Your Ultimate Guide to Sourcing Alumina Oxide Ceramic

Introduction: Navigating the Global Market for alumina oxide ceramic

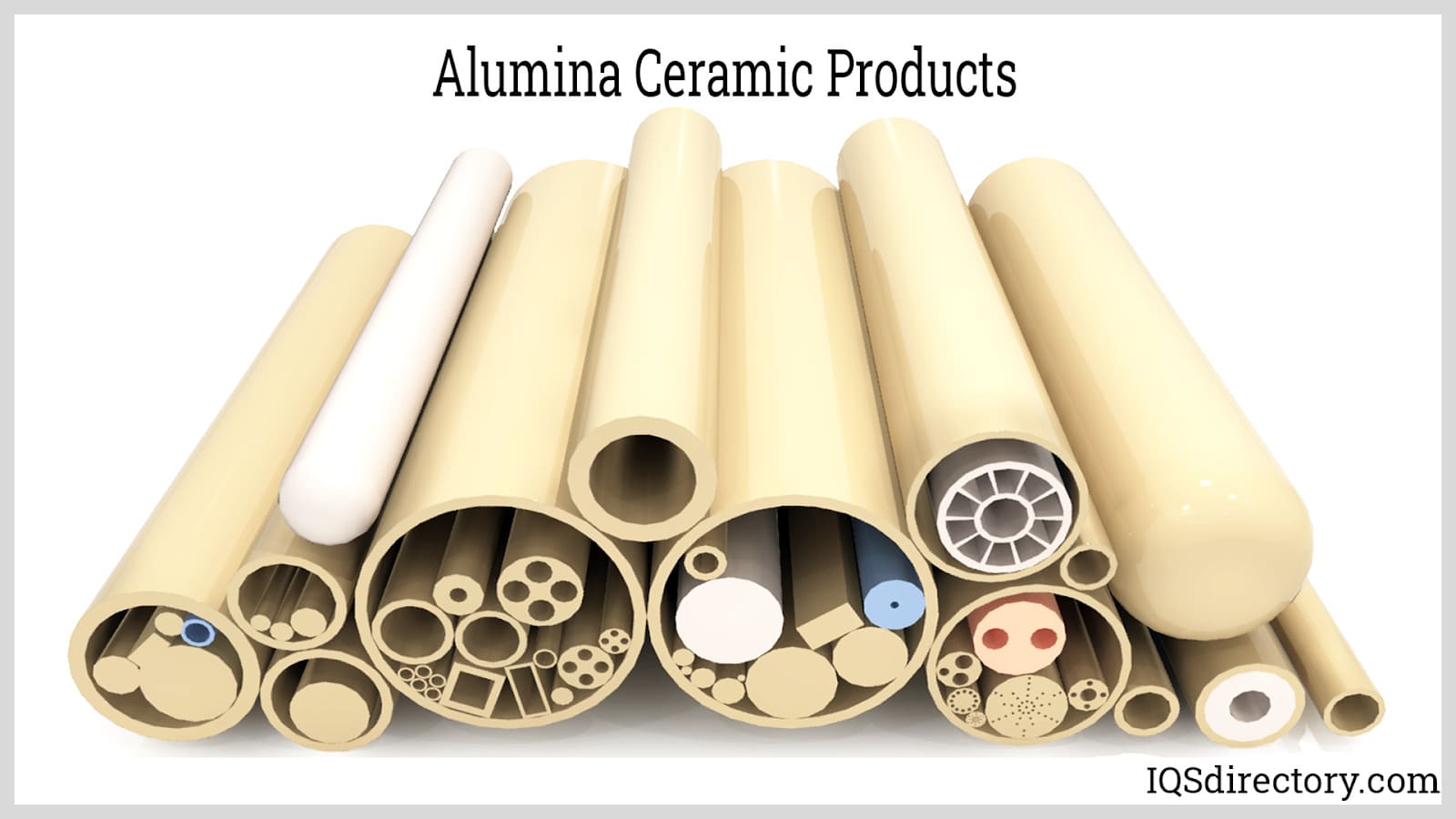

Navigating the complexities of the global market for alumina oxide ceramic is essential for international B2B buyers seeking high-performance materials. Known for its exceptional hardness, thermal stability, and insulation properties, alumina ceramic has become a cornerstone in industries such as aerospace, medical technology, and electronics. Its capability to withstand extreme temperatures—often exceeding 1700°C—positions it as a vital material in environments where reliability and durability are paramount.

