Your Ultimate Guide to Sourcing Conveyor Screw

Introduction: Navigating the Global Market for conveyor screw

In today’s competitive global market, the role of conveyor screws in material handling cannot be overstated. These systems are integral to the efficient transport of bulk materials across various industries, including agriculture, food processing, chemicals, and construction. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe (such as Italy and Germany)—understanding the nuances of conveyor screw systems is essential for optimizing operations and enhancing productivity.

This comprehensive guide delves into the critical aspects of conveyor screws, covering various types, materials, manufacturing standards, and quality control measures. It also provides insights into supplier selection, cost considerations, and market trends, ensuring that buyers are equipped to make informed sourcing decisions. By exploring frequently asked questions, we address common concerns and clarify the complexities surrounding conveyor screw systems.

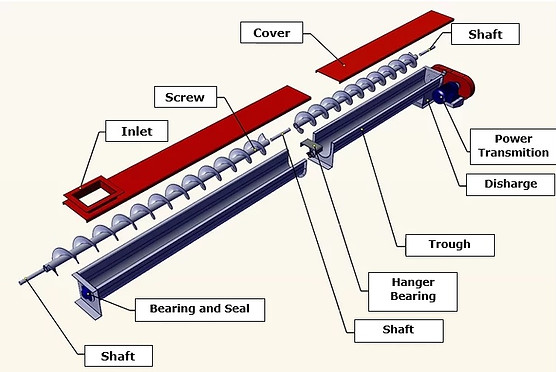

Illustrative Image (Source: Google Search)

Empowering B2B buyers with actionable insights, this guide serves as a vital resource for navigating the intricacies of the conveyor screw market. Whether you are looking to enhance your existing operations or seeking innovative solutions to improve efficiency, this guide will provide the knowledge necessary to choose the right equipment tailored to your specific needs. Ultimately, informed sourcing can lead to significant cost savings, increased reliability, and improved overall performance in your material handling processes.

Understanding conveyor screw Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Shafted Screw Conveyor | Features a central shaft with helical flights. | Grain handling, cement, food processing | Pros: Efficient for bulk materials; Cons: Requires more maintenance due to the shaft. |

| Shaftless Screw Conveyor | No central shaft, allowing for more flexibility in design. | Waste management, sludge handling | Pros: Reduced wear and tear; Cons: Limited capacity compared to shafted versions. |

| Screw Feeder | Regulates material flow from a hopper or silo. | Chemical, food, and plastic industries | Pros: Precise control over flow rates; Cons: More complex installation. |

| Vertical Screw Conveyor | Designed to transport materials vertically. | Mining, agriculture, and construction | Pros: Space-saving design; Cons: Higher energy consumption for vertical lifts. |

| Ribbon Screw Conveyor | Features a ribbon-like flight for mixing and transporting. | Food processing, pharmaceuticals | Pros: Excellent for blending materials; Cons: Less efficient for dense materials. |

Shafted Screw Conveyor

Shafted screw conveyors are the most traditional type, featuring a central shaft with helical flights that transport materials along a fixed trough. They are highly efficient for handling bulk materials such as grains, cement, and various food products. When considering a shafted screw conveyor, buyers should evaluate their specific material characteristics, as the type of flight and trough design can significantly impact performance. Maintenance is a key consideration, as the shaft can lead to wear and require regular inspections.

Shaftless Screw Conveyor

Shaftless screw conveyors eliminate the central shaft, which allows for more flexible designs and reduced wear on the system. This type is particularly effective for handling materials that are sticky or have a high moisture content, making it ideal for waste management and sludge handling applications. Buyers should consider the overall capacity and the specific handling requirements of their materials, as shaftless systems may not support as high a throughput as their shafted counterparts. However, their lower maintenance needs can be a significant advantage.

