Your Ultimate Guide to Sourcing Burn Barrel For Trash

Introduction: Navigating the Global Market for burn barrel for trash

In an era where waste management is becoming increasingly critical, the importance of burn barrels for trash disposal cannot be overstated. These versatile containers serve as an effective solution for managing waste, particularly in regions where infrastructure for waste collection may be lacking. As international B2B buyers explore options for sustainable waste disposal, understanding the nuances of burn barrels—ranging from types and materials to manufacturing quality control—is essential for making informed purchasing decisions.

This comprehensive guide delves into various aspects of burn barrels, including their designs, the materials used in their construction, and the standards for manufacturing and quality control. Additionally, it outlines key considerations for sourcing from reputable suppliers, examines cost factors, and provides insights into market trends across different regions, including Africa, South America, the Middle East, and Europe.

By equipping buyers with actionable insights and practical knowledge, this guide empowers them to navigate the global market for burn barrels effectively. It addresses frequently asked questions, ensuring that B2B buyers are well-prepared to make decisions that align with both their operational needs and environmental commitments. Embracing this resource will facilitate a more responsible approach to waste management, ultimately contributing to a cleaner and more sustainable future.

Understanding burn barrel for trash Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Steel Barrel | Made from heavy-duty steel, typically 55 gallons | General waste disposal, rural areas | Pros: Durable, affordable, widely available. Cons: Can emit harmful pollutants, not eco-friendly. |

| Double-Layer Insulated Barrel | Features double walls for better insulation | Industrial waste management | Pros: Reduces heat loss and emissions. Cons: Higher initial cost, requires proper maintenance. |

| Eco-Friendly Burn Barrel | Designed with advanced air flow and filtration systems | Eco-conscious businesses | Pros: Minimizes emissions, complies with regulations. Cons: More expensive, may require training for use. |

| Portable Burn Barrel | Lightweight and easy to transport, often collapsible | Remote locations, temporary sites | Pros: Versatile, ideal for mobile waste management. Cons: Less durable, can be less effective for large volumes. |

| Customizable Burn Barrel | Options for modifications based on specific needs | Specialized waste processing | Pros: Tailored solutions for unique waste types. Cons: Longer lead times, potentially higher costs. |

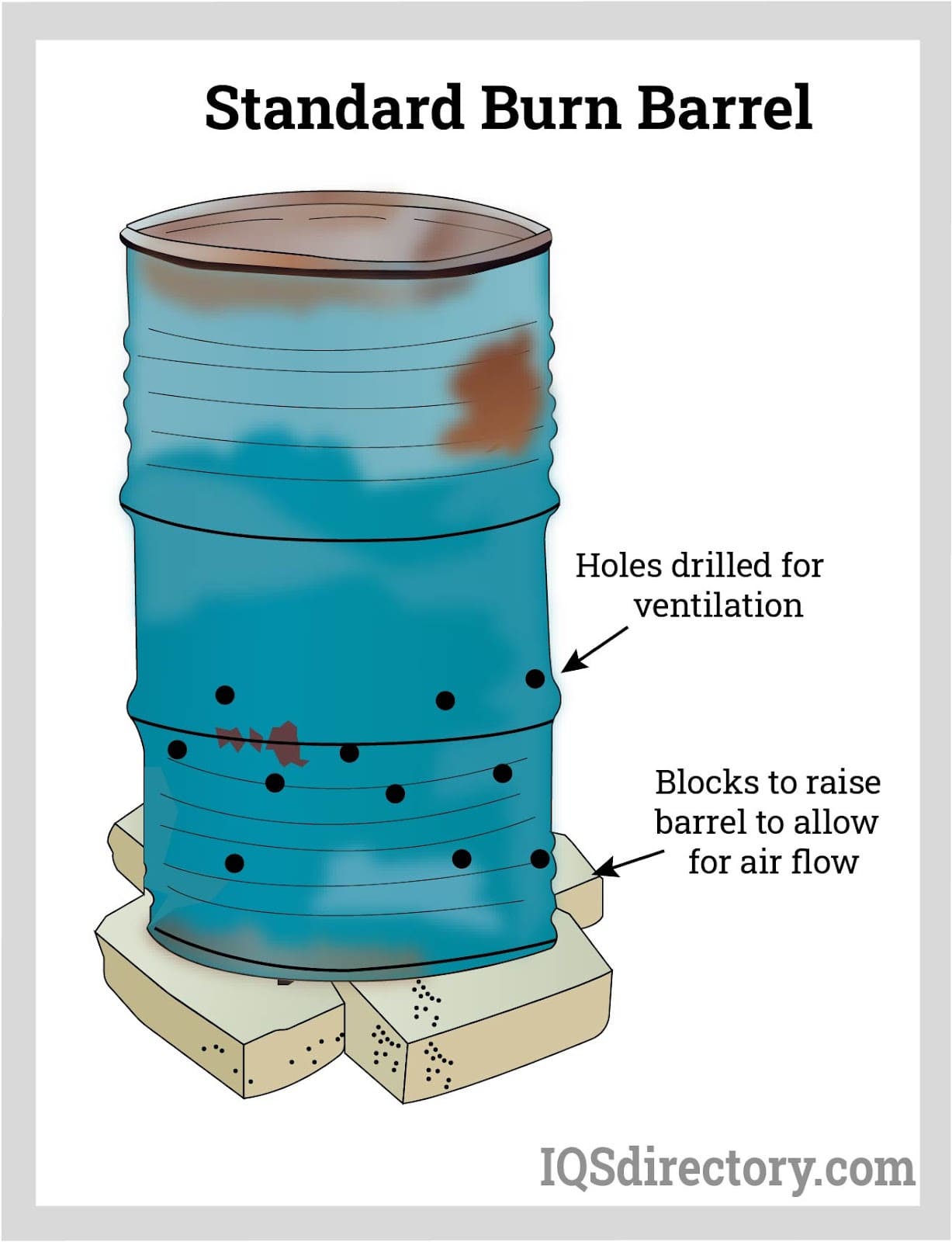

Standard Steel Barrel

The standard steel barrel, usually 55 gallons, is a common choice for burning trash in rural areas. Its heavy-duty construction allows it to withstand high temperatures, making it suitable for general waste disposal. B2B buyers should consider its affordability and availability, but they must also be aware of the environmental implications, as burning trash in these barrels can release harmful pollutants.

Illustrative Image (Source: Google Search)

Double-Layer Insulated Barrel

This type of burn barrel features a double-layer construction that enhances insulation, allowing for more efficient combustion. It is particularly beneficial in industrial waste management settings where reducing emissions is critical. While the initial investment is higher, the long-term benefits of reduced emissions and heat loss can justify the cost for businesses focused on sustainability.

Eco-Friendly Burn Barrel

Designed with advanced air flow and filtration systems, eco-friendly burn barrels are ideal for businesses that prioritize environmental responsibility. These barrels minimize harmful emissions and help companies comply with waste disposal regulations. Although they come with a higher price tag, the benefits of reduced environmental impact and compliance can outweigh the costs, particularly for eco-conscious organizations.

Portable Burn Barrel

The portable burn barrel is lightweight and often collapsible, making it ideal for use in remote locations or temporary sites. This versatility allows businesses to manage waste effectively in various settings, from construction sites to outdoor events. However, buyers should consider that while portable options are convenient, they may not be as durable or effective for handling large volumes of waste.

Customizable Burn Barrel

Customizable burn barrels allow businesses to modify the design based on their specific waste management needs. This flexibility is especially valuable for industries that generate unique waste types that require specialized handling. While these barrels can offer tailored solutions, buyers should be prepared for potentially longer lead times and higher costs associated with customization.

Related Video: Burn Barrel Easy and Efficient! (Burning)

Key Industrial Applications of burn barrel for trash

| Industry/Sector | Specific Application of burn barrel for trash | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Disposal of agricultural waste such as crop residues | Reduces waste on-site, improves land management, and minimizes pests | Sourcing barrels that meet local environmental regulations and are durable for outdoor use |

| Construction and Demolition | Burning of non-recyclable materials like wood debris | Efficient waste disposal, reduces transportation costs, and minimizes landfill use | Ensure compliance with local laws regarding burning waste materials, and consider safety features |

| Food Processing | Disposal of organic waste and packaging materials | Enhances waste management efficiency and reduces landfill contributions | Seek barrels designed to handle specific waste types and check for ease of use and maintenance |

| Remote Community Management | Waste disposal in areas lacking formal waste services | Provides a practical solution for waste management and reduces environmental impact | Look for portable and robust designs that can withstand various environmental conditions |

| Forestry | Burning of forestry waste and slash | Helps in land clearing, pest control, and preparing land for new growth | Consider barrels that can handle larger volumes and are designed for outdoor use in rugged conditions |

Agriculture

In the agricultural sector, burn barrels are often utilized for the disposal of crop residues and other organic waste. This practice helps farmers manage waste efficiently on-site, reducing the risk of pest infestations and disease spread. For international buyers, especially in regions like Africa and South America, sourcing burn barrels that comply with local environmental regulations is critical. Durability and resistance to weather conditions are essential features to consider, ensuring that the barrels can withstand the rigors of outdoor use.

Construction and Demolition

In construction and demolition, burn barrels serve as an effective solution for disposing of non-recyclable materials, particularly wood debris. This method allows companies to reduce transportation costs associated with waste disposal and minimizes the environmental footprint by diverting waste from landfills. Buyers in this sector must ensure that the barrels meet local regulations regarding the burning of construction waste and are equipped with safety features to prevent accidents.

Food Processing

Food processing facilities can benefit from using burn barrels for the disposal of organic waste and packaging materials. By incinerating these materials, businesses can enhance their waste management processes, leading to improved operational efficiency and reduced landfill contributions. International B2B buyers should look for burn barrels specifically designed for handling organic waste, with features that facilitate easy use and maintenance, ensuring compliance with health and safety standards.

Remote Community Management

In remote communities lacking formal waste management services, burn barrels provide a practical solution for waste disposal. This application is particularly relevant in rural areas of Africa and South America, where access to sanitation infrastructure may be limited. Buyers should prioritize sourcing portable and robust burn barrels that can withstand harsh environmental conditions, making them suitable for varied terrains and climates.

Forestry

The forestry industry frequently uses burn barrels for the disposal of slash and other forestry waste. This method aids in land clearing, pest control, and preparing land for new growth, contributing to sustainable forestry practices. When sourcing burn barrels for this purpose, it is essential to consider models that can accommodate larger volumes of waste and are designed for rugged outdoor use, ensuring efficiency and safety during operation.

Related Video: How to Make a Burn Barrel (Step by Step) | Backyardscape

Strategic Material Selection Guide for burn barrel for trash

Material Analysis for Burn Barrels

When selecting materials for burn barrels intended for trash disposal, international B2B buyers must consider various factors that affect performance, durability, and compliance with local regulations. Below, we analyze four common materials used in the construction of burn barrels, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in diverse regions.

1. Steel

Key Properties: Steel is known for its high strength and excellent temperature resistance, typically rated to withstand temperatures up to 1,500°F (815°C). It also exhibits good corrosion resistance when coated or treated.

Pros & Cons: Steel burn barrels are durable and can handle high heat, making them suitable for burning a variety of waste. However, they can be heavy and may require more complex manufacturing processes. The cost of steel can vary significantly based on market conditions, but it generally falls in the medium to high range.

Impact on Application: Steel is compatible with most waste types, but buyers should be cautious about burning materials that can produce toxic emissions, such as plastics.

Considerations for International Buyers: Compliance with local environmental regulations is crucial. Buyers in Europe, for instance, must adhere to stringent EU standards regarding emissions. In regions like Africa and South America, understanding local waste management policies is essential.

2. Aluminum

Key Properties: Aluminum is lightweight and has a melting point of approximately 1,220°F (660°C). It is also resistant to corrosion, which is beneficial for outdoor use.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, making it easier to transport and handle. However, its lower melting point limits its use for high-temperature applications, and it can be more expensive than steel.

Impact on Application: Aluminum burn barrels are suitable for lighter waste materials but may not perform well with heavier or more combustible items that generate higher temperatures.

Considerations for International Buyers: Buyers should check for compliance with local standards, particularly in Europe, where aluminum recycling is highly regulated. In the Middle East, the demand for lightweight materials may drive preference for aluminum barrels.

3. Galvanized Steel

Key Properties: Galvanized steel is coated with a layer of zinc, providing enhanced corrosion resistance. It retains the strength of steel while offering better protection against rust.

Pros & Cons: The main advantage of galvanized steel is its durability and resistance to corrosion, making it ideal for outdoor use. However, the galvanization process can add to manufacturing costs, placing it in the medium to high cost range.

Impact on Application: Galvanized steel is effective for burning various types of waste while reducing the risk of corrosion from exposure to the elements.

Considerations for International Buyers: Buyers should ensure that the galvanized coating meets local environmental regulations to avoid toxic emissions during burning. Compliance with standards such as ASTM in the U.S. or DIN in Germany is essential.

4. Cast Iron

Key Properties: Cast iron has excellent heat retention properties and can withstand high temperatures, typically rated up to 2,000°F (1,093°C).

Pros & Cons: The durability and heat retention of cast iron make it ideal for burn barrels. However, it is heavy and can be more expensive to manufacture and transport, placing it in the high-cost category.

Impact on Application: Cast iron is suitable for heavy-duty applications, including burning dense waste materials. However, its weight can be a disadvantage in terms of mobility.

Considerations for International Buyers: Buyers should consider the logistical challenges associated with transporting heavy materials. In regions like Africa and South America, the cost of transport may influence the decision to use cast iron.

Summary Table

| Material | Typical Use Case for burn barrel for trash | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General waste disposal | High strength and temperature resistance | Heavy and complex manufacturing | Medium to High |

| Aluminum | Lightweight waste disposal | Lightweight and easy to handle | Lower melting point | Medium to High |

| Galvanized Steel | Outdoor waste burning | Corrosion resistance | Higher manufacturing costs | Medium to High |

| Cast Iron | Heavy-duty waste burning | Excellent heat retention | Heavy and expensive to transport | High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions that align with both operational needs and regulatory compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for burn barrel for trash

Manufacturing Processes for Burn Barrels

The manufacturing of burn barrels for trash involves several critical stages that ensure the final product is safe, durable, and effective for waste disposal. Understanding these processes can help international B2B buyers make informed purchasing decisions.

Material Preparation

The first step in manufacturing burn barrels is material preparation. Typically, steel is the preferred material due to its strength and heat resistance. Buyers should ensure that the steel used is of high quality, often sourced from reputable suppliers who can provide material certifications. Common specifications include:

- Gauge Thickness: Thicker gauges (e.g., 16-gauge or lower) offer better durability and heat resistance.

- Corrosion Resistance: Consider materials that are galvanized or coated to prevent rust, especially in humid environments common in regions like Africa and South America.

Forming

Once the materials are prepared, the next stage is forming. This process involves shaping the steel into the desired barrel configuration. Key techniques include:

- Roll Forming: Steel sheets are fed through rollers to create a cylindrical shape. This method ensures uniformity and strength.

- Hydraulic Pressing: For components that require additional shaping or detailing, hydraulic presses can be utilized to form specific features such as handles or air vents.

Assembly

After forming, the individual components are assembled. This stage is crucial for ensuring the structural integrity of the burn barrel. Common practices include:

- Welding: Strong welds are essential for joining parts together. Buyers should inquire about the welding standards used, such as AWS (American Welding Society) guidelines.

- Bolting: In some designs, components may be bolted together, allowing for easier assembly and disassembly.

Finishing

Finishing treatments are vital to enhance the barrel’s durability and resistance to environmental factors. This includes:

- Surface Treatment: Processes such as powder coating or painting can be applied to prevent rust and improve aesthetics. Buyers should verify that the finishes are suitable for high-temperature applications.

- Quality Checks: After finishing, each barrel should undergo inspections to ensure that coatings are applied uniformly and that there are no defects.

Quality Assurance in Manufacturing

Quality assurance (QA) is critical in the manufacturing of burn barrels to meet international standards and ensure safety and reliability. B2B buyers should look for suppliers who adhere to recognized quality management systems.

International Standards

Key international standards relevant to burn barrel manufacturing include:

- ISO 9001: This standard outlines the requirements for a quality management system. It ensures that the manufacturer consistently provides products that meet customer and regulatory requirements.

- CE Marking: In Europe, the CE mark signifies conformity with health, safety, and environmental protection standards. Buyers in Europe should ensure their suppliers have the necessary certifications.

Industry-Specific Standards

In addition to general standards, there are industry-specific certifications to consider:

- API (American Petroleum Institute): For barrels used in specific industrial applications, compliance with API standards may be necessary, particularly if the barrels are intended for hazardous materials.

- ASTM (American Society for Testing and Materials): Compliance with ASTM standards can also be beneficial, particularly for material specifications and testing methods.

Quality Control Checkpoints

To maintain high-quality manufacturing processes, several checkpoints are established throughout production:

- Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials for compliance with specifications before they enter production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures adherence to quality standards. Regular checks on welding, forming, and assembly are vital.

- Final Quality Control (FQC): Before shipping, a final inspection should be conducted to ensure that the finished barrels meet all quality and safety standards.

Common Testing Methods

B2B buyers should be aware of the testing methods used to verify the quality of burn barrels:

- Pressure Testing: Ensures that the barrels can withstand operational pressures without leaking or deforming.

- Heat Resistance Testing: Evaluates the barrel’s performance under high temperatures to confirm that it can safely contain burning materials.

- Corrosion Resistance Testing: Determines the effectiveness of protective coatings against rust and degradation.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, buyers can take several steps:

- Audits: Conduct regular audits of potential suppliers to assess their quality management systems and adherence to international standards.

- Quality Reports: Request documentation of quality control processes, including inspection and testing results.

- Third-Party Inspections: Engage third-party inspection services to verify the quality of products before shipping. This is particularly important for buyers in Africa and South America, where local quality standards may vary.

Navigating Quality Control Nuances for International Buyers

International buyers must be aware of specific nuances when it comes to quality control:

- Cultural Differences: Quality expectations may differ across regions. Understanding local standards and practices is essential for effective communication with suppliers.

- Regulatory Compliance: Buyers should ensure that suppliers are compliant with both local and international regulations, which may include environmental standards for waste management.

- Documentation: Proper documentation of quality checks and certifications is crucial for international trade. Buyers should maintain a clear record of all communications and agreements regarding quality standards.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for burn barrels is essential for B2B buyers. By focusing on material quality, adherence to international standards, and rigorous quality control measures, buyers can make informed decisions that ensure they procure safe and effective products for waste management.

Related Video: HOW TO MAKE A BURN BARREL— THE SECRET TO BURNING CLEANER!

Comprehensive Cost and Pricing Analysis for burn barrel for trash Sourcing

Understanding the Cost Structure of Burn Barrels for Trash

When sourcing burn barrels for trash management, it is crucial to understand the cost structure involved. The primary cost components include:

-

Materials: The type of material used in the construction of burn barrels significantly impacts costs. Steel is commonly used due to its durability, while more eco-friendly options may be available at a premium. The choice of material will also affect the barrel’s resistance to corrosion and its lifespan.

-

Labor: Labor costs encompass wages for workers involved in manufacturing the barrels. Labor rates can vary significantly across regions, impacting the overall price. Automation in production can reduce labor costs but may require a higher initial investment.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs, which in turn influences the pricing of the final product.

-

Tooling: Tooling costs involve the equipment and molds necessary for production. Custom designs or specialized barrels may incur additional tooling expenses, which are usually amortized over the production volume.

-

Quality Control (QC): Ensuring product quality is essential, particularly for international buyers concerned about compliance with local regulations. Investing in robust QC processes can increase initial costs but will likely lead to fewer returns and higher customer satisfaction.

-

Logistics: Shipping and handling costs vary based on destination, volume, and mode of transport. For international shipments, factors such as port fees, customs duties, and Incoterms must be considered.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary widely based on market conditions, competition, and the supplier’s financial health.

Key Price Influencers in Burn Barrel Sourcing

Several factors can influence the pricing of burn barrels:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can lead to significant discounts. Suppliers are often willing to negotiate better rates for larger orders, making it beneficial for buyers with consistent needs.

-

Specifications/Customization: Custom features such as size, lid types, or additional safety elements can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or environmental compliance) can lead to increased costs but may provide long-term savings through durability and compliance with regulations.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge a premium, but their reliability can mitigate risks associated with product quality and delivery.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect landed costs and should be negotiated to ensure clarity on who bears shipping and insurance costs.

Buyer Tips for Cost Efficiency

International B2B buyers should consider the following strategies to enhance cost efficiency when sourcing burn barrels:

-

Negotiate: Leverage volume commitments to negotiate better pricing. Don’t hesitate to ask for discounts or better payment terms, especially if you can provide a long-term purchasing commitment.

-

Total Cost of Ownership (TCO): Assess the total cost of ownership, which includes purchase price, maintenance, and potential disposal costs. A higher upfront cost may be justified if the barrel lasts longer or requires less maintenance.

-

Pricing Nuances: Be aware of currency fluctuations and international shipping costs, which can vary based on geopolitical factors. Consider securing contracts in your local currency to mitigate risks.

-

Research and Compare: Conduct thorough market research to compare prices and quality among different suppliers. Utilize trade shows and industry forums to connect with potential vendors and gain insights into current market conditions.

Disclaimer

The prices and costs discussed are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes before making purchasing decisions.

Spotlight on Potential burn barrel for trash Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘burn barrel for trash’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for burn barrel for trash

When considering the procurement of burn barrels for trash disposal, understanding the essential technical properties and industry terminology is crucial for making informed purchasing decisions. This section highlights key specifications and trade terms relevant to international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Burn barrels are typically constructed from metals such as steel or aluminum. The material grade significantly affects durability and resistance to corrosion and high temperatures. For instance, galvanized steel barrels provide enhanced rust resistance, making them suitable for outdoor use in diverse weather conditions. -

Thickness

– The thickness of the barrel’s walls is vital for withstanding high temperatures and the stresses of burning waste. A thicker gauge (e.g., 14-gauge vs. 18-gauge) indicates a more robust product, which is essential for ensuring safety and longevity, especially in industrial or frequent-use scenarios. -

Capacity

– Burn barrels come in various sizes, commonly ranging from 30 to 55 gallons. Understanding the capacity is essential for compliance with local regulations and for meeting waste disposal needs efficiently. Larger barrels may require more space but can reduce the frequency of waste disposal, thereby optimizing operational efficiency. -

Ventilation Design

– Proper ventilation is crucial for efficient burning and minimizing smoke emissions. Burn barrels should feature strategically placed holes or a vented lid to facilitate airflow, ensuring that waste burns more completely and safely. This property is particularly important in regions with strict environmental regulations. -

Weight

– The weight of the burn barrel impacts its portability and stability. Heavier barrels are typically more stable in windy conditions but may be cumbersome to move. Understanding the weight can assist buyers in selecting barrels that meet their operational logistics and site-specific needs.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of burn barrels, buyers should consider sourcing from OEMs to ensure quality and compatibility with specific waste management systems. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory levels and costs effectively. Suppliers may offer better pricing at higher MOQs, which can be beneficial for larger operations. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and availability for specific products. It is a standard procedure in B2B transactions, allowing buyers to compare offers from multiple suppliers and negotiate better terms. -

Incoterms (International Commercial Terms)

– Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth transactions. -

Lead Time

– Lead time refers to the amount of time from placing an order to receiving the product. Understanding lead times is critical for inventory management and planning, especially for businesses that require burn barrels for ongoing operations or seasonal needs. -

Warranty

– A warranty is a guarantee provided by the manufacturer regarding the quality and lifespan of the product. Knowing the warranty terms can help buyers assess the long-term value of their investment in burn barrels and ensure they have recourse in case of defects.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can enhance their procurement strategies and make informed decisions regarding burn barrels for trash disposal.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the burn barrel for trash Sector

Market Overview & Key Trends

The global burn barrel for trash market is influenced by various factors, including regulatory changes, environmental awareness, and technological advancements. As urbanization increases, especially in developing regions such as Africa and South America, the demand for efficient waste management solutions rises. Local authorities are increasingly implementing stricter waste disposal regulations, which creates opportunities for B2B buyers to source compliant and environmentally friendly products.

Emerging technologies are reshaping the market dynamics. Innovations such as closed combustion systems and advanced filtration technologies are gaining traction, allowing for cleaner waste burning processes. These technologies not only reduce harmful emissions but also enhance the efficiency of waste management practices. Additionally, the rise of smart waste management solutions, including IoT-enabled burn barrels that monitor waste levels and emissions, offers new avenues for operational optimization.

International B2B buyers should also be aware of the regional differences in sourcing trends. For example, European markets are leaning towards zero-waste policies and sustainable product sourcing, while buyers in the Middle East may prioritize durability and efficiency due to the harsh environmental conditions. Understanding these regional nuances can help businesses make informed decisions when sourcing burn barrels.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration for B2B buyers in the burn barrel sector. The environmental impact of burning waste is significant, as it often releases toxic pollutants that harm air quality and contribute to climate change. Consequently, buyers must prioritize products that mitigate these effects, such as burn barrels designed to minimize emissions and incorporate advanced combustion technologies.

Ethical supply chains are equally important. Buyers should seek suppliers that adhere to sustainable practices, including responsible sourcing of materials and transparent operations. Certifications such as ISO 14001 (Environmental Management) and other green certifications can serve as indicators of a supplier’s commitment to sustainability.

In addition, sourcing materials that are recyclable or made from recycled content can enhance the overall sustainability profile of the burn barrels. By investing in eco-friendly products, B2B buyers not only comply with regulations but also align with the growing consumer demand for sustainable practices, ultimately leading to enhanced brand reputation and customer loyalty.

Brief Evolution/History

The use of burn barrels for trash has evolved significantly over the past few decades. Traditionally viewed as a practical solution for waste disposal in rural and suburban areas, burn barrels have come under scrutiny due to their environmental impact. The introduction of stricter environmental regulations in many countries has prompted manufacturers to innovate and develop cleaner burning technologies.

Historically, the materials used for burn barrels were often subpar, leading to quick degradation and inefficiency. However, advancements in materials science have resulted in the creation of more durable and efficient burn barrels. These modern iterations not only comply with regulatory standards but also cater to the needs of environmentally conscious consumers, making them a viable option for sustainable waste management practices.

Related Video: The Ultimate DIY Burn Barrel Guide

Frequently Asked Questions (FAQs) for B2B Buyers of burn barrel for trash

-

What should I consider when vetting suppliers for burn barrels?

When vetting suppliers, ensure they have a proven track record in manufacturing burn barrels that comply with local and international safety standards. Verify their certifications, such as ISO 9001 for quality management. Request references from previous clients and assess their ability to provide custom solutions based on your specific needs. It’s also beneficial to evaluate their production capacity and the materials used, as these factors directly impact the durability and safety of the burn barrels. -

Can I customize burn barrels to meet my specific needs?

Yes, many manufacturers offer customization options for burn barrels, including size, material, and design features such as lids or vents. When discussing customization, clearly outline your requirements, including any specific regulations you need to comply with in your region. Request samples or prototypes if possible to ensure that the final product aligns with your expectations. Customization can also extend to branding or labeling, enhancing your corporate identity. -

What are the typical minimum order quantities (MOQ) and lead times for burn barrels?

Minimum order quantities for burn barrels can vary widely depending on the supplier and the level of customization required. Commonly, MOQs range from 100 to 500 units. Lead times typically depend on the supplier’s production capacity and the complexity of the order, often ranging from 4 to 12 weeks. Always confirm these details during negotiations and consider your inventory needs to avoid excess stock or shortages. -

What payment terms should I expect when purchasing burn barrels?

Payment terms can vary by supplier but generally include options such as a deposit upfront (usually 30-50%) and the balance upon delivery or before shipment. Some suppliers may also offer letter of credit (LC) arrangements, which can provide additional security for international transactions. Always clarify payment methods accepted, such as bank transfers or credit cards, and ensure that terms are documented in the purchase agreement to avoid misunderstandings. -

How can I ensure the quality of the burn barrels I purchase?

To ensure quality, request detailed specifications and quality assurance (QA) documentation from the supplier. Inquire about their QA processes and whether they conduct regular inspections during production. Certifications like CE marking or compliance with local regulations can also indicate adherence to quality standards. If feasible, consider arranging for third-party inspections before shipment, especially for large orders. -

What logistics considerations should I keep in mind when importing burn barrels?

Logistics are crucial in international trade. Consider the shipping method (sea, air, or land) based on cost and urgency. Verify if the supplier can handle shipping logistics or if you need to engage a freight forwarder. Be aware of customs regulations and potential tariffs in your country, as these can affect the total cost. Ensure that all shipping documents are accurate and complete to avoid delays at customs. -

What should I do in case of a dispute with a supplier?

In the event of a dispute, first, attempt to resolve the issue directly with the supplier through clear communication. Document all interactions and agreements to provide a reference. If a resolution cannot be reached, refer to the dispute resolution clause in your contract, which may specify mediation or arbitration as steps to follow. Engaging a legal advisor familiar with international trade can also be beneficial to understand your rights and obligations. -

Are there specific regulations I need to comply with when using burn barrels?

Yes, regulations regarding the use of burn barrels can vary significantly by country and region. In many areas, there are strict guidelines on what materials can be burned and how to operate burn barrels safely to minimize environmental impact. Check with local environmental agencies or regulatory bodies to ensure compliance with laws related to air quality and waste disposal. It’s crucial to stay informed about any changes in legislation that may affect your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for burn barrel for trash

The strategic sourcing of burn barrels for trash presents an opportunity for international B2B buyers to enhance their waste management practices while adhering to environmental standards. As the global focus shifts towards sustainability, it is crucial to recognize the risks associated with traditional trash burning methods, particularly in terms of health and environmental impact. Buyers should prioritize sourcing products that comply with local regulations and promote eco-friendly waste disposal methods.

Key takeaways for B2B buyers include the importance of investing in advanced technologies, such as closed combustion systems that minimize emissions. Additionally, consider partnerships with suppliers who emphasize the reduction of harmful materials in their products, thereby contributing to a safer waste management landscape.

Looking ahead, the demand for sustainable waste solutions is set to grow, driven by increasing regulatory pressures and public awareness. International buyers from Africa, South America, the Middle East, and Europe are encouraged to engage with suppliers who share a commitment to innovative waste management practices. By prioritizing strategic sourcing, businesses can not only improve their operational efficiency but also play a vital role in fostering a healthier environment for future generations.

Illustrative Image (Source: Google Search)