Unlock Strategic Sourcing of Global Metals for B2B Success

Introduction: Navigating the Global Market for global metals

In the dynamic realm of global trade, metals have evolved from mere commodities to critical assets that fuel innovation and drive industry growth. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, the strategic selection of metals can significantly impact operational efficiency and long-term investment success. Whether it’s the booming construction sectors in Egypt, the automotive industries in Brazil, or advanced manufacturing in the UK, understanding the right metal types and their applications is paramount.

This guide serves as a comprehensive resource, meticulously crafted to navigate the complexities of sourcing metals and alloys. It encompasses a thorough exploration of various metal types and their unique properties, manufacturing processes, and stringent quality control standards. Additionally, it provides actionable insights into evaluating suppliers, understanding cost structures, and anticipating market trends.

Furthermore, the guide addresses frequently asked questions to streamline procurement processes and empower buyers to make informed decisions. By leveraging the insights within this guide, B2B buyers can enhance their sourcing strategies, mitigate risks, and secure high-quality materials that meet their specific industry demands. Embrace the opportunity to transform your procurement approach and gain a competitive edge in the ever-evolving global metals market.

Understanding global metals Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Titanium Alloys | High strength-to-weight ratio, exceptional corrosion resistance | Aerospace, Medical, Oil & Gas | Pros: Lightweight and durable; Cons: Costly and challenging to machine |

| Stainless Steel | Corrosion-resistant, high tensile strength | Food Processing, Medical, Construction | Pros: Durable, low maintenance; Cons: Higher cost, can be heavier |

| Aluminum Alloys | Lightweight, good corrosion resistance | Aerospace, Automotive, Packaging | Pros: Lightweight, excellent machinability; Cons: Lower strength compared to steel |

| Carbon Steel | High strength, cost-effective | Structural Components, Machinery | Pros: Affordable, versatile; Cons: Prone to rust, requires coating |

| Copper Alloys | Excellent electrical conductivity, malleable | Electrical Applications, Plumbing | Pros: High conductivity, good corrosion resistance; Cons: Expensive, can deform easily |

Titanium Alloys

Titanium alloys are recognized for their exceptional strength-to-weight ratio and resistance to corrosion, making them ideal for demanding applications in the aerospace, medical, and oil and gas sectors. B2B buyers should focus on suppliers that provide comprehensive quality certifications and have experience in machining titanium, as its high cost and specific machining requirements necessitate a reliable supply chain. Ensuring logistical efficiency is crucial to minimize lead times associated with titanium sourcing.

Stainless Steel

Stainless steel is a versatile metal characterized by its high resistance to corrosion and robust mechanical properties. It is widely used in food processing, medical, and construction applications. Buyers should specify the grade of stainless steel required, as different grades offer varying levels of corrosion resistance and strength. While the initial investment may be higher, the durability and low maintenance costs can lead to long-term savings, particularly in regulated industries where hygiene is critical.

Aluminum Alloys

Aluminum alloys are lightweight and exhibit good corrosion resistance, making them particularly suited for aerospace, automotive, and packaging applications. When sourcing aluminum, buyers must consider the specific alloy type, as variations can significantly affect strength and machinability. While aluminum alloys are easier to work with than many metals, their lower strength compared to steel may limit their use in structural applications, necessitating careful evaluation of project requirements.

Carbon Steel

Carbon steel is favored for its high strength and cost-effectiveness, making it a staple in construction and machinery applications. It offers excellent machinability and is widely available, which benefits B2B buyers seeking reliable sourcing options. However, carbon steel is susceptible to rust and corrosion, requiring protective coatings or treatments for outdoor or humid environments. Buyers should consider the total cost of ownership, including maintenance, when selecting carbon steel for projects.

Copper Alloys

Copper alloys are renowned for their excellent electrical conductivity and malleability, making them ideal for electrical applications and plumbing systems. B2B buyers should be aware that while copper provides superior conductivity, it can be more expensive than other metals and may deform under stress. When sourcing copper alloys, it is essential to evaluate application-specific requirements, such as thermal and electrical performance, to ensure optimal material selection.