This comprehensive guide delves into the multifaceted world of alumina oxide ceramic, offering in-depth insights into various types and grades of alumina, the intricacies of manufacturing processes, and the stringent quality control measures that ensure product excellence. Buyers will find valuable information about sourcing high-purity materials, understanding the cost structures, and identifying reputable suppliers across different regions, including Africa, South America, the Middle East, and Europe.

By equipping international buyers with actionable insights and best practices, this guide empowers informed sourcing decisions that optimize supply chains and enhance product offerings. Whether you are in France, Spain, or any other key market, understanding the nuances of alumina oxide ceramic can significantly impact your operational efficiency and competitive advantage.

Understanding alumina oxide ceramic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Purity Alumina | Purity levels of 99% and above; fine grain size | Electronics, Aerospace, Medical | Pros: Excellent thermal stability and electrical insulation. Cons: Higher cost due to processing. |

| 95% Alumina | Good balance between cost and performance; larger grain size | Industrial Applications, Cutting Tools | Pros: Cost-effective for many applications. Cons: Lower wear resistance compared to high-purity grades. |

| Alumina-Zirconia | Enhanced toughness and wear resistance | High-Performance Ceramics, Tooling | Pros: Superior mechanical properties. Cons: More complex manufacturing process. |

| Porous Alumina | High porosity for filtration and lightweight structures | Filtration, Catalyst Supports | Pros: Excellent for specific filtration needs. Cons: Limited mechanical strength. |

| Alumina Composites | Combined with other materials to enhance properties | Aerospace, Automotive Components | Pros: Tailored properties for specific applications. Cons: Can be expensive and require specialized processing. |

High-Purity Alumina

High-purity alumina, with purity levels exceeding 99%, is characterized by its fine grain size and exceptional thermal stability. This type is ideal for applications in electronics and aerospace, where reliability under extreme conditions is critical. When purchasing, buyers should consider the higher cost associated with the processing but can expect superior performance, especially in environments that demand high electrical insulation and thermal resistance.

95% Alumina

95% alumina provides a good compromise between cost and performance, making it suitable for a variety of industrial applications, including cutting tools. Its larger grain size results in reasonable wear resistance and mechanical strength. Buyers should weigh the benefits of cost-effectiveness against the lower durability compared to higher purity grades, particularly in high-wear environments.

Alumina-Zirconia

Alumina-zirconia composites combine alumina with zirconia to enhance toughness and wear resistance. This type is particularly advantageous in high-performance ceramics and tooling applications, where mechanical properties are paramount. Buyers should note that while these composites offer superior performance, the complexity of their manufacturing process can lead to increased costs and longer lead times.

Porous Alumina

Porous alumina is designed for specific applications requiring high porosity, such as filtration and catalyst supports. Its lightweight structure is ideal for applications where weight reduction is essential. However, buyers must consider the trade-off in mechanical strength, which may limit its use in load-bearing applications.

Alumina Composites

Alumina composites involve the integration of alumina with other materials to tailor specific properties for applications in aerospace and automotive components. These composites are designed to meet unique performance requirements, offering enhanced durability and resistance. While they provide significant advantages in customization, buyers should be aware of the potential for higher costs and the need for specialized manufacturing processes.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of alumina oxide ceramic

| Industry/Sector | Specific Application of alumina oxide ceramic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Thermal barrier coatings for engine components | Enhances durability and thermal resistance, improving engine efficiency | High purity alumina with controlled grain size; reliable suppliers with aerospace certifications |

| Electronics | Insulators in high-voltage applications | Provides excellent electrical insulation and thermal stability | Consistency in material properties; compliance with international standards |

| Medical Devices | Components in dental and orthopedic implants | Biocompatibility and strength ensure longevity and reliability | Sourcing high-purity alumina; certifications for medical applications |

| Nuclear Energy | Radiation-resistant components | Ensures safety and longevity in high-radiation environments | Suppliers must meet stringent safety and quality regulations |

| Mining and Mineral Processing | Wear-resistant linings and components | Reduces maintenance costs and downtime due to superior wear resistance | Availability of custom sizes and shapes; ability to handle large orders |

