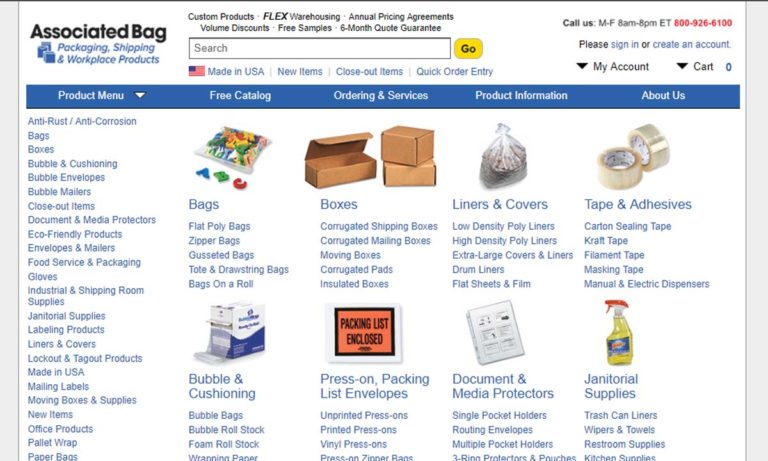

Your Ultimate Guide to Sourcing Associated Bags

Introduction: Navigating the Global Market for associated bags

Navigating the global market for associated bags is essential for international B2B buyers seeking to meet diverse consumer demands while ensuring sustainable practices. Associated bags, which include everything from tote bags to backpacks, play a pivotal role in branding and consumer convenience. As global markets become increasingly interconnected, understanding the nuances of sourcing these products can significantly impact your competitive edge.

This comprehensive guide delves into the critical aspects of associated bags, covering various types, sustainable materials, manufacturing processes, quality control, and supplier selection. By providing insights into cost considerations and market trends, we equip buyers from Africa, South America, the Middle East, and Europe—such as Turkey and Nigeria—with the knowledge to make informed sourcing decisions.

With a focus on actionable strategies, this guide emphasizes the importance of sustainable and ethical sourcing practices, which are now key expectations among consumers and businesses alike. As you explore the intricacies of the associated bags market, you will gain valuable insights into how to select the right suppliers, navigate challenges, and leverage best practices for your sourcing strategy. This empowers you to enhance your product offerings while contributing positively to the global supply chain landscape.

Understanding associated bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tote Bags | Open top, large capacity, often made from durable materials | Retail, promotional events, eco-friendly campaigns | Pros: Versatile, reusable; Cons: Limited security for contents. |

| Backpacks | Two straps, designed for carrying on the back, often with multiple compartments | Education, travel, outdoor activities | Pros: Comfortable, hands-free; Cons: Bulkier design may not suit all brands. |

| Messenger Bags | Single shoulder strap, flap cover, compact design | Urban commuting, tech accessories, marketing | Pros: Stylish, easy access; Cons: Limited storage compared to larger bags. |

| Duffel Bags | Cylindrical shape, large opening, often with handles and shoulder strap | Sports, travel, gym use | Pros: Spacious, easy to pack; Cons: Can be cumbersome when full. |

| Laptop Bags | Padded compartments for laptops, various styles available | Corporate, education, tech industries | Pros: Protective, professional appearance; Cons: Can be expensive, limited to tech users. |

Tote Bags

Tote bags are characterized by their open-top design and large capacity, making them ideal for carrying a variety of items. They are commonly used in retail settings, promotional events, and eco-friendly campaigns, particularly as reusable alternatives to plastic bags. When purchasing tote bags, B2B buyers should consider the material’s durability and the potential for branding through custom printing, which can enhance visibility during marketing efforts.

Backpacks

Backpacks feature two shoulder straps and are designed for ease of carrying, often equipped with multiple compartments for organization. They are widely used in education, travel, and outdoor activities, appealing particularly to younger demographics. B2B buyers should assess the comfort, material quality, and customization options available, as these factors can significantly influence user satisfaction and brand loyalty.