Related Video: What Are The Different Atomic Models? Dalton, Rutherford, Bohr and Heisenberg Models Explained

Key Industrial Applications of global metals

| Industry/Sector | Specific Application of global metals | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft components (e.g., frames, engines) | Enhanced performance and fuel efficiency | Supplier certifications, material traceability, lead times |

| Construction | Structural steel for buildings and bridges | Durability and safety in infrastructure | Compliance with local regulations, quality standards |

| Automotive | Engine parts and body panels | Lightweight materials for improved fuel economy | Alloy specifications, machining capabilities |

| Energy (Oil & Gas) | Pipelines and offshore platforms | Corrosion resistance and reliability | Supplier reliability, material certifications |

| Electronics | Circuit boards and connectors | High conductivity and performance | Precision machining, sourcing from certified suppliers |

Aerospace

In the aerospace industry, global metals such as titanium and aluminum alloys are crucial for manufacturing aircraft components, including frames and engines. These materials provide enhanced performance and fuel efficiency due to their high strength-to-weight ratios. International B2B buyers must prioritize suppliers with robust quality certifications and proven experience in aerospace applications, as compliance with stringent safety standards is essential. Additionally, the supply chain’s reliability is critical to avoid delays in production schedules.

Construction

Structural steel is a foundational element in the construction industry, utilized for building frameworks and bridges. Its durability and safety features make it a preferred choice for large-scale infrastructure projects. Buyers should ensure that their suppliers adhere to local regulations and quality standards, as construction projects often undergo rigorous inspections. Understanding the specific grade and treatment of steel is also vital to ensure it meets the demands of the intended application, especially in regions prone to extreme weather conditions.

Automotive

In automotive manufacturing, global metals are employed in engine parts and body panels to achieve lightweight structures that enhance fuel economy and performance. Aluminum alloys and high-strength steels are commonly used to meet these objectives. B2B buyers in this sector should focus on the specific alloy specifications and the supplier’s machining capabilities, as precision is crucial for optimal performance. Additionally, considering the environmental impact and recyclability of metals can align with the industry’s growing sustainability efforts.

Energy (Oil & Gas)

The energy sector, particularly oil and gas, relies heavily on metals for pipelines and offshore platforms. The materials used must exhibit exceptional corrosion resistance and reliability under extreme conditions. Buyers should prioritize sourcing from suppliers with strong track records in these applications and who can provide relevant material certifications. Given the high stakes of energy projects, ensuring supplier reliability and compliance with international standards is critical to mitigate risks associated with project delays or failures.

Electronics

In the electronics industry, metals such as copper and specialized alloys are essential for circuit boards and connectors. These materials offer high conductivity and performance, which are vital for the functionality of electronic devices. International B2B buyers should seek suppliers who specialize in precision machining and can provide certified materials that meet specific performance criteria. Ensuring that suppliers can accommodate customization requests for complex geometries will also enhance the overall effectiveness of the sourcing strategy.

Related Video: Uses Of Metals – Gold, Copper, Aluminium, Steel | Properties of Matter | Chemistry | FuseSchool

Strategic Material Selection Guide for global metals

When selecting materials for global metals, international B2B buyers must consider a range of factors including performance characteristics, application suitability, and compliance with regional standards. Below is an analysis of four common materials used in various industries, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is renowned for its high corrosion resistance, strength, and durability. It performs well in a variety of temperatures and pressures, making it suitable for demanding environments such as food processing and medical applications.

Pros & Cons: The primary advantage of stainless steel is its longevity and low maintenance requirements, which can lead to reduced lifecycle costs. However, it can be more expensive than other materials, and its weight may be a consideration in applications where weight savings are critical.

Impact on Application: Stainless steel is compatible with a wide range of media, including food products and pharmaceuticals, making it an essential choice for industries where hygiene is paramount.

Considerations for B2B Buyers: Buyers should ensure compliance with international standards such as ASTM or EN. Understanding the specific grade of stainless steel is crucial, as different grades offer varying levels of corrosion resistance and mechanical properties.

Aluminum Alloys

Key Properties: Aluminum alloys are lightweight, with good corrosion resistance and excellent machinability. They are commonly used in aerospace and automotive applications where weight reduction is essential.

