Your Ultimate Guide to Sourcing Air Cylinders Pneumatic

Introduction: Navigating the Global Market for air cylinders pneumatic cylinder

In today’s rapidly evolving industrial landscape, air cylinders, or pneumatic cylinders, play a pivotal role in automating processes across various sectors. Their ability to convert compressed air into precise linear motion makes them indispensable for enhancing operational efficiency, minimizing downtime, and reducing costs. As international B2B buyers navigate the complexities of sourcing pneumatic solutions, understanding the intricacies of air cylinders becomes crucial for making informed decisions.

This comprehensive guide delves into the essential aspects of air cylinders, covering a wide range of topics including types of cylinders, materials used in their construction, manufacturing standards and quality control, leading suppliers, cost considerations, and market trends. By exploring these elements, buyers from Africa, South America, the Middle East, and Europe—including key markets like Spain and the UK—will gain valuable insights into the best practices for selecting the right pneumatic solutions for their specific applications.

Additionally, the guide addresses frequently asked questions, providing clarity on common concerns and misconceptions. With this resource, B2B buyers will be empowered to make strategic sourcing decisions that align with their operational needs, ultimately driving productivity and fostering growth in their respective industries. Equip yourself with the knowledge needed to navigate the global market for air cylinders effectively, ensuring your business remains competitive and responsive to emerging demands.

Understanding air cylinders pneumatic cylinder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| General Purpose Air Cylinders | Simple structure, versatile bore sizes, cost-effective | Manufacturing, assembly lines | Pros: Economical, widely available. Cons: May lack advanced features. |

| Compact Air Cylinders | Short stroke, lightweight, space-saving design | Robotics, automated assembly | Pros: Ideal for tight spaces. Cons: Limited stroke length. |

| Guided Air Cylinders | Built-in guide rods for stability and precision | Lifting, positioning, pressing operations | Pros: Enhanced accuracy and stability. Cons: Higher cost due to complexity. |

| Locking Air Cylinders | Integrated brake/locking mechanisms for controlled stopping | Safety applications, vertical load holding | Pros: Secure load holding. Cons: May require more maintenance. |

| Rodless Air Cylinders | No traditional piston rod, uses magnetic or mechanical coupling | Long-stroke applications, conveyor systems | Pros: Space-efficient, versatile. Cons: Potentially higher initial investment. |

General Purpose Air Cylinders

General purpose air cylinders are characterized by their simple design and adaptability, making them suitable for a wide range of applications. They come in various bore sizes and stroke lengths, allowing for customization based on specific needs. B2B buyers should consider factors like pressure ratings and environmental conditions when selecting these cylinders, as they are frequently used in manufacturing and assembly lines due to their cost-effectiveness.

Compact Air Cylinders

Compact air cylinders are designed for applications where space is limited. They typically feature a shorter stroke while maintaining sufficient force output, making them ideal for robotic arms and automated assembly processes. Buyers should evaluate the required force and speed specifications to ensure compatibility with their systems. The lightweight design provides flexibility in installation but may limit the range of motion.

Guided Air Cylinders

Guided air cylinders include built-in guide rods, which enhance stability and precision during operation. This feature is particularly beneficial in applications that require accurate positioning and resistance to side loads, such as lifting and pressing. When purchasing guided cylinders, B2B buyers should assess the load requirements and the environment in which the cylinder will operate, as these factors influence performance and longevity.

Locking Air Cylinders

Locking air cylinders are equipped with mechanisms that allow them to hold their position securely, making them suitable for applications that require controlled stopping, such as vertical load holding. Buyers should consider the locking mechanism’s reliability and maintenance needs when selecting these cylinders. While they offer enhanced safety features, they may also involve higher maintenance and operational costs.

Rodless Air Cylinders

Rodless air cylinders eliminate the traditional piston rod, using alternative methods such as magnetic or mechanical coupling to transfer motion. This design allows for longer stroke lengths in confined spaces, making them ideal for material handling and conveyor systems. B2B buyers should evaluate the application requirements, such as speed and load capacity, as the initial investment may be higher compared to conventional cylinders.

