers: Conduct thorough research on potential suppliers, including reviews and testimonials. Building relationships with reliable suppliers can lead to better pricing and service.

Disclaimer

Prices for graphite crucibles can vary widely based on the factors discussed above. The information provided is indicative and should be validated with suppliers for accurate quotes tailored to specific needs.

Spotlight on Potential graphite crucible Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘graphite crucible’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for graphite crucible

When selecting graphite crucibles for industrial applications, understanding their essential technical properties and trade terminology is crucial for making informed purchasing decisions. Below are the key specifications and terms that international B2B buyers should be familiar with.

Key Technical Properties

-

Material Grade

– Graphite crucibles are primarily made from high-purity graphite or a mixture of graphite and clay. The material grade directly affects the crucible’s thermal conductivity, resistance to thermal shock, and overall durability. Higher purity levels minimize contamination risks, making them ideal for applications in metallurgy and precious metal refining. -

Thermal Conductivity

– This property refers to the crucible’s ability to conduct heat. High thermal conductivity is essential in melting applications, as it allows for faster melting times and more efficient energy use. Crucibles with superior thermal conductivity can significantly improve production efficiency, which is a critical consideration for manufacturers. -

Porosity

– Porosity indicates the volume of voids in the material. Low porosity is desirable as it reduces the likelihood of contamination during the melting process and enhances the crucible’s strength. A low-porosity crucible is particularly important in precision applications such as semiconductor manufacturing, where material purity is paramount. -

Tolerance and Dimensions

– Tolerance specifies the permissible limits of variation in a physical dimension. In graphite crucibles, maintaining tight tolerances ensures consistent performance and compatibility with melting equipment. Buyers should look for suppliers who can provide precise dimensions to meet their specific operational requirements. -

Thermal Shock Resistance

– This property describes the crucible’s ability to withstand rapid temperature changes without cracking or degrading. High thermal shock resistance is crucial for applications involving frequent heating and cooling cycles, such as in foundries or metal casting.

Illustrative Image (Source: Google Search)

- Crucible Shape and Size

– Different applications require different shapes and sizes of crucibles. Understanding the specific requirements for your application will help in selecting the appropriate crucible. Customization options can also be crucial for unique industrial processes.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can ensure high-quality, customized graphite crucibles tailored to specific needs. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, particularly for smaller businesses or those testing new suppliers. -

RFQ (Request for Quote)

– An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Submitting an RFQ can help businesses compare options and negotiate better deals, making it an essential tool in procurement. -

Incoterms

– Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery responsibilities, which is essential for international transactions. -

Lead Time

– This term refers to the time taken from placing an order to the delivery of the product. Knowing the lead time is crucial for project planning and inventory management, especially in industries where timing is critical. -

Certification

– Certifications (e.g., ISO, ASTM) indicate that a product meets certain industry standards. Buyers should look for suppliers whose crucibles are certified to ensure quality and compliance with industry regulations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their purchasing strategies and ensure they select the most suitable graphite crucibles for their specific applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the graphite crucible Sector

Market Overview & Key Trends

The graphite crucible market is witnessing significant transformation driven by various global factors. Key among these is the increasing demand for high-purity graphite crucibles in metallurgy, particularly for non-ferrous metals such as aluminum, brass, and precious metals like gold and silver. This demand is bolstered by the burgeoning sectors of renewable energy and electric vehicles, which require high-performance materials for battery production and thermal management.

Emerging trends in B2B sourcing highlight the integration of advanced manufacturing technologies, including automation and precision machining. These innovations enable suppliers to produce crucibles with enhanced thermal resistance and lower porosity, which are critical for maintaining material integrity at high temperatures. Additionally, digital platforms for procurement are gaining traction, allowing international buyers from regions like Africa, South America, the Middle East, and Europe to easily compare prices, lead times, and product specifications.

Market dynamics are influenced by geopolitical factors, with trade policies and tariffs impacting sourcing decisions. For instance, buyers in Europe and the Middle East may face challenges due to fluctuating import duties on graphite products. To mitigate risks, it is advisable for buyers to diversify their supplier base and consider local manufacturers who can offer quicker response times and reduced shipping costs.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the graphite crucible sector. The environmental impact of graphite mining and processing is significant, prompting a shift toward ethical sourcing practices. International B2B buyers are increasingly prioritizing suppliers who can demonstrate responsible sourcing of raw materials, minimizing ecological damage, and adhering to regulatory standards.

The importance of ethical supply chains cannot be overstated, as consumers and regulators alike are demanding greater transparency. Suppliers that possess certifications, such as ISO 14001 for environmental management, or those using ‘green’ materials in their production processes, are more likely to appeal to conscientious buyers. For instance, selecting crucibles made from recycled graphite can significantly reduce carbon footprints and promote circular economy practices.

Moreover, businesses should engage with suppliers who invest in sustainable technologies, such as energy-efficient manufacturing processes and waste reduction systems. By aligning procurement strategies with sustainability goals, B2B buyers not only enhance their brand reputation but also contribute positively to global environmental efforts.

