Your Ultimate Guide to Sourcing Ceramic Insulators

Introduction: Navigating the Global Market for ceramic insulators

In today’s interconnected world, the demand for reliable and efficient electrical insulation solutions has never been more critical. Ceramic insulators stand at the forefront of this need, delivering exceptional performance across a diverse range of applications—from high-voltage power lines to intricate electronic devices. Their unparalleled durability, thermal stability, and electrical insulation properties make them indispensable in ensuring the safety and efficiency of electrical systems worldwide.

This comprehensive guide serves as an essential resource for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. It covers an extensive scope, including the various types of ceramic insulators, materials used in their manufacturing, quality control processes, and a detailed overview of suppliers. Additionally, it delves into market trends and cost considerations, enabling buyers to make informed decisions that align with their specific needs.

By equipping buyers with actionable insights and practical knowledge, this guide empowers you to navigate the global market effectively. Whether you are assessing the suitability of ceramic insulators for your next project or comparing them to alternative materials, the information provided will help you optimize sourcing strategies and enhance operational resilience. Discover how to leverage ceramic insulators to bolster your infrastructure and ensure long-term success in your industry.

Understanding ceramic insulators Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pin-Type Insulators | Cylindrical shape, mounted on utility poles | Power transmission, telecommunication cables | Pros: High mechanical strength, weather-resistant. Cons: Limited flexibility in design. |

| Bushing Insulators | Multi-tier design, prevents water ingress | Electrical transformers, substations | Pros: Excellent insulation, minimizes electrical hazards. Cons: Higher initial cost. |

| Suspension Insulators | Designed to suspend conductors, withstand mechanical stress | Overhead power lines, railway electrification | Pros: Durable, effective at maintaining cable tension. Cons: Requires careful installation. |

| Thermal Insulators | High thermal stability, chemical inertness | Industrial ovens, kilns, electric heaters | Pros: Retains insulating properties at high temperatures. Cons: Limited flexibility for certain applications. |

| Ceramic Wool Insulators | Lightweight, easily molded into various shapes | High-temperature applications, heating enclosures | Pros: Excellent thermal insulation, easy to install. Cons: Not suitable for high mechanical load applications. |

Pin-Type Insulators

Pin-type insulators are cylindrical in shape and are commonly mounted on utility poles. They are designed to provide mechanical support while ensuring electrical insulation. These insulators are particularly suitable for power transmission and telecommunication applications due to their high mechanical strength and resistance to environmental conditions. When considering pin-type insulators, buyers should prioritize their durability and performance in adverse weather, although the limited design flexibility may be a drawback in certain projects.

Bushing Insulators

Bushing insulators feature a multi-tier design that effectively prevents water ingress, making them ideal for use in electrical transformers and substations. Their construction allows for excellent electrical insulation, significantly reducing the risk of electrical hazards. Buyers should consider the long-term reliability and safety that bushing insulators offer, despite their higher initial costs compared to other types. Their robust nature makes them a worthwhile investment for critical infrastructure.