Related Video: Types of Pneumatic Cylinders Explained

Key Industrial Applications of air cylinders pneumatic cylinder

| Industry/Sector | Specific Application of air cylinders pneumatic cylinder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Assembly line automation for vehicle parts | Increases production efficiency and reduces labor costs | Quality standards, compatibility with existing systems |

| Food and Beverage Processing | Packaging and filling machinery operations | Ensures high-speed operation and hygiene compliance | Corrosion resistance, ease of cleaning, and maintenance needs |

| Material Handling | Automated sorting and palletizing systems | Enhances accuracy and speed in material movement | Load capacity, stroke length, and space constraints |

| Medical Equipment Production | Assembly and testing of medical devices | Guarantees precision and reliability in critical operations | Compliance with medical standards, reliability, and support |

| Robotics | Actuation in robotic arms for precise movements | Improves automation capabilities and reduces downtime | Customization options, response time, and durability |

Automotive Manufacturing

In the automotive sector, air cylinders are pivotal in assembly line automation, where they facilitate the movement and assembly of various vehicle parts. By converting compressed air into linear motion, these cylinders enhance the speed and efficiency of production processes, significantly lowering labor costs. International buyers should consider sourcing cylinders that meet specific quality standards and ensure compatibility with their existing automation systems to optimize performance.

Food and Beverage Processing

Air cylinders play a crucial role in packaging and filling machinery within the food and beverage industry. They ensure high-speed operation while maintaining stringent hygiene standards, which is vital for compliance with health regulations. Buyers in this sector should prioritize cylinders that offer corrosion resistance and are easy to clean, as these features directly impact operational efficiency and product safety.

Material Handling

In material handling applications, air cylinders are used in automated sorting and palletizing systems. They provide precise control over the movement of goods, enhancing the speed and accuracy of operations. For businesses focused on logistics and warehousing, it is essential to consider the load capacity and stroke length of the cylinders, as well as any space constraints that may affect installation and operation.

Medical Equipment Production

Within the medical equipment sector, air cylinders are integral to the assembly and testing of devices. They ensure precision and reliability, which are critical in environments where safety is paramount. Buyers should seek pneumatic cylinders that comply with medical standards and offer exceptional reliability, along with strong support from suppliers to address any operational issues that may arise.

Robotics

Air cylinders are vital in the robotics industry, particularly in robotic arms that require precise movements. They enhance automation capabilities, enabling faster production cycles and reducing downtime. B2B buyers should look for options that offer customization to meet specific application needs, as well as cylinders that provide rapid response times and durability to withstand continuous use in demanding environments.

Related Video: Pneumatic Cylinder: How Does It Work?

Strategic Material Selection Guide for air cylinders pneumatic cylinder

When selecting materials for air cylinders, it is crucial to understand how each material’s properties affect performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in the construction of pneumatic cylinders, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

Aluminum

Key Properties: Aluminum is lightweight yet strong, with a good temperature rating up to 120°C (248°F) and excellent corrosion resistance, particularly when anodized. It is also a good conductor of heat.

Pros & Cons: The primary advantage of aluminum is its low weight, which enhances the speed and efficiency of pneumatic systems. It is also cost-effective and easy to manufacture, making it a popular choice for general-purpose air cylinders. However, aluminum can be less durable than steel under high-pressure applications and may not withstand extreme temperatures as effectively.

Impact on Application: Aluminum cylinders are suitable for applications in environments where weight reduction is critical, such as in robotics or automated assembly lines. However, they may not be ideal for heavy-duty applications requiring high pressure or extreme temperatures.

Considerations for International Buyers: Buyers should ensure that aluminum components comply with relevant standards such as ASTM B221 (for extruded aluminum) and consider local regulations regarding material sourcing and environmental impact.

Stainless Steel

Key Properties: Stainless steel offers high strength, excellent corrosion resistance, and can withstand temperatures up to 300°C (572°F). It is also resistant to various chemicals, making it suitable for diverse applications.