Pros & Cons: The key advantage of aluminum alloys is their lightweight nature, which contributes to improved fuel efficiency in transportation applications. However, they typically have lower strength compared to steel, which can limit their use in high-stress applications.

Impact on Application: Aluminum alloys are particularly effective in applications requiring good thermal and electrical conductivity, but their lower strength may necessitate careful consideration in structural applications.

Considerations for B2B Buyers: Buyers should evaluate the specific alloy type and its properties, as different compositions can significantly impact performance. Compliance with regional standards is also important, particularly in sectors like aerospace where safety is critical.

Carbon Steel

Key Properties: Carbon steel is known for its high strength and cost-effectiveness. It is widely used in structural components and machinery due to its excellent machinability.

Pros & Cons: The main advantage of carbon steel is its affordability and versatility, making it a popular choice for a variety of applications. However, it is prone to rust and corrosion, which necessitates protective coatings or treatments.

Impact on Application: Carbon steel is suitable for structural applications but may require additional protection in humid or outdoor environments to ensure durability.

Considerations for B2B Buyers: Buyers should consider the environmental conditions the steel will be exposed to and factor in the costs of protective treatments. Familiarity with local standards and regulations, such as those from ASTM or ISO, is also essential.

Copper Alloys

Key Properties: Copper alloys are characterized by excellent electrical conductivity and malleability, making them ideal for electrical applications and plumbing systems.

Pros & Cons: The primary advantage of copper alloys is their superior conductivity, which is crucial in electrical applications. However, they can be more expensive than other metals and may deform under stress.

Impact on Application: Copper alloys are particularly effective in applications where electrical performance is critical, but their cost and mechanical limitations may restrict their use in high-strength applications.

Considerations for B2B Buyers: Buyers should carefully assess the specific requirements of their applications, including thermal and electrical performance. Compliance with industry standards is crucial, especially in electrical applications where safety is paramount.

| Material | Typical Use Case for global metals | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, medical equipment | High corrosion resistance | Higher cost than other materials | High |

| Aluminum Alloys | Aerospace, automotive components | Lightweight and excellent machinability | Lower strength compared to steel | Medium |

| Carbon Steel | Structural components, machinery | Affordable and versatile | Prone to rust, requires coatings | Low |

| Copper Alloys | Electrical applications, plumbing | Excellent electrical conductivity | Expensive and can deform easily | High |

This analysis provides a comprehensive overview of key materials in the global metals market, helping B2B buyers make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for global metals

In the competitive landscape of global metals, understanding the manufacturing processes and quality assurance protocols is essential for B2B buyers looking to optimize their sourcing strategies. This section explores the key stages in the manufacturing of metals and the rigorous quality control measures that ensure products meet international standards. By gaining insights into these processes, buyers can make informed decisions that align with their operational requirements and compliance needs.

Manufacturing Processes

The production of metals typically involves several stages, each critical to ensuring the final product’s quality and performance. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

This initial stage involves selecting and preparing raw materials, such as ores or recycled metals. Key techniques include:

- Melting and Alloying: The raw materials are melted in a furnace, allowing for the addition of other elements to create alloys with desired properties.

- Casting: The molten metal is poured into molds to form ingots, which are then cooled and solidified. This method is crucial for producing large quantities of metal shapes.

For B2B buyers, verifying the sourcing of raw materials is essential. Suppliers should demonstrate compliance with environmental and ethical sourcing standards, ensuring that materials are not only of high quality but also responsibly sourced.

Forming

Once the raw materials are prepared, they undergo various forming processes to shape them into usable products. Common techniques include:

- Extrusion: Metal is forced through a die to create long shapes with consistent cross-sections, ideal for tubing and structural components.

- Rolling: This involves passing metal through rollers to reduce thickness and improve surface finish. Hot rolling is typically used for larger sections, while cold rolling provides enhanced surface quality and tighter tolerances.

Buyers should inquire about the forming techniques used by suppliers and their impact on product characteristics, such as strength and flexibility.

Assembly

In cases where products consist of multiple components, assembly processes come into play. Techniques may include:

- Welding: Joining metals using heat, which can be critical for structural integrity in heavy-duty applications.

- Mechanical Fastening: Utilizing bolts, screws, or rivets to connect parts, often used in assembly lines for efficiency.

Understanding the assembly techniques is vital for buyers, particularly when considering the end-use of the products and ensuring compatibility with existing systems.

Finishing

The final stage involves various finishing processes to enhance product performance and aesthetics. Techniques include:

- Surface Treatment: Processes such as anodizing, galvanizing, or powder coating are used to improve corrosion resistance and appearance.

- Machining: Precision cutting and shaping to achieve tight tolerances and intricate designs.

B2B buyers should ensure that the finishing processes align with their specific requirements, especially in regulated industries where surface quality can significantly impact functionality.

Quality Assurance

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that products meet both industry standards and buyer specifications. Key components of a robust QA system include adherence to international standards and the implementation of systematic checkpoints throughout the production cycle.

International Standards

Compliance with international standards, such as ISO 9001, is essential for quality management systems. This standard emphasizes a process-oriented approach to ensure consistent quality and customer satisfaction. Additionally, industry-specific certifications such as CE (for products sold in the European Economic Area) and API (for oil and gas equipment) further validate the quality of metal products.

B2B buyers should prioritize suppliers who are certified under these standards, as it indicates a commitment to quality and continuous improvement.

Quality Control Checkpoints

Quality control (QC) involves systematic inspection and testing at various stages of the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring during production to detect and correct issues in real-time.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify they meet all specifications before shipment.

Implementing these QC checkpoints helps mitigate risks associated with product defects and ensures that buyers receive high-quality materials.

Common Testing Methods

Various testing methods are employed to assess the quality of metals, including:

- Tensile Testing: Measures the strength and ductility of materials by subjecting them to controlled tension.

- Hardness Testing: Evaluates a material’s resistance to deformation, which is crucial for applications requiring durability.

- Chemical Analysis: Ensures the composition of alloys meets specific standards, critical for performance in demanding environments.

B2B buyers should request details on the testing methods employed by their suppliers, as this information is vital for understanding product reliability.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers can take several steps:

- Supplier Audits: Conducting regular audits of suppliers’ facilities can provide insights into their manufacturing processes and quality control measures.

- Reviewing Quality Reports: Requesting detailed QC reports and testing certificates can help buyers verify compliance with specified standards.

- Third-Party Inspections: Engaging independent inspectors can provide an unbiased assessment of product quality and supplier capabilities.

Understanding the nuances of QC certifications is particularly important for international B2B buyers. Variances in regulations and standards across regions can impact product quality and compliance. Buyers should familiarize themselves with the specific certifications relevant to their markets, especially when sourcing from regions with differing regulatory landscapes.

Conclusion

Navigating the complexities of manufacturing processes and quality assurance in the global metals market requires diligence and strategic insight. By understanding the stages of metal production and the associated quality control measures, B2B buyers from Africa, South America, the Middle East, and Europe can make informed sourcing decisions. This knowledge not only enhances procurement efficiency but also contributes to long-term operational success in their respective industries.

Related Video: The Future of Manufacturing | An Overview

Comprehensive Cost and Pricing Analysis for global metals Sourcing

In the realm of global metals sourcing, understanding the intricate cost structure and pricing dynamics is essential for B2B buyers aiming to optimize their procurement strategies. The costs associated with metals encompass several components, each influencing the final price and overall procurement efficiency.

Cost Components

-

Materials: The raw materials constitute a significant portion of the total cost. Prices can fluctuate based on market demand, availability, and geopolitical factors. For instance, sourcing high-demand metals like titanium or tungsten may incur higher costs compared to more readily available materials like stainless steel.

-

Labor: Labor costs vary significantly by region and can impact the pricing of metals. Countries with higher wage standards may reflect these costs in their pricing structures. Understanding the labor market in the supplier’s region can provide insight into potential cost variations.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and administrative expenses. Suppliers in regions with higher operational costs may pass these expenses onto buyers, affecting overall pricing.

Illustrative Image (Source: Google Search)

-

Tooling: Custom tooling for specific metal products can be a substantial investment. Buyers should evaluate whether the tooling costs are included in the quoted price or if they will be an additional expense.

-

Quality Control (QC): Rigorous quality control processes are essential for ensuring product reliability. Suppliers that adhere to international standards and certifications may charge a premium for their products, but this investment can lead to lower failure rates and greater long-term savings.

-

Logistics: Transportation costs are critical in determining the final price. Factors such as shipping distance, mode of transport, and any potential tariffs or import duties should be considered. International buyers, particularly from regions like Africa and South America, should factor in these logistics costs when evaluating suppliers.

-

Margin: Supplier profit margins can vary widely. Understanding the competitive landscape and negotiating effectively can help buyers secure more favorable pricing.

Price Influencers

Several factors influence the pricing of metals, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Establishing a minimum order quantity (MOQ) can provide leverage in negotiations.

-

Specifications/Customization: Custom specifications can increase costs. Buyers should balance the need for specific properties with the potential for higher pricing.

-

Materials and Quality/Certifications: Higher quality materials or those with specific certifications will command a premium. Buyers should prioritize quality that aligns with their operational needs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge more but can offer greater assurance of quality and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities for shipping costs, insurance, and risk, affecting the total landed cost of the metals.

Buyer Tips

To navigate the complexities of metals sourcing effectively, B2B buyers should consider the following strategies:

-

Negotiation: Leverage volume and long-term contracts to negotiate better prices. Building a strong relationship with suppliers can yield additional benefits, such as improved payment terms or priority in production schedules.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as durability, maintenance, and potential wastage to identify the most cost-effective options.

-

Pricing Nuances: Be aware of regional pricing variations and how local economic conditions impact supplier pricing. Buyers from Europe may encounter different pricing strategies than those in Africa or South America.

-

Disclaimer for Indicative Prices: Pricing in the metals market can be highly volatile and influenced by numerous external factors. Buyers should always seek updated quotes and conduct thorough market research to ensure they are making informed purchasing decisions.

By understanding these cost components and price influencers, B2B buyers can enhance their sourcing strategies, mitigate risks, and achieve optimal value in their procurement of metals on the global stage.

Spotlight on Potential global metals Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘global metals’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for global metals

Understanding the technical properties of metals and the associated trade terminology is crucial for B2B buyers navigating the complex landscape of global metals. This section outlines essential specifications and common industry terms that will empower decision-makers to make informed purchasing choices.

Key Technical Properties

-

Material Grade

– Definition: Material grade refers to the classification of a metal based on its chemical composition, mechanical properties, and intended use.

– B2B Importance: Selecting the right grade is vital for ensuring that the metal meets the specific performance requirements of an application. For instance, higher grades of stainless steel offer better corrosion resistance, making them suitable for medical or food processing applications. -

Tolerance

– Definition: Tolerance is the allowable variation in a material’s dimensions and properties. It specifies the limits within which a material must conform to meet design specifications.

– B2B Importance: Understanding tolerance levels is essential for ensuring compatibility with other components and for maintaining the integrity of the final product. Tight tolerances may be necessary for precision engineering applications, while looser tolerances can suffice for less critical uses. -

Yield Strength

– Definition: Yield strength is the amount of stress a material can withstand before it deforms permanently.

– B2B Importance: This property is crucial for applications that require durability and structural integrity. Buyers must consider yield strength when selecting metals for load-bearing structures or components subjected to high stress. -

Corrosion Resistance

– Definition: Corrosion resistance is the ability of a material to withstand deterioration due to chemical or electrochemical reactions with its environment.

– B2B Importance: For industries like construction and oil & gas, choosing metals with high corrosion resistance can significantly reduce maintenance costs and extend the lifespan of products, enhancing overall value. -

Ductility

– Definition: Ductility measures a material’s ability to deform under tensile stress, indicating how much it can be stretched without breaking.

– B2B Importance: Metals with high ductility are easier to work with in forming and shaping processes, making them ideal for applications that require complex geometries or extensive fabrication.

