Your Ultimate Guide to Sourcing Conveyor Belt Parts

Introduction: Navigating the Global Market for conveyor belt parts

In today’s fast-paced global economy, the efficiency of material handling processes can significantly impact operational success. Conveyor belt parts are pivotal in enhancing productivity across various industries—from manufacturing to logistics—by ensuring the seamless movement of goods. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe increasingly seek reliable and cost-effective solutions, understanding the nuances of conveyor belt components becomes essential.

This comprehensive guide delves into the myriad types of conveyor belt parts, including rollers, belts, and pulleys, detailing the materials used in their construction and the implications for performance and longevity. Moreover, we explore critical aspects of manufacturing and quality control, ensuring that buyers are equipped with the knowledge to identify high-quality components.

Illustrative Image (Source: Google Search)

Additionally, the guide provides insights into sourcing strategies, supplier evaluation, and cost considerations, all tailored to empower buyers in making informed decisions. By addressing common FAQs, we aim to demystify the complexities of the conveyor belt parts market.

With the right knowledge, buyers can optimize their procurement processes, enhance operational efficiency, and ultimately drive profitability. Whether you are in Kenya, Nigeria, or elsewhere, this guide serves as a vital resource for navigating the global market and securing the best conveyor belt solutions for your business needs.

Understanding conveyor belt parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Belt Conveyors | Continuous flat belt; versatile material options | Manufacturing, Warehousing | Pros: Easy to install, suitable for various loads. Cons: Limited in buffering capabilities. |

| Modular Belt Conveyors | Composed of interlocked plastic pieces; easy to repair | Food processing, Packaging | Pros: Easy maintenance, adaptable to different layouts. Cons: Higher initial cost than flat belts. |

| Roller Bed Conveyors | Surface made of rollers; minimizes friction | Distribution, Assembly Lines | Pros: Efficient for heavy loads, low friction. Cons: Requires more space for installation. |

| Curved Belt Conveyors | Ability to navigate turns; flexible design | Airport baggage handling, Warehousing | Pros: Space-saving design, efficient product flow. Cons: More complex installation and maintenance. |

| Heavy-Duty Rollers | Designed for high load capacities; robust construction | Mining, Construction | Pros: Can handle extreme conditions and heavy loads. Cons: Higher cost and may require specialized maintenance. |

Flat Belt Conveyors

Flat belt conveyors consist of a continuous belt that moves materials along a flat surface. They are versatile, often made from synthetic fabrics or natural materials, making them suitable for a wide range of applications, from manufacturing to warehousing. When considering flat belts, buyers should evaluate the load capacity and the environment in which they will be used, as these factors can influence performance and longevity.

Modular Belt Conveyors

Modular belt conveyors feature a series of interlocked plastic segments that can be easily replaced or repaired. This type of conveyor is particularly effective in food processing and packaging applications due to its ease of cleaning and flexibility in design. Buyers should consider the initial investment versus long-term maintenance costs, as modular systems may be pricier upfront but save money through reduced downtime and repairs.

Roller Bed Conveyors

Roller bed conveyors utilize rollers as the conveyor surface, allowing for efficient movement of heavy items with minimal friction. They are ideal for distribution centers and assembly lines where heavy loads are common. When purchasing roller bed systems, buyers should assess the weight and dimensions of the materials being transported, as well as the space available for installation, to ensure optimal performance.

Curved Belt Conveyors

Curved belt conveyors are designed to navigate turns and bends, making them ideal for applications such as airport baggage handling and warehousing. Their space-saving design allows for efficient product flow, but installation can be more complex than straight conveyors. Buyers should weigh the benefits of increased efficiency against the potential for higher installation and maintenance costs.

Heavy-Duty Rollers

Heavy-duty rollers are engineered to withstand rigorous conditions and high load capacities, making them essential in industries like mining and construction. These robust components ensure reliable material handling in challenging environments. B2B buyers should consider the specific demands of their operations, including load types and environmental conditions, to choose the right heavy-duty rollers that will provide durability and performance.