Pros & Cons: The main advantage of stainless steel is its durability and resistance to corrosion, making it ideal for harsh environments, including food processing and chemical industries. However, it is heavier and more expensive than aluminum, and its manufacturing process can be more complex, potentially leading to longer lead times.

Impact on Application: Stainless steel cylinders are well-suited for applications requiring high strength and corrosion resistance, such as in the food and beverage industry or in marine environments. However, the increased weight may be a limitation in applications where speed is critical.

Considerations for International Buyers: Buyers in regions such as Europe and the Middle East should ensure compliance with standards like ASTM A276 for stainless steel and consider the implications of higher material costs on project budgets.

Composite Materials

Key Properties: Composite materials, often made from a combination of polymers and fibers, can offer excellent strength-to-weight ratios and high corrosion resistance. They can also be engineered to withstand specific temperature and pressure conditions.

Pros & Cons: The key advantage of composites is their lightweight nature and flexibility in design, which allows for innovative applications. However, they can be more expensive and may require specialized manufacturing processes, which can complicate supply chains.

Impact on Application: Composite cylinders are ideal for applications where weight savings are critical, such as aerospace or automotive industries. However, their performance can vary significantly based on the specific composite used, which necessitates careful selection.

Considerations for International Buyers: Buyers should be aware of the varying standards for composites across regions, including ISO standards for composite materials, and ensure that suppliers can meet these requirements.

Brass

Key Properties: Brass is known for its excellent machinability, good corrosion resistance, and ability to withstand moderate temperatures and pressures. It typically operates effectively up to 150°C (302°F).

Pros & Cons: Brass is easy to machine and offers good aesthetic qualities, making it suitable for applications where appearance matters. However, it is heavier than aluminum and can be more expensive, especially for larger components.

Impact on Application: Brass cylinders are commonly used in applications requiring precise movement and where aesthetics are important, such as in decorative machinery. However, they may not be suitable for high-pressure applications.

Considerations for International Buyers: Buyers should consider the implications of brass sourcing, particularly in regions with strict regulations on metal sourcing and environmental impact, ensuring compliance with standards such as ASTM B36.

| Material | Typical Use Case for air cylinders pneumatic cylinder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General-purpose automation and robotics | Lightweight and cost-effective | Less durable under high pressure | Low |

| Stainless Steel | Food processing and chemical industries | High strength and corrosion resistance | Heavier and more expensive | High |

| Composite | Aerospace and automotive applications | Excellent strength-to-weight ratio | More expensive and complex to manufacture | Med |

| Brass | Decorative machinery and precise movement applications | Good machinability and aesthetics | Heavier and potentially more costly | Med |

This strategic material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for air cylinders pneumatic cylinder

Air cylinders, or pneumatic cylinders, are critical components in automation, and their manufacturing processes and quality assurance protocols play a vital role in ensuring their reliability and performance. Understanding these processes is essential for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This section delves into the typical manufacturing stages, key techniques, and quality control measures that underpin the production of air cylinders.

Manufacturing Processes

The manufacturing of air cylinders involves several key stages:

1. Material Preparation

Material selection is crucial for the durability and performance of air cylinders. Common materials include:

– Aluminum: Lightweight and corrosion-resistant, ideal for many applications.

– Stainless Steel: Offers high strength and resistance to rust and wear, suitable for harsh environments.

– Special Coatings: Various surface treatments enhance corrosion resistance and durability.

The raw materials are sourced from certified suppliers to ensure quality. They are then cut, machined, and prepared for the next stage, ensuring they meet dimensional and surface finish specifications.