Common Trade Terms

- OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is crucial for buyers looking to source components that integrate seamlessly with existing systems, ensuring compatibility and quality.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Buyers should be aware of MOQs to manage inventory effectively and optimize procurement costs. A high MOQ can impact cash flow and storage requirements. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting pricing information for specific quantities of products.

– Relevance: RFQs are essential for obtaining competitive pricing and terms from multiple suppliers, enabling buyers to make cost-effective purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Relevance: Familiarity with Incoterms helps buyers understand their obligations in international transactions, ensuring clarity in logistics and cost management. -

Lead Time

– Definition: Lead time is the time taken from placing an order to receiving the goods.

– Relevance: Understanding lead times is crucial for planning and inventory management. Buyers must consider lead times when sourcing metals to ensure timely delivery and project completion.

By grasping these technical specifications and trade terms, B2B buyers can navigate the complexities of the global metals market more effectively, ultimately enhancing their procurement strategies and operational efficiency.

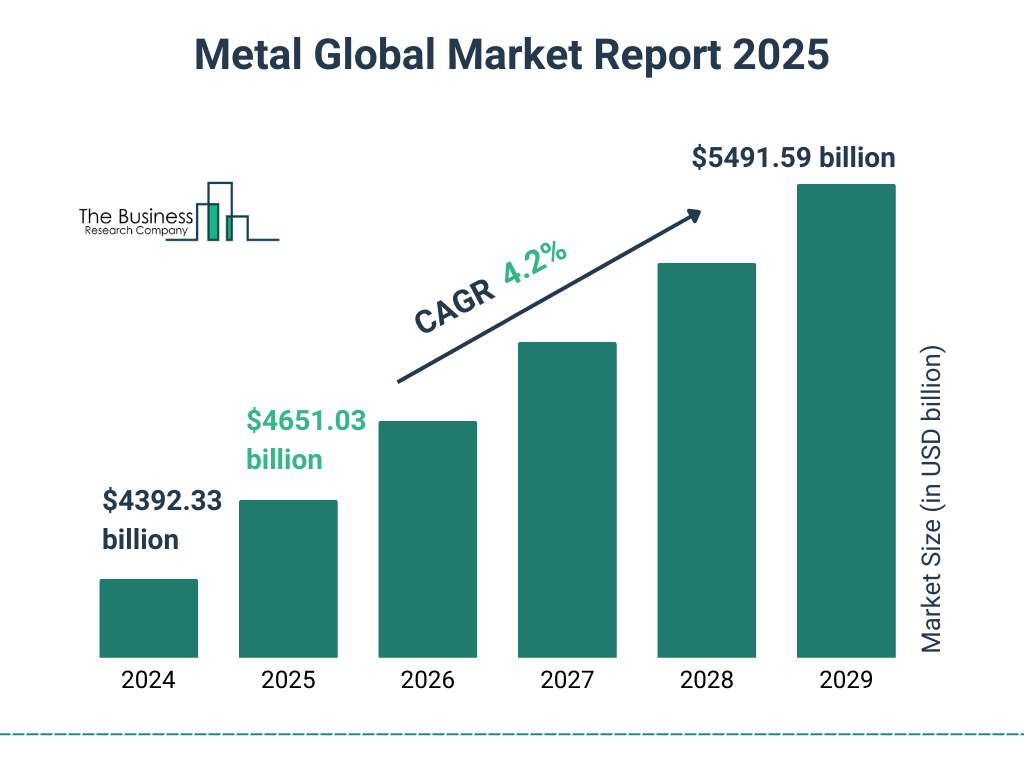

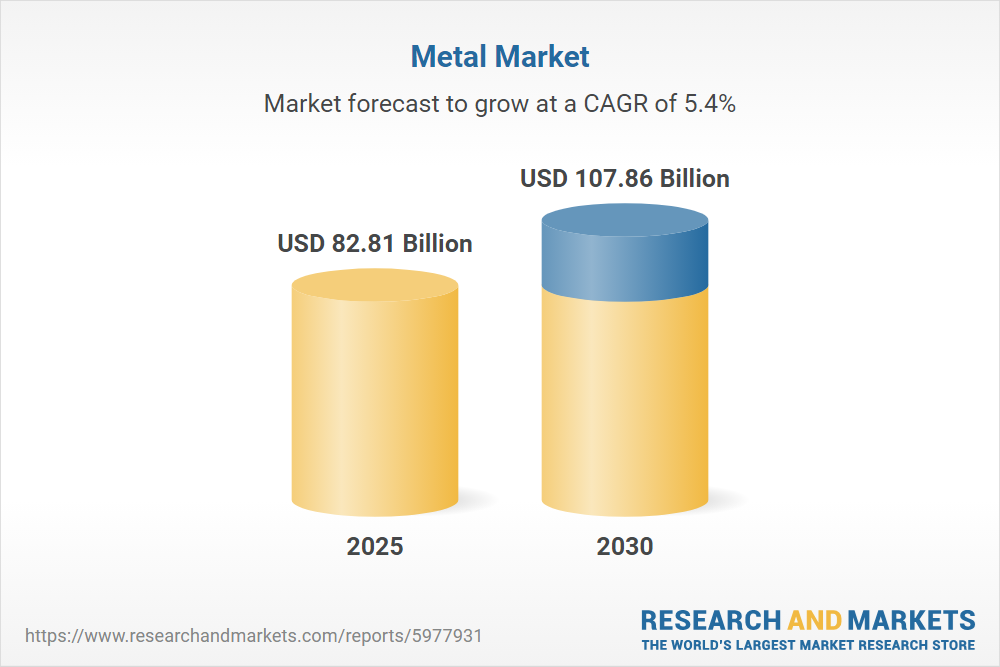

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the global metals Sector

In the global metals sector, several market dynamics and key trends are shaping the landscape for international B2B buyers. The demand for metals is being driven by urbanization, infrastructure development, and technological advancements across various industries. As countries in Africa, South America, the Middle East, and Europe continue to invest in renewable energy and sustainable infrastructure, metals such as steel, aluminum, and copper are gaining prominence.

Emerging technologies such as automation and artificial intelligence are revolutionizing sourcing strategies, enabling buyers to optimize their procurement processes. Digital platforms and marketplaces are enhancing transparency and efficiency, allowing buyers to compare suppliers and materials more effectively. Additionally, the trend towards circular economy practices is prompting companies to explore secondary materials and recycling options, which can reduce costs and environmental impact. For buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with their operational goals and sustainability commitments.

