Your Ultimate Guide to Sourcing Chipboard Boxes

Introduction: Navigating the Global Market for chipboard boxes

Chipboard boxes represent a crucial element in the global packaging landscape, serving as versatile and eco-friendly solutions for a myriad of industries. From food packaging to pharmaceuticals, these lightweight yet sturdy boxes provide reliable protection while offering an appealing canvas for branding and product presentation. As international B2B buyers from Africa, South America, the Middle East, and Europe seek sustainable and cost-effective packaging options, understanding the nuances of chipboard boxes becomes paramount.

This comprehensive guide delves into the various types of chipboard boxes available, exploring their unique materials and manufacturing processes. It highlights the importance of quality control and compliance with international standards, essential for ensuring product safety and longevity. Additionally, we will provide insights into selecting the right suppliers, understanding cost structures, and navigating the complexities of the global market.

By equipping you with actionable insights and practical knowledge, this guide empowers you to make informed sourcing decisions tailored to your specific needs. Whether you are a buyer in Turkey looking to enhance your retail packaging or a distributor in Colombia aiming to optimize logistics, the information within these pages is designed to enhance your operational efficiency and market competitiveness. Embrace the potential of chipboard boxes as you navigate the intricate world of global procurement.

Understanding chipboard boxes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| One-Piece Folding Cartons | Made from a single sheet with flaps; lightweight and foldable | Food products, cosmetics, retail items | Pros: Cost-effective, easy to store. Cons: Limited protection for heavy items. |

| Two-Piece Rigid Boxes | Composed of a separate base and lid; offers enhanced durability | Luxury goods, gift packaging, electronics | Pros: Premium appearance, excellent protection. Cons: Higher cost, bulkier. |

| Custom Die-Cut Boxes | Tailored shapes and sizes; versatile for unique products | Specialty items, promotional products | Pros: Highly customizable, strong branding opportunities. Cons: Longer lead times, potentially higher costs. |

| Slipcases and Sleeves | Protective outer layer for inner trays; stylish presentation | Retail displays, gift packaging, media products | Pros: Enhanced branding, additional protection. Cons: Complexity in design, may require assembly. |

| Food-Grade Chipboard Boxes | Coated for moisture resistance and safety; compliant with regulations | Food packaging, snacks, cereals | Pros: Meets hygiene standards, preserves freshness. Cons: Limited to food applications. |

One-Piece Folding Cartons

One-piece folding cartons are constructed from a single sheet of chipboard that is designed to fold into shape. This design is particularly advantageous for packaging lightweight items such as food products, cosmetics, and retail goods. When sourcing these cartons, buyers should consider the weight capacity and printing options available, as custom designs can enhance brand visibility while keeping costs manageable.

Two-Piece Rigid Boxes

Two-piece rigid boxes consist of a separate base and lid, providing enhanced durability and a premium unboxing experience. Ideal for luxury goods, gift packaging, and electronics, these boxes are often sought after for their aesthetic appeal. B2B buyers should evaluate the thickness of the chipboard and the quality of the finish, as these factors influence both protection and presentation.

Custom Die-Cut Boxes

Custom die-cut boxes are designed to fit unique product shapes, offering flexibility for brands looking to stand out. These boxes are often used for specialty items and promotional products, making them a powerful branding tool. When considering custom die-cut options, buyers should weigh the benefits of unique presentation against longer lead times and potentially higher costs.

Slipcases and Sleeves

Slipcases and sleeves provide an additional layer of protection for inner trays or boxes, enhancing both aesthetics and security during transport. Commonly used for retail displays and gift packaging, these solutions allow for creative branding opportunities. Buyers should assess the complexity of the design and the assembly process, as these factors can affect overall logistics and costs.

Food-Grade Chipboard Boxes

Food-grade chipboard boxes are specially coated to ensure compliance with hygiene regulations, making them suitable for packaging food items like snacks and cereals. These boxes help preserve product freshness while meeting safety standards. When sourcing food-grade options, B2B buyers must confirm that the boxes meet local and international food packaging regulations to ensure compliance and consumer safety.