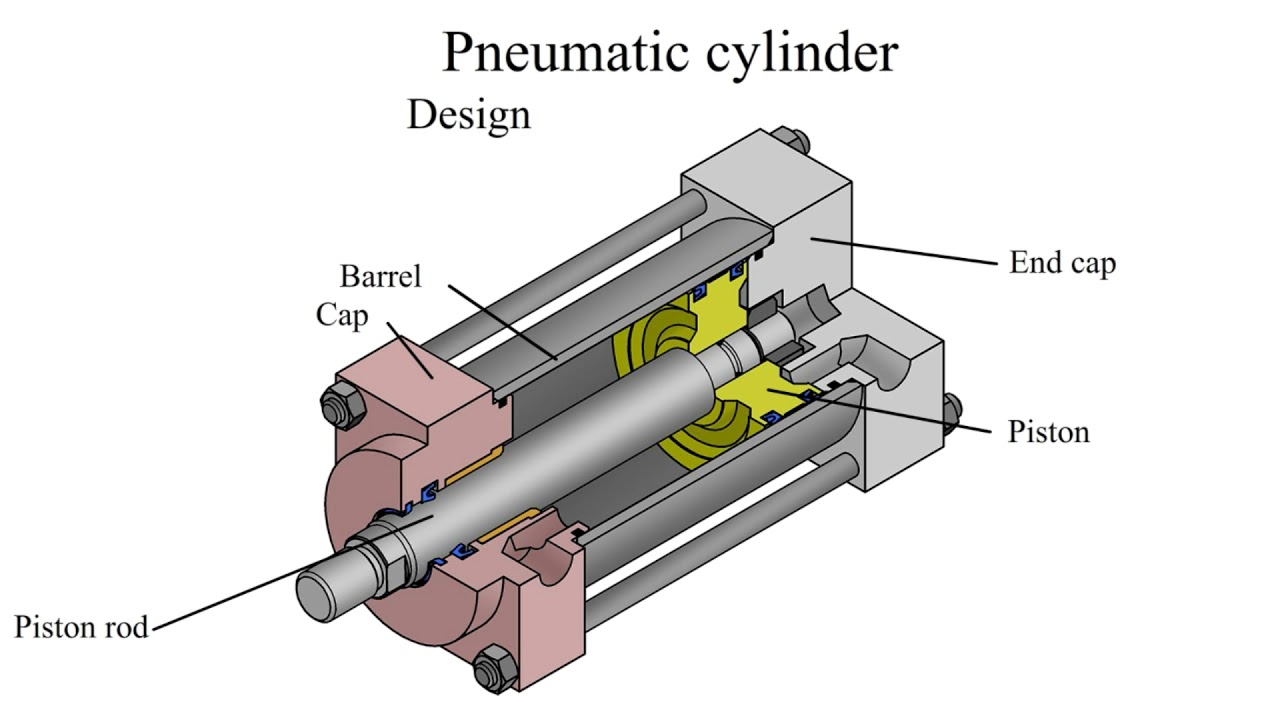

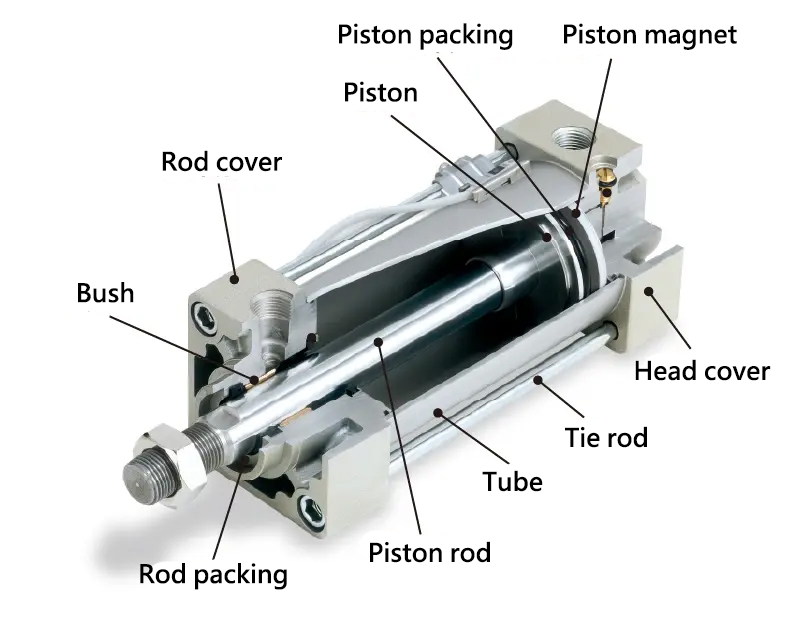

2. Forming

This stage involves shaping the components of the air cylinder, which typically includes:

– Cylindrical Tubes: Formed using extrusion or rolling processes, ensuring uniform thickness and strength.

