Your Ultimate Guide to Sourcing Band Heater

Introduction: Navigating the Global Market for band heater

In today’s competitive global landscape, the demand for efficient heating solutions has surged, making band heaters essential components across various industries. These specialized heating devices are pivotal in ensuring optimal temperature control during manufacturing processes, from plastic extrusion to food production. The precision and reliability of band heaters not only enhance productivity but also significantly reduce energy costs, making them a valuable investment for businesses worldwide.

This comprehensive guide delves into the multifaceted world of band heaters, providing international B2B buyers with critical insights necessary for informed sourcing decisions. Buyers will explore the diverse types of band heaters, including mica, ceramic, and mineral insulated variants, each tailored for specific applications and temperature requirements. Additionally, the guide covers essential materials, manufacturing and quality control processes, and a curated list of reputable suppliers.

Understanding the cost factors associated with band heaters, along with market trends and regional differences, is crucial for making strategic purchasing choices. The guide also addresses common FAQs, equipping buyers with the knowledge to navigate potential challenges effectively.

Whether you are sourcing from Africa, South America, the Middle East, or Europe, this guide empowers you to make confident, data-driven decisions, ensuring your operations are supported by the best heating solutions available in the market.

Understanding band heater Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mica Band Heaters | Lightweight, cost-effective, good thermal conductivity | Plastic molding, packaging equipment | Pros: Affordable, efficient for low-temp applications. Cons: Limited lifespan in high-temp environments. |

| Ceramic Band Heaters | High-temperature resistance, durable | Injection molds, pipeline heating | Pros: Excellent heat retention, long lifespan. Cons: Higher initial cost compared to mica heaters. |

| Mineral Insulated Band Heaters | Superior durability, high-temperature capability | High-tech resin molding, aerospace applications | Pros: Long-lasting, resistant to contamination. Cons: More complex installation, higher price point. |

| Silicone Rubber Heaters | Flexible, lightweight, excellent for uneven surfaces | Food processing, laboratory equipment | Pros: Versatile, easy to install. Cons: Limited temperature range compared to metal options. |

| Foil Heaters | Thin, lightweight, flexible design | Electronics, medical devices | Pros: Space-saving, customizable shapes. Cons: Not suitable for high-temperature applications. |

Mica Band Heaters

Mica band heaters are widely used in applications requiring moderate heating, such as plastic molding and packaging. Their lightweight design and cost-effectiveness make them appealing for budget-conscious buyers. However, their lifespan diminishes in high-temperature settings, making it crucial for B2B buyers to consider their specific application requirements and temperature ranges to avoid premature failures.

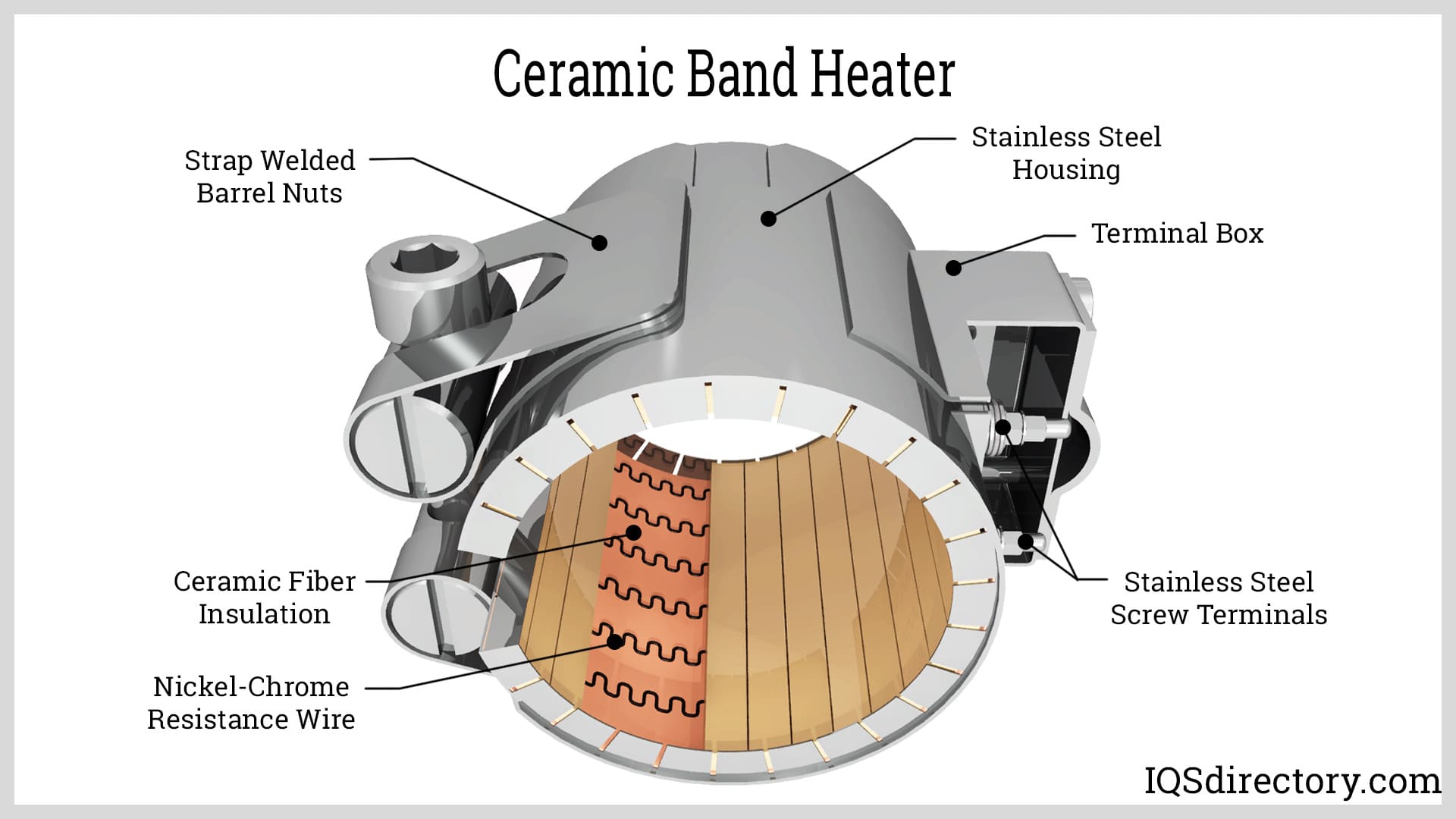

Ceramic Band Heaters

Ceramic band heaters are designed for high-temperature applications, reaching up to 1400°F (760°C). They are ideal for injection molds and pipeline heating due to their excellent heat retention and durability. While they come at a higher initial cost, the long lifespan and performance justify the investment for businesses needing consistent heating solutions in demanding environments.

Mineral Insulated Band Heaters

These heaters excel in high-heat applications, capable of withstanding temperatures up to 1600°F (871°C). Their robust construction makes them perfect for high-tech resin molding and aerospace applications. B2B buyers should note the higher price point and installation complexity, but their durability and resistance to contamination can offer significant long-term value.

Silicone Rubber Heaters

Silicone rubber heaters provide flexibility and lightweight design, making them suitable for uneven surfaces in food processing and laboratory settings. They are easy to install and versatile, catering to various shapes and sizes. However, their temperature range is limited compared to metal band heaters, so businesses must assess their heating needs carefully before choosing this option.

Foil Heaters

Foil heaters are thin, lightweight, and flexible, making them ideal for applications in electronics and medical devices where space is a constraint. Their customizable shapes allow for innovative designs, but they are not suitable for high-temperature environments. B2B buyers should weigh the benefits of space-saving designs against the limitations of temperature performance when considering these heaters for their operations.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of band heater

| Industry/Sector | Specific Application of Band Heater | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Plastics Manufacturing | Heating extruder nozzles for consistent material flow | Enhances production efficiency and reduces scrap rates | Ensure compatibility with specific extruder models and temperature ranges. |

| Food Processing | Heating food processing equipment | Maintains optimal temperatures for food safety and quality | Compliance with food-grade standards and easy cleaning features. |

| Pharmaceuticals | Heating of viscous materials in production processes | Ensures precise temperature control for product consistency | Requires materials that meet regulatory standards for safety and reliability. |

| Automotive | Heating components during manufacturing processes | Improves product quality and reduces cycle times | Consider high-temperature resistance and durability of materials used. |

| Textile Industry | Heating dyeing and finishing equipment | Enhances color consistency and reduces processing time | Look for custom solutions tailored to specific machinery needs. |

Plastics Manufacturing

In the plastics manufacturing sector, band heaters are critical for heating the nozzles of extruders. These heaters provide consistent and uniform heat, ensuring that materials flow smoothly through the extrusion process. By maintaining optimal temperatures, businesses can minimize material waste and enhance production efficiency. For international buyers, it is essential to source heaters that are compatible with specific extruder models and can operate within the required temperature ranges to avoid operational disruptions.

Food Processing

In the food processing industry, band heaters are used to maintain the required temperatures in various equipment, such as mixers and cookers. This is crucial for ensuring food safety and quality, as precise temperature control helps prevent spoilage and ensures proper cooking. Buyers from regions like Africa and South America should prioritize sourcing heaters that comply with food-grade standards and are designed for easy cleaning, which is vital for maintaining hygiene in food processing environments.

Pharmaceuticals

In pharmaceutical manufacturing, band heaters are employed to heat viscous materials in production processes, such as in the formulation of creams and ointments. These heaters ensure precise temperature control, which is essential for achieving product consistency and meeting strict regulatory standards. International buyers must consider sourcing materials that are reliable and compliant with safety regulations to ensure the integrity of pharmaceutical products.

Automotive

In the automotive industry, band heaters are utilized for heating components during manufacturing processes, such as in the production of plastics and rubber parts. The consistent heat provided by these heaters improves product quality and reduces cycle times, leading to more efficient production. Buyers should focus on sourcing high-temperature resistant heaters that can withstand the demanding conditions of automotive manufacturing.

Textile Industry

In the textile industry, band heaters are used in dyeing and finishing equipment to maintain the necessary temperatures for fabric processing. This ensures color consistency and reduces the time required for processing, leading to improved operational efficiency. For international buyers, it is important to look for custom heating solutions that can be tailored to specific machinery requirements, ensuring optimal performance in textile applications.

Related Video: How is a Mica Band or Mica Strip Heater made?

Strategic Material Selection Guide for band heater

When selecting materials for band heaters, international B2B buyers should consider several factors that influence performance, durability, and cost. Below is a detailed analysis of four common materials used in band heaters, focusing on their properties, advantages, disadvantages, and implications for specific applications.

Mica Band Heaters

Key Properties: Mica band heaters can operate at temperatures up to 900°F (482°C). They are known for their excellent thermal conductivity and relatively low weight, which makes them suitable for various applications.

Pros & Cons: The primary advantage of mica heaters is their cost-effectiveness and ease of installation. However, they may not be as durable as other materials, especially in high-stress environments. Their susceptibility to moisture can also limit their use in humid conditions.

Impact on Application: Mica heaters are ideal for low-temperature applications such as plastic molding. They are compatible with various media, but caution is needed in environments with high moisture levels.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards, as mica heaters may not meet all industrial regulations. Familiarity with ASTM standards can help in selecting appropriate products.

Ceramic Band Heaters

Key Properties: Ceramic band heaters can withstand temperatures up to 1400°F (760°C) and are known for superior heat retention and insulation properties.

Pros & Cons: The durability of ceramic heaters is a significant advantage, making them suitable for mid-temperature applications. However, they are generally more expensive than mica heaters and can be more complex to manufacture, leading to higher costs.

Impact on Application: These heaters are particularly effective for pipeline heating and injection molds, where consistent temperature is critical. They can handle a variety of media, including corrosive substances.

Considerations for International Buyers: Compliance with DIN standards is crucial for buyers in Europe. Additionally, the higher cost may be a barrier for some businesses in developing regions, so evaluating the long-term return on investment is essential.

Mineral Insulated Band Heaters

Key Properties: Mineral insulated band heaters can operate at temperatures up to 1600°F (871°C) and are designed for high-heat applications.

Pros & Cons: These heaters are highly durable and resistant to contamination, making them ideal for harsh environments. However, their manufacturing complexity can lead to higher costs.

Impact on Application: They are particularly suited for injection molding processes involving high-tech resins, where consistent high temperatures are necessary. Their robust construction allows them to handle various media without degradation.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider the specific standards for high-temperature applications, ensuring compliance with JIS or ASTM standards. The investment in these heaters can be justified by their longevity and reliability in demanding applications.

Stainless Steel Band Heaters

Key Properties: Stainless steel band heaters can handle temperatures up to 1200°F (649°C) and are known for their corrosion resistance and structural integrity.

Pros & Cons: Their durability and resistance to environmental factors make them suitable for a wide range of applications. However, they can be more expensive than other materials and may require specialized manufacturing techniques.

Impact on Application: Stainless steel heaters are particularly effective in food processing and pharmaceutical applications, where hygiene is paramount. They can withstand exposure to various chemicals, making them versatile.

Considerations for International Buyers: Compliance with food safety standards is critical for buyers in Europe and North America. Understanding local regulations regarding materials and manufacturing processes is essential to ensure product acceptance.

| Material | Typical Use Case for band heater | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mica Band Heaters | Plastic molding | Cost-effective | Less durable, moisture sensitive | Low |

| Ceramic Band Heaters | Pipeline heating, injection molds | Superior heat retention | Higher cost, complex manufacturing | Medium |

| Mineral Insulated Heaters | High-tech resin injection molding | Highly durable, contamination resistant | Higher manufacturing complexity | High |

| Stainless Steel Heaters | Food processing, pharmaceutical applications | Corrosion resistant, durable | Higher cost, specialized manufacturing | High |

This comprehensive analysis of band heater materials provides international B2B buyers with the insights needed to make informed purchasing decisions, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for band heater

The manufacturing processes for band heaters are complex and require meticulous attention to detail to ensure high performance and reliability. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes is vital for making informed purchasing decisions. Below is a comprehensive overview of the typical manufacturing stages and quality assurance practices involved in band heater production.

Manufacturing Processes

1. Material Preparation

The first stage involves sourcing and preparing the raw materials essential for band heater production. Key materials include:

- Heating Elements: Typically made from nichrome wire, which is known for its resistance to oxidation and ability to withstand high temperatures.

- Insulation Materials: Commonly used materials include mica, ceramic, or mineral insulation. These materials are crucial for thermal efficiency and safety.

- Outer Sheath: Stainless steel is often utilized for its durability and corrosion resistance.

Before manufacturing begins, materials undergo stringent inspections to ensure they meet specified standards for quality and performance.

2. Forming

In this stage, raw materials are shaped into the desired configurations. This includes:

- Cutting: Heating elements are cut to length according to design specifications.

- Bending: The insulation and outer sheath are bent to form a cylindrical shape that will fit snugly around the target application, such as an extrusion nozzle.

Advanced techniques such as laser cutting and CNC machining may be used to ensure precision in forming components.

3. Assembly

The assembly process is critical for ensuring the functionality of the band heater. Key steps include:

- Inserting Heating Elements: The nichrome wire is carefully placed within the insulating material.

- Attaching the Outer Sheath: The stainless steel casing is then fitted over the insulation, creating a protective layer.

- Wiring: Electrical connections are made to ensure the heater can be powered effectively.

Quality checks are implemented at various points during assembly to verify that components fit correctly and meet design specifications.

4. Finishing

The final stage of manufacturing includes:

- Surface Treatment: This may involve polishing or coating the outer sheath to enhance durability and resistance to environmental factors.

- Final Inspection: Each band heater undergoes a thorough inspection to ensure it meets all specifications before it is packaged for shipment.

Quality Assurance

Quality assurance is a critical aspect of band heater manufacturing, ensuring that the final products are reliable and safe for use in various applications. International B2B buyers should be familiar with the following quality standards and practices.

Relevant International Standards

- ISO 9001: This is a globally recognized quality management standard that ensures consistent quality in products and services. Manufacturers often seek ISO 9001 certification to demonstrate their commitment to quality.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For manufacturers producing heaters for the oil and gas sector, adherence to API standards may be essential.

QC Checkpoints

Quality control checkpoints are integrated into the manufacturing process to maintain high standards:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During production, ongoing inspections are performed to monitor the manufacturing processes and catch any defects early.

- Final Quality Control (FQC): Before packaging, finished products are thoroughly tested for performance, safety, and compliance with specifications.

Common Testing Methods

Manufacturers employ various testing methods to ensure product quality:

- Electrical Testing: Ensures that the heating elements function correctly and efficiently.

- Thermal Testing: Assesses the performance of the band heater under various temperature conditions.

- Durability Testing: Evaluates the longevity and resistance of materials under operational stresses.

Verifying Supplier Quality Control

B2B buyers must ensure that their suppliers maintain rigorous quality control measures. Here are practical steps to verify supplier QC:

- Conduct Audits: Regular audits of the supplier’s manufacturing processes can help verify adherence to quality standards. Buyers should request access to audit reports.

- Request Documentation: Suppliers should provide documentation, including quality control procedures, inspection reports, and certifications.

- Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the supplier’s quality assurance practices.

QC/Cert Nuances for International Buyers

International B2B buyers must navigate several nuances regarding quality control and certifications:

- Regional Standards: Different regions may have varying standards for safety and performance. Buyers should ensure their suppliers comply with local regulations in their target markets.

- Language Barriers: Ensure that all quality documentation is available in a language that is comprehensible to the buyer’s team to avoid miscommunication.

- Supply Chain Transparency: Buyers should seek suppliers who are willing to provide transparency regarding their supply chain and quality control processes, which can help mitigate risks associated with sourcing materials globally.

By understanding the manufacturing processes and quality assurance practices involved in band heater production, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This comprehensive knowledge fosters strong supplier relationships and ensures the procurement of reliable heating solutions that enhance production efficiency.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for band heater Sourcing

In the realm of sourcing band heaters, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. The following analysis provides insights into the key components that influence costs and pricing, along with strategic tips for effective sourcing.

Cost Components

-

Materials: The choice of materials significantly impacts the cost of band heaters. Common materials include nichrome wire for heating elements, mica or ceramic insulation, and stainless steel for the outer sheath. Higher-quality materials generally lead to increased durability and efficiency but also raise costs.

-

Labor: Labor costs vary by region and are influenced by the complexity of the manufacturing process. Skilled labor is essential for producing high-quality heaters, and labor costs can be a significant portion of the overall expense.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production processes can help minimize these costs, impacting the final pricing of band heaters.

-

Tooling: Custom tooling for specific designs or specifications can add to the initial costs. However, investing in the right tooling can enhance production efficiency and reduce costs in the long run.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the heaters meet industry standards and customer specifications. While this adds to the upfront costs, it can prevent expensive recalls and enhance customer satisfaction.

-

Logistics: Shipping and handling costs can vary significantly based on location, volume, and the chosen Incoterms. Buyers must consider these costs when calculating the total expenditure for sourcing band heaters.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market standards for margins in the band heater industry can help buyers gauge whether a price is competitive.

Price Influencers

Several factors can influence the pricing of band heaters:

-

Volume/MOQ: Bulk purchases often yield lower per-unit costs. Negotiating minimum order quantities (MOQs) can lead to substantial savings.

-

Specifications/Customization: Custom-designed heaters tailored to specific applications may come at a premium. Clear communication of requirements can help manage expectations regarding costs.

-

Materials: The choice of materials directly affects pricing. Premium materials may improve performance but will increase the initial investment.

-

Quality/Certifications: Heaters that comply with international quality standards or hold specific certifications may be priced higher. These certifications often assure reliability, which can justify the cost.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge more due to perceived value and trustworthiness.

-

Incoterms: The agreed-upon Incoterms can influence total costs. Understanding the implications of terms like FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) is essential for budgeting.

Buyer Tips

-

Negotiation: Engage in active negotiation with suppliers. Leverage volume commitments or long-term partnerships to secure better pricing.

-

Cost Efficiency: Evaluate the total cost of ownership (TCO) rather than just the purchase price. Consider factors such as energy efficiency and longevity when assessing value.

-

Pricing Nuances for International Buyers: Buyers from different regions may face unique challenges, such as tariffs and exchange rates. Understanding local market conditions can enhance negotiation strategies.

-

Supplier Research: Conduct thorough research on potential suppliers, focusing on their manufacturing capabilities, lead times, and customer reviews. This can aid in selecting a partner that aligns with your quality and cost expectations.

Disclaimer

Prices for band heaters can vary widely based on the aforementioned factors. The information provided serves as a guideline for understanding the cost structure and pricing dynamics in the industry, and actual prices may differ based on specific negotiations and market conditions.

Spotlight on Potential band heater Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘band heater’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for band heater

Critical Technical Properties of Band Heaters

When selecting band heaters for your manufacturing processes, understanding their technical properties is essential for ensuring optimal performance and efficiency. Here are some key specifications to consider:

-

Material Grade

The material used in band heaters significantly affects their performance. Common materials include mica, ceramic, and stainless steel. Each material has its unique thermal conductivity and durability characteristics, impacting its suitability for various applications. For instance, mica band heaters are cost-effective for low-temperature operations, while ceramic heaters excel in high-temperature scenarios. -

Temperature Range

Band heaters come with different maximum temperature capabilities, typically ranging from 482°F (250°C) to 1600°F (871°C). Selecting a band heater with the appropriate temperature range is critical for ensuring the heater can perform effectively in your specific application, such as extrusion or injection molding. -

Watt Density

Watt density refers to the amount of heat output per unit area of the heater. Higher watt densities can achieve quicker heating, which is vital in fast-paced production environments. However, too high a watt density can lead to overheating and premature failure, making it essential to balance watt density with the application requirements. -

Tolerance

Tolerance indicates the acceptable deviation in dimensions and performance specifications. In industrial applications, tight tolerances are crucial for ensuring that the band heater fits properly around the components, leading to uniform heating and preventing hot spots that could cause material degradation. -

Insulation Type

The insulation material, such as ceramic or mica, impacts both safety and efficiency. Effective insulation minimizes heat loss and protects surrounding components from excessive temperatures, which is especially important in environments where safety is a priority. -

Voltage Rating

Band heaters operate at specific voltage levels, which can vary between 120V, 240V, and 480V. Understanding the voltage requirements of your equipment is essential for compatibility and safety in your operations.

Common Trade Terminology

Familiarity with industry jargon can streamline communication with suppliers and enhance your procurement processes. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding the OEM relationship is crucial for ensuring that the band heaters you purchase are compatible with your existing machinery. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps in budgeting and planning purchases, especially when sourcing band heaters from international suppliers.

Illustrative Image (Source: Google Search)

- RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This process is vital for buyers looking to compare costs and terms before making procurement decisions.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

These are standardized trade terms used in international sales contracts that define the responsibilities of buyers and sellers. Understanding Incoterms is essential for managing shipping costs and responsibilities, particularly in cross-border transactions. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. This is a critical factor for production schedules, especially for industries relying on timely equipment delivery. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the performance and longevity of a product. Understanding the warranty terms is crucial for risk management and ensuring that you are protected against defects or failures in band heaters.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing band heaters, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the band heater Sector

Market Overview & Key Trends

The global band heater market is experiencing significant growth driven by the increasing demand for efficient heating solutions across various sectors, including manufacturing, food processing, and automotive industries. In particular, emerging markets in Africa and South America are witnessing a surge in industrial activities, which is propelling the need for reliable heating technologies. Technological advancements, such as the integration of smart heating solutions and IoT capabilities, are reshaping how manufacturers approach temperature control and energy management. For international B2B buyers, understanding these dynamics is crucial to leveraging opportunities in cost reduction and efficiency improvements.

One of the current trends is the shift towards custom heating solutions, which cater to specific industrial needs. Companies are increasingly looking for tailored products that can fit unique applications, thus ensuring maximum performance. Additionally, the demand for high-temperature and energy-efficient band heaters is on the rise, reflecting a broader industry focus on sustainability and operational efficiency. Buyers from Europe, particularly Italy, are prioritizing suppliers that offer innovative heating technologies that align with strict environmental regulations.

Moreover, the emergence of e-commerce platforms for industrial procurement is changing the sourcing landscape. Buyers can now access a wider range of products and suppliers, enabling them to compare prices and specifications more effectively. This shift is particularly beneficial for buyers in the Middle East and Africa, where traditional supply chains may be less developed.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central concern for B2B buyers in the band heater sector. As industries face increasing pressure to reduce their environmental impact, the sourcing of materials and manufacturing processes is under scrutiny. Buyers are encouraged to prioritize suppliers that adhere to sustainable practices, such as using recyclable materials and minimizing waste during production. The environmental impact of band heaters, particularly in terms of energy consumption and material sourcing, can significantly influence purchasing decisions.

Ethical supply chains are also gaining importance. Buyers should seek suppliers who can provide transparency regarding their sourcing practices, ensuring that raw materials are obtained responsibly and sustainably. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) can serve as indicators of a supplier’s commitment to sustainability. Additionally, utilizing “green” materials—such as those derived from renewable resources—can further enhance a company’s sustainability profile while providing a competitive edge in the marketplace.

Incorporating sustainability into procurement strategies not only mitigates environmental risks but can also lead to cost savings in the long run. For instance, energy-efficient band heaters can lower operational costs while also aligning with corporate sustainability goals, making them an attractive option for conscientious buyers.

Brief Evolution/History

The evolution of band heaters has been marked by significant technological advancements since their inception in the mid-20th century. Initially developed for basic temperature control, early band heaters were limited in their efficiency and range. Over the decades, innovations in materials science, such as the introduction of mica and ceramic insulation, have vastly improved their thermal performance and durability.

As industries have become more sophisticated, the demand for precision heating solutions has led to the development of advanced features, such as integrated temperature controls and smart technology capabilities. Today, band heaters are integral to various applications, from plastic molding to food processing, reflecting their adaptability and importance in modern manufacturing. For B2B buyers, understanding this evolution highlights the importance of selecting suppliers who are at the forefront of these technological advancements, ensuring they remain competitive in a fast-evolving market.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of band heater

-

What factors should I consider when vetting suppliers for band heaters?

When vetting suppliers, prioritize their industry experience, reputation, and certifications. Check for compliance with international standards, such as ISO certifications, and assess their capacity for customization. Request references or case studies from previous clients, especially those in your region, to gauge reliability and product performance. Evaluate their communication efficiency and responsiveness, as these factors can significantly impact your procurement process. -

Can I customize band heaters to meet specific requirements?

Yes, many manufacturers offer customization options for band heaters. You can specify dimensions, materials, and temperature ratings based on your application needs. Discuss your requirements with potential suppliers early in the negotiation process to understand their capabilities. Custom solutions may involve additional lead time and costs, so factor these into your project timelines and budgets. -

What are the typical minimum order quantities (MOQs) and lead times for band heaters?

Minimum order quantities can vary significantly among suppliers, often ranging from 10 to 100 units for standard products. Custom band heaters usually have higher MOQs due to production complexity. Lead times typically span from 2 to 6 weeks, depending on the supplier’s capacity and the complexity of your order. Always clarify these terms upfront to avoid unexpected delays in your supply chain. -

What payment terms should I expect when sourcing band heaters internationally?

Payment terms can vary widely, but common options include upfront payment, partial payment upon order confirmation, and the balance before shipment. For first-time buyers, suppliers may require advance payment to mitigate risk. Utilizing secure payment methods like letters of credit can provide additional protection. Always negotiate terms that align with your cash flow and risk management strategies. -

How can I ensure quality assurance and certification for my band heaters?

Request quality assurance documentation from suppliers, including inspection reports and certifications that verify compliance with industry standards (e.g., CE, UL). Some suppliers may also provide warranties or guarantees on their products. Conducting a factory audit, if feasible, can also help assess their quality control processes. Regular follow-ups and clear communication regarding quality expectations are essential throughout the procurement process. -

What logistics considerations should I keep in mind when importing band heaters?

When importing band heaters, consider shipping methods, customs regulations, and potential tariffs that may apply in your region. Engage with logistics providers who are experienced in handling industrial equipment to ensure timely and safe delivery. It’s advisable to track shipments and have contingency plans in case of delays. Collaborating with a local customs broker can facilitate smoother clearance and compliance with import regulations. -

What steps should I take in case of a dispute with a supplier?

Establish clear communication protocols and document all agreements in writing to minimize disputes. If issues arise, first attempt to resolve them amicably through direct negotiation. If necessary, refer to the contract’s dispute resolution clause, which may include mediation or arbitration. Engage legal counsel if the dispute escalates, especially in international contexts where jurisdiction and laws may differ. -

What role do local regulations play in sourcing band heaters for my business?

Local regulations can significantly impact the sourcing of band heaters, particularly concerning safety and environmental standards. Ensure that the products meet local compliance requirements to avoid penalties or product recalls. Research regulations that pertain to electrical equipment in your region, and consult with local authorities or compliance experts if needed. Suppliers familiar with your market’s regulatory landscape can be invaluable in navigating these complexities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for band heater

In conclusion, the strategic sourcing of band heaters is a critical factor for international B2B buyers looking to enhance operational efficiency and product quality. Key takeaways include the importance of selecting the right type of band heater—whether mica, ceramic, or mineral insulated—based on specific application needs and temperature requirements. Additionally, understanding the components and configurations of band heaters can lead to informed purchasing decisions that ultimately reduce costs and improve performance.

B2B buyers from Africa, South America, the Middle East, and Europe must prioritize collaboration with reputable suppliers who offer custom solutions and advanced technologies. By leveraging these partnerships, companies can not only optimize their heating processes but also drive innovation in their respective industries.

As we look ahead, the demand for energy-efficient and high-performance heating solutions will continue to grow. International buyers are encouraged to stay informed about technological advancements and market trends in the band heater sector. Embracing strategic sourcing practices will position companies to capitalize on emerging opportunities and achieve sustainable growth.