Related Video: Belt conveyor | Tutorial | Types | Applications | Grades | Splicing | Joining | Steel cord | Safety

Key Industrial Applications of conveyor belt parts

| Industry/Sector | Specific Application of conveyor belt parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly lines using flat belt conveyors | Increases throughput and reduces labor costs | Material quality, load capacity, and maintenance support |

| Food Processing | Modular belt systems for product handling | Ensures hygiene and compliance with standards | Food-grade materials, ease of cleaning, and customization |

| Mining and Quarrying | Heavy-duty rollers for bulk material transport | Enhances durability and operational efficiency | Load capacity, resistance to harsh environments, and warranty |

| Logistics and Warehousing | Gravity roller conveyors for sorting packages | Streamlines operations and minimizes errors | Roller type, spacing, and compatibility with existing systems |

| Pharmaceuticals | Belt conveyors for packaging and labeling | Improves accuracy and speed in processing | Compliance with regulations, material safety, and flexibility |

Manufacturing

In the manufacturing sector, flat belt conveyors are widely employed on assembly lines to transport products between workstations. These systems significantly enhance throughput by automating the movement of materials, thus reducing reliance on manual labor. For international buyers, especially from regions like Africa and South America, sourcing durable belts with high load capacities is crucial to ensure consistent performance. Additionally, buyers should consider suppliers that offer robust maintenance support to minimize downtime.

Food Processing

Modular belt systems are essential in food processing applications for transporting items through various stages, such as washing, cooking, and packaging. These belts are designed with hygiene in mind, facilitating easy cleaning and compliance with food safety standards. Buyers in the Middle East and Europe must prioritize food-grade materials and the ability to customize belt configurations to suit specific product types. Understanding local regulations regarding food safety can also guide sourcing decisions.

Mining and Quarrying

Heavy-duty rollers are integral in the mining and quarrying industries, where they support the transport of bulk materials such as ores and aggregates. These rollers are engineered to withstand extreme conditions, including heavy loads and abrasive materials, thereby enhancing operational efficiency. For buyers in Africa and South America, it is vital to assess the load capacity and environmental resistance of the rollers. Additionally, a strong warranty can provide assurance of quality and longevity.

Logistics and Warehousing

In logistics and warehousing, gravity roller conveyors are utilized to sort and transport packages efficiently. These systems help streamline operations, reduce handling errors, and improve overall productivity. Buyers from Europe and Africa should consider the type of rollers (standard or heavy-duty) and their spacing, as these factors impact the system’s performance. Compatibility with existing conveyor systems is also a key consideration to ensure seamless integration.

Pharmaceuticals

Belt conveyors are critical in the pharmaceutical industry for packaging and labeling processes. They enhance accuracy and speed, which are essential in meeting strict regulatory requirements. International buyers must ensure that the materials used in these conveyors comply with industry standards for safety and cleanliness. Additionally, flexibility in design to accommodate various product sizes and shapes can be a significant advantage when sourcing conveyor parts.

Strategic Material Selection Guide for conveyor belt parts

When selecting materials for conveyor belt parts, international B2B buyers must consider several factors, including the properties of the materials, their suitability for specific applications, and compliance with regional standards. Below, we analyze four common materials used in conveyor belt components, focusing on their key properties, advantages and disadvantages, and implications for various applications.

Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It can withstand high temperatures and pressures, typically rated up to 300°C (572°F). Steel also exhibits good corrosion resistance when treated or coated.

Pros & Cons:

Steel’s primary advantage is its strength and longevity, making it ideal for industrial environments like mining and construction. However, it can be heavier and more expensive than other materials, and its manufacturing complexity can lead to higher costs. Additionally, uncoated steel can rust if exposed to moisture, requiring protective coatings.

Impact on Application:

Steel is particularly effective in applications involving heavy loads and abrasive materials. Its strength allows for the transport of bulk items without risk of failure.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A36 for structural steel and consider local regulations regarding corrosion resistance and environmental impact, especially in humid regions like parts of Africa and South America.

Polyurethane

Key Properties:

Polyurethane is a versatile polymer known for its excellent abrasion resistance and flexibility. It can operate effectively in a temperature range of -30°C to 80°C (-22°F to 176°F) and offers good chemical resistance.