– Pistons and Rods: Machined to precise specifications, often employing CNC (Computer Numerical Control) technology for accuracy.

– Tie Rods and Covers: These components are also machined, ensuring they fit together perfectly to maintain structural integrity.

Advanced forming techniques may include forging or die casting, depending on the design and performance requirements.

3. Assembly

The assembly process is critical for ensuring the proper functioning of the air cylinder. Key steps include:

– Component Assembly: The cylinder tube, piston, and other components are assembled using fixtures to maintain alignment.

– Sealing: Piston packing and rod packing are installed to prevent air leakage. The quality of these seals is vital for operational efficiency.

– Installation of Accessories: Features such as sensors or cushioning devices may be added during assembly to enhance functionality.

Automation in assembly can improve consistency and reduce labor costs, but skilled technicians are often required for quality checks.

4. Finishing

Finishing processes enhance the performance and aesthetics of the air cylinders. This may include:

– Surface Treatments: Anodizing for aluminum parts, plating for corrosion resistance, and polishing for a smooth finish.

– Quality Inspections: Each finished cylinder undergoes rigorous inspection to ensure it meets specifications.

Quality Assurance

Quality assurance (QA) is paramount in the manufacturing of air cylinders, ensuring they meet international standards and customer expectations.

International Standards

B2B buyers should be aware of the following relevant standards:

– ISO 9001: This quality management standard ensures that manufacturers have a systematic approach to quality assurance.

– CE Marking: Required for products sold in the European Economic Area, demonstrating compliance with safety and environmental protection standards.

– API Standards: Relevant for cylinders used in the oil and gas industry, ensuring they meet specific operational requirements.

Quality Control Checkpoints

Quality control is typically divided into several stages:

– Incoming Quality Control (IQC): Inspection of raw materials to ensure they meet required specifications before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to identify and rectify issues as they arise.

– Final Quality Control (FQC): Comprehensive testing of finished products, including dimensional checks, pressure tests, and functional tests.

Common Testing Methods

Testing methods for air cylinders can include:

– Hydraulic Testing: To ensure the cylinder can withstand operational pressures.

– Leak Testing: Using pressure decay or bubble tests to identify any leaks in the system.

– Functional Testing: Ensuring the cylinder operates as intended under load conditions.

Verifying Supplier Quality Control

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential:

- Supplier Audits: Conducting on-site audits to assess manufacturing capabilities, quality control systems, and compliance with international standards.

- Quality Reports: Requesting detailed quality assurance reports, including test results and certifications.

- Third-Party Inspections: Engaging independent inspection agencies to validate the quality of products before shipment.

Quality Control Considerations for International Buyers

When sourcing air cylinders internationally, buyers should consider:

– Cultural and Regulatory Differences: Understanding the specific quality standards and practices in the supplier’s country.

– Communication: Establishing clear communication channels to address any quality concerns promptly.

– Logistics: Ensuring that quality is maintained throughout the supply chain, from manufacturing to delivery.

In summary, the manufacturing processes and quality assurance for air cylinders are complex but critical for ensuring reliability and performance. By understanding these elements, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to more successful procurement and operational efficiency in their own applications.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for air cylinders pneumatic cylinder Sourcing

When sourcing air cylinders (pneumatic cylinders), international B2B buyers must understand the comprehensive cost structure and pricing dynamics that influence their procurement decisions. This analysis will cover key cost components, price influencers, and actionable tips for buyers, particularly from Africa, South America, the Middle East, and Europe.

Cost Components

- Materials: The primary materials used in air cylinders include high-grade aluminum, stainless steel, and specialized coatings for corrosion resistance. The choice of materials significantly impacts the overall cost, with higher-quality materials commanding a premium due to their durability and performance in demanding applications.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs, such as parts of Africa and South America, can provide competitive pricing. However, skilled labor is essential for quality control and precision assembly, which may increase costs in developed regions.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, which can then be reflected in the pricing of the cylinders.