Related Video: Handmade Chipboard Box

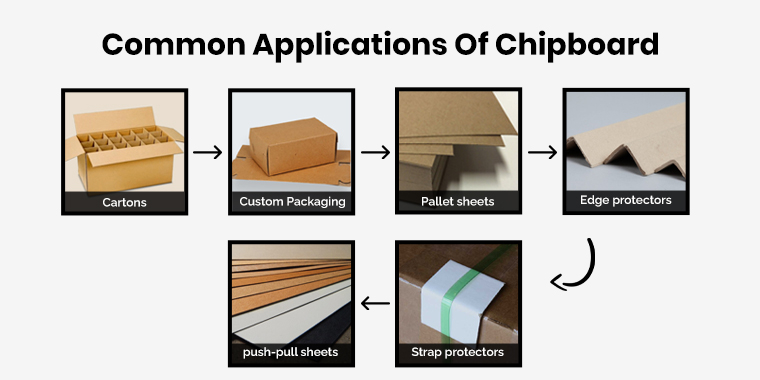

Key Industrial Applications of chipboard boxes

| Industry/Sector | Specific Application of chipboard boxes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Packaging for cereals and snacks | Ensures product freshness and compliance with hygiene regulations | Need for food-grade coatings and compliance with local standards |

| Consumer Products | Custom packaging for cosmetics and electronics | Enhances brand visibility and shelf appeal | Importance of print quality and customization options |

| Pharmaceuticals | Packaging for medicines and medical devices | Provides tamper-evident features and meets safety regulations | Must adhere to strict regulatory compliance and quality standards |

| Tool and Hardware | Packaging for small tools and components | Keeps products organized and secure during transit | Durability and protection against impact during shipping |

| Stationery Products | Packaging for office supplies like folders and notepads | Facilitates efficient handling and presentation | Custom sizing and design flexibility to accommodate various products |

Food Processing

In the food processing industry, chipboard boxes serve as reliable packaging for products like cereals and snacks. These boxes often feature food-grade coatings that protect contents from contamination and moisture, ensuring compliance with stringent hygiene regulations. For international buyers, especially in Africa and South America, understanding local food safety standards is crucial. Additionally, sourcing partners should provide options that maintain product freshness and are capable of bulk supply to meet high demand.

Consumer Products

Chipboard boxes are widely used in packaging for cosmetics and electronics due to their excellent printability and ability to showcase branding. These boxes not only protect the products but also enhance their visual appeal on retail shelves. For B2B buyers in Europe and the Middle East, the ability to customize designs and sizes is vital to stand out in competitive markets. When sourcing, businesses should prioritize suppliers who offer high-quality printing and sustainable materials, aligning with consumer preferences for eco-friendly packaging.

Illustrative Image (Source: Google Search)

Pharmaceuticals

In the pharmaceutical sector, chipboard boxes are essential for packaging medicines and medical devices. Their design can include tamper-evident features that ensure product safety, which is crucial for compliance with health regulations. International buyers must ensure that their suppliers can meet the rigorous quality standards required in the pharmaceutical industry. This includes sourcing from manufacturers who can provide certifications and demonstrate adherence to safety protocols.

Tool and Hardware

Chipboard boxes are commonly used for packaging small tools and components, providing robust organization and protection during transport. These boxes are designed to withstand impacts and keep contents secure, which is essential for B2B buyers in industries such as construction and manufacturing. When sourcing, it’s important to consider the durability of the chipboard and the ability to customize box sizes to accommodate various tool dimensions, ensuring optimal shipping and storage solutions.