Sustainability & Ethical Sourcing in B2B

The importance of sustainability in the global metals sector cannot be overstated. Environmental concerns related to mining, refining, and processing metals have led to increased scrutiny of supply chains. B2B buyers are now prioritizing ethical sourcing practices, seeking suppliers that adhere to environmental regulations and demonstrate a commitment to sustainable operations.

Materials with ‘green’ certifications, such as recycled steel or aluminum, are becoming increasingly sought after. These certifications not only validate the environmental impact of sourcing decisions but also enhance brand reputation in a market that values corporate responsibility. Buyers should conduct thorough due diligence on their suppliers, ensuring that they employ sustainable practices throughout their operations—from extraction to delivery. By aligning with ethical suppliers, companies can mitigate risks associated with reputational damage and regulatory compliance while contributing positively to their communities and the environment.

Brief Evolution/History

The evolution of the global metals sector has been marked by significant technological advancements and shifts in sourcing practices. Initially, metal procurement was primarily focused on availability and cost. However, as industries have evolved, so too have the complexities of sourcing. The introduction of advanced manufacturing techniques and stringent quality control measures has transformed how metals are produced and supplied.

In recent years, the emphasis has shifted towards sustainability and ethical sourcing, reflecting broader societal values. This shift has been particularly pronounced in regions like Europe, where regulatory frameworks increasingly mandate environmentally responsible practices. As a result, B2B buyers are now tasked with navigating a landscape that balances cost-effectiveness with sustainability and ethical considerations, making informed sourcing decisions more critical than ever.

Related Video: Made in the world: Better understanding global trade flows

Frequently Asked Questions (FAQs) for B2B Buyers of global metals

-

How can I effectively vet suppliers for metal sourcing?

When vetting suppliers, prioritize their industry reputation, certifications (like ISO 9001), and experience in your specific metal requirements. Request references from previous clients, and evaluate their production capabilities through site visits or virtual audits. It’s also beneficial to assess their financial stability and ensure they comply with local and international regulations, particularly in the regions you operate, to mitigate risks associated with supply chain disruptions. -

What customization options should I consider when sourcing metals?

Customization options can include specific alloy compositions, dimensions, and surface treatments to meet your project requirements. Discuss your needs directly with potential suppliers to understand their capabilities and limitations. Ensure that they have the necessary technology and expertise for precision machining or finishing processes. Additionally, request samples or prototypes to evaluate their ability to meet your specifications before placing larger orders. -

What are typical minimum order quantities (MOQs) and lead times for metal products?

MOQs can vary significantly based on the metal type, supplier, and specific product requirements, often ranging from a few hundred to several thousand kilograms. Lead times also depend on production schedules, customization needs, and shipping logistics. Always clarify these details upfront and factor in potential delays due to customs or regional regulations, especially when sourcing internationally, to better plan your procurement timelines. -

What quality assurance measures should I expect from suppliers?

Suppliers should implement rigorous quality assurance protocols, including material testing, compliance with international standards (like ASTM or EN), and regular audits of their manufacturing processes. Request certificates of compliance and inspection reports for each batch. Understanding their quality control processes will help you ensure that the metals you receive will meet your specifications and industry standards, reducing the risk of defects or failures in your applications. -

How should I handle disputes with international suppliers?

Disputes can arise from misunderstandings regarding product specifications, delivery schedules, or payment terms. Establish clear contracts that outline expectations, responsibilities, and consequences for non-compliance. In the event of a dispute, maintain open communication with the supplier to resolve issues amicably. If necessary, consider mediation or arbitration as alternatives to litigation, as they can be more cost-effective and quicker, especially in international contexts. -

What logistics considerations should I keep in mind when sourcing metals?

Logistics plays a crucial role in metal sourcing. Evaluate the supplier’s shipping capabilities, including their experience with international freight and customs procedures. Consider the impact of shipping costs on your overall budget, and explore options for consolidated shipments to reduce expenses. Additionally, ensure that you have a clear understanding of delivery timelines and potential risks, such as geopolitical factors, that could affect transit. -

What payment terms are common in international metal sourcing?

Payment terms can vary widely based on supplier policies and the nature of the transaction. Common terms include advance payment, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that protect your interests while ensuring the supplier’s confidence in the transaction. Be aware of currency fluctuations and international banking fees, which can affect the total cost. Always document payment agreements clearly to avoid misunderstandings. -

How can I keep track of market trends in the global metals industry?

Staying informed about market trends requires a proactive approach. Regularly consult industry reports, trade publications, and market analysis from reputable sources. Joining industry associations and participating in trade shows can provide valuable networking opportunities and insights into emerging trends. Additionally, consider subscribing to newsletters or online platforms that focus on metals pricing, supply chain developments, and regulatory changes, ensuring you remain competitive in your sourcing strategies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for global metals

In conclusion, navigating the global metals market requires a strategic approach to sourcing that encompasses not only the selection of high-quality materials but also a deep understanding of market dynamics and supplier reliability. International B2B buyers from Africa, South America, the Middle East, and Europe must prioritize collaboration with suppliers who demonstrate transparency, adherence to international standards, and a commitment to innovation. By leveraging advanced alloys and manufacturing processes, companies can enhance operational efficiency and drive sustainable growth.

Key takeaways include the importance of evaluating material properties specific to industry needs, understanding cost structures to optimize procurement, and staying abreast of evolving regulatory frameworks that impact sourcing decisions. As global supply chains continue to evolve, buyers should adopt a proactive stance, embracing agility and adaptability in their sourcing strategies.

Looking ahead, the demand for specialized metals will only increase as industries push for enhanced performance and sustainability. B2B buyers are encouraged to explore new partnerships and technologies that will not only meet current needs but also anticipate future challenges. Engage with trusted suppliers today to ensure your business remains competitive in this rapidly changing landscape.