-

Tooling: Initial tooling costs can be significant, especially for custom or specialized designs. These costs are typically amortized over the production run, meaning larger orders can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring that air cylinders meet industry standards and certifications is crucial. The costs associated with quality assurance processes can influence the final price, as rigorous testing and certification processes may require additional investment.

-

Logistics: Shipping and handling costs depend on the distance from the manufacturer to the buyer, as well as the chosen shipping method. International buyers should consider potential tariffs, customs duties, and insurance when calculating total logistics costs.

-

Margin: Manufacturers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary based on competition, market demand, and the perceived value of the product.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Ordering in bulk often results in lower unit prices, making it crucial for buyers to assess their needs and negotiate favorable terms.

-

Specifications/Customization: Customized air cylinders tailored to specific applications can incur additional costs. Buyers should evaluate the necessity of these custom features against their budget constraints.

-

Materials: The choice between standard and premium materials will influence pricing. Buyers should weigh the long-term benefits of investing in higher-quality materials against immediate cost savings.

-

Quality/Certifications: Products with certifications (e.g., ISO, CE) may be priced higher due to the assurance of quality and reliability. Buyers should assess the importance of these certifications based on their application requirements.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: The terms of shipping (Incoterms) dictate who bears the cost and risk at various stages of transportation. Understanding these terms is essential for calculating total landed costs.

Buyer Tips

-

Negotiate: Leverage volume purchasing and long-term contracts to negotiate better pricing. Suppliers may be willing to offer discounts for larger orders or repeat business.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), including maintenance, downtime, and operational efficiency, rather than just the initial purchase price. Investing in higher-quality cylinders may reduce long-term costs.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates and regional economic conditions that can affect pricing. Understanding local market dynamics can provide leverage during negotiations.

-

Conduct Market Research: Stay informed about industry trends, competitor pricing, and emerging technologies. This knowledge can empower buyers to make informed decisions and negotiate effectively.

Disclaimer

The prices mentioned in this analysis are indicative and can vary widely based on factors such as location, supplier, and market conditions. Buyers should conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential air cylinders pneumatic cylinder Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘air cylinders pneumatic cylinder’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for air cylinders pneumatic cylinder

Air cylinders, also known as pneumatic cylinders, are essential components in various industrial automation applications. Understanding their technical properties and relevant trade terminology is crucial for B2B buyers, especially when making informed purchasing decisions. Below are critical specifications and commonly used terms in the industry.

Key Technical Properties

-

Material Grade

– Definition: The material used in the construction of air cylinders, typically high-grade aluminum or stainless steel.

– Importance: The choice of material affects durability, corrosion resistance, and weight. For industries operating in harsh environments, selecting the right material can significantly enhance the lifespan of the cylinder. -

Bore Size

– Definition: The internal diameter of the cylinder where the piston operates.

– Importance: Bore size directly influences the force output of the cylinder. A larger bore can generate more force, making it essential to match the bore size to the specific application requirements. -

Stroke Length

– Definition: The distance the piston travels from its fully extended position to its fully retracted position.

– Importance: Stroke length determines the range of motion available for the application. Buyers must ensure that the stroke length fits the operational needs of their machinery. -

Operating Pressure

– Definition: The maximum pressure at which the cylinder can operate effectively.

– Importance: Operating pressure affects performance and safety. Understanding the required operating pressure helps in selecting cylinders that can handle the specific demands of an application without risking failure. -

Cushioning

– Definition: A feature that slows down the piston as it approaches the end of its stroke to prevent sudden impacts.

– Importance: Proper cushioning enhances the operational efficiency and longevity of the cylinder by reducing wear and tear on both the cylinder and the connected machinery. -

Cycle Rate

– Definition: The number of complete extension and retraction cycles the cylinder can perform within a specific time frame.

– Importance: Cycle rate is critical for applications requiring high-speed operations. Buyers need to consider the cycle rate to ensure that the cylinder meets their production demands without overheating or malfunctioning.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Usage: Buyers often deal with OEMs for sourcing high-quality components that are compatible with their systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of a product that a supplier is willing to sell.