Brief Evolution/History

The use of graphite crucibles dates back to ancient civilizations, where they were employed in metalworking due to their ability to withstand high temperatures. Over the centuries, advancements in material science have transformed the crucible from a simple clay-and-graphite combination to highly engineered products capable of meeting modern industrial demands.

The rise of the semiconductor and glass production industries in the late 20th century further propelled the development of specialized graphite crucibles, leading to innovations in purity and thermal conductivity. Today, the graphite crucible market is characterized by a diverse range of products tailored to specific applications, reflecting both the evolving needs of industries and the increasing emphasis on sustainability and ethical sourcing.

This historical perspective offers B2B buyers valuable insights into the reliability and adaptability of graphite crucibles, reinforcing their role as essential tools in various high-temperature applications across multiple sectors.

Related Video: Crude Oil Prices & Global Trade Market Seen Stabilising After Trump Announced Iran Israel Ceasefire

Frequently Asked Questions (FAQs) for B2B Buyers of graphite crucible

-

How can I effectively vet suppliers of graphite crucibles?

When vetting suppliers, start by assessing their industry reputation and experience. Look for certifications that demonstrate quality control, such as ISO 9001. Request references from previous clients, particularly those in your region or industry. Consider suppliers that offer transparent manufacturing processes and invite site visits if possible. Additionally, check if they have experience with international trade, including compliance with local regulations in your market. -

Can I customize graphite crucibles to meet my specific needs?

Yes, many suppliers offer customization options for graphite crucibles. You can specify dimensions, materials, and even unique features that align with your application. When discussing customization, provide detailed specifications and discuss your intended use case to ensure the supplier can meet your requirements. Always request samples or prototypes to evaluate the customization before placing larger orders. -

What are the typical minimum order quantities (MOQs) and lead times for graphite crucibles?

MOQs can vary significantly by supplier and the complexity of your order. Generally, expect MOQs to range from 50 to 500 units. Lead times can also differ based on customization and supplier capabilities, typically ranging from 4 to 12 weeks. It’s essential to discuss these factors upfront and factor them into your project timelines to avoid disruptions in your operations. -

What payment terms are common in international B2B transactions for graphite crucibles?

Payment terms can vary, but common practices include upfront deposits (typically 30-50%) with the balance due upon delivery. Some suppliers may offer payment through letters of credit or escrow services to enhance security. Ensure to negotiate terms that protect your interests, especially in international transactions, and clarify any additional costs, such as shipping or customs duties. -

How do I ensure quality assurance and certifications for graphite crucibles?

Request copies of the supplier’s quality assurance certifications and production standards. Key certifications to look for include ISO 9001 and any industry-specific certifications. Inquire about their testing procedures, including thermal resistance and material purity tests. Consider conducting third-party inspections or audits to verify compliance before finalizing your purchase. -

What logistics considerations should I be aware of when importing graphite crucibles?

When importing, consider shipping methods, costs, and potential tariffs that may apply. Work closely with your supplier to understand packaging requirements to avoid damage during transit. It’s crucial to select logistics partners experienced in handling industrial materials. Additionally, ensure that you have the necessary import licenses and understand the customs clearance process in your region. -

How can I handle disputes with suppliers regarding graphite crucible orders?

To minimize disputes, establish clear contracts that outline terms of service, quality expectations, and delivery schedules. If a dispute arises, maintain open communication to resolve issues amicably. Utilize mediation services if direct discussions fail. If necessary, refer to the contract’s dispute resolution clause, which may include arbitration or legal proceedings in a specified jurisdiction. -

What should I do if I receive defective graphite crucibles?

Upon receiving defective goods, document the issues with photos and detailed descriptions. Immediately contact your supplier to report the problem, referencing your order number and any relevant agreements. Most reputable suppliers will have return policies for defective items, allowing for replacements or refunds. Ensure you understand their return process and timelines to expedite resolution.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for graphite crucible

In the competitive landscape of graphite crucible sourcing, international B2B buyers must prioritize strategic sourcing to ensure they acquire high-quality, reliable products tailored to their specific needs. Key takeaways include understanding the diverse applications of graphite crucibles across industries such as metallurgy, jewelry making, and glass production, which underscores their essential role in high-temperature processes. Buyers should focus on suppliers that offer customization, rapid delivery, and high-purity materials to meet stringent operational requirements.

Furthermore, aligning with manufacturers who emphasize innovation and quality control can significantly enhance production efficiency and product reliability. As demand for sustainable practices grows, selecting suppliers committed to environmentally friendly production methods can also provide a competitive edge.

Looking ahead, the global market for graphite crucibles is set to expand, driven by increasing industrial activities in regions like Africa, South America, the Middle East, and Europe. Buyers are encouraged to engage proactively with suppliers to explore new technologies and materials that can enhance their manufacturing capabilities. Act now to secure partnerships that not only fulfill your current needs but also position your business for future growth and innovation in the graphite crucible market.