Pros & Cons:

The main advantage of polyurethane is its lightweight nature, which reduces energy costs in conveyor operations. It also provides good grip and cushioning, making it suitable for delicate items. However, it may not withstand high temperatures or heavy loads as well as steel, and its cost can be higher than other plastics.

Impact on Application:

Polyurethane is ideal for applications in food processing and packaging, where gentle handling is crucial. Its chemical resistance makes it suitable for environments with exposure to oils or solvents.

Considerations for International Buyers:

Buyers should check for compliance with food safety standards like FDA regulations and consider local certifications that ensure material safety, especially in the food and beverage sectors prevalent in South America and Europe.

Rubber

Key Properties:

Rubber is known for its elasticity and ability to absorb shock. It performs well in temperatures ranging from -40°C to 100°C (-40°F to 212°F) and offers good resistance to wear and tear.

Pros & Cons:

Rubber’s flexibility and shock-absorbing properties make it ideal for applications requiring noise reduction and impact resistance. However, it can degrade under UV exposure and may require more frequent replacement, leading to higher long-term costs.

Impact on Application:

Rubber is commonly used in conveyor systems for transporting fragile items or in environments where noise reduction is critical, such as in packaging or assembly lines.

Considerations for International Buyers:

Buyers should ensure that the rubber meets relevant standards such as ASTM D2000 for rubber materials, particularly in regions with varying climatic conditions like Africa and the Middle East.

Stainless Steel

Key Properties:

Stainless steel is renowned for its corrosion resistance and ability to maintain structural integrity at high temperatures. It typically operates effectively in environments up to 500°C (932°F) and is resistant to a variety of chemicals.

Pros & Cons:

The key advantage of stainless steel is its durability and low maintenance requirements, making it suitable for harsh environments. However, it is more expensive than carbon steel and can be challenging to fabricate, which may increase initial costs.

Impact on Application:

Stainless steel is ideal for applications in food processing, pharmaceuticals, and chemical handling, where hygiene and corrosion resistance are paramount.

Considerations for International Buyers:

Compliance with standards like ASTM A304 for stainless steel is crucial. Buyers should also consider local regulations regarding material safety and environmental impact, especially in industries with strict hygiene requirements in Europe and the Middle East.

Summary Table

| Material | Typical Use Case for conveyor belt parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications (mining, construction) | High strength and durability | Heavier and more expensive | High |

| Polyurethane | Food processing and packaging | Lightweight and good abrasion resistance | Limited temperature and load capacity | Medium |

| Rubber | Fragile item transport | Shock absorption and flexibility | Degrades under UV exposure | Medium |

| Stainless Steel | Food processing and pharmaceuticals | Corrosion resistance and hygiene | Higher cost and fabrication complexity | High |

This strategic material selection guide equips international B2B buyers with the insights needed to make informed decisions when sourcing conveyor belt parts, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor belt parts

Conveyor belt parts are crucial components in various industries, serving as the backbone of material handling systems. Understanding the manufacturing processes and quality assurance measures for these parts is essential for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This section provides a comprehensive overview of the typical manufacturing processes and quality control (QC) standards relevant to conveyor belt parts.

Manufacturing Processes for Conveyor Belt Parts

The manufacturing process of conveyor belt parts generally involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring that the final product meets both performance and durability standards.

Material Preparation

-

Selection of Raw Materials: The first step involves selecting appropriate materials based on the specific application of the conveyor system. Common materials include various grades of steel, rubber, plastic, and composite materials. The choice of material impacts factors such as load capacity, durability, and environmental resistance.

-

Material Treatment: Depending on the material selected, various treatments may be applied. For instance, steel components might undergo processes like annealing or galvanization to enhance their strength and corrosion resistance.

Forming

-

Cutting and Shaping: Raw materials are cut into required shapes and sizes using techniques such as laser cutting, plasma cutting, or water jet cutting. Precision in this stage is essential to ensure compatibility with other components.

-

Molding and Extrusion: For rubber and plastic parts, molding and extrusion processes are used. Molding techniques, such as injection molding, allow for the creation of complex shapes with high precision, while extrusion is often used for continuous profiles like conveyor belts.

Assembly

-

Component Assembly: After forming, parts are assembled using techniques like welding, riveting, or bolting. Automated assembly lines may be employed to increase efficiency and ensure consistent quality.

-

Integration of Components: In many cases, conveyor systems require the integration of various components, including motors, rollers, and belts. This requires careful alignment and testing to ensure smooth operation.

Finishing

-

Surface Treatment: Final surface treatments, such as powder coating, painting, or anodizing, are applied to enhance appearance and protect against wear and corrosion.

-

Final Inspection: Before packaging, each part undergoes a final inspection to ensure it meets design specifications and quality standards.

Quality Assurance for Conveyor Belt Parts

Quality assurance in the manufacturing of conveyor belt parts is vital for ensuring reliability and performance. International standards such as ISO 9001 provide a framework for quality management systems, while industry-specific standards like CE marking and API certification may apply depending on the sector.

Relevant International Standards

- ISO 9001: This standard focuses on effective quality management systems and is applicable across various industries. Compliance signifies that a manufacturer consistently meets customer requirements and enhances satisfaction.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For conveyor systems used in oil and gas applications, API standards ensure that products meet rigorous safety and performance criteria.

QC Checkpoints

-

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival to ensure they meet specified quality standards before manufacturing begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are performed to monitor processes and detect defects early. This can include dimensional checks and performance testing of components.

-

Final Quality Control (FQC): After assembly, final inspections ensure that the complete conveyor system meets all specifications and standards. This may include load testing and operational checks.

Common Testing Methods

- Mechanical Testing: Tests such as tensile strength, hardness, and impact resistance are conducted to evaluate the mechanical properties of materials used.

- Fatigue Testing: This assesses how materials perform under repeated stress conditions, crucial for parts subjected to continuous operation.

- Environmental Testing: Components may undergo testing for resistance to extreme temperatures, humidity, and corrosive environments, particularly for applications in challenging conditions.

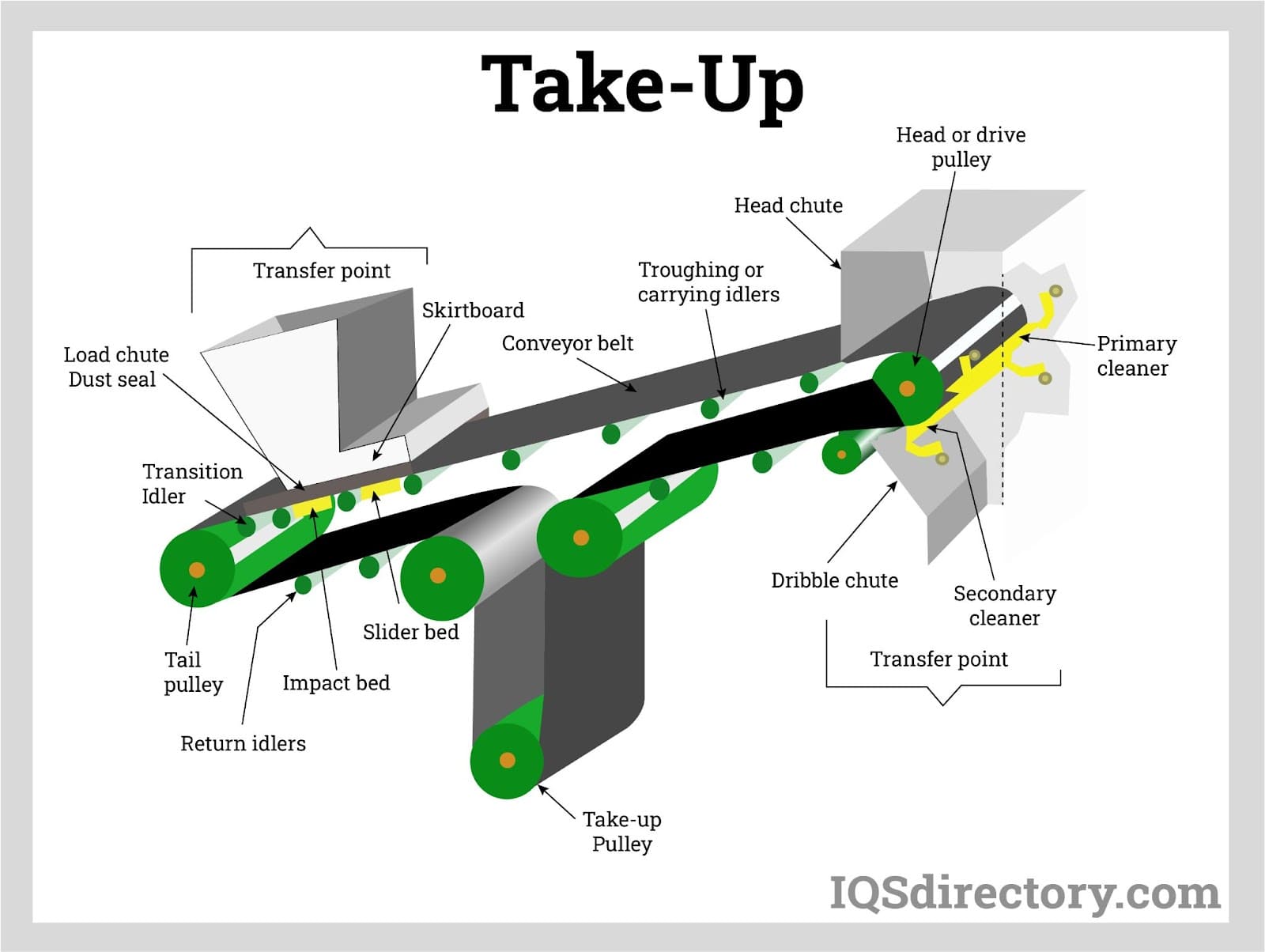

Illustrative Image (Source: Google Search)

Verification of Supplier Quality Control

For B2B buyers, verifying the quality control processes of suppliers is essential to mitigate risks and ensure product reliability. Here are several strategies:

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality management systems, and compliance with international standards. This provides insight into their operational capabilities and commitment to quality.

-

Review Quality Reports: Request access to quality assurance reports, including results from IQC, IPQC, and FQC inspections. These documents should detail the methodologies used and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality management practices. This is particularly beneficial for international buyers who may not be able to visit suppliers directly.

-

Certifications: Verify that suppliers hold relevant certifications (e.g., ISO 9001, CE marking) and that these are up-to-date. This can often be done through the certifying body’s website.

Considerations for International B2B Buyers

For buyers from regions such as Africa, South America, the Middle East, and Europe, it’s important to understand the nuances of quality control that may differ by region. Factors such as local regulations, industry standards, and logistical challenges can influence the procurement process.

-

Regional Compliance: Ensure that suppliers comply with local regulations and standards relevant to your specific market. This may require additional certifications or testing.

-

Cultural Differences: Be aware of cultural differences that may affect communication and business practices. Building strong relationships with suppliers can facilitate better quality assurance.

-

Logistics and Supply Chain: Consider the logistics involved in shipping conveyor belt parts internationally. Delays in supply chains can affect quality, so ensure that your suppliers have robust logistics plans in place.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing conveyor belt parts, ensuring they select suppliers that meet their operational needs and quality expectations.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for conveyor belt parts Sourcing

When sourcing conveyor belt parts, understanding the comprehensive cost structure is essential for international B2B buyers. This analysis focuses on the various cost components involved, pricing influencers, and practical tips to optimize procurement strategies.

Cost Components

-

Materials: The primary cost driver in conveyor belt parts is the raw materials used. Common materials include steel, plastic, and rubber, each influencing the overall cost differently. For example, heavy-duty steel rollers are typically more expensive than standard plastic ones due to their durability and load-bearing capacity.

-

Labor: Labor costs encompass both direct labor involved in manufacturing and indirect labor associated with maintenance and operations. Regions with lower labor costs may offer competitive pricing, but it’s crucial to consider the quality and expertise of the workforce.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and factory management. Efficient manufacturing processes can reduce overhead, thus affecting the final price of the parts.

-

Tooling: Custom parts may require specialized tooling, which can significantly impact costs. Buyers should inquire about tooling fees, especially for unique specifications or lower volume orders.

-

Quality Control (QC): Implementing rigorous QC processes is vital for ensuring product reliability. However, these processes also add to the overall cost. Certifications (e.g., ISO, CE) may require additional investment but can enhance product credibility.

-

Logistics: Transportation costs, including shipping and handling, play a crucial role in the total cost. Factors such as distance, shipping methods, and customs duties can significantly affect logistics expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the supplier’s pricing strategy can help buyers negotiate better terms.

Price Influencers

Several factors can influence the pricing of conveyor belt parts:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Establishing a long-term relationship with suppliers may also provide leverage for better pricing.

-

Specifications and Customization: Custom parts tailored to specific operational needs can incur higher costs. Buyers should evaluate whether customization is necessary or if off-the-shelf solutions can suffice.

-

Materials Quality and Certifications: Higher quality materials and relevant certifications can drive up costs but may offer better longevity and performance, reducing the Total Cost of Ownership (TCO) in the long run.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can impact pricing. Suppliers from regions with advanced manufacturing capabilities might command higher prices but offer better quality assurance.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and customs clearance. This knowledge can help avoid unexpected costs.

Buyer Tips

To navigate the complexities of sourcing conveyor belt parts effectively:

-

Negotiate: Engage suppliers in discussions about pricing structures. Leverage volume purchases and long-term contracts to negotiate better terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership by considering not just the initial purchase price but also maintenance, replacement, and operational costs over the product’s life cycle.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and local market conditions that can affect pricing.

-

Research Local Suppliers: In regions like Africa and South America, exploring local suppliers may yield cost advantages due to lower shipping costs and shorter lead times.

By comprehensively analyzing costs and understanding pricing dynamics, B2B buyers can make informed decisions that optimize their sourcing strategies for conveyor belt parts, ensuring both quality and value.

Disclaimer: The prices mentioned in this analysis are indicative and may vary based on market conditions and specific supplier agreements. Always conduct thorough market research and obtain multiple quotes before making purchasing decisions.

Spotlight on Potential conveyor belt parts Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘conveyor belt parts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for conveyor belt parts

Understanding the technical properties and terminology associated with conveyor belt parts is crucial for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe. This knowledge not only aids in making informed purchasing decisions but also enhances operational efficiency and compliance with local regulations.

Key Technical Properties

-

Material Grade

– Definition: The classification of the materials used in conveyor belts and components, such as rubber, plastic, or metal.

– Importance: Material grade affects durability, resistance to wear and tear, and suitability for specific applications. For instance, a higher-grade rubber belt might be necessary for heavy-duty applications in mining, while food-grade materials are essential in food processing. -

Load Capacity

– Definition: The maximum weight that a conveyor belt can safely transport.

– Importance: Understanding load capacity helps buyers select the appropriate conveyor system for their needs. Exceeding the load capacity can lead to system failure, increased maintenance costs, and potential safety hazards. -

Belt Width and Length

– Definition: The dimensions of the conveyor belt that determine its capacity to handle materials.

– Importance: The correct width and length are essential for ensuring efficient material handling. A belt that is too narrow may cause material spillage, while one that is excessively wide may lead to unnecessary costs. -

Belt Thickness

– Definition: The thickness of the conveyor belt material.

– Importance: Thicker belts generally offer more durability and resistance to wear, making them suitable for heavier loads or harsh environments. Buyers should consider their specific operational conditions when assessing belt thickness. -

Tension Rating

– Definition: The amount of force the belt can withstand before breaking or deforming.

– Importance: A proper tension rating ensures that the belt operates effectively without slippage. This is particularly vital in high-speed applications where consistent tension is required to maintain efficiency. -

Resistance to Environmental Factors

– Definition: The ability of the conveyor belt to withstand factors such as temperature, chemicals, and moisture.

– Importance: Buyers must consider the environmental conditions in which the conveyor will operate. For example, belts used in cold climates may require special materials to prevent cracking.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM products helps buyers identify quality components that meet industry standards. It also allows for better warranty and support options. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is critical for budgeting and inventory management. Buyers should align their purchasing strategies with suppliers’ MOQs to avoid excess costs. -

RFQ (Request for Quotation)

– Definition: A formal document that a buyer sends to suppliers to solicit price quotes for specific products or services.

– Importance: An RFQ helps buyers receive competitive pricing and terms from multiple suppliers, enabling them to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts.

– Importance: Familiarity with Incoterms is essential for international trade, as they clarify who is responsible for shipping, insurance, and tariffs. This knowledge can prevent disputes and misunderstandings during the procurement process. -

Lead Time

– Definition: The amount of time that passes from the start of a process until its completion.

– Importance: Understanding lead times is crucial for planning and inventory management. Buyers should consider lead times when assessing suppliers to ensure timely delivery of critical components. -

Warranty

– Definition: A promise made by a manufacturer or seller to repair or replace a product if necessary within a specified period.

– Importance: A solid warranty can provide peace of mind and protect against potential defects or failures. Buyers should assess warranty terms to ensure they align with their operational needs.

By understanding these technical properties and trade terminologies, international B2B buyers can enhance their procurement strategies, ensuring they select the right conveyor belt parts for their specific applications while also fostering stronger relationships with suppliers.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the conveyor belt parts Sector

Market Overview & Key Trends

The global conveyor belt parts market is experiencing robust growth, driven by increasing demand across various sectors such as manufacturing, mining, and logistics. Key drivers include the need for enhanced efficiency in material handling and the rising trend of automation in industrial processes. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for making informed sourcing decisions.

Emerging technologies such as the Internet of Things (IoT) and predictive maintenance are transforming how conveyor systems are managed. IoT-enabled sensors allow for real-time monitoring of conveyor belt performance, leading to proactive maintenance strategies that minimize downtime and improve overall productivity. Additionally, the rise of e-commerce is pushing logistics companies to invest in sophisticated conveyor systems to streamline operations.

In terms of sourcing trends, there is a noticeable shift towards local sourcing to mitigate supply chain disruptions experienced during global crises. Buyers from Africa and South America are increasingly seeking regional suppliers to ensure timely delivery and reduce transportation costs. Furthermore, the focus on customization is growing, with buyers looking for parts that can be tailored to specific operational needs, enhancing efficiency and performance.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration for B2B buyers in the conveyor belt parts sector. The environmental impact of manufacturing processes and materials used in conveyor systems cannot be overlooked. Buyers are now more inclined to partner with suppliers who prioritize eco-friendly practices, such as reducing waste and energy consumption during production.

Ethical sourcing is equally important, as it ensures that materials used in conveyor belt parts are obtained responsibly. Buyers should seek suppliers with transparent supply chains that adhere to international labor standards and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can provide assurance regarding the sustainability practices of suppliers.

Moreover, the adoption of ‘green’ materials, such as recycled plastics or sustainably sourced metals, is gaining traction. These materials not only reduce the carbon footprint but also meet the growing consumer demand for environmentally friendly products. By prioritizing sustainability and ethical sourcing, B2B buyers can enhance their brand reputation and meet regulatory requirements while contributing positively to the environment.

Brief Evolution/History

The conveyor belt industry has evolved significantly since its inception in the late 18th century. Originally designed for simple material transport, conveyor systems have transformed into complex automated solutions integral to modern manufacturing and logistics. The introduction of powered belts in the early 20th century revolutionized material handling, allowing for continuous movement and increased efficiency.

As industries expanded, so did the types of conveyor belts and parts, leading to specialized designs for diverse applications, from heavy-duty mining operations to delicate food processing environments. Today, advancements in materials science and automation technology continue to drive innovation in the sector, enabling B2B buyers to access more efficient, reliable, and customizable conveyor solutions. Understanding this evolution is vital for buyers looking to invest in conveyor belt parts that align with current and future market demands.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor belt parts

-

What should I consider when vetting suppliers for conveyor belt parts?

When vetting suppliers, focus on their industry experience, product quality, and customer reviews. Verify their certifications, such as ISO standards, which indicate compliance with international quality management systems. Additionally, assess their financial stability and capacity to meet your demand. Request samples to evaluate the quality of the conveyor belt parts. Engaging in direct communication can also provide insights into their responsiveness and willingness to customize solutions for your specific needs. -

Can I customize conveyor belt parts to fit my specific operational needs?

Yes, many suppliers offer customization options for conveyor belt parts. Customization can include dimensions, materials, and features tailored to your specific applications. When discussing customization, provide detailed specifications and requirements to your supplier. It’s advisable to collaborate closely during the design process to ensure the final product meets your operational standards. Be aware that custom parts may have longer lead times and higher costs than standard options. -

What are the typical minimum order quantities (MOQs) and lead times for conveyor belt parts?

Minimum order quantities can vary significantly by supplier and type of part. Generally, MOQs for conveyor belt components range from 50 to several hundred units, depending on the complexity and customization involved. Lead times can also differ; standard parts may ship within a few weeks, while custom components may take longer—often 6 to 12 weeks. Always confirm these details upfront to align your purchasing strategy with your operational needs. -

What payment terms should I expect when sourcing conveyor belt parts internationally?

Payment terms typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit (often 30-50%) upfront, especially for custom orders. Ensure you discuss and agree on payment terms before finalizing the order to avoid any misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees when dealing with international suppliers. -

How can I ensure quality assurance and certifications for the conveyor belt parts I purchase?

Request detailed documentation regarding quality assurance processes from your supplier. Look for industry-standard certifications like ISO 9001, which indicate rigorous quality management practices. It’s also beneficial to ask for test reports or certifications specific to the materials used. Conducting a factory audit or hiring a third-party inspection service can provide additional assurance of product quality before shipment. -

What logistics considerations should I keep in mind when importing conveyor belt parts?

Logistics play a crucial role in the timely delivery of conveyor belt parts. Confirm the shipping methods available (air, sea, or land) and their associated costs. Understand the customs regulations in your country to avoid unexpected delays or additional fees. Collaborating with a reliable freight forwarder can simplify the logistics process, ensuring compliance with international shipping laws and efficient handling of documentation. -

How should I handle disputes with suppliers regarding conveyor belt parts?

Establish clear communication channels and document all agreements to mitigate potential disputes. If issues arise, first attempt to resolve them directly with the supplier through open dialogue. If necessary, refer to the contract or purchase agreement for resolution steps. In cases where resolution fails, consider involving a mediator or legal advisor familiar with international trade laws to ensure fair handling of the situation. -

What are the best practices for maintaining conveyor belt parts to extend their lifespan?

Regular maintenance is key to extending the lifespan of conveyor belt parts. Implement a routine inspection schedule to identify wear and tear early. Ensure proper lubrication for moving parts and keep the conveyor clean to prevent material buildup. Training staff on operational best practices can also reduce unnecessary stress on the system. Investing in quality parts initially can also result in lower long-term maintenance costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for conveyor belt parts

Strategic sourcing in the realm of conveyor belt parts is essential for optimizing operational efficiency and ensuring the long-term sustainability of your supply chain. As international B2B buyers from diverse markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing high-quality conveyor components can significantly impact your bottom line. Prioritizing suppliers who offer robust warranties, reliable delivery schedules, and innovative solutions will not only enhance your production capabilities but also foster resilience against global supply chain disruptions.

Key Takeaways:

– Quality Matters: Invest in durable and efficient components tailored to your specific industry needs.

– Supplier Relationships: Build partnerships with reputable suppliers that understand your market dynamics.

– Continuous Improvement: Regularly assess your sourcing strategies to adapt to changing market conditions and technological advancements.

As you look ahead, consider leveraging digital tools and analytics to streamline your procurement processes. By doing so, you can stay ahead of competitors and better respond to market demands. Engage with your suppliers to explore collaborative opportunities that can lead to innovative solutions, ultimately positioning your business for success in a dynamic landscape.