– Usage: Understanding MOQ is essential for budgeting and inventory management, particularly for small businesses that may not require large quantities. -

RFQ (Request for Quotation)

– Definition: A document sent by a buyer to suppliers requesting a price quote for specific products or services.

– Usage: RFQs are crucial in the procurement process, allowing buyers to compare prices and terms from different suppliers.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Usage: Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery responsibilities, which are critical in cross-border trade. -

Lead Time

– Definition: The amount of time from placing an order to receiving the product.

– Usage: Understanding lead times is vital for planning production schedules and inventory levels, especially in industries with tight deadlines. -

Pneumatic Actuator

– Definition: A device that uses compressed air to produce mechanical motion.

– Usage: Air cylinders are a type of pneumatic actuator, and understanding this term helps buyers in specifying the right components for their automation needs.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions, ensuring they select the right air cylinders for their specific applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the air cylinders pneumatic cylinder Sector

Market Overview & Key Trends

The air cylinders pneumatic cylinder market is experiencing robust growth, driven by the increasing demand for automation across various industries such as automotive, food processing, and manufacturing. Key market dynamics include the shift towards lightweight materials and the integration of advanced technologies like IoT and AI. International B2B buyers from regions like Africa, South America, the Middle East, and Europe should note that the adoption of smart pneumatic systems is on the rise, enhancing operational efficiency through real-time monitoring and predictive maintenance.

Emerging sourcing trends indicate a preference for suppliers who offer customizable solutions, allowing businesses to tailor pneumatic cylinders to specific applications. Additionally, the global push for sustainability is influencing procurement decisions, with buyers increasingly seeking eco-friendly products and practices. The rise of digital platforms for sourcing and procurement is also noteworthy, as they provide buyers with greater access to suppliers, enabling quicker decision-making processes and competitive pricing.

Moreover, geopolitical factors, including trade agreements and tariffs, can significantly impact sourcing strategies. Buyers must stay informed about these dynamics to mitigate risks and ensure a steady supply chain. As industries continue to modernize, the demand for high-performance air cylinders that deliver reliability and efficiency will only intensify, making it imperative for buyers to align their sourcing strategies with these market trends.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration in the air cylinders pneumatic cylinder sector, as the environmental impact of manufacturing processes becomes increasingly scrutinized. International B2B buyers are encouraged to prioritize suppliers who demonstrate a commitment to sustainable practices, such as reducing energy consumption and minimizing waste. The use of recyclable materials in the production of pneumatic cylinders can significantly reduce their environmental footprint.

Ethical sourcing is equally important, as buyers should seek suppliers who adhere to fair labor practices and maintain transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are indicators of a supplier’s dedication to sustainability and quality. Additionally, the utilization of green materials and processes, such as low-VOC coatings and biodegradable lubricants, can further enhance the sustainability profile of pneumatic cylinders.

By incorporating sustainability and ethical sourcing into procurement strategies, B2B buyers can not only meet regulatory requirements but also align with the growing consumer preference for environmentally responsible products. This approach not only enhances brand reputation but also fosters long-term partnerships with suppliers committed to sustainable development.

Brief Evolution/History

The evolution of air cylinders can be traced back to the early days of industrial automation in the 19th century, when steam power was the primary source of energy. The transition to compressed air as a driving force emerged in the early 20th century, leading to the development of pneumatic systems that offered greater efficiency and flexibility. Over the decades, advancements in materials science and manufacturing techniques have led to the production of more durable and reliable air cylinders, enabling their widespread adoption across various industries.

Today, the integration of smart technology into pneumatic systems marks a significant shift in the sector, as manufacturers strive to enhance performance through automation and data analytics. This ongoing evolution reflects the industry’s responsiveness to changing market demands and technological advancements, providing B2B buyers with increasingly sophisticated solutions tailored to their specific operational needs.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of air cylinders pneumatic cylinder

-

What should I consider when vetting suppliers for air cylinders?