Aerospace Applications

In the aerospace sector, alumina oxide ceramics are utilized as thermal barrier coatings for engine components. These coatings provide exceptional thermal resistance, allowing engines to operate at higher temperatures without compromising performance. For international buyers, especially from regions with developing aerospace industries like Africa and South America, sourcing high-purity alumina with controlled grain size is critical. Additionally, suppliers should possess relevant aerospace certifications to ensure compliance with industry standards.

Electronics Applications

Alumina ceramics serve as insulators in high-voltage electronic applications, providing excellent electrical insulation and thermal stability. This application is crucial for manufacturers in Europe and the Middle East, where electronics must meet rigorous performance criteria. Buyers should prioritize sourcing materials with consistent properties and compliance with international standards to avoid failures in critical applications.

Medical Device Applications

In the medical field, alumina oxide ceramics are used in dental and orthopedic implants due to their biocompatibility and mechanical strength. This ensures that implants can withstand the stresses of daily use while remaining safe for patients. B2B buyers in this sector, particularly in Europe, must focus on sourcing high-purity alumina and ensure that suppliers have the necessary certifications for medical applications to guarantee product reliability.

Nuclear Energy Applications

Alumina ceramics are essential in the nuclear energy sector for producing radiation-resistant components. These materials are designed to endure harsh environments, ensuring safety and longevity. For international buyers, particularly in the Middle East where nuclear energy is emerging, it is vital to work with suppliers who meet stringent safety and quality regulations, as the consequences of material failure can be severe.

Mining and Mineral Processing Applications

In mining and mineral processing, alumina oxide ceramics are employed for wear-resistant linings and components. These materials significantly reduce maintenance costs and downtime due to their superior wear resistance, making them invaluable in harsh operational conditions. Buyers should consider suppliers’ ability to provide custom sizes and shapes, as well as their capacity to handle large orders, which is often necessary in this sector.

Related Video: How to Make Alumina Ceramic Industrial Parts

Strategic Material Selection Guide for alumina oxide ceramic

Analysis of Common Materials for Alumina Oxide Ceramic

When selecting materials for alumina oxide ceramics, international B2B buyers must consider various types of alumina based on their specific applications. Here, we analyze four common alumina materials, focusing on their properties, advantages, limitations, and implications for buyers in Africa, South America, the Middle East, and Europe.

1. High Purity Alumina (99.9% Al₂O₃)

Key Properties:

High purity alumina exhibits exceptional hardness, thermal stability, and electrical insulation properties, making it suitable for high-performance applications. It can withstand temperatures above 1700°C and offers excellent resistance to corrosion and wear.

Pros & Cons:

The main advantage of high purity alumina is its superior mechanical strength and durability, which makes it ideal for demanding environments such as aerospace and electronics. However, its high cost and complexity in manufacturing can limit its use in less critical applications.

Impact on Application:

This material is particularly effective in applications where extreme conditions are present, such as in aerospace components and high-voltage insulators. Its compatibility with aggressive media enhances its utility in chemical processing industries.

Considerations for Buyers:

B2B buyers should ensure compliance with international standards such as ASTM and DIN. The higher cost may be justified for critical applications, but buyers in emerging markets should evaluate local availability and sourcing options.

2. 95% Alumina

Key Properties:

With a composition of 95% Al₂O₃, this material balances cost and performance. It offers good thermal stability and wear resistance, though not as high as its 99.9% counterpart.

Pros & Cons:

The primary advantage is its cost-effectiveness, making it suitable for a wider range of applications, including industrial machinery and wear-resistant components. However, it may not perform as well under extreme conditions, limiting its use in high-temperature environments.

Impact on Application:

95% alumina is commonly used in applications such as grinding media and cutting tools, where moderate wear resistance is required. Its chemical resistance makes it suitable for various industrial processes.