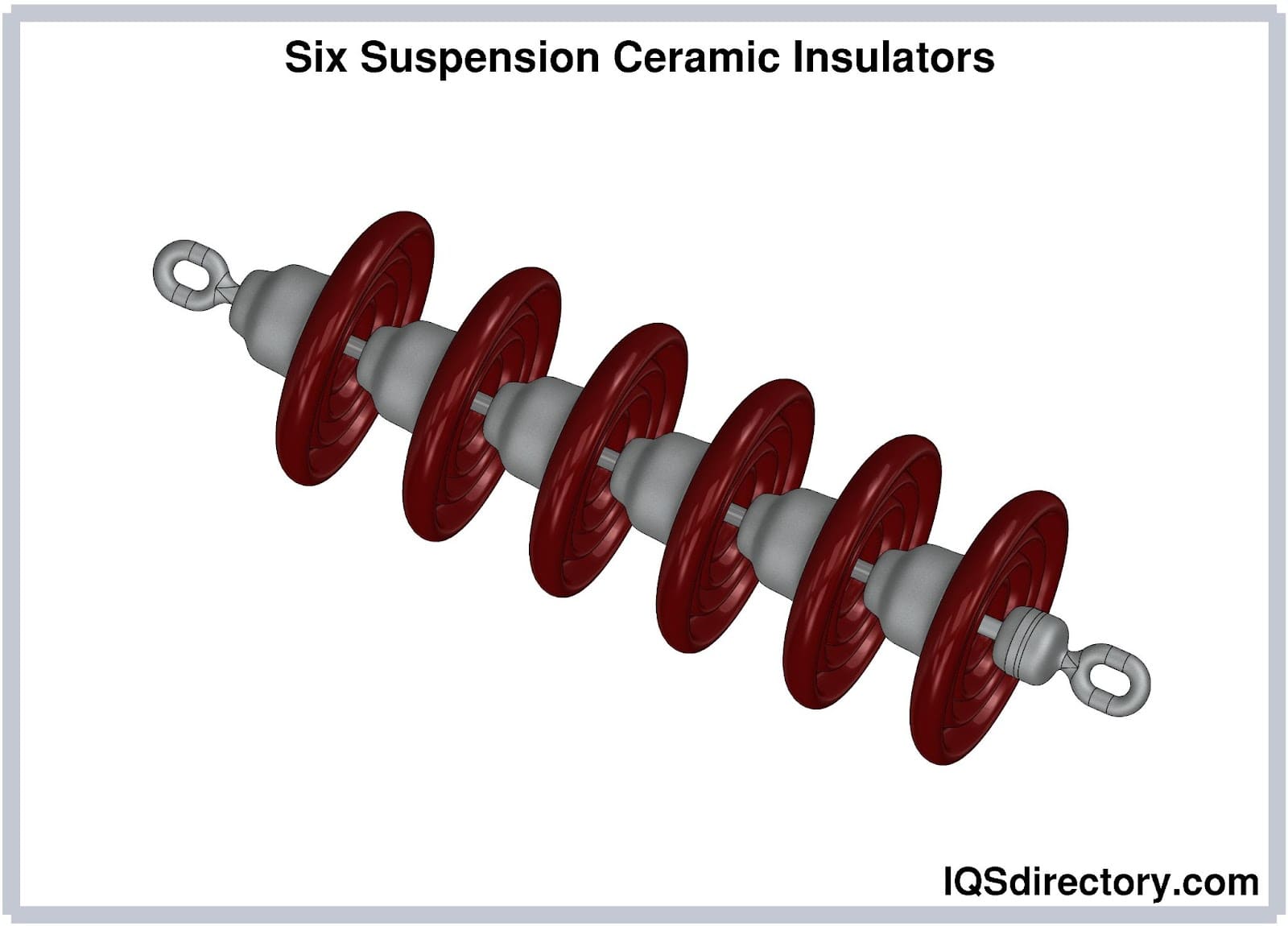

Suspension Insulators

Suspension insulators are specifically designed to suspend conductors and manage mechanical stress, making them vital in overhead power lines and railway electrification systems. They excel at maintaining cable tension, which is crucial for preventing sagging and ensuring system integrity. Buyers should evaluate the installation requirements and mechanical load capacities when selecting suspension insulators, as proper installation is essential for optimal performance.

Thermal Insulators

Thermal insulators are characterized by their high thermal stability and chemical inertness, making them suitable for environments with extreme temperatures, such as industrial ovens and kilns. Their ability to retain insulating properties even under high thermal cycling is a significant advantage. When purchasing thermal insulators, buyers should focus on the specific temperature ranges and chemical exposure levels relevant to their applications, while noting that flexibility might be limited for certain uses.

Ceramic Wool Insulators

Ceramic wool insulators are lightweight and can be molded into various shapes, providing excellent thermal insulation for high-temperature applications. They are particularly effective in heating enclosures and industrial processes. Buyers should appreciate the ease of installation and the thermal efficiency of ceramic wool, but must also consider their limitations in handling high mechanical loads, which may necessitate alternative solutions in certain contexts.

Related Video: Why do High Voltage Ceramic Insulators have Discs? | An In-Depth Exploration

Key Industrial Applications of ceramic insulators

| Industry/Sector | Specific Application of Ceramic Insulators | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Energy & Utilities | High-Voltage Power Transmission | Enhanced safety and reliability in power distribution systems | Ensure compliance with local standards and certifications |

| Telecommunications | Coaxial Cables and Antennas | Improved signal integrity and reduced electromagnetic interference | Evaluate material quality and compatibility with existing systems |

| Manufacturing & Heavy Industry | Industrial Ovens and Furnaces | Increased thermal efficiency and reduced maintenance costs | Consider temperature ratings and mechanical strength requirements |

| Electrical & Electronics | Circuit Boards and IC Packaging | Protection against short circuits and electrical faults | Assess dielectric strength and thermal shock resistance |

| Transportation Infrastructure | Railway Electrification Systems | Reliable performance under mechanical stress and environmental factors | Focus on durability and resistance to weather conditions |

Energy & Utilities

In the energy sector, ceramic insulators are crucial for high-voltage power transmission lines. They provide electrical insulation that prevents dangerous leakages and ensures the safety of both infrastructure and personnel. For international buyers, especially from regions like Africa and South America, sourcing insulators that meet local safety standards is vital. Additionally, they should consider the insulators’ resistance to environmental stressors such as humidity and pollution, which can vary significantly across different geographical areas.

Telecommunications

Ceramic insulators are widely used in coaxial cables and antennas within the telecommunications industry. They help maintain signal integrity by minimizing electromagnetic interference (EMI), crucial for high-frequency applications. B2B buyers in Europe and the Middle East should prioritize suppliers who offer insulators with proven performance in high-frequency environments. It’s also important to evaluate the compatibility of these insulators with existing systems to ensure seamless integration.

Manufacturing & Heavy Industry

In industrial settings, ceramic insulators are employed in ovens and furnaces to provide thermal insulation. Their ability to withstand high temperatures while maintaining insulating properties leads to greater energy efficiency and reduced maintenance needs. Buyers from South America and Africa should focus on sourcing insulators that can endure the specific temperature ranges of their operations. Additionally, understanding the chemical inertness of the ceramics used can prevent degradation over time in harsh industrial environments.

Electrical & Electronics

Ceramic insulators are essential in circuit boards and integrated circuit (IC) packaging, protecting against electrical faults and short circuits. Their high dielectric strength ensures reliable performance in compact electronic devices. International buyers, particularly from Europe and Asia, must assess the thermal shock resistance and dielectric properties of the insulators to ensure they meet the demanding specifications of modern electronics. Collaborating with reputable manufacturers who can provide detailed technical specifications will be crucial.

Transportation Infrastructure

In the transportation sector, ceramic insulators are used in railway electrification systems, providing reliable insulation under mechanical stress. These insulators ensure that live conductors remain isolated, enhancing safety and operational efficiency. Buyers from the Middle East and Africa should consider the durability of the insulators against extreme weather conditions, as well as their mechanical strength to withstand the rigors of transportation infrastructure. Selecting suppliers with a proven track record in similar applications can significantly reduce risks associated with material failure.

Related Video: Ceramic manufacturing process in Gayafores factory.

Strategic Material Selection Guide for ceramic insulators

When selecting ceramic insulators for various applications, understanding the properties, advantages, and limitations of different ceramic materials is crucial for B2B buyers. Below is an analysis of four common materials used in ceramic insulators, tailored for international buyers from Africa, South America, the Middle East, and Europe.

1. Alumina (Aluminum Oxide)

Key Properties: Alumina is known for its high dielectric strength, excellent thermal stability, and resistance to chemical corrosion. It can withstand temperatures up to 1,600°C and has a low thermal conductivity, making it suitable for high-temperature applications.

Pros & Cons: The durability of alumina makes it a preferred choice for many industrial applications. However, it is relatively brittle, which can lead to failure under mechanical stress. The manufacturing process can be complex and costly, impacting the overall price of the final product.

Impact on Application: Alumina is commonly used in high-voltage applications and environments where thermal stability is essential. Its compatibility with various media, including oils and gases, makes it versatile.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and JIS. The cost may vary significantly based on local sourcing capabilities and manufacturing processes.

2. Zirconia (Zirconium Dioxide)

Key Properties: Zirconia exhibits exceptional thermal insulation properties and high resistance to thermal shock. It has a melting point of approximately 2,700°C, making it suitable for extreme temperature environments.

Pros & Cons: The main advantage of zirconia is its ability to maintain mechanical strength at high temperatures. However, its cost is generally higher than other ceramic materials, which may limit its use in budget-sensitive projects. Additionally, its manufacturing process can be more complex.

Impact on Application: Zirconia is ideal for applications in high-temperature furnaces and kilns. Its low thermal conductivity and high strength make it suitable for use in environments with rapid temperature fluctuations.

Considerations for International Buyers: Buyers should be aware of the specific performance requirements in their region, as well as the availability of zirconia products. Compliance with local and international standards is essential to ensure safety and reliability.

3. Silicon Nitride

Key Properties: Silicon nitride is known for its high mechanical strength, excellent thermal stability, and low thermal expansion. It can operate at temperatures up to 1,400°C and offers good resistance to oxidation and corrosion.

Pros & Cons: The material is highly durable and resistant to wear, making it suitable for demanding applications. However, it can be more expensive than other ceramics, and its brittleness may lead to challenges in handling and installation.

Impact on Application: Silicon nitride is often used in electrical insulators for high-frequency applications due to its low dielectric loss. It is also effective in environments where resistance to thermal shock and mechanical stress is required.

Considerations for International Buyers: Buyers should assess the local market for silicon nitride products, as availability may vary. Understanding the specific industry standards in their region will help ensure compliance and performance.

4. Porcelain

Key Properties: Porcelain is a type of ceramic that combines kaolin, feldspar, and quartz. It has good electrical insulation properties and can withstand moderate temperatures (up to 1,200°C).

Pros & Cons: Porcelain is cost-effective and widely available, making it a popular choice for many applications. However, it is less durable than other ceramics and can be prone to cracking under mechanical stress.

Impact on Application: Porcelain is commonly used in lower voltage applications, such as insulators for power lines and electrical fittings. Its moderate thermal resistance makes it suitable for environments with less extreme conditions.

Considerations for International Buyers: Buyers should consider local manufacturing capabilities and the availability of porcelain products. Compliance with regional standards is crucial for ensuring product reliability and safety.

Summary Table

| Material | Typical Use Case for ceramic insulators | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina | High-voltage applications | High durability and thermal stability | Brittle and complex manufacturing | Medium |

| Zirconia | High-temperature furnaces | Exceptional thermal insulation | Higher cost and complex manufacturing | High |

| Silicon Nitride | High-frequency electrical insulators | High mechanical strength and thermal stability | Expensive and brittle | High |

| Porcelain | Power line insulators | Cost-effective and widely available | Less durable and prone to cracking | Low |

This guide provides a comprehensive overview of ceramic materials for insulators, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic insulators

Manufacturing Processes for Ceramic Insulators

Understanding the manufacturing processes involved in producing ceramic insulators is crucial for international B2B buyers looking to ensure quality and reliability in their electrical applications. The manufacturing process typically involves several key stages:

Material Preparation

The first step in the manufacturing of ceramic insulators involves the selection and preparation of raw materials. Common materials include alumina, kaolin, and other ceramic compounds. These materials are crushed, milled, and mixed to achieve the desired consistency and properties. The blending process may also incorporate additives that enhance the mechanical strength, thermal stability, and dielectric properties of the final product.

Key Techniques:

– Milling: Ensures uniform particle size for optimal performance.

– Mixing: Homogenizes materials to achieve consistent characteristics.

Forming

Once the materials are prepared, the next stage is forming the insulator shape. This can be done through various techniques:

- Pressing: A common method for creating dense ceramic bodies. Powders are compacted under high pressure in molds to form the desired shape.

- Extrusion: Involves forcing the mixed ceramic material through a die to create long shapes, ideal for insulators with uniform cross-sections.

- Slip Casting: A technique where a liquid clay mixture (slip) is poured into molds, allowing for intricate designs and shapes.

Each method offers unique advantages, such as the ability to create complex geometries or achieve specific material densities.

Assembly

In cases where insulators consist of multiple components (e.g., insulator stacks), assembly is the next crucial step. Components are carefully aligned and joined using specialized techniques, such as adhesive bonding or mechanical fastening. This stage ensures that each piece maintains its integrity and functionality in the final product.

Finishing

The finishing stage involves firing the formed insulators in a kiln at high temperatures to achieve the desired hardness and durability. Post-firing processes may include:

- Glazing: Applying a glassy coating to improve aesthetics and enhance electrical performance.

- Machining: Precision machining may be required to meet specific dimensional tolerances.

This stage is vital for ensuring that the insulators can withstand harsh environmental conditions and provide reliable electrical insulation.

Quality Assurance (QA) in Ceramic Insulator Manufacturing

Quality assurance is critical in the manufacturing of ceramic insulators, as it directly impacts safety, performance, and compliance with international standards. Here are the key elements of a robust QA process:

International Standards

B2B buyers should be aware of the relevant international standards that govern the manufacturing and testing of ceramic insulators. These may include:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Indicates that the product complies with EU safety, health, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, specific API standards may apply.

Quality Control Checkpoints

Effective quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon delivery to ensure they meet specified standards. Non-compliance can affect the final product’s quality.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues early, reducing the risk of defects.

- Final Quality Control (FQC): A thorough inspection of the finished product, ensuring it meets all design specifications and performance criteria.

Common Testing Methods

To validate the quality and reliability of ceramic insulators, various testing methods are employed:

- Dielectric Strength Testing: Measures the insulator’s ability to withstand electrical stress without conducting electricity.

- Thermal Shock Testing: Assesses the insulator’s performance under rapid temperature changes, simulating real-world conditions.

- Mechanical Strength Testing: Evaluates the insulator’s ability to withstand mechanical loads and stresses.

Verifying Supplier Quality Control

International B2B buyers must take proactive steps to verify the quality control measures of potential suppliers. Here are some actionable insights:

- Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes, quality control systems, and adherence to international standards.

- Request Quality Assurance Reports: Suppliers should provide documentation detailing their quality control processes and results from testing and inspections.

- Utilize Third-Party Inspection Services: Engaging independent inspection agencies can offer an objective evaluation of the supplier’s quality management practices and product quality.

Quality Control Nuances for International Buyers

When sourcing ceramic insulators from suppliers in Africa, South America, the Middle East, and Europe, buyers should be mindful of regional differences in quality standards and practices. Here are a few considerations:

- Understanding Local Standards: Familiarize yourself with local regulations and standards that may apply to ceramic insulators in the supplier’s country.

- Cultural Differences: Communication styles and business practices can vary significantly across regions. Building strong relationships with suppliers can facilitate better quality assurance.

- Logistical Challenges: Consider the implications of shipping and handling when sourcing from distant suppliers. Ensure that the insulators are adequately packaged and protected during transit to prevent damage.

By understanding the manufacturing processes and quality assurance measures involved in ceramic insulator production, B2B buyers can make informed decisions that enhance the reliability and safety of their electrical applications. Investing time in supplier verification and quality assurance will ultimately lead to better product performance and reduced operational risks.

Related Video: Ceramic tiles manufacturing process by Ceratec – How it’s made?

Comprehensive Cost and Pricing Analysis for ceramic insulators Sourcing

Ceramic insulators are vital components in electrical systems, and understanding their cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the various cost components and price influencers while providing actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

- Materials: The primary cost driver in ceramic insulators is the raw materials used, such as alumina, zirconia, and other ceramic compounds. Prices for these materials can fluctuate based on global supply and demand, impacting overall costs.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs vary significantly depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this can also affect quality and production capacity.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, equipment maintenance, and depreciation. Efficient manufacturing processes can help keep overheads low.

-

Tooling: The initial investment in molds and machinery to produce ceramic insulators can be substantial. Custom designs typically require more specialized tooling, which can increase costs.

-

Quality Control (QC): Rigorous QC processes are essential to ensure the reliability and safety of ceramic insulators. These costs should be factored into the pricing, as they can vary based on the complexity of the insulator and industry standards.

-

Logistics: Shipping costs can be significant, especially for international transactions. Factors such as shipping distance, mode of transport, and Incoterms (International Commercial Terms) play a role in determining logistics expenses.

-

Margin: Supplier margins can vary widely based on market competition, brand reputation, and the value-added services offered. Understanding supplier pricing strategies can aid in negotiation.

Price Influencers

-

Volume/MOQ: Bulk purchasing often leads to reduced prices per unit. Buyers should consider negotiating minimum order quantities (MOQ) to leverage volume discounts.

-

Specifications/Customization: Custom designs and specifications can increase costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Materials Quality/Certifications: Higher quality materials and certifications (e.g., ISO standards) may come at a premium. However, investing in quality can lead to reduced maintenance and longer product lifespans.

-

Supplier Factors: Supplier reputation, production capacity, and reliability can influence pricing. Building long-term relationships with suppliers may yield better pricing and service.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is crucial for accurately calculating total costs. Different terms can affect who bears the risk and costs during transit.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Highlighting long-term partnership potential can lead to better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance costs, and longevity of the insulators. A lower initial price might not always equate to the best value.

-

Pricing Nuances: Be aware of regional pricing variations. For example, suppliers in Europe may have different cost structures compared to those in Africa or South America, influenced by local economic conditions and labor costs.

-

Market Research: Conduct thorough market research to understand current pricing trends and competitor offerings. This information can empower buyers during negotiations.

Disclaimer

Prices for ceramic insulators can vary widely based on the factors outlined above. It is essential for buyers to request quotes from multiple suppliers and consider all associated costs when making purchasing decisions. This analysis serves as a guideline, and actual prices may differ based on specific circumstances and market conditions.

Spotlight on Potential ceramic insulators Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ceramic insulators’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ceramic insulators

Ceramic insulators are vital components in electrical systems, and understanding their technical properties and trade terminology is essential for international B2B buyers. Here’s a detailed overview of the key specifications and industry jargon relevant to ceramic insulators.

Key Technical Properties

-

Material Grade

Ceramic insulators are categorized by their material composition, which affects their performance characteristics. Common grades include alumina (Al2O3), silicon nitride (Si3N4), and zirconia (ZrO2). The choice of material impacts electrical insulation properties, thermal stability, and mechanical strength. For buyers, selecting the appropriate material grade is crucial for ensuring reliability and longevity in specific applications. -

Dielectric Strength

This property measures the insulator’s ability to withstand electrical stress without breaking down. High dielectric strength is essential for applications in high-voltage environments, ensuring safety and preventing electrical failures. For B2B buyers, understanding dielectric strength helps in selecting insulators that meet safety standards and operational requirements. -

Thermal Conductivity

Thermal conductivity indicates how well a material conducts heat. For ceramic insulators, low thermal conductivity is preferred, especially in high-temperature applications like furnaces and kilns. Buyers should evaluate thermal conductivity to ensure that the insulators will perform effectively in their intended operational environment without compromising safety. -

Mechanical Strength

Mechanical strength refers to the insulator’s ability to withstand physical stresses such as tension and compression. This is particularly important in applications where insulators support heavy loads or are exposed to environmental stressors. Buyers must consider mechanical strength to avoid premature failure and ensure long-term performance. -

Tolerance

Tolerance defines the permissible limit of variation in dimensions and properties of the insulator. It is critical for ensuring proper fit and function in assembly processes. Buyers should pay attention to tolerance specifications to guarantee compatibility with existing equipment and systems. -

Thermal Shock Resistance

This property measures the insulator’s ability to withstand rapid changes in temperature without cracking or failing. High thermal shock resistance is crucial for applications that involve fluctuating temperatures. Buyers should prioritize this characteristic to maintain the integrity of their systems under varying thermal conditions.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ceramic insulators, buyers often deal with OEMs that provide custom solutions tailored to specific applications, ensuring compatibility and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for buyers, particularly those in Africa, South America, the Middle East, and Europe, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs that align with their project needs and budget.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

An RFQ is a document used to solicit price proposals from suppliers. It outlines the specifications, quantities, and required delivery times for ceramic insulators. Submitting a detailed RFQ enables buyers to receive competitive pricing and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, risk, and insurance. Familiarity with Incoterms is essential for B2B buyers to negotiate favorable terms and avoid misunderstandings during the procurement process. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. For ceramic insulators, lead times can vary based on manufacturing capabilities and supply chain logistics. Buyers should account for lead times in project planning to ensure timely delivery and avoid delays in project execution. -

Certification Standards

These are regulatory benchmarks that ceramic insulators must meet to ensure safety and performance. Common certifications include ISO, IEC, and ANSI. Buyers should verify that their suppliers adhere to relevant certification standards to ensure quality and compliance with international regulations.

Understanding these technical properties and trade terms is essential for B2B buyers in making informed purchasing decisions regarding ceramic insulators. This knowledge enables them to select the right products that meet their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ceramic insulators Sector

Market Overview & Key Trends

The global ceramic insulators market is witnessing robust growth, driven by increasing demand across various sectors such as power generation, telecommunications, and consumer electronics. One significant driver is the push towards renewable energy sources, which necessitates enhanced electrical infrastructure, including high-voltage transmission systems. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the regional dynamics is crucial. Countries like Mexico and Vietnam are ramping up their electrical grid capacities, creating a burgeoning market for reliable ceramic insulators.

Emerging trends in the sourcing of ceramic insulators include a shift towards advanced manufacturing techniques, such as additive manufacturing, which allows for greater customization and efficiency. Additionally, the integration of IoT in monitoring and maintaining insulator integrity is gaining traction, ensuring optimal performance and reducing downtime. Buyers should stay informed about these technological advancements to leverage them in their procurement strategies.

The market dynamics also reflect a rising focus on cost-effective solutions. International buyers are increasingly looking for suppliers who can offer competitive pricing without compromising on quality. Establishing long-term partnerships with manufacturers who demonstrate reliability and innovation will be key for navigating the competitive landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of procurement strategies in the ceramic insulators sector. The environmental impact of production processes, including energy consumption and waste generation, is under scrutiny. Buyers are urged to prioritize suppliers who adopt sustainable practices, such as using recycled materials and implementing energy-efficient manufacturing techniques.

Ethical sourcing is equally important; ensuring that suppliers adhere to labor laws and environmental regulations fosters a responsible supply chain. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) provide assurance that suppliers are committed to sustainability and quality.

Moreover, the market is seeing a rise in demand for ‘green’ materials, which can include eco-friendly ceramic compositions. Buyers should actively seek out manufacturers who can provide transparent information regarding the lifecycle of their products, as well as any sustainability certifications that may apply. This focus not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible products.

Brief Evolution/History

Ceramic insulators have a rich history, dating back to the early days of electricity. Initially used in the late 19th century for telegraph lines, their application expanded rapidly with the growth of electrical infrastructure. As technology advanced, the production processes improved, leading to the development of high-performance ceramics that could withstand extreme conditions.

Today, ceramic insulators are integral to modern electrical systems, providing safety and reliability in various applications. The evolution of materials science has introduced advanced ceramics with enhanced properties, making them suitable for high-voltage applications and extreme environments. For B2B buyers, understanding this evolution is crucial for selecting the most effective solutions for their specific needs.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic insulators

-

What should I consider when vetting suppliers for ceramic insulators?

When vetting suppliers, evaluate their industry experience, production capacity, and quality assurance processes. Check for certifications such as ISO 9001, which indicates adherence to quality management standards. Request references and case studies from previous clients, particularly in your region, to assess their reliability and service level. Additionally, consider their geographical location and logistics capabilities, as these factors can impact lead times and shipping costs. -

Can I customize ceramic insulators to meet specific project requirements?

Yes, many manufacturers offer customization options for ceramic insulators. Discuss your specific requirements regarding size, shape, voltage rating, and environmental resistance with potential suppliers. Ensure that they have the capability to produce custom designs without compromising on quality. It’s advisable to request samples or prototypes before placing a bulk order to verify that the customization meets your expectations. -

What are typical minimum order quantities (MOQs) and lead times for ceramic insulators?

MOQs for ceramic insulators can vary widely depending on the supplier and the complexity of the product. Generally, MOQs can range from 100 to several thousand units. Lead times typically span from 4 to 12 weeks, influenced by factors such as customization, manufacturing processes, and shipping logistics. When negotiating, clarify these details upfront to avoid any surprises during the procurement process. -

What payment terms should I expect when sourcing ceramic insulators internationally?

Payment terms can differ significantly among suppliers, but common practices include upfront deposits (20-50%) with the balance due upon delivery. Some suppliers may offer flexible terms, such as letters of credit or payment upon inspection. Always ensure that the payment terms are clearly outlined in the contract to protect your investment. Consider using escrow services for larger orders to mitigate risks. -

How can I ensure quality assurance and certification for ceramic insulators?

To ensure quality, request documentation that verifies compliance with international standards, such as IEC or ANSI. Suppliers should provide test reports demonstrating electrical and thermal performance. Additionally, inquire about their quality control processes, including inspections at various production stages. Regular audits and on-site visits can further help assess their quality assurance practices.

-

What logistics considerations should I keep in mind when sourcing ceramic insulators?

Logistics play a crucial role in the procurement of ceramic insulators. Evaluate shipping options, costs, and estimated delivery times based on your location. Understand the import regulations in your country, including customs duties and taxes. Collaborating with a logistics partner experienced in international trade can help streamline the process and mitigate potential delays. -

How can I resolve disputes with suppliers over ceramic insulator orders?

To resolve disputes effectively, establish clear communication channels and maintain detailed records of all transactions, including contracts, emails, and shipment details. If a dispute arises, initiate a discussion with the supplier to seek a mutually acceptable resolution. If direct communication fails, consider mediation or arbitration as stipulated in your contract. Always ensure that your contracts include dispute resolution clauses to guide the process. -

What are the risks associated with sourcing ceramic insulators internationally, and how can I mitigate them?

Risks include quality discrepancies, shipment delays, and currency fluctuations. To mitigate these risks, conduct thorough due diligence on suppliers, including financial stability assessments. Establish clear contracts that define quality standards, delivery timelines, and payment terms. Diversifying your supplier base can also reduce dependency on a single source, providing alternatives in case of issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ceramic insulators

In conclusion, the strategic sourcing of ceramic insulators is pivotal for enhancing the reliability and safety of electrical systems across various industries. B2B buyers from Africa, South America, the Middle East, and Europe should recognize the unique advantages offered by ceramic materials, including their exceptional mechanical strength, high dielectric properties, and resistance to thermal shock. By prioritizing suppliers who demonstrate expertise in manufacturing tailored ceramic solutions, businesses can mitigate risks associated with electrical faults, improve operational efficiency, and ensure compliance with safety standards.

Investing in high-quality ceramic insulators not only safeguards infrastructure but also contributes to long-term cost savings through reduced maintenance and increased lifespan of equipment. As the global demand for reliable electrical insulation continues to grow, now is the time for international buyers to evaluate their sourcing strategies critically.

Take proactive steps towards establishing partnerships with reputable manufacturers, leveraging technological advancements in ceramics, and exploring innovative applications to stay ahead in the competitive landscape. Embrace the future of electrical insulation—your strategic sourcing decisions today will shape the performance and safety of your operations tomorrow.