When vetting suppliers for air cylinders, focus on their industry experience, reputation, and quality certifications (e.g., ISO 9001). Request references from previous clients, particularly those in your region, to gauge their reliability. Evaluate their manufacturing capabilities and the materials they use, as this impacts the durability of the cylinders. Additionally, assess their customer service responsiveness and technical support, as these factors can influence your ongoing relationship and problem resolution. -

Can I customize air cylinders to meet specific application needs?

Yes, many suppliers offer customization options for air cylinders, including modifications in size, stroke length, mounting configurations, and materials. When discussing customization, provide detailed specifications about your application requirements and any industry standards that need to be met. It’s advisable to confirm the supplier’s ability to provide prototypes or samples before placing a bulk order, ensuring that the customizations meet your expectations. -

What are the typical minimum order quantities (MOQs) and lead times for air cylinders?

Minimum order quantities (MOQs) for air cylinders can vary significantly based on the supplier, with some requiring as few as 10 units while others may have MOQs in the hundreds. Lead times generally range from a few weeks to several months, depending on customization requirements and the supplier’s production capacity. Always confirm MOQs and lead times during negotiations to align with your project timelines and budget.

-

What payment options are commonly available for international B2B transactions?

Payment options for international B2B transactions typically include wire transfers, letters of credit, and online payment platforms like PayPal. Each method has its pros and cons regarding security, transaction fees, and speed. Discuss payment terms upfront and consider using escrow services for larger orders to mitigate risks. Be aware of currency exchange rates and potential tariffs that may affect the total cost of your order. -

What quality assurance measures should I look for in air cylinder suppliers?

Ensure that your suppliers implement stringent quality assurance measures, such as regular inspections and testing of their products. Request documentation of quality certifications, such as ISO or CE markings, which indicate compliance with international standards. Inquire about their testing procedures, including pressure tests and performance evaluations, to confirm that the air cylinders meet your operational requirements and industry regulations. -

How can I ensure smooth logistics and shipping for my air cylinder orders?

To ensure smooth logistics, discuss shipping options with your supplier, including freight forwarding services and potential customs clearance assistance. Specify your preferred delivery method (air or sea) based on urgency and cost considerations. Establish clear timelines for shipping and delivery, and track shipments to preempt any delays. Additionally, familiarize yourself with import regulations in your country to avoid unexpected customs issues. -

What should I do if I encounter disputes with my air cylinder supplier?

In case of disputes, start by communicating directly with your supplier to resolve the issue amicably. Maintain a detailed record of all correspondence and agreements to support your case. If direct communication fails, consider mediation or arbitration as alternative dispute resolution methods. It is advisable to include clear terms regarding dispute resolution in your contracts, specifying jurisdiction and legal frameworks applicable to both parties. -

What certifications should I look for when sourcing air cylinders internationally?

Look for certifications relevant to your industry and region, such as ISO 9001 for quality management, ISO 14001 for environmental management, and CE marking for products sold within the European Union. These certifications demonstrate compliance with international standards and can impact the acceptance of products in your market. Additionally, inquire about any regional certifications necessary for specific applications, especially in sectors like food processing or healthcare, to ensure compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for air cylinders pneumatic cylinder

In conclusion, strategic sourcing of air cylinders is pivotal for international B2B buyers seeking to enhance operational efficiency and reliability in automation processes. Understanding the diverse types of pneumatic cylinders—ranging from general purpose to rodless designs—enables buyers to select solutions that best fit their specific applications. The emphasis on quality materials and design innovations ensures that these components can withstand varying environmental conditions, ultimately contributing to lower maintenance costs and improved productivity.

For buyers in Africa, South America, the Middle East, and Europe, leveraging strategic sourcing practices not only facilitates cost savings but also fosters partnerships with reliable suppliers who understand local market dynamics. As industries evolve, the demand for advanced pneumatic solutions will only increase, making it essential for businesses to stay informed about the latest trends and technologies.

As you consider your sourcing strategies, remember to prioritize supplier relationships and invest in technology that enhances your operational capabilities. Embrace the future of automation with confidence, ensuring that your pneumatic systems are equipped to meet the demands of a rapidly changing global market. Engage with suppliers today to secure a competitive advantage for tomorrow.