Stationery Products

In the stationery industry, chipboard boxes are frequently used for packaging items like folders, notepads, and paper reams. These boxes facilitate efficient handling and present a professional image to consumers. For international buyers, especially in emerging markets, sourcing options should focus on custom sizes and designs that meet diverse product requirements. Additionally, ensuring that suppliers can provide a consistent supply of high-quality chipboard is essential for maintaining inventory levels and meeting customer expectations.

Related Video: Box Making with Chipboard Step by Step

Strategic Material Selection Guide for chipboard boxes

When selecting materials for chipboard boxes, understanding the properties, advantages, and limitations of various options is crucial for B2B buyers. This guide analyzes several common materials used in chipboard box manufacturing, providing insights that can help international buyers make informed decisions.

1. Recycled Paperboard

Key Properties:

Recycled paperboard is made from post-consumer waste, offering a sustainable option that is lightweight and easily customizable. It typically has a moderate strength rating suitable for many packaging applications.

Pros & Cons:

The primary advantage of recycled paperboard is its eco-friendliness, appealing to businesses focused on sustainability. However, it may have lower durability compared to virgin paperboard, making it less suitable for heavy or fragile items.

Impact on Application:

Recycled paperboard is ideal for products that do not require extensive protection, such as cosmetics and lightweight consumer goods. Its compatibility with various printing techniques enhances branding opportunities.

Considerations for International Buyers:

Buyers should ensure that the recycled paperboard meets local regulations regarding recycled content and safety standards, such as those set by ASTM or ISO. This material is widely accepted in Europe and increasingly favored in Africa and South America.

2. Virgin Paperboard

Key Properties:

Virgin paperboard is produced from new wood fibers, providing superior strength and a smooth surface finish. It can withstand higher temperatures and pressures compared to recycled options.

Pros & Cons:

The main advantage of virgin paperboard is its robustness, making it suitable for high-value products and applications requiring additional protection. However, it is typically more expensive and less sustainable than recycled alternatives.

Impact on Application:

This material is commonly used in the food and pharmaceutical industries, where hygiene and product integrity are paramount. Its strength makes it suitable for packaging delicate items that require extra care during transit.

Considerations for International Buyers:

Buyers must consider the sourcing of virgin fibers, as sustainability practices vary by region. Compliance with food safety standards (e.g., FDA in the U.S. or EFSA in Europe) is essential for food-related applications.

3. Coated Chipboard

Key Properties:

Coated chipboard features a layer of protective coating that enhances moisture resistance and durability. This material can endure various environmental conditions, making it versatile for different applications.

Pros & Cons:

The coating provides significant advantages in terms of moisture protection and overall durability. However, the manufacturing process can be more complex, leading to higher production costs.

Impact on Application:

Coated chipboard is particularly effective for food packaging and items that may encounter moisture during shipping and storage. Its enhanced durability makes it suitable for e-commerce applications where boxes are subjected to rough handling.

Considerations for International Buyers:

Buyers should verify that the coatings used comply with local regulations, especially in the food sector. Understanding the specific environmental conditions in their regions (e.g., humidity levels in the Middle East) can influence the choice of coated chipboard.

4. Specialty Chipboard (Anti-Static, etc.)

Key Properties:

Specialty chipboard variants, such as anti-static or flame-retardant options, are designed for specific applications. These materials often incorporate additives that provide unique properties.

Pros & Cons:

The key advantage of specialty chipboard is its tailored performance for niche applications, such as electronics packaging. However, these specialized materials can be significantly more expensive and may have longer lead times.

Impact on Application:

Specialty chipboard is essential for industries requiring specific safety standards, such as electronics and pharmaceuticals. Their unique properties ensure product safety and compliance with industry regulations.

Considerations for International Buyers:

Buyers should assess the availability of these specialty materials in their regions and ensure compliance with relevant industry standards (e.g., ESD standards for electronics). Understanding the supply chain for these materials is crucial, especially in emerging markets.

Summary Table

| Material | Typical Use Case for chipboard boxes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Recycled Paperboard | Cosmetics, lightweight consumer goods | Eco-friendly and customizable | Lower durability for heavy items | Low |

| Virgin Paperboard | Food packaging, pharmaceuticals | Superior strength and hygiene | More expensive and less sustainable | Medium |

| Coated Chipboard | Food packaging, e-commerce | Moisture resistance and durability | Higher production complexity | High |

| Specialty Chipboard | Electronics, pharmaceuticals | Tailored performance for niche needs | Higher costs and longer lead times | High |

This strategic material selection guide equips international B2B buyers with the knowledge needed to choose the right chipboard box materials based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for chipboard boxes

The manufacturing process of chipboard boxes involves several critical stages that ensure both quality and efficiency. Understanding these processes can empower B2B buyers to make informed decisions when sourcing packaging solutions.

Manufacturing Process

1. Material Preparation

The initial phase of manufacturing chipboard boxes focuses on sourcing and preparing raw materials. Chipboard is primarily made from recycled paper pulp, wood chips, and sawdust. Sustainable sourcing is crucial, especially for international buyers who prioritize eco-friendly practices. The materials are collected from post-consumer waste and manufacturing byproducts, contributing to a circular economy.

Once sourced, the raw materials undergo chipping, where they are broken down into smaller pieces. This is followed by pulping, where the chips are mixed with water and processed to create a slurry. The slurry is then dried to achieve a low moisture content, essential for producing strong, durable chipboard.

2. Forming

The forming stage involves creating the chipboard sheets. The dried pulp is mixed with eco-friendly adhesives and then pressed under high temperatures and pressures. This process binds the fibers together, creating sheets of chipboard with varying thicknesses based on product requirements. The thickness can be customized, which is particularly beneficial for B2B buyers needing specific dimensions for their products.

3. Assembly

Once the chipboard sheets are formed, they are cut and shaped into boxes. This can involve several techniques, including die-cutting for custom shapes or folding for standard box designs. The assembly process may include adding features such as flaps, lids, or locking mechanisms to enhance usability and protection during shipping.

Illustrative Image (Source: Google Search)

4. Finishing

The final stage in the manufacturing process includes surface treatments and finishing touches. Chipboard boxes can be coated with waterproof finishes or printed with branding and product information. These treatments not only enhance the aesthetic appeal but also improve the durability and functionality of the boxes, particularly for products exposed to moisture or rough handling during transit.

Quality Assurance

For B2B buyers, understanding the quality assurance (QA) processes is crucial to ensure they receive high-quality chipboard boxes that meet their specific needs.

International Standards

Many manufacturers adhere to international quality standards, such as ISO 9001, which focuses on quality management systems. This certification ensures that the manufacturing process meets consistent quality benchmarks. In addition to ISO standards, industry-specific certifications, such as CE marking for compliance with European health and safety regulations and API standards for the oil and gas sector, may also apply depending on the intended use of the chipboard boxes.

Quality Control Checkpoints

Quality control is typically segmented into several checkpoints:

-

Incoming Quality Control (IQC): This phase assesses raw materials upon arrival at the facility. Suppliers should provide documentation proving that materials meet specified standards.

-

In-Process Quality Control (IPQC): During production, samples are taken at various stages to monitor quality. Parameters such as thickness, adhesive strength, and surface integrity are evaluated to prevent defects.

-

Final Quality Control (FQC): Once the boxes are assembled and finished, a comprehensive inspection is conducted. This includes visual checks for defects, measurements for compliance with specifications, and testing for durability and resistance to moisture.

Common Testing Methods

Testing methods for chipboard boxes may include:

-

Burst Strength Test: Measures the force required to rupture the chipboard, indicating its strength and durability.

-

Edge Crush Test (ECT): Evaluates the stacking strength of the boxes, important for shipping and storage.

-

Moisture Content Test: Ensures that the chipboard is within acceptable moisture limits to prevent warping or degradation.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify a supplier’s quality control processes:

-

Audits: Conducting on-site audits allows buyers to review the manufacturing practices, quality control measures, and compliance with international standards. This firsthand insight can be invaluable in assessing a supplier’s capabilities.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance history, including defect rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and the quality of finished products. This is particularly important for buyers from regions like Africa and South America, where local regulatory frameworks may differ significantly from European standards.

Quality Control Nuances for International Buyers

International B2B buyers should be aware of the nuances in quality control that can arise from geographical differences. For instance, standards and certifications may vary significantly between regions, such as the EU, Africa, and the Middle East. Buyers must ensure that their suppliers are not only compliant with local regulations but also capable of meeting international quality standards that align with their market requirements.

Additionally, understanding the logistics of shipping chipboard boxes across borders is essential. Factors such as humidity, temperature, and handling during transit can affect the quality of the boxes. Thus, buyers should work closely with suppliers to develop packaging solutions that maintain integrity throughout the supply chain.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for chipboard boxes is vital for international B2B buyers. By focusing on sustainable practices, adhering to quality standards, and ensuring thorough verification of suppliers, businesses can secure reliable and high-quality packaging solutions that meet their operational needs.

Related Video: How plywood is made in the Factory & how Paste laminate on chipboard

Comprehensive Cost and Pricing Analysis for chipboard boxes Sourcing

When sourcing chipboard boxes, international B2B buyers must navigate a multifaceted cost structure influenced by various components and external factors. Understanding these elements can significantly enhance procurement strategies and cost management.

Cost Components of Chipboard Boxes

-

Materials: The primary cost driver in chipboard box manufacturing is the raw material, which consists of recycled paper pulp and wood byproducts. Prices can fluctuate based on global demand for recycled materials and the availability of sources. Buyers should assess the quality and sustainability of materials, as higher-grade options may incur additional costs but offer better performance and compliance with regulations.

-

Labor: Labor costs vary by region and manufacturing facility. Countries with lower wage standards may provide cost advantages, but this should be weighed against quality and reliability. Skilled labor is essential for processes such as die-cutting and printing, which can impact the final product’s quality.

-

Manufacturing Overhead: This encompasses fixed and variable costs associated with production, including utilities, maintenance, and factory operations. Efficient production processes can help minimize overhead, thereby reducing overall costs.

-

Tooling: Custom tooling, necessary for die-cut boxes and unique designs, represents a significant investment. The cost is amortized over the production run, so larger orders can mitigate tooling expenses per unit.

-

Quality Control (QC): Implementing robust QC measures ensures product consistency and compliance with industry standards. While this incurs additional costs, it helps prevent losses due to defects and enhances buyer confidence.

-

Logistics: Shipping costs can vary significantly based on distance, mode of transport, and volume. Incoterms influence the pricing structure as they define the responsibilities of buyers and sellers regarding shipping costs, insurance, and customs clearance.

-

Margin: Suppliers typically incorporate a profit margin into their pricing. Understanding market conditions and supplier dynamics can aid buyers in negotiating favorable terms.

Price Influencers

Several factors can affect the pricing of chipboard boxes:

-

Volume/MOQ: Higher order volumes can lead to lower per-unit costs due to economies of scale. However, suppliers may have Minimum Order Quantities (MOQs) that could affect smaller buyers.

-

Specifications/Customization: Custom designs, sizes, and printing will increase costs. Buyers should balance the need for customization with budget constraints.

-

Materials Quality/Certifications: The quality of materials and adherence to certifications (e.g., food safety standards for food packaging) can significantly impact pricing. Buyers should verify that suppliers meet necessary compliance requirements, which can also affect shipping and handling costs.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may offer better quality but at a premium price, while emerging suppliers might present cost-saving opportunities.

-

Incoterms: The choice of Incoterms can affect total landed costs. Options such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift responsibilities and costs between buyer and seller.

Buyer Tips for Cost Efficiency

-

Negotiate with Multiple Suppliers: Engage with several suppliers to compare prices and services. Leverage competitive quotes to negotiate better terms.

-

Consider Total Cost of Ownership (TCO): Look beyond initial costs. Evaluate long-term implications, including durability, shipping frequency, and potential waste, to determine the true cost over time.

-

Explore Regional Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from regional manufacturers can reduce logistics costs and lead times.

-

Stay Informed on Market Trends: Monitoring fluctuations in material costs and global supply chain dynamics can help buyers anticipate price changes and make informed purchasing decisions.

-

Focus on Sustainable Options: Investing in eco-friendly packaging can enhance brand value and may qualify for tax incentives or grants, offsetting some costs.

Disclaimer

Prices mentioned in this guide are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing tailored to your needs.

Spotlight on Potential chipboard boxes Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘chipboard boxes’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for chipboard boxes

Understanding the technical properties and terminology related to chipboard boxes is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances negotiation capabilities and supplier relationships.

Key Technical Properties of Chipboard Boxes

-

Material Grade

– Definition: This refers to the quality and type of chipboard used in manufacturing the boxes. Common grades include C-flute, B-flute, and E-flute, which vary in thickness and strength.

– Importance: Selecting the appropriate material grade ensures that the packaging will withstand the rigors of shipping and handling, especially for fragile or high-value items. Buyers should assess the intended use to determine the necessary strength and durability. -

Thickness

– Definition: Measured in millimeters, thickness indicates the density of the chipboard. Standard thickness ranges from 0.5mm to 2.5mm.

– Importance: Thicker chipboard provides better protection against impacts and punctures, making it ideal for shipping heavy or sensitive products. Buyers should consider thickness based on the weight and fragility of their goods. -

Tolerance

– Definition: Tolerance refers to the allowable variation in dimensions and weight of the chipboard boxes. It is typically expressed in millimeters.

– Importance: Accurate tolerances are crucial for ensuring that boxes fit their contents properly and can be stacked or stored efficiently. This is particularly important for automated packing systems and maximizing shipping space. -

Coating and Finishing

– Definition: Chipboard boxes may be coated with moisture-resistant or food-safe finishes. Coatings can include wax, lamination, or special inks.

– Importance: The right coating not only enhances durability but also complies with industry regulations, particularly in food and pharmaceuticals. Buyers should verify that coatings align with their product safety requirements. -

Weight Capacity

– Definition: This specification indicates the maximum load a chipboard box can safely carry without compromising its structural integrity.

– Importance: Knowing the weight capacity is essential for ensuring that the packaging can handle the intended contents. This is particularly relevant for logistics and supply chain management to prevent damage during transit.

Common Trade Terms in Chipboard Box Procurement

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable suppliers who can provide custom solutions tailored to specific needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their budgets and inventory levels effectively. It’s crucial to negotiate MOQs that align with business needs, especially for smaller companies. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to invite them to submit a proposal for specific products or services.

– Importance: An RFQ outlines requirements and expectations, facilitating clear communication with potential suppliers. It is an essential step in the sourcing process to ensure competitive pricing. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce that define responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risk management, which is vital for international trade negotiations. -

Sustainability Certification

– Definition: A label indicating that the chipboard is sourced from sustainable resources and meets certain environmental standards.

– Importance: Many companies today prioritize sustainability in their procurement processes. Certifications can enhance brand reputation and meet regulatory requirements, especially in environmentally-conscious markets.

By familiarizing themselves with these properties and terms, international B2B buyers can make better-informed decisions regarding chipboard box procurement, ensuring that they select the right products for their specific needs while optimizing their supply chain efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the chipboard boxes Sector

The chipboard boxes market is experiencing significant growth, driven by a combination of factors that influence international B2B buyers. As industries evolve, chipboard packaging is becoming increasingly favored due to its lightweight nature, cost-effectiveness, and eco-friendly attributes. This trend is particularly relevant for buyers in Africa, South America, the Middle East, and Europe, where packaging solutions must meet diverse logistical and regulatory requirements.

Market Overview & Key Trends

-

Global Demand Surge: The demand for chipboard boxes has increased as e-commerce and retail sectors expand. Businesses are seeking packaging that not only protects products but also enhances branding. Customizable chipboard boxes are ideal for various applications, from consumer goods to pharmaceuticals.

-

Technological Advancements: Innovations in manufacturing techniques, such as digital printing and automated cutting, are streamlining the production of chipboard boxes. This allows for quicker turnaround times and the ability to produce small batches economically, catering to the growing trend of personalized packaging.

-

Emerging Markets: Regions like Africa and South America are seeing a rise in local manufacturing capabilities, reducing reliance on imports. This shift encourages buyers to explore regional suppliers who can offer competitive pricing and reduced lead times.

-

Supply Chain Resilience: The COVID-19 pandemic highlighted vulnerabilities in global supply chains. As a result, many companies are diversifying their sourcing strategies, opting for suppliers that can provide flexibility and reliability, particularly in regions where logistics can be challenging.

-

Regulatory Compliance: International buyers must stay informed about varying regulations concerning packaging materials. This includes understanding safety standards, especially for food and pharmaceutical applications, which can vary significantly across regions.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration in the chipboard box sector, with increasing pressure from consumers and regulatory bodies to adopt environmentally friendly practices. Chipboard boxes, made from recycled materials, inherently support a circular economy. However, buyers should prioritize suppliers who adhere to sustainable practices throughout their supply chains.

-

Environmental Impact: The production of chipboard boxes typically uses less energy and generates lower carbon emissions compared to traditional packaging materials. Buyers should seek out manufacturers who utilize renewable energy sources in their production processes.

-

Ethical Supply Chains: Transparency in sourcing is paramount. Buyers are encouraged to partner with suppliers that provide detailed information about their sourcing practices, ensuring that raw materials are obtained responsibly and ethically.

-

Green Certifications: Look for suppliers that hold recognized certifications such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These certifications indicate adherence to sustainable forestry practices and can enhance the credibility of the packaging in the marketplace.

-

Innovative Materials: Some manufacturers are exploring biodegradable coatings and inks, further reducing the environmental impact of chipboard packaging. Buyers should inquire about these innovations as they can enhance sustainability credentials without compromising quality.

Brief Evolution/History

Chipboard boxes have evolved significantly since their inception, originally designed for simple storage and transport. Over the years, advances in technology and materials science have transformed chipboard into a versatile packaging solution. The introduction of sustainable practices has further driven its adoption, making it a preferred choice across various industries. As global markets continue to prioritize eco-friendly solutions, chipboard packaging stands poised to meet the demands of modern consumers while supporting sustainable development goals.

By understanding these dynamics, international B2B buyers can make informed decisions when sourcing chipboard boxes, ensuring they align with both their operational needs and sustainability objectives.

Related Video: How Shipping Containers Control Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of chipboard boxes

-

What should I consider when vetting chipboard box suppliers?

When vetting chipboard box suppliers, prioritize their industry experience and reputation. Look for suppliers with established certifications such as ISO 9001 for quality management and FSC certification for sustainability. Evaluate their production capabilities, including customization options and minimum order quantities (MOQs). Check references or reviews from previous clients, especially those in your region, to gauge reliability. Additionally, consider their responsiveness and willingness to collaborate on design and logistics, as these factors can significantly impact your supply chain efficiency. -

Can chipboard boxes be customized for my products?

Yes, chipboard boxes can be highly customized to fit your specific product requirements. Many manufacturers offer options for size, thickness, printing, and finishing, allowing you to create a box that enhances your brand image. When discussing customization, provide detailed specifications, including dimensions, weight, and any special requirements (e.g., moisture-resistant coatings). Be prepared for potential lead times depending on the complexity of the design and the supplier’s production schedule. Always request samples to evaluate the quality before placing a larger order.

-

What are the typical minimum order quantities (MOQs) and lead times for chipboard boxes?

MOQs for chipboard boxes vary by supplier and the level of customization required. Generally, standard sizes may have lower MOQs, while custom designs could require larger orders. Lead times can range from a few days to several weeks, influenced by factors such as production capacity, order complexity, and shipping logistics. When negotiating with suppliers, discuss your timelines and any urgency in your requirements. Consider building a relationship with a supplier for better flexibility in future orders. -

What payment terms are common when sourcing chipboard boxes internationally?

Payment terms for international orders of chipboard boxes can differ significantly among suppliers. Common practices include upfront payments, partial payments (e.g., 30% deposit), and payment upon delivery. Ensure you understand the supplier’s terms and negotiate to find a balance that minimizes risk while maintaining cash flow. Utilizing secure payment methods, such as letters of credit or escrow services, can provide added security for both parties. Always clarify currency exchange rates and any additional fees that may apply. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality assurance, request documentation of the supplier’s quality control processes and any relevant certifications. Key certifications to look for include ISO 9001 for quality management and ISO 14001 for environmental management. Verify that the chipboard boxes meet local and international standards, especially if packaging food or pharmaceuticals. Conduct regular quality audits or arrange for third-party inspections to confirm that the supplier adheres to your specifications and industry regulations. -

What logistical considerations should I keep in mind when sourcing chipboard boxes?

Logistics play a crucial role in sourcing chipboard boxes, particularly for international transactions. Evaluate the supplier’s shipping options, including freight methods and estimated delivery times. Be mindful of customs regulations and import duties that may apply in your country. Collaborate with your supplier to establish a clear shipping schedule and track shipments to avoid delays. Understanding the logistics involved can help you manage costs and ensure timely delivery to meet your operational needs. -

How can I resolve disputes with chipboard box suppliers?

Dispute resolution can be complex, especially in international trade. To minimize conflicts, establish clear communication channels and document all agreements, including specifications, timelines, and payment terms. If disputes arise, attempt to resolve them amicably through direct communication. Should this fail, refer to any contractual agreements regarding mediation or arbitration. Familiarize yourself with the legal frameworks governing international trade in your region, and consider consulting a legal expert if necessary to navigate disputes effectively. -

What trends are currently shaping the chipboard box market that I should be aware of?

Current trends in the chipboard box market include increasing demand for sustainable packaging solutions and innovations in manufacturing processes. Many companies are shifting toward eco-friendly materials and practices, driven by consumer preferences and regulatory pressures. Additionally, the rise of e-commerce has spurred demand for customized packaging that enhances the unboxing experience. Stay informed about these trends to align your sourcing strategy with market demands, ensuring your packaging solutions are not only functional but also resonate with your target audience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for chipboard boxes

In conclusion, chipboard boxes present a compelling packaging solution for international B2B buyers across diverse sectors. Their lightweight nature, customization options, and eco-friendly materials make them a versatile choice for shipping, retail, and consumer goods. Strategic sourcing of chipboard packaging not only ensures that businesses secure quality materials but also enables them to optimize costs, enhance brand presentation, and meet regulatory requirements specific to their regions, including Africa, South America, the Middle East, and Europe.

As global demand for sustainable packaging solutions continues to rise, it is crucial for buyers to evaluate suppliers based on their manufacturing processes, compliance standards, and ability to deliver tailored solutions. Engaging with local and international suppliers can provide valuable insights into market trends and innovations, fostering a competitive edge in a rapidly evolving landscape.

Looking ahead, businesses should proactively seek partnerships that align with their sustainability goals and operational needs. By embracing strategic sourcing for chipboard boxes, companies can not only enhance their supply chain resilience but also contribute positively to environmental stewardship. Take the next step in your procurement journey—explore custom chipboard packaging options today and position your business for success in the global marketplace.