Considerations for Buyers:

Buyers should assess the specific requirements of their applications against the properties of 95% alumina. Compliance with local standards is crucial, and buyers should be aware of the material’s limitations in extreme conditions.

3. Alumina-Toughened Zirconia (ATZ)

Key Properties:

ATZ combines alumina with zirconia to enhance toughness and wear resistance. This composite material can withstand high temperatures and offers improved fracture toughness compared to standard alumina.

Pros & Cons:

The key advantage of ATZ is its enhanced durability, making it suitable for high-stress applications. However, the manufacturing process is more complex, which can increase costs and lead times.

Impact on Application:

ATZ is particularly effective in applications requiring high mechanical strength and resistance to thermal shock, such as in cutting tools and biomedical implants.

Considerations for Buyers:

International buyers should consider the specific mechanical requirements of their applications and the benefits of ATZ over traditional alumina. Understanding the local market for ATZ and its compliance with international standards is essential for procurement.

4. Low-Temperature Co-Fired Ceramics (LTCC)

Key Properties:

LTCC materials are designed for lower firing temperatures, allowing for the integration of electronic components. They provide good thermal and electrical insulation, making them suitable for electronic applications.

Pros & Cons:

The main advantage of LTCC is its ability to combine multiple materials in a single process, reducing manufacturing complexity. However, their performance at high temperatures may not match that of high-purity alumina, limiting their use in extreme environments.

Impact on Application:

LTCC is widely used in electronic devices, including capacitors and sensors, where thermal and electrical properties are crucial.

Considerations for Buyers:

B2B buyers should evaluate the compatibility of LTCC with their electronic components and ensure compliance with relevant standards. Understanding the trade-offs between performance and cost is vital for effective decision-making.

Summary Table

| Material | Typical Use Case for alumina oxide ceramic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High Purity Alumina (99.9% Al₂O₃) | Aerospace components, high-voltage insulators | Superior strength and durability | High cost and manufacturing complexity | High |

| 95% Alumina | Industrial machinery, grinding media | Cost-effective for moderate applications | Limited performance under extreme conditions | Medium |

| Alumina-Toughened Zirconia (ATZ) | Cutting tools, biomedical implants | Enhanced toughness and wear resistance | More complex manufacturing process | High |

| Low-Temperature Co-Fired Ceramics (LTCC) | Electronic devices, capacitors | Integrates multiple materials easily | Limited high-temperature performance | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for alumina oxide ceramic

The manufacturing of alumina oxide ceramics involves a series of intricate processes that ensure the material meets the high-performance standards required in various industries. This section provides an in-depth look at the typical manufacturing stages and quality assurance practices essential for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

Manufacturing Processes

1. Material Preparation

The foundation of high-quality alumina ceramics begins with the selection and preparation of raw materials. The primary source is bauxite ore, which undergoes the Bayer process to extract aluminum oxide (Al₂O₃).

- Purity Levels: Alumina is available in various purity grades ranging from 85% to 99.9%. The choice of grade significantly affects the mechanical and thermal properties of the final product. For example, high-purity alumina (over 99%) is often used in advanced applications like electronics and aerospace due to its superior characteristics.

- Additives: To enhance specific properties, additives such as silica or magnesia are mixed with the alumina powder. The selection of additives should be aligned with the intended application of the final product.

2. Forming

Once the materials are prepared, the next stage involves shaping the alumina into the desired form. This is achieved through various techniques:

- Dry Pressing: A common method where the powder is compacted into molds under high pressure.

- Isostatic Pressing: Provides uniform pressure from all directions, enhancing the density of the final product.

- Injection Molding: Suitable for complex shapes, this process involves mixing alumina with a binder and injecting it into a mold.

- 3D Printing: An emerging technique that allows for intricate designs and reduced waste.

The choice of forming method depends on factors such as production volume, complexity of the shapes, and cost considerations.

3. Drying and Pre-Firing

After forming, the shaped components, referred to as “green” parts, are dried to remove moisture.

- Controlled Environment: It’s critical to maintain optimal temperature and humidity to prevent cracking during this stage.

- Bisque Firing: Some manufacturers perform a preliminary firing (bisque firing) to enhance structural integrity before the final sintering process.

4. Sintering

Sintering is a crucial stage where the dried components are subjected to high temperatures (typically between 1,500°C and 1,700°C) in kilns.

- Transformation: This process causes the alumina particles to bond, resulting in a solid, dense ceramic structure.

- Shrinkage Consideration: Expect approximately 15-20% shrinkage during sintering, which must be accounted for in the design phase.

5. Finishing

The final stage involves refining the sintered parts to achieve desired specifications.

- Machining Techniques: Advanced methods such as laser cutting, ultrasonic machining, and diamond grinding are employed to achieve precise dimensions and surface finishes.

- Polishing and Coating: Depending on the application, parts may undergo polishing for aesthetic purposes or coating for enhanced performance.

Quality Assurance

Ensuring the quality of alumina ceramics is paramount, particularly for international B2B transactions. Here are key aspects of quality assurance that buyers should consider:

International Standards

B2B buyers should ensure that suppliers comply with relevant international quality standards such as:

- ISO 9001: This standard outlines criteria for a quality management system and is crucial for suppliers to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- Industry-Specific Standards: Depending on the application, certifications like CE (European Conformity) for products sold in Europe or API (American Petroleum Institute) for oil and gas applications may be required.

Quality Control Checkpoints

Quality control should be integrated into the manufacturing process with checkpoints at various stages:

- Incoming Quality Control (IQC): Assessing raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Monitoring production processes to detect and address issues in real-time.

- Final Quality Control (FQC): Conducting rigorous testing of the finished products before shipment to guarantee they meet the required specifications.

Common Testing Methods

Various testing methods can be employed to validate the quality of alumina ceramics:

- Mechanical Testing: Assessing properties such as hardness, tensile strength, and wear resistance.

- Thermal Testing: Evaluating thermal stability and resistance to thermal shock.

- Chemical Testing: Ensuring the material’s chemical composition aligns with specifications.

Verifying Supplier Quality Control

B2B buyers should adopt comprehensive strategies to verify the quality control processes of potential suppliers:

- Supplier Audits: Conduct regular audits to assess compliance with quality standards and manufacturing practices. This can include site visits and reviews of production processes.

- Quality Reports: Request detailed quality assurance reports that outline testing results, compliance with standards, and any corrective actions taken.

- Third-Party Inspections: Engage independent inspection agencies to conduct thorough evaluations of supplier facilities and products.

Conclusion

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices for alumina oxide ceramics is essential. By focusing on material preparation, forming techniques, and stringent quality control measures, buyers can ensure they source high-quality products that meet their industrial needs. Establishing robust verification processes will further enhance confidence in supplier capabilities, leading to successful partnerships in the global marketplace.

Related Video: Machining Process of Alumina Ceramic

Comprehensive Cost and Pricing Analysis for alumina oxide ceramic Sourcing

When sourcing alumina oxide ceramics, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This knowledge enables organizations to make informed purchasing decisions and optimize their supply chains.

Cost Structure Components

-

Materials: The primary cost driver in alumina oxide ceramic sourcing is the raw materials, specifically aluminum oxide. The purity of alumina (ranging from 85% to 99.9%) significantly affects pricing. High-purity alumina commands a premium due to its enhanced properties and performance in demanding applications.

-

Labor: Manufacturing alumina ceramics involves skilled labor for processes such as shaping, sintering, and finishing. Labor costs vary by region; for example, labor may be less expensive in South America than in Europe, influencing overall pricing.

-

Manufacturing Overhead: This includes costs associated with machinery maintenance, utilities, and facility operations. Efficient manufacturing processes can reduce overhead, impacting the final price of the product.

-

Tooling: The initial investment in molds and tooling can be substantial, particularly for custom shapes. The amortization of these costs over production volume plays a crucial role in pricing.

-

Quality Control (QC): Rigorous QC processes ensure that alumina ceramics meet specified standards. The costs associated with testing and certification (e.g., ISO certifications) can add to the overall expense but are necessary for maintaining product integrity.

-

Logistics: Shipping costs can vary significantly based on the distance, mode of transport, and Incoterms used. International buyers should be aware of these factors, as they can lead to substantial variations in total costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s market position, reputation, and the uniqueness of the product offered.

Price Influencers

-

Volume/MOQ: Higher order volumes often lead to better pricing due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their production needs.

-

Specifications/Customization: Custom designs or specific performance requirements can increase costs. Buyers should clearly define their specifications to avoid unexpected price hikes.

-

Materials: The choice of additives and the quality of alumina used can significantly affect the price. Sourcing high-quality materials may incur higher costs but can result in better performance and longevity.

-

Quality/Certifications: Products that meet international quality standards (e.g., ASTM, ISO) may be priced higher but provide assurance of reliability, which is crucial in industries like aerospace and medical.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can influence pricing. Established suppliers may charge more due to their proven track record and reliability.

-

Incoterms: Understanding Incoterms is vital for determining who bears the risk and costs associated with shipping. Options like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially regarding bulk orders. Leverage your purchasing power to negotiate better terms and discounts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, maintenance, and disposal costs over the product’s lifecycle.

-

Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional market conditions that can affect pricing. Understanding local supply chains and currency fluctuations can aid in better budgeting.

Disclaimer

Prices for alumina oxide ceramics can fluctuate based on market conditions, supplier policies, and specific buyer requirements. Always seek multiple quotes and conduct thorough market research to ensure competitive pricing.

Spotlight on Potential alumina oxide ceramic Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘alumina oxide ceramic’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for alumina oxide ceramic

Key Technical Properties of Alumina Oxide Ceramic

When considering alumina oxide ceramics for industrial applications, understanding their critical specifications is essential for making informed purchasing decisions. Here are some key properties that B2B buyers should evaluate:

-

Material Grade

– Definition: Alumina ceramics are available in various grades, typically ranging from 85% to 99.9% purity.

– Importance: Higher purity grades provide superior mechanical and thermal properties, making them suitable for demanding applications in aerospace, electronics, and medical fields. Selecting the appropriate grade can significantly affect product performance and longevity. -

Hardness

– Definition: Hardness is a measure of a material’s resistance to localized plastic deformation.

– Importance: Alumina ceramics exhibit exceptional hardness, often exceeding 9 on the Mohs scale. This property is crucial for applications requiring wear resistance, such as in cutting tools and abrasive components. Understanding the hardness level helps buyers predict durability and maintenance needs. -

Thermal Stability

– Definition: Thermal stability refers to the ability of a material to maintain its properties at high temperatures.

– Importance: Alumina can withstand temperatures above 1600°C without significant degradation. This characteristic is vital for applications in high-temperature environments, such as furnace linings and aerospace components, ensuring operational reliability. -

Electrical Insulation

– Definition: Electrical insulation is the ability of a material to resist the flow of electric current.

– Importance: Alumina ceramics possess excellent electrical insulating properties, making them ideal for applications in electronics and electrical engineering. This property is particularly important for components like insulators and substrates that require high dielectric strength. -

Tensile Strength

– Definition: Tensile strength is the maximum stress a material can withstand while being stretched or pulled before breaking.

– Importance: Alumina ceramics typically have high tensile strength, which is crucial for structural applications. Understanding the tensile strength helps buyers assess the material’s suitability for load-bearing applications and its potential performance under stress. -

Thermal Conductivity

– Definition: Thermal conductivity measures how well a material conducts heat.

– Importance: While alumina ceramics are generally good insulators, specific formulations can enhance thermal conductivity, making them suitable for heat sinks and other thermal management applications. Evaluating thermal conductivity is essential for applications where temperature control is critical.

Common Trade Terminology in the Alumina Ceramic Industry

Understanding industry-specific terminology is vital for effective communication and negotiation in B2B transactions. Here are some key terms related to alumina oxide ceramics:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Buyers often work with OEMs to source customized alumina ceramic components tailored to specific requirements, ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers plan their procurement strategies, especially when dealing with specialized materials like alumina ceramics, which may require significant investment. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent by a buyer to suppliers requesting pricing and terms for specific products.

– Importance: Submitting an RFQ allows buyers to compare offers from different suppliers, facilitating informed decision-making based on price, quality, and delivery timelines. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that delineate responsibilities between buyers and sellers.

– Importance: Familiarity with Incoterms is essential for understanding shipping costs, risk management, and the obligations of both parties in international transactions, especially when dealing with bulky materials like alumina ceramics. -

Lead Time

– Definition: Lead time is the amount of time taken from the placement of an order to the delivery of the product.

– Importance: Understanding lead times is crucial for production planning and inventory management, particularly when sourcing specialized alumina ceramics that may require longer production cycles. -

Sintering

– Definition: Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction.

– Importance: Knowledge of sintering techniques and their effects on the properties of alumina ceramics is essential for buyers to ensure they receive products that meet their performance specifications.

Illustrative Image (Source: Google Search)

By grasping these properties and terms, international B2B buyers can navigate the complexities of the alumina oxide ceramic market more effectively, ensuring they make choices that align with their operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the alumina oxide ceramic Sector

Market Overview & Key Trends

The alumina oxide ceramic sector is experiencing significant growth driven by advancements in various industries, including aerospace, electronics, and medical devices. The global demand for high-performance materials that can withstand extreme temperatures and corrosive environments is propelling this trend. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note the following key market dynamics:

-

Technological Advancements: Innovations in manufacturing processes, such as 3D printing and advanced sintering techniques, are enhancing the precision and efficiency of alumina ceramic production. This shift is enabling manufacturers to create complex geometries and reduce waste.

-

Increased Customization: There is a growing demand for customized alumina ceramic products tailored to specific applications. Buyers are encouraged to engage with suppliers who offer flexible manufacturing capabilities and can accommodate unique specifications.

-

Supply Chain Resilience: Recent global disruptions have highlighted the importance of a resilient supply chain. B2B buyers should prioritize suppliers with robust sourcing strategies and diversified raw material procurement to mitigate risks associated with geopolitical tensions and trade fluctuations.

-

Emerging Markets: Regions such as Africa and South America are witnessing an uptick in industrial activities, leading to increased investments in high-performance materials. Buyers in these markets should keep an eye on local suppliers who can provide competitive pricing and shorter lead times.

-

Sustainable Practices: There is an increasing focus on sustainability within the alumina ceramic sector. Buyers are encouraged to collaborate with manufacturers who adopt environmentally friendly practices, such as waste reduction and energy-efficient processes.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial factor in the decision-making process for B2B buyers in the alumina oxide ceramic sector. The environmental impact of sourcing and manufacturing processes is under scrutiny, prompting organizations to adopt ethical supply chains. Here are several considerations for buyers:

-

Environmental Footprint: The production of alumina ceramics can be resource-intensive. Buyers should seek suppliers who utilize sustainable practices, such as recycling water used in production and minimizing emissions during the sintering process.

-

Ethical Supply Chains: Ensuring that raw materials are sourced responsibly is essential. Buyers should verify that their suppliers adhere to ethical mining practices, particularly for bauxite, the primary raw material for alumina ceramics.

-

Green Certifications: Look for suppliers that hold recognized environmental certifications, such as ISO 14001 or equivalent. These certifications indicate a commitment to sustainability and can enhance the credibility of your supply chain.

-

Sustainable Materials: Consider suppliers who offer eco-friendly alternatives or additives that can improve the performance of alumina ceramics while reducing environmental impact. This not only meets regulatory requirements but also appeals to environmentally conscious customers.

Brief Evolution/History

The development of alumina oxide ceramics dates back to the early 20th century, with initial applications in electrical insulation and abrasives. As industries evolved, the demand for advanced materials with superior mechanical and thermal properties surged, leading to innovations in processing and manufacturing techniques. Over the decades, alumina ceramics have found applications in various high-tech sectors, including aerospace, healthcare, and electronics, establishing themselves as indispensable components in modern engineering. The ongoing research and development in this field continue to enhance the performance and sustainability of alumina ceramics, ensuring their relevance in future applications.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of alumina oxide ceramic

-

What should I look for when vetting suppliers of alumina oxide ceramic?

When vetting suppliers, focus on their experience, production capabilities, and quality control measures. Request certifications such as ISO 9001 to ensure adherence to quality standards. Verify their track record by checking customer reviews and testimonials. Additionally, inquire about their sourcing of raw materials, as high-purity alumina significantly impacts product performance. Conducting site visits or audits can also provide insights into their manufacturing processes and reliability. -

Can I customize the alumina oxide ceramic products to meet specific requirements?

Yes, many suppliers offer customization options. Discuss your specific needs regarding purity levels, dimensions, and surface finishes. Customization may also include integrating additives for enhanced properties. Be clear about your application requirements and any specific industry standards that must be met. Ensure that the supplier has the technology and expertise to accommodate your custom specifications without compromising quality. -

What are the typical minimum order quantities (MOQ) and lead times for alumina oxide ceramic?

MOQs vary widely depending on the supplier and the complexity of the product. Generally, they can range from a few pieces for standard products to hundreds for custom orders. Lead times can also differ, typically ranging from 4 to 12 weeks. It is crucial to discuss these factors upfront, as longer lead times may affect your project timelines. Suppliers should provide clear timelines for production and shipping based on your order size. -

What payment options are available when purchasing alumina oxide ceramic?

Most suppliers offer various payment options, including bank transfers, letters of credit, and sometimes online payment platforms. It’s advisable to negotiate terms that suit both parties, such as partial payments upfront and the balance upon delivery. Be cautious of suppliers requiring full payment in advance, especially if you are working with them for the first time. Discussing payment terms early can help avoid disputes later. -

How can I ensure the quality of alumina oxide ceramics I purchase?

To ensure quality, request certifications and test reports from the supplier that demonstrate compliance with industry standards. Establish a quality assurance process that includes incoming inspections upon receipt of materials. You may also consider third-party testing for critical applications. Discuss the supplier’s quality control processes, including their handling of defects and returns, to understand their commitment to delivering high-quality products. -

What logistics considerations should I keep in mind when sourcing alumina oxide ceramics?

Logistics is crucial for timely delivery and cost management. Discuss shipping options, lead times, and costs upfront with your supplier. Consider the logistics capabilities in your region, including customs clearance and local transportation. Ensure that the supplier has a reliable shipping partner and understands the regulations for shipping ceramics, especially if you are importing into regions with strict import laws. Proper packaging is also essential to prevent damage during transit.

Illustrative Image (Source: Google Search)

-

What should I do if there is a dispute with my supplier regarding alumina oxide ceramics?

In the event of a dispute, communication is key. Begin by addressing the issue directly with your supplier to seek a resolution. Refer to your purchase agreement for terms regarding quality, delivery, and returns. If necessary, escalate the matter to higher management within the supplier’s organization. As a last resort, consider involving a third-party mediator or legal counsel if the dispute cannot be resolved amicably. Having a clear contract that outlines dispute resolution procedures can help avoid complications. -

Are there specific certifications I should look for when purchasing alumina oxide ceramics for international trade?

Yes, depending on your industry, look for certifications such as ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific industry-related certifications (e.g., ASTM, ANSI). These certifications demonstrate a supplier’s commitment to quality and regulatory compliance. Additionally, if your application involves food, medical, or aerospace sectors, ensure the materials meet relevant safety and performance standards to avoid regulatory issues during importation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for alumina oxide ceramic

In conclusion, strategic sourcing of alumina oxide ceramic presents a significant opportunity for international B2B buyers. Understanding the diverse grades and properties of alumina is essential for selecting the right materials tailored to specific industrial applications. With its exceptional hardness, thermal stability, and insulation capabilities, alumina ceramics are indispensable in high-performance sectors such as aerospace, medical, and electronics.

Key takeaways include the importance of partnering with reliable suppliers who can ensure high-purity materials and advanced manufacturing techniques. As global demand for alumina ceramics continues to rise, especially in emerging markets across Africa, South America, the Middle East, and Europe, establishing strong relationships with manufacturers will be critical.

Looking ahead, buyers are encouraged to engage actively in the sourcing process, leveraging technological advancements such as 3D printing and innovative machining methods to optimize production efficiency. By prioritizing strategic sourcing, companies can enhance their competitive edge and ensure the longevity and reliability of their applications. Embrace the future of alumina oxide ceramic sourcing and position your business for success in a rapidly evolving market.