Messenger Bags

Messenger bags are distinguished by their single shoulder strap and flap cover, offering a compact design that allows for easy access to contents. They are popular among urban commuters, tech accessory brands, and marketing professionals. When sourcing messenger bags, buyers should evaluate the bag’s style, accessibility, and branding opportunities, as these elements can enhance the product’s appeal in competitive markets.

Duffel Bags

Duffel bags have a cylindrical shape and a large opening, making them suitable for sports, travel, and gym use. Their spacious interiors allow for easy packing, but they can become cumbersome when fully loaded. B2B buyers should consider the bag’s weight, material, and the inclusion of additional features such as pockets or shoulder straps to enhance functionality and user experience.

Laptop Bags

Laptop bags are specifically designed to protect laptops with padded compartments and come in various styles, including briefcases and backpacks. They are essential for corporate environments, education sectors, and tech industries. Buyers should prioritize the level of protection offered, the professional appearance of the bag, and the potential for customization, as these factors can directly affect user satisfaction and brand image in a competitive landscape.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of associated bags

| Industry/Sector | Specific Application of associated bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Shopping and promotional bags | Enhances brand visibility and customer experience | Focus on sustainable materials and ethical sourcing practices |

| Agriculture | Crop packaging and transport bags | Protects produce during transport, reducing spoilage and waste | Ensure durability and compliance with local agricultural standards |

| Pharmaceuticals | Medical supply and distribution bags | Ensures safe transport of sensitive products, maintaining integrity | Require certifications for safety and quality standards |

| Food & Beverage | Food delivery and takeaway bags | Supports hygiene and convenience for customers | Sourcing biodegradable options to align with sustainability goals |

| Fashion & Apparel | Luxury packaging and branded bags | Elevates brand image and customer perception | Consider customization options to enhance brand identity |

Retail

In the retail sector, associated bags are primarily used as shopping and promotional bags. These bags not only facilitate the purchase process but also serve as a marketing tool, enhancing brand visibility as customers carry them. For international B2B buyers, sourcing bags made from sustainable materials is increasingly important due to consumer demand for eco-friendly products. Ethical sourcing from suppliers with certifications can further enhance brand reputation and consumer trust.

Agriculture

In agriculture, associated bags are essential for crop packaging and transport. These bags protect produce from damage during transit, significantly reducing spoilage and waste. For buyers in regions like Africa and South America, sourcing durable bags that comply with local agricultural standards is critical. Additionally, selecting suppliers who understand the local market dynamics can ensure that the bags meet specific agricultural needs while supporting local economies.

Pharmaceuticals

The pharmaceutical industry relies on associated bags for the safe distribution of medical supplies. These bags are designed to maintain the integrity of sensitive products, which is crucial for compliance with health regulations. International buyers must prioritize sourcing from manufacturers that adhere to strict safety and quality standards, including necessary certifications. This ensures that the bags protect the products during transport, ultimately safeguarding public health.

Food & Beverage

In the food and beverage sector, associated bags are widely used for food delivery and takeaway services. These bags not only ensure hygiene but also provide convenience for consumers. B2B buyers should consider sourcing biodegradable options to align with sustainability initiatives and consumer preferences for environmentally friendly packaging. Collaborating with suppliers who have a commitment to sustainable practices can enhance brand loyalty and reduce environmental impact.

Fashion & Apparel

For the fashion and apparel industry, associated bags serve as luxury packaging and branded bags that elevate the overall customer experience. These bags can significantly enhance brand image and customer perception, making them a vital component of the marketing strategy. Buyers should seek manufacturers that offer customization options to align with their branding needs while ensuring that the materials used are both high-quality and ethically sourced. This approach not only meets consumer expectations but also reinforces the brand’s commitment to sustainability.

Related Video: Introduction to Uses and Gratifications Theory

Strategic Material Selection Guide for associated bags

When selecting materials for associated bags, international B2B buyers must consider various factors that impact product performance, cost, and suitability for specific applications. Here, we analyze four common materials used in the production of associated bags, detailing their properties, advantages, disadvantages, and implications for buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

1. Polyester

Key Properties: Polyester is known for its excellent tensile strength, resistance to stretching and shrinking, and quick-drying capabilities. It performs well under a wide range of temperatures and is resistant to mildew and abrasion.