Screw Feeder

Screw feeders are specialized conveyors designed to regulate the flow of material from a storage hopper or silo. They are commonly used in industries such as chemicals, food, and plastics, where precise control over flow rates is crucial. When purchasing a screw feeder, buyers should assess the required flow rate and material characteristics, as these factors influence the design and size of the feeder. Although they offer precise control, the installation can be more complex and may require additional components.

Vertical Screw Conveyor

Vertical screw conveyors are engineered to transport materials in a vertical direction, making them ideal for applications where space is limited. Commonly used in mining, agriculture, and construction, these conveyors can effectively move bulk materials upward. Buyers should be aware that while vertical systems save space, they typically consume more energy compared to horizontal systems. Evaluating the specific lifting requirements and energy costs is essential for making an informed purchasing decision.

Ribbon Screw Conveyor

Ribbon screw conveyors feature a ribbon-like flight design that allows for both mixing and transporting of materials. This type is particularly beneficial in industries such as food processing and pharmaceuticals, where blending is required during transport. When considering a ribbon screw conveyor, buyers should focus on the material density and flow characteristics, as these factors can affect efficiency. While they excel in mixing, they may not be the best choice for dense materials due to their lower conveying efficiency.

Related Video: Types of Screw conveyor, Screw Feeder.

Key Industrial Applications of conveyor screw

| Industry/Sector | Specific Application of Conveyor Screw | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Transporting grain and feed | Increases efficiency in bulk material handling | Sourcing durable materials to withstand wear and tear |

| Food Processing | Conveying ingredients in food production | Ensures hygienic transport of materials | Compliance with food safety standards and certifications |

| Chemical Manufacturing | Moving powders and granules in chemical production | Reduces contamination and enhances material flow | Need for corrosion-resistant materials, especially for hazardous substances |

| Mining and Minerals | Handling ores and minerals during processing | Improves operational efficiency and reduces waste | Consideration for heavy-duty designs to handle abrasive materials |

| Waste Management | Transporting waste materials for recycling or disposal | Supports sustainable practices and reduces labor costs | Need for reliable and low-maintenance systems to minimize downtime |

Agriculture

In the agriculture sector, conveyor screws are essential for transporting grain and feed from one location to another, such as from silos to processing plants. They help streamline the handling of bulk materials, reducing the need for manual labor and minimizing the risk of spillage. For buyers in Africa and South America, it’s crucial to source conveyor screws that are built to withstand varying environmental conditions, including humidity and temperature fluctuations, which can affect material properties.

Food Processing

In food processing, conveyor screws play a vital role in moving ingredients through various stages of production, from raw materials to finished products. This application ensures that materials are transported in a hygienic manner, preventing contamination. European buyers, particularly from countries like Italy and Germany, should prioritize suppliers who adhere to strict food safety standards and certifications, ensuring that the materials used in the conveyor systems are compliant with health regulations.

Chemical Manufacturing

Conveyor screws are widely used in the chemical manufacturing industry for the efficient transport of powders and granules. This application is crucial for maintaining the integrity of the materials while minimizing contamination risks. Buyers in the Middle East and Africa should focus on sourcing conveyor screws made from corrosion-resistant materials, especially when handling hazardous substances, to ensure safety and compliance with local regulations.

Mining and Minerals

In the mining and minerals sector, conveyor screws facilitate the movement of ores and minerals during processing operations. This application is vital for improving operational efficiency and reducing waste, as it allows for continuous material flow. International buyers from South America and Africa must consider heavy-duty designs that can withstand abrasive materials and harsh environments, ensuring longevity and reliability in their operations.

Waste Management

Conveyor screws are instrumental in the waste management sector, where they are used to transport waste materials for recycling or disposal. This application supports sustainable practices by streamlining the handling of waste, ultimately reducing labor costs and improving efficiency. For buyers in Europe and the Middle East, sourcing reliable and low-maintenance conveyor screw systems is essential to minimize downtime and maintain continuous operations.

Related Video: Screw Conveyor vs. Screw Feeder

Strategic Material Selection Guide for conveyor screