Your Ultimate Guide to Sourcing Central Machining

Introduction: Navigating the Global Market for central machining

Precision is the cornerstone of modern manufacturing, and central machining plays a pivotal role in delivering high-quality, reliable components across various industries. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the intricacies of central machining is essential for optimizing your supply chain and ensuring compliance with stringent industry standards. This guide will navigate you through the complexities of sourcing CNC machining parts, which are integral to sectors such as aerospace, automotive, and industrial automation.

The scope of this guide encompasses a comprehensive overview of the types of machining services, including CNC turning, milling, and multi-axis machining, along with their respective applications. You’ll gain insights into material selection—balancing performance with cost—and learn about manufacturing workflows that ensure quality control and precision finishing. Additionally, we will explore supplier discovery and evaluation techniques, providing you with tools to leverage digital platforms effectively.

By delving into cost drivers, negotiation strategies, and regional market dynamics, this guide equips you with actionable insights to make informed sourcing decisions. Whether you’re seeking to enhance supplier relationships or streamline procurement processes, the knowledge contained herein will empower you to navigate the global market for central machining with confidence, ultimately driving value and efficiency in your operations.

Understanding central machining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Turning | Produces cylindrical parts with rotational symmetry | Shafts, bushings, pins, connectors | Cost-effective for round shapes; fast production, but limited to cylindrical forms. |

| CNC Milling | Utilizes rotating cutters for complex shapes and surfaces | Housings, brackets, engine covers | Highly flexible design capabilities; excellent surface finish, but higher costs for intricate geometries. |

| 5-Axis Machining | Allows machining on multiple planes in a single setup | Aerospace components, medical devices | Enables complex features efficiently; requires specialized suppliers and may have higher programming costs. |

| CNC Drilling and Tapping | High precision holes and threads; versatile in application | Mounting plates, flanges, connector bases | Accurate threading and hole placement; limited in overall part complexity. |

| Multi-Task Machining | Combines turning, milling, and drilling in one machine | Industrial connectors, actuator components | Increases throughput; ideal for high-volume production, but may require higher initial investment. |

CNC Turning

CNC turning is a highly efficient method for producing cylindrical components, characterized by its ability to achieve tight tolerances and a smooth finish. This technique is particularly suitable for parts like shafts and bushings, commonly used in automotive and mechanical assemblies. B2B buyers should consider the supplier’s experience with specific materials and the potential need for post-turning processes, such as grinding, to meet stringent performance specifications.

CNC Milling

CNC milling stands out for its versatility, employing rotating cutters to shape complex geometries. This method is ideal for applications requiring intricate designs, such as housings and structural brackets in the automotive and aerospace sectors. Buyers should assess the supplier’s capability to handle varying material types and thicknesses, as well as their adherence to quality standards, to ensure that the final product meets all operational requirements.

5-Axis Machining

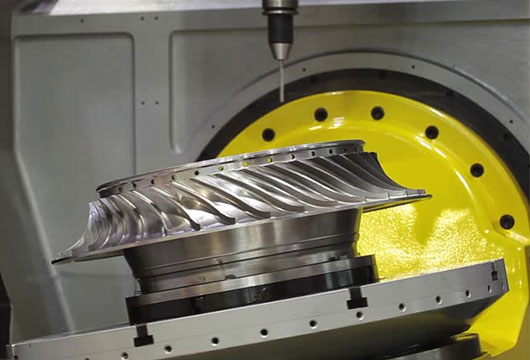

5-axis machining allows for the production of complex components in a single setup, significantly reducing lead times and enhancing precision. This technology is particularly beneficial for industries requiring high complexity, such as aerospace and medical device manufacturing. When sourcing suppliers, B2B buyers should prioritize those with advanced programming capabilities and experience with multi-faceted designs to maximize efficiency and minimize errors.

CNC Drilling and Tapping

CNC drilling and tapping focus on creating precise holes and threads, crucial for components like mounting plates and flanges. This method is highly effective for applications that demand accuracy and reliability. Buyers should evaluate the supplier’s expertise in drilling and tapping processes, as well as their ability to maintain tolerances, to ensure the components fit seamlessly into larger assemblies.

Multi-Task Machining

Multi-task machining integrates turning, milling, and drilling into one operation, optimizing workflow and increasing production speed. This method is particularly advantageous for high-volume production of components like connectors and actuators. B2B buyers should consider the initial investment required for such machinery, as well as the potential for long-term cost savings through efficiency gains and reduced lead times.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of central machining

| Industry/Sector | Specific Application of Central Machining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for aircraft engines | Ensures reliability and safety; compliance with strict regulations | Supplier’s certification (e.g., AS9100), material traceability |

| Oil & Gas | Machined parts for drilling equipment | Enhances operational efficiency and reduces downtime | Experience with high-strength materials like Inconel, lead times |

| Automotive | Engine and transmission components | Improves performance and efficiency; cost-effective manufacturing | Supplier’s ability to meet stringent tolerances and surface finishes |

| Medical Devices | Custom housings and surgical instruments | Ensures biocompatibility and precision; critical for patient safety | Compliance with medical standards (e.g., ISO 13485), material selection |

| Industrial Machinery | Components for automation systems | Increases productivity and reduces maintenance costs | Supplier’s expertise in high-volume production and quick turnaround |

Aerospace

In the aerospace sector, central machining is crucial for producing precision components such as turbine blades, structural supports, and engine mounts. These components must meet rigorous safety and performance standards due to the high stakes involved in aviation. For international buyers, particularly from Europe and the Middle East, sourcing suppliers with AS9100 certification is essential to ensure compliance and reliability. Additionally, understanding material properties and machining capabilities is critical to avoid delays and ensure that parts meet stringent tolerances.

Oil & Gas

Central machining plays a vital role in the oil and gas industry, particularly in the manufacturing of components for drilling rigs and pipelines. Parts such as valves, flanges, and drill bits require high durability and resistance to harsh environments. Buyers from regions like Africa and South America must prioritize suppliers with experience in machining high-strength materials like Inconel and those who can provide quick lead times to minimize operational downtime. The ability to produce complex geometries while adhering to international quality standards is also a key consideration.

Automotive

In the automotive industry, central machining is used to manufacture critical components such as engine blocks, transmission parts, and chassis components. The focus is on achieving high precision and performance while maintaining cost-effectiveness. For buyers, especially in regions like Europe and South America, it’s vital to partner with suppliers who can meet exacting tolerances and deliver high-quality surface finishes. Understanding the supplier’s capability to handle both low and high-volume production runs can significantly impact project timelines and costs.

Medical Devices

Central machining is essential in the medical device sector for producing custom housings, surgical instruments, and implantable devices. The precision required in these components is paramount for patient safety and device efficacy. International buyers, particularly from Europe and the Middle East, should ensure that suppliers comply with medical standards such as ISO 13485. Additionally, selecting the right materials that offer biocompatibility and durability is crucial, as it directly affects the performance and safety of medical devices.

Industrial Machinery

In industrial machinery, central machining is leveraged to create components used in automation systems, robotics, and heavy equipment. These parts, often subject to high wear and tear, need to be designed for longevity and efficiency. Buyers from Africa and South America should focus on suppliers with expertise in high-volume production capabilities and fast turnaround times. Understanding the supplier’s ability to provide robust machining solutions that enhance productivity while minimizing maintenance costs is vital for successful sourcing.

Related Video: Essential Machining Skills: Working with a Lathe, Part One

Strategic Material Selection Guide for central machining

When selecting materials for central machining, international B2B buyers must consider a range of factors, including the specific properties of each material, their performance in various applications, and compliance with industry standards. Below is an analysis of four common materials used in central machining, highlighting their key properties, advantages and disadvantages, impacts on applications, and considerations for buyers in different regions.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal and electrical conductivity. It performs well under moderate temperature and pressure conditions, making it suitable for various applications.

Pros & Cons: The primary advantage of aluminum is its machinability, allowing for fast production cycles and complex shapes. However, it can be less durable than other metals, particularly in high-stress applications, and may require additional surface treatments for enhanced strength.

Impact on Application: Aluminum is widely used in aerospace, automotive, and consumer electronics due to its favorable strength-to-weight ratio. It is compatible with various media, including air and water, but may not be suitable for aggressive chemicals without proper coatings.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B211 for aluminum alloys. In regions like Europe and the UAE, aluminum’s recyclability is a significant advantage, aligning with sustainability goals.

Stainless Steel

Key Properties: Stainless steel is known for its high strength, excellent corrosion resistance, and ability to withstand high temperatures. It is available in various grades, each with specific properties tailored for different applications.

Pros & Cons: The durability and resistance to corrosion make stainless steel ideal for harsh environments, such as marine or chemical processing. However, it is more challenging to machine than aluminum, which can lead to higher production costs and longer lead times.

Impact on Application: Stainless steel is commonly used in food processing, medical devices, and industrial machinery. Its compatibility with a wide range of media, including corrosive substances, makes it a preferred choice in many sectors.

Considerations for International Buyers: Buyers must be aware of international standards like ASTM A240 for stainless steel. In regions like South America, where corrosion resistance is critical, selecting the appropriate grade can significantly impact product longevity.

Titanium

Key Properties: Titanium is renowned for its exceptional strength-to-weight ratio and resistance to corrosion, especially in high-temperature environments. It also exhibits biocompatibility, making it suitable for medical applications.

Pros & Cons: The primary advantage of titanium is its strength, which allows for lightweight designs in demanding applications. However, it is difficult to machine, requiring specialized tooling and techniques, which can increase costs and lead times.

Impact on Application: Titanium is widely used in aerospace, automotive, and medical industries. Its compatibility with harsh environments and high-performance applications makes it a top choice for components subjected to extreme conditions.

Considerations for International Buyers: Compliance with standards such as ASTM F136 for titanium alloys is crucial. Buyers in the Middle East and Europe should consider the additional costs associated with machining titanium, balancing performance requirements with budget constraints.

Inconel

Key Properties: Inconel is a family of nickel-chromium superalloys known for their high strength and resistance to oxidation and corrosion at elevated temperatures. It maintains its mechanical properties under extreme conditions.

Pros & Cons: The key advantage of Inconel is its ability to perform reliably in high-temperature applications, such as gas turbines and chemical processing. However, it is expensive and challenging to machine, requiring advanced tooling and techniques.

Impact on Application: Inconel is ideal for aerospace, oil and gas, and power generation applications. Its compatibility with high-pressure and high-temperature media makes it a critical material in these industries.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B168 for Inconel. In regions like Africa, where resource extraction is prevalent, understanding the material’s cost implications is vital for project budgeting.

Summary Table

| Material | Typical Use Case for central machining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace, automotive, electronics | Lightweight and machinable | Less durable under stress | Low |

| Stainless Steel | Food processing, medical devices | High strength and corrosion resistance | More difficult to machine | Medium |

| Titanium | Aerospace, medical applications | Exceptional strength-to-weight ratio | Difficult and costly to machine | High |

| Inconel | Aerospace, oil and gas | High performance in extreme conditions | Expensive and challenging to machine | High |

This guide provides a strategic overview of material selection for central machining, enabling international B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for central machining

Manufacturing Processes for Central Machining

Central machining encompasses several critical manufacturing stages that ensure precision and quality in the production of machined components. For B2B buyers, understanding these processes is essential for effective supplier selection and managing expectations for quality and delivery.

1. Material Preparation

The first step in central machining involves careful material selection and preparation. The choice of material—whether metals, plastics, or composites—affects machining techniques, costs, and end-use performance. Common materials include:

- Aluminium: Lightweight and easy to machine, ideal for automotive and electronic applications.

- Stainless Steel: Offers corrosion resistance and strength, commonly used in aerospace and medical devices.

- Titanium: Known for its strength-to-weight ratio, but more challenging to machine due to its properties.

Once the material is selected, it is cut to size, ensuring it meets the specifications required for the subsequent machining processes. This phase may involve processes like sawing, shearing, or laser cutting.

2. Forming and Machining

The core of central machining is the actual forming process, which typically involves various CNC (Computer Numerical Control) machining techniques. Key methods include:

- CNC Turning: Ideal for cylindrical components, this method rotates the material against a cutting tool to achieve precise dimensions.

- CNC Milling: Utilizes rotating cutters to remove material from flat or contoured surfaces, suitable for complex geometries.

- 5-Axis Machining: Allows for intricate designs to be machined in one setup, significantly reducing lead times and improving accuracy.

These techniques are selected based on the component’s geometry, material properties, and required tolerances. Precision is critical at this stage, as any deviations can lead to increased costs and delays.

3. Assembly

In cases where components are part of a larger system, assembly is a crucial phase. This might involve:

- Mechanical Assembly: Assembling parts using screws, bolts, or other fasteners.

- Welding or Bonding: For components that require a more permanent connection.

- Integration Testing: Ensuring that assembled parts function correctly within their intended applications.

Effective communication with suppliers about assembly requirements can prevent misunderstandings and ensure that final products meet specifications.

4. Finishing Processes

Finishing processes enhance the aesthetic and functional properties of machined components. Common finishing techniques include:

- Grinding: Improves surface finish and dimensional accuracy.

- Polishing: Provides a smooth, shiny surface, often required in aesthetic applications.

- Coating: Protective coatings can enhance corrosion resistance and durability.

Selecting the right finishing process can significantly affect the final product’s performance, cost, and appearance.

Quality Assurance in Central Machining

Quality assurance (QA) is integral to the central machining process, ensuring that components meet both customer specifications and international standards. For B2B buyers, understanding QA processes can safeguard against risks associated with non-compliance and subpar products.

International and Industry-Specific Standards

Several standards govern quality in machining, which B2B buyers should be familiar with:

- ISO 9001: This global standard outlines criteria for a quality management system, focusing on continuous improvement and customer satisfaction.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for companies operating in the oil and gas sector, ensuring that products meet industry-specific requirements.

Understanding these standards helps buyers assess the credibility of potential suppliers.

Quality Control Checkpoints

Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect and rectify issues early.

- Final Quality Control (FQC): A thorough examination of finished products before shipment to verify compliance with specifications.

These checkpoints help in identifying defects early, reducing waste, and ensuring high-quality outputs.

Common Testing Methods

Various testing methods are employed to validate the quality of machined components, including:

- Dimensional Inspection: Verifying that parts meet specified dimensions using tools like calipers and gauges.

- Non-Destructive Testing (NDT): Techniques like ultrasonic or magnetic particle testing to detect internal flaws without damaging the part.

- Functional Testing: Ensuring that components perform as intended in their application.

B2B buyers should inquire about the specific testing methods employed by suppliers to ensure that their products will meet necessary performance criteria.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers should consider the following strategies:

- Supplier Audits: Conducting regular audits to evaluate the supplier’s quality management processes and compliance with standards.

- Requesting Quality Reports: Suppliers should provide detailed QC reports that outline inspection results, testing methods, and any non-conformances.

- Third-Party Inspections: Engaging independent inspection services can provide unbiased assessments of supplier capabilities and product quality.

Particularly for international buyers from Africa, South America, the Middle East, and Europe, understanding local regulations and compliance requirements is essential. Additionally, cultural differences in business practices may affect communication and expectations regarding quality.

Quality Control Nuances for International Buyers

When sourcing from international suppliers, B2B buyers must navigate several nuances:

- Language Barriers: Ensure clear communication regarding specifications and quality expectations to avoid misunderstandings.

- Time Zone Differences: Be aware of potential delays in communication and response times due to different time zones.

- Regulatory Compliance: Familiarize yourself with local regulations that may affect product specifications and quality assurance processes.

By being proactive in these areas, international B2B buyers can better manage their supply chains and ensure the quality of the components they source.

Conclusion

A thorough understanding of manufacturing processes and quality assurance in central machining is vital for B2B buyers. By focusing on material preparation, machining techniques, assembly, and finishing processes, along with robust quality assurance practices, buyers can confidently select suppliers that meet their needs and maintain high standards of quality.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for central machining Sourcing

Understanding the cost structure and pricing dynamics of central machining is essential for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This section provides a comprehensive analysis of the key cost components, price influencers, and actionable buyer tips to navigate this complex landscape.

Cost Components

-

Materials: The choice of material significantly impacts the overall cost. Metals such as titanium or Inconel, while strong and suitable for high-performance applications, are more expensive and challenging to machine. In contrast, materials like aluminum are more cost-effective and easier to work with. Understanding material properties and their implications on machining will help buyers make informed decisions.

-

Labor: Skilled labor is a critical cost factor in machining. Regions with higher labor costs may see increased pricing for precision machining services. However, countries with a robust engineering workforce may offer a balance between quality and cost, making it essential for buyers to assess labor availability and skill levels in potential sourcing regions.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient machining operations can lower overhead costs, which can be passed on to buyers. Suppliers with modern facilities and optimized processes often provide better pricing.

-

Tooling: Tooling costs vary based on the complexity of the components being machined. Custom tools for specific parts can be expensive, and these costs are often amortized over the production volume. Buyers should consider the tooling lifecycle and its impact on pricing, especially for low-volume orders.

Illustrative Image (Source: Google Search)

-

Quality Control (QC): Implementing rigorous QC processes ensures that components meet specified tolerances and quality standards. While this adds to the cost, it is essential for maintaining reliability in critical applications. Buyers should inquire about the supplier’s QC practices and certifications to assess potential costs.

-

Logistics: Shipping and handling costs can fluctuate based on distance, volume, and shipping terms (Incoterms). International buyers need to factor in logistics costs, as they can significantly affect the total landed cost of components.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market demand, competition, and supplier reputation. Understanding the market dynamics can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: Higher order volumes generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize costs without overcommitting.

-

Specifications/Customization: Custom parts or complex specifications often increase costs. Clear communication of requirements can prevent costly redesigns and delays.

-

Materials: As mentioned, material selection directly impacts pricing. Buyers should weigh the benefits of premium materials against cost implications.

-

Quality and Certifications: Suppliers with recognized quality certifications (like ISO 9001) may charge more but offer greater assurance of product reliability.

-

Supplier Factors: The supplier’s location, capabilities, and market position can influence pricing. Engaging with suppliers who have strong reputations in specific regions can yield better pricing and quality.

-

Incoterms: Understanding shipping terms is crucial for managing costs effectively. Different Incoterms can shift responsibilities and costs between buyers and suppliers, impacting the total cost of ownership.

Buyer Tips

-

Negotiate: Leverage volume and long-term relationships to negotiate better pricing. Suppliers may be more willing to provide discounts for consistent orders.

-

Focus on Cost-Efficiency: Consider the total cost of ownership, including production, logistics, and potential downtime from quality issues. A slightly higher upfront cost may lead to significant savings over time.

-

Understand Pricing Nuances: Pricing can vary widely based on region and market conditions. Buyers from different areas should conduct market research to understand local pricing trends.

-

Engage Early: Involve machining partners early in the design process to optimize designs for manufacturability, potentially reducing costs.

Disclaimer

The prices discussed are indicative and can vary based on the factors outlined. Buyers should conduct thorough assessments and obtain quotes from multiple suppliers to ensure competitive pricing and value.

Spotlight on Potential central machining Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘central machining’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for central machining

Critical Technical Properties in Central Machining

When sourcing central machining services, understanding specific technical properties is essential for ensuring component quality and performance. Here are some of the most crucial specifications to consider:

-

Material Grade

– The material grade specifies the type of metal or composite used in manufacturing. Common materials include aluminum, stainless steel, titanium, and plastics. Each material has unique properties affecting strength, weight, corrosion resistance, and machinability. Selecting the right material is vital for meeting application requirements and ensuring long-term durability. -

Tolerance

– Tolerance refers to the allowable variation in dimensions of a machined part. In B2B manufacturing, tolerances can range from ±0.01 mm for high-precision applications to ±0.5 mm for less critical components. High tolerance precision is crucial in industries like aerospace and medical devices, where even minor discrepancies can lead to significant operational failures or safety risks. -

Surface Finish

– The surface finish denotes the texture and quality of the surface of a machined part. It is typically specified in terms of Ra (average roughness). A smoother finish can enhance performance characteristics, such as reducing friction and improving aesthetics. Understanding the required surface finish is essential for applications involving close contact or high-speed operations. -

Machining Method

– The machining method describes the technique used to manufacture parts, such as CNC milling, turning, or grinding. Each method has specific capabilities and limitations concerning geometrical complexity, material type, and production speed. Selecting the appropriate machining method is crucial for optimizing production efficiency and minimizing costs. -

Lead Time

– Lead time is the time taken from order placement to delivery of the finished parts. In the context of central machining, shorter lead times can provide a competitive advantage, allowing businesses to respond quickly to market demands. B2B buyers should evaluate suppliers’ production capabilities and schedules to align with their project timelines. -

Production Volume

– This property refers to the quantity of parts produced in a single batch. It can significantly influence pricing, with economies of scale often reducing the cost per unit for larger orders. Understanding the production volume needs helps in negotiating pricing and managing inventory effectively.

Common Trade Terminology in Central Machining

Familiarity with industry jargon is essential for effective communication and negotiation with suppliers. Below are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

– OEMs are companies that produce parts or equipment that are sold under another company’s brand. Understanding the role of OEMs is critical for B2B buyers, as they often dictate the specifications and standards required for components. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and purchasing decisions. Suppliers may have varying MOQs based on production capabilities and material costs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific machining services or components. This process is crucial for procurement teams to gather competitive bids and make informed sourcing decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined international shipping terms that outline the responsibilities of buyers and sellers in the delivery of goods. Understanding these terms helps B2B buyers manage logistics, costs, and risk during international transactions. -

CNC (Computer Numerical Control)

– CNC refers to the automation of machine tools via computer programming. This technology is central to modern machining processes, enabling high precision and repeatability in manufacturing components. -

DFM (Design for Manufacture)

– DFM is a design approach that considers manufacturing processes to optimize production efficiency and cost. Engaging with suppliers who understand DFM principles can lead to better product designs and lower overall costs.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, foster effective supplier relationships, and ultimately enhance their procurement strategies in central machining.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the central machining Sector

Market Overview & Key Trends

The central machining sector is experiencing significant transformation driven by globalization, technological advancements, and evolving buyer expectations. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe engage in a competitive landscape, they must navigate several key trends. One notable driver is the increasing demand for precision-engineered components in critical industries, including aerospace, automotive, and renewable energy. This demand compels buyers to seek suppliers who not only meet rigorous quality standards but also demonstrate agility in adapting to changing market conditions.

Technological innovations, particularly in CNC machining and automation, are reshaping sourcing strategies. The rise of Industry 4.0, characterized by interconnected machinery and data-driven decision-making, allows buyers to enhance operational efficiency and reduce lead times. Furthermore, digital platforms are emerging as vital tools for supplier discovery and evaluation, enabling buyers to vet potential partners across borders more effectively. These platforms facilitate transparent communication and foster collaboration, which are crucial for maintaining supply chain integrity.

Market dynamics are also influenced by geopolitical factors and regional economic conditions. Buyers must be vigilant about trade policies, tariffs, and the political stability of supplier countries. For instance, the UAE’s strategic location and investment in advanced manufacturing technology position it as a key player for buyers in the Middle East and beyond. Understanding these dynamics enables B2B buyers to make informed sourcing decisions that align with their long-term strategic goals.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical consideration in the central machining sector, impacting sourcing strategies for international B2B buyers. The environmental footprint of machining processes, particularly in terms of energy consumption and waste generation, drives the need for more sustainable practices. Buyers are increasingly prioritizing suppliers that adopt eco-friendly manufacturing techniques, such as using biodegradable lubricants and minimizing scrap material.

Ethical sourcing has gained prominence as businesses recognize the importance of transparency in their supply chains. Buyers should seek suppliers who adhere to ethical labor practices and are committed to social responsibility. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) serve as benchmarks for assessing supplier compliance with sustainability standards.

Incorporating ‘green’ materials into machining processes is another avenue for promoting sustainability. For instance, sourcing components made from recycled metals or biodegradable plastics not only reduces environmental impact but also aligns with the growing consumer demand for sustainable products. Buyers should engage with suppliers who can demonstrate their commitment to sustainability through certifications and proven practices, ensuring that their sourcing decisions contribute to a more sustainable future.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The central machining industry has evolved significantly since its inception in the early 20th century, transitioning from manual operations to highly automated, computer-controlled processes. Initially dominated by traditional machining methods, the sector began embracing CNC technology in the 1960s, enhancing precision and efficiency. This evolution coincided with the rise of globalization, allowing manufacturers to tap into diverse markets and establish supply chains that span continents.

Today, central machining is at the forefront of advanced manufacturing, leveraging digital technologies such as IoT and AI to optimize production workflows. This progression underscores the importance of staying ahead of technological trends for B2B buyers, ensuring they partner with suppliers capable of meeting the demands of modern manufacturing while adhering to quality and sustainability standards. As the sector continues to advance, buyers must remain agile, adapting their sourcing strategies to capitalize on emerging opportunities and mitigate potential risks.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of central machining

-

What criteria should I use to vet potential machining suppliers?

When vetting machining suppliers, prioritize their experience in your industry and their track record with similar components. Assess their certifications (ISO 9001, AS9100 for aerospace), technological capabilities, and customer reviews. Request case studies or references from previous clients to gauge their reliability. Additionally, consider their financial stability and capacity for scalability to ensure they can meet your long-term production needs without compromising quality. -

Can I customize my machining orders, and what is the process?

Yes, most machining suppliers offer customization options for parts. Begin by providing detailed specifications, including materials, tolerances, and intended applications. A good supplier will engage in discussions to refine your requirements and may offer design suggestions based on their manufacturing expertise. Ensure you have clear communication about any design changes and their implications on lead times and costs. -

What are typical minimum order quantities (MOQs) and lead times for machining services?

MOQs vary significantly based on the supplier and the complexity of the components. Generally, expect MOQs to range from 50 to 500 pieces for standard parts, while custom designs may have higher MOQs. Lead times can also vary; simple components might take 2-4 weeks, while more complex or customized parts may require 6-12 weeks. Always discuss these factors upfront to align expectations and avoid potential delays. -

What payment terms should I expect when sourcing machining services?

Payment terms can differ widely among suppliers. Common arrangements include a 30% deposit upfront with the balance due upon delivery or net 30 days after receipt of goods. For larger orders or new relationships, suppliers may request more substantial upfront payments. It’s advisable to clarify these terms in your contract and consider using a letter of credit for international transactions to mitigate financial risks. -

How can I ensure quality assurance and compliance with international standards?

Request documentation of the supplier’s quality control processes and certifications. Many suppliers will provide a quality assurance plan detailing inspection methods, testing procedures, and compliance with international standards. Inquire about their capability for first article inspection (FAI) and ongoing quality checks. Establish clear quality metrics in your contract to ensure that the final product meets your specifications. -

What logistics considerations should I be aware of when sourcing internationally?

Logistics are critical in international sourcing. Understand the shipping methods available and their costs, including customs duties and tariffs. Collaborate with your supplier on packaging requirements to prevent damage during transit. It’s also important to establish who will handle logistics and whether the supplier offers support with documentation for customs clearance. Timely communication is essential to manage any potential delays. -

How should I handle disputes or quality issues with a machining supplier?

Establish a clear dispute resolution process in your contract, including timelines for addressing issues. If a quality problem arises, promptly communicate your concerns to the supplier and provide documentation, such as photos or inspection reports. Maintain a professional approach while seeking a resolution, whether through rework, replacement, or credit. If necessary, consider involving a third-party mediator to facilitate discussions. -

What are some common challenges in international machining sourcing, and how can I mitigate them?

Common challenges include language barriers, time zone differences, and varying quality standards. To mitigate these, establish clear communication protocols and use standardized documentation. Conduct regular virtual meetings to stay aligned on project progress. Additionally, consider partnering with a local representative or agent who understands the regional market and can facilitate smoother interactions with suppliers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for central machining

In the rapidly evolving landscape of central machining, strategic sourcing remains pivotal for B2B buyers. The emphasis on precision, quality, and reliability cannot be overstated, particularly for industries such as aerospace, automotive, and energy. By carefully selecting machining partners, buyers can mitigate risks, streamline supply chains, and ensure compliance with international standards.

Key takeaways include the importance of understanding machining capabilities, material selection, and the implications of part design on cost and lead time. Prioritizing suppliers who not only meet technical specifications but also offer design insights can significantly enhance product development efficiency.

As international B2B buyers from Africa, South America, the Middle East, and Europe navigate this complex marketplace, leveraging digital tools for supplier evaluation and fostering strong partnerships will be essential. The future of central machining holds promising advancements in technology and processes, making it imperative for buyers to stay informed and adaptable.

Engage proactively with suppliers, explore innovative machining solutions, and position your organization at the forefront of the manufacturing sector. Embrace the potential of strategic sourcing to drive value and excellence in your operations.