Pros & Cons: The durability of polyester makes it a popular choice for bags intended for heavy use. It is relatively inexpensive and can be produced in various weights and textures. However, polyester is less environmentally friendly unless recycled versions (rPET) are used, which may have higher costs and manufacturing complexities.

Impact on Application: Polyester bags are suitable for various media, including clothing, sports equipment, and promotional items. However, they may not be ideal for high-temperature applications due to potential degradation.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding material safety and environmental impact. Certifications like the Global Recycled Standard (GRS) can enhance credibility, especially in markets where sustainability is a priority.

2. Nylon

Key Properties: Nylon is recognized for its high strength, elasticity, and resistance to wear and tear. It also has excellent abrasion resistance and performs well in low-temperature environments.

Pros & Cons: The lightweight nature of nylon makes it suitable for bags that require portability. Its durability is a significant advantage, but nylon can be more expensive than polyester. Additionally, it may absorb moisture, which can be a drawback in humid climates.

Impact on Application: Nylon is ideal for outdoor and travel bags due to its resilience against harsh conditions. However, its moisture retention may limit its use in applications where water resistance is critical.

Considerations for International Buyers: Buyers should be aware of the varying quality grades of nylon and ensure that suppliers adhere to standards such as ASTM or ISO for consistency. The cost may also vary significantly based on the type of nylon used.

3. Canvas

Key Properties: Canvas is a heavy-duty fabric made from cotton or a blend of cotton and synthetic fibers. It offers good breathability, durability, and resistance to wear.

Pros & Cons: The natural fibers in canvas provide a classic aesthetic, making it appealing for fashion-oriented bags. While it is durable, canvas can be heavier than synthetic options and may require special treatments to enhance water resistance.

Impact on Application: Canvas is well-suited for tote bags, backpacks, and promotional items. Its breathability makes it ideal for applications where ventilation is necessary, but it may not perform well in wet conditions without proper treatment.

Considerations for International Buyers: Buyers should consider the environmental impact of cotton sourcing and look for suppliers who adhere to sustainable practices. Certifications like OEKO-TEX can assure buyers of the fabric’s safety and sustainability.

4. PVC (Polyvinyl Chloride)

Key Properties: PVC is a synthetic plastic polymer that is known for its durability, water resistance, and ability to be molded into various shapes.

Pros & Cons: The waterproof nature of PVC makes it an excellent choice for bags intended for wet environments. However, it can be less breathable than fabric options, leading to moisture buildup inside the bag. Additionally, the environmental impact of PVC production is a concern.

Impact on Application: PVC is commonly used in waterproof bags, such as those for outdoor activities or swimming. Its rigidity may limit its use in applications requiring flexibility.

Considerations for International Buyers: Compliance with environmental regulations is crucial, especially in regions with strict policies on plastic use. Buyers should seek suppliers who offer eco-friendly alternatives or recycled PVC options.

Summary Table

| Material | Typical Use Case for associated bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Sports bags, promotional items | Durable and cost-effective | Less eco-friendly unless recycled | Medium |

| Nylon | Outdoor and travel bags | High strength and lightweight | Moisture absorption | High |

| Canvas | Tote bags, backpacks | Classic aesthetic and breathable | Heavier and less water-resistant | Medium |

| PVC | Waterproof bags for outdoor use | Excellent water resistance | Less breathable and environmental concerns | Medium |

This guide provides a comprehensive overview of material selection for associated bags, offering actionable insights for B2B buyers to make informed decisions that align with their operational needs and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for associated bags

Manufacturing Processes for Associated Bags

The production of associated bags involves a series of well-defined stages that ensure the final product meets the quality and design specifications set by brands. Understanding these stages is crucial for B2B buyers who are looking to partner with manufacturers that can deliver high-quality products efficiently.

Main Stages of Manufacturing

-

Material Preparation

– Sourcing Materials: The first step involves selecting high-quality materials, such as leather, canvas, nylon, or recycled materials like rPET. Buyers should ensure that their suppliers use sustainable materials, as this is increasingly becoming a consumer expectation.

– Pre-processing: Materials are often treated to enhance durability and performance. This may include processes like waterproofing or dyeing. -

Forming

– Cutting: Materials are cut into predefined shapes and sizes based on the design specifications. This is often done using cutting machines or by hand for more intricate designs.

– Printing and Embellishing: Any logos, patterns, or embellishments are applied at this stage, utilizing techniques such as screen printing, heat transfer, or embroidery. -

Assembly

– Sewing: The cut pieces are then sewn together. This requires skilled labor and may involve various stitching techniques, such as double stitching for strength or decorative stitching for aesthetic appeal.

– Attachment of Components: Additional components like zippers, buckles, or handles are attached during this stage, requiring precision to ensure functionality and durability. -

Finishing

– Quality Checks: Before the products are packaged, they undergo initial quality checks to ensure they meet the specified standards.

– Final Touches: This may include cleaning, pressing, and adding any final embellishments. Products are then prepared for packaging.

Key Techniques in Manufacturing

- Computer-Aided Design (CAD): This technology is used for creating precise patterns and designs, allowing for greater accuracy and customization.

- Automated Cutting Machines: These machines increase efficiency and reduce material waste by ensuring precise cuts.

- Sustainable Practices: Techniques such as waterless dyeing and the use of recycled materials are becoming more prevalent in the manufacturing of associated bags.

Quality Assurance in Bag Manufacturing

Quality assurance (QA) is paramount in the production of associated bags. Ensuring that products meet international standards not only enhances brand reputation but also reduces returns and customer dissatisfaction.

International and Industry-Specific Standards

- ISO 9001: This international standard specifies requirements for a quality management system (QMS) and is essential for manufacturers aiming to provide consistent quality.

- CE Marking: Indicates that the product complies with EU safety, health, and environmental protection standards.

- API Certification: Relevant for manufacturers producing bags for specific industries, ensuring compliance with applicable regulations.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications. This step is critical to prevent defects in the final product.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing help identify issues early in the process, minimizing waste and rework.

- Final Quality Control (FQC): Completed products undergo a thorough inspection to ensure they conform to design specifications and quality standards before packaging.

Common Testing Methods

- Tensile Strength Testing: Measures the durability of materials under stress.

- Colorfastness Testing: Assesses how well materials retain their color under various conditions.

- Water Resistance Testing: Ensures that bags can withstand exposure to water without compromising their integrity.

Verifying Supplier Quality Control

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies:

- Supplier Audits: Conduct regular audits to assess the manufacturer’s compliance with quality standards and ethical practices. This should include a review of their quality management system.

- Request Quality Reports: Ask for documentation of quality checks and test results. These reports should detail the procedures followed and the outcomes of various tests.

- Third-Party Inspections: Engage independent inspection agencies to evaluate the manufacturing processes and quality of products before shipment. This can provide an unbiased assessment of the supplier’s capabilities.

Quality Control Nuances for International Buyers

When sourcing from international manufacturers, B2B buyers should be aware of specific nuances that may affect quality assurance:

- Cultural Differences: Different regions may have varying interpretations of quality standards. Establish clear expectations and guidelines to bridge these gaps.

- Regulatory Compliance: Ensure that the supplier understands and adheres to the regulatory requirements of the buyer’s target market. This is particularly important for exports to regions with stringent regulations.

- Communication Barriers: Maintain open lines of communication to address any potential issues promptly. Language differences can lead to misunderstandings, so consider employing translators if necessary.

By understanding the manufacturing processes and quality assurance measures involved in producing associated bags, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who can deliver high-quality products that meet market demands.

Related Video: Plastic Bag Mass Production Factory in Korea. Plastic Bag Manufacturing Process.

Comprehensive Cost and Pricing Analysis for associated bags Sourcing

Understanding the cost structure and pricing dynamics of associated bags is essential for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. This analysis breaks down key cost components, identifies pricing influencers, and offers actionable tips for buyers.

Cost Components

-

Materials

The choice of materials significantly impacts the overall cost. Sustainable options, such as recycled Polyester (rPET) or organic cotton, might have higher upfront costs but can enhance brand reputation and appeal to environmentally conscious consumers. Bulk purchasing can reduce costs, so consider long-term contracts with suppliers. -

Labor

Labor costs vary widely depending on the manufacturing location. Countries with lower labor costs may offer significant savings, but it’s crucial to ensure ethical labor practices. Certifications like SA8000 can guide buyers in selecting suppliers who maintain fair labor standards. -

Manufacturing Overhead

This includes utilities, facility maintenance, and indirect labor costs. Understanding the overhead structure of potential suppliers can provide insight into their pricing strategies. Manufacturers with high efficiency and low overhead may offer more competitive prices. -

Tooling

Initial tooling costs can be substantial, particularly for custom designs. It’s important to factor these costs into the total project budget, especially for smaller orders where these costs can be disproportionately high. -

Quality Control (QC)

Investing in quality assurance is crucial. Implementing stringent QC processes can prevent costly defects and returns, ultimately saving money in the long run. Buyers should inquire about the QC measures employed by manufacturers to ensure product consistency. -

Logistics

Shipping and handling costs can vary significantly based on the distance from the manufacturer to the buyer’s location. Understanding Incoterms (International Commercial Terms) can help buyers manage these costs effectively, as they outline responsibilities for shipping, insurance, and tariffs. -

Margin

Manufacturers typically apply a profit margin to their costs, which can vary based on their business model and market positioning. Negotiating terms that align with your budget while ensuring fair compensation for suppliers is essential.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity)

Larger orders often lead to lower per-unit costs. Negotiating favorable MOQs can help achieve better pricing, but it’s crucial to balance inventory levels with demand. -

Specifications/Customization

Customized products can incur additional costs. Clearly defining specifications upfront can help avoid unexpected expenses later in the process. -

Materials

Premium materials will increase costs. Buyers should weigh the benefits of using high-quality materials against their budget constraints. -

Quality Certifications

Products certified for quality (like ISO standards) may come at a premium but can enhance product reliability and marketability. -

Supplier Factors

The reputation, reliability, and track record of suppliers can influence pricing. Established suppliers may charge more due to their proven capabilities. -

Incoterms

Understanding Incoterms can affect pricing by clarifying responsibilities for shipping costs, insurance, and customs duties, impacting the overall cost to the buyer.

Buyer Tips

-

Negotiation: Building strong relationships with suppliers can lead to better pricing. Don’t hesitate to negotiate terms, especially for larger orders or long-term partnerships.

-

Cost Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider logistics, potential returns, and quality when assessing overall value.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and their impact on pricing. Establishing contracts in stable currencies can mitigate risks.

-

Market Research: Understand regional market conditions, including local tariffs and trade agreements, to make informed sourcing decisions.

Disclaimer

Prices can vary significantly based on multiple factors, including market conditions, supplier negotiations, and order specifics. Always conduct thorough due diligence and request multiple quotes to ensure competitive pricing.

Spotlight on Potential associated bags Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘associated bags’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for associated bags

When sourcing associated bags, understanding the technical properties and trade terminology is essential for making informed decisions. This knowledge not only enhances product selection but also improves negotiation outcomes and supplier relationships.

Key Technical Properties

-

Material Grade

– Definition: Material grade refers to the quality and type of material used in bag production, such as polyester, nylon, or leather.

– B2B Importance: Selecting the right material grade impacts durability, aesthetic appeal, and functionality. High-quality materials can command higher prices but may also lead to increased customer satisfaction and brand loyalty. -

Tolerance

– Definition: Tolerance indicates the allowable variation in dimensions and specifications during manufacturing.

– B2B Importance: Maintaining strict tolerances ensures that bags meet design specifications and quality standards. This is critical for brands that require precise fits for components, such as zippers and straps, ultimately affecting product performance. -

Weight Capacity

– Definition: Weight capacity is the maximum load that a bag can carry without compromising its structure.

– B2B Importance: Knowing the weight capacity is vital for ensuring that the bags can meet their intended use, whether for travel, sports, or everyday carry. This specification can influence customer trust and brand reputation. -

Water Resistance

– Definition: Water resistance indicates the ability of a bag material to repel water.

– B2B Importance: For buyers targeting outdoor or travel markets, water resistance is a key feature that can set a product apart. It enhances the usability of bags in diverse environments, appealing to a broader customer base. -

Recyclability

– Definition: Recyclability refers to the ability of the bag’s materials to be reprocessed into new products after their lifecycle.

– B2B Importance: With an increasing focus on sustainability, buyers should prioritize bags made from recyclable materials. This can significantly enhance brand image and attract environmentally conscious consumers.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that manufactures products based on the specifications provided by another company, allowing brands to outsource production.

– Importance: For international buyers, partnering with OEMs can streamline operations and reduce capital expenditures, enabling a focus on design and marketing rather than manufacturing. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest number of units a supplier is willing to sell.

– Importance: Understanding MOQ is crucial for budgeting and inventory planning. Buyers must balance the need for cost efficiency against the risk of overstocking or understocking products. -

RFQ (Request for Quotation)

– Definition: An RFQ is a formal document that solicits price quotes from suppliers for specific products or services.

– Importance: Utilizing RFQs helps standardize the procurement process, ensuring that buyers receive comparable pricing and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a series of international rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is essential for mitigating risks related to shipping, insurance, and customs clearance. Clear understanding can facilitate smoother transactions and reduce misunderstandings.

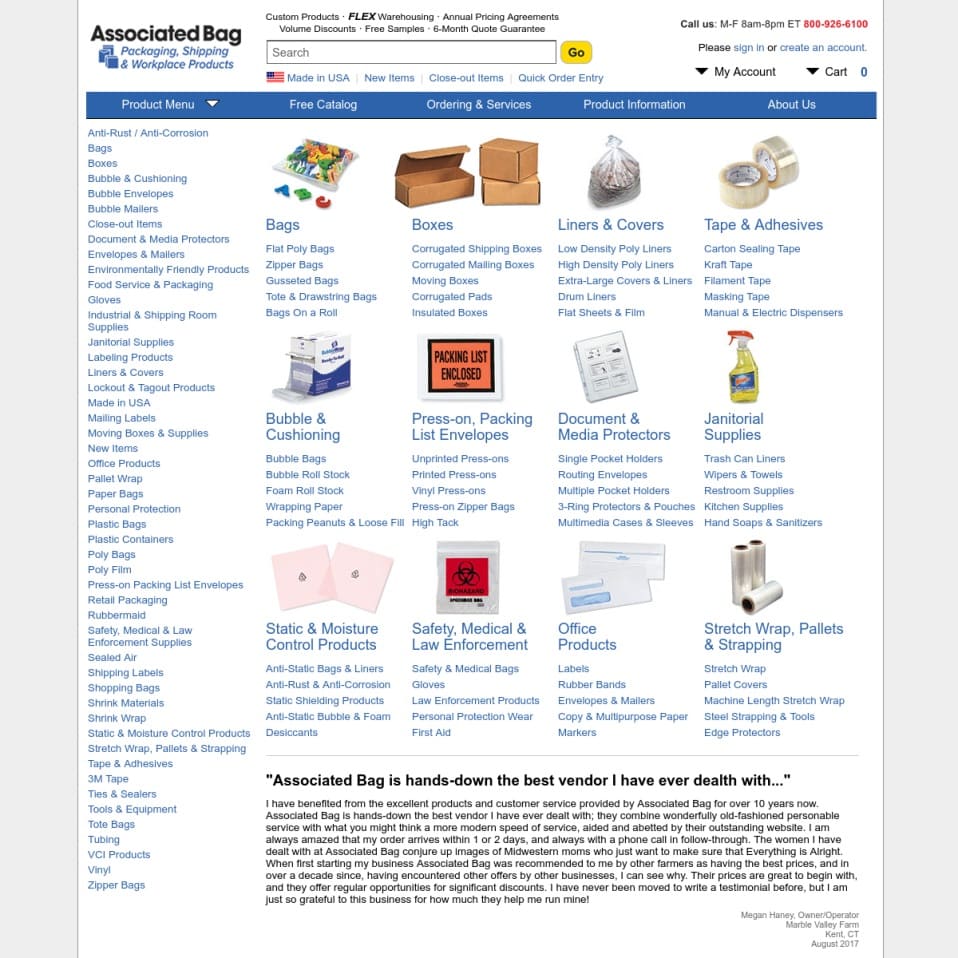

Illustrative Image (Source: Google Search)

- Lead Time

– Definition: Lead time is the period between placing an order and receiving the goods.

– Importance: Knowing the lead time is critical for inventory management and planning marketing campaigns. Shorter lead times can provide a competitive advantage, especially in fast-moving markets.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions, negotiate effectively, and enhance their sourcing strategies in the associated bags market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the associated bags Sector

In the associated bags sector, several global drivers are shaping market dynamics and influencing sourcing strategies for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The rise of e-commerce has accelerated demand for versatile, durable, and aesthetically appealing bags, catering to both consumer preferences and logistical needs. Furthermore, supply chain disruptions from recent global events have prompted businesses to rethink their sourcing strategies, emphasizing the importance of diversification to mitigate risks associated with reliance on single suppliers or regions.

Emerging technologies are also transforming the way businesses approach sourcing. Innovations such as digital supply chain management tools, AI-driven demand forecasting, and blockchain for traceability are becoming integral to ensuring efficiency and transparency. B2B buyers are increasingly leveraging these technologies to optimize inventory management and enhance collaboration with suppliers. For instance, companies utilizing AI can predict trends and adjust their sourcing strategies proactively, ensuring they stay ahead of market demands.

As sustainability becomes a critical consideration, many brands are re-evaluating their product lines and sourcing practices to align with eco-conscious consumer expectations. This shift is not just a trend but a fundamental change that buyers must embrace to remain competitive. The growing importance of sustainability is evident in the increasing demand for associated bags made from eco-friendly materials, which reflects a significant opportunity for B2B buyers to align their offerings with market expectations.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

The environmental impact of the associated bags sector is profound, with traditional manufacturing processes contributing to pollution and waste. B2B buyers are now faced with the pressing need to prioritize sustainability in their sourcing strategies. Ethical supply chains are increasingly essential, not only to meet regulatory requirements but also to satisfy consumer demand for socially responsible products. Buyers should seek out suppliers who adhere to recognized sustainability standards, ensuring that materials and processes are environmentally friendly and socially equitable.

Certifications such as the Global Recycled Standard (GRS) and the OEKO-TEX® Standard 100 are crucial indicators of sustainable practices. Brands that utilize recycled materials, such as recycled polyester (rPET) and organic cotton, can significantly reduce their carbon footprint while appealing to eco-conscious consumers. Additionally, ethical certifications like SA8000 and WRAP ensure that suppliers maintain fair labor practices and safe working conditions, further enhancing the integrity of the supply chain. By prioritizing these sustainable practices, B2B buyers can build resilient brands that resonate with a growing demographic of environmentally aware customers.

Brief Evolution/History

The associated bags sector has evolved significantly over the past few decades, influenced by changing consumer preferences and technological advancements. Initially dominated by traditional manufacturing methods, the industry has witnessed a shift towards more sustainable and innovative practices. The introduction of OEM (Original Equipment Manufacturer) partnerships has allowed brands to leverage the expertise of established manufacturers, improving product quality and reducing costs.

As consumer awareness regarding environmental issues has increased, brands have adapted by incorporating sustainable materials and ethical sourcing practices into their production processes. This evolution reflects a broader trend within the fashion and retail industries, where sustainability and ethical considerations are now paramount. B2B buyers must remain agile and informed about these trends to successfully navigate the complexities of the associated bags market, ensuring they meet both their business objectives and the expectations of their customers.

Related Video: How Shipping Containers Control Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of associated bags

-

How can I effectively vet suppliers for associated bags?

To ensure you’re partnering with reliable suppliers, conduct thorough due diligence. Verify their certifications such as ISO, GRS, or WRAP, which indicate adherence to quality and ethical standards. Request samples of their products to assess quality and craftsmanship. Additionally, seek references from other international buyers and investigate their production capabilities, financial stability, and market reputation. Utilizing platforms like Alibaba or Global Sources can also provide insights into supplier ratings and reviews. -

What customization options are available for associated bags?

Many manufacturers offer extensive customization options, including materials, colors, sizes, and branding elements like logos and tags. Discuss your specific needs early in the negotiation process. Some suppliers may provide design services to help refine your concepts. It’s essential to request prototypes to evaluate the customization before mass production. Remember that more complex customizations may affect lead times and costs, so plan accordingly. -

What are the typical minimum order quantities (MOQs) and lead times?

MOQs can vary significantly based on the supplier and the complexity of the order. Generally, for standard associated bags, MOQs can range from 100 to 1,000 units. Lead times also depend on the order size and the supplier’s location, typically ranging from 30 to 120 days. Always confirm these details during initial discussions and negotiate terms that align with your inventory management strategy to avoid excess stock or supply shortages. -

What payment terms should I expect when sourcing bags internationally?

Payment terms can vary, but common practices include a 30-50% deposit upfront, with the balance due before shipment or upon receipt. Some suppliers may offer letters of credit or escrow services for added security. It’s crucial to discuss payment methods (e.g., wire transfer, PayPal) and negotiate terms that minimize risk. Ensure that all agreements are documented in your contract to avoid disputes later on. -

How can I ensure quality assurance and certification compliance?

Implement a robust quality assurance process that includes pre-production samples, in-line inspections, and final quality checks before shipping. Request that suppliers provide documentation of their certifications and quality control processes. Consider hiring third-party inspection services to conduct audits and verify compliance with your specified standards. Establish clear quality benchmarks in your contract to ensure accountability. -

What logistics considerations should I keep in mind when importing bags?

Logistics play a crucial role in international sourcing. Understand the shipping methods available (air, sea, or land) and their associated costs and timelines. Factor in customs duties, tariffs, and taxes based on your destination country. Collaborate with a logistics provider experienced in international shipping to streamline the process and handle documentation. Additionally, consider the supplier’s location and its impact on shipping times and costs. -

What steps can I take to resolve disputes with suppliers?

Establish clear communication channels and document all agreements to minimize misunderstandings. If disputes arise, attempt to resolve them amicably through direct negotiation. If necessary, escalate the issue to higher management on both sides. Consider mediation or arbitration as alternatives to litigation, as they can be more cost-effective and quicker. Ensure your contracts include clauses that outline the dispute resolution process to safeguard your interests. -

How do I assess the environmental and ethical practices of my suppliers?

To evaluate a supplier’s commitment to sustainability and ethical practices, request documentation of their environmental policies and social compliance certifications. Assess their sourcing of materials, such as recycled or sustainably sourced options. Engage in discussions about their labor practices and workplace conditions. Additionally, consider visiting their facilities if feasible to gain firsthand insight into their operations and commitment to ethical standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for associated bags

Strategic sourcing in the associated bags industry is not merely a trend but a pivotal strategy for international B2B buyers aiming to thrive in a competitive landscape. By prioritizing sustainable and ethical practices, companies can enhance their brand reputation and meet the growing consumer demand for responsibility in sourcing. Collaborating with certified suppliers ensures adherence to high-quality standards while fostering positive workplace environments.

Moreover, embracing supply chain diversification is essential for mitigating risks associated with geopolitical instability and market fluctuations. By establishing a regional balance in sourcing, businesses can secure operational resilience and adaptability, as evidenced by successful companies like Apple.

As the landscape evolves, international buyers from Africa, South America, the Middle East, and Europe—particularly in regions like Turkey and Nigeria—are encouraged to leverage these insights to refine their sourcing strategies. By investing in robust partnerships and remaining agile, companies can not only navigate challenges but also capitalize on emerging opportunities. The future of associated bags is promising; now is the time to act and ensure your sourcing strategies are aligned with these critical insights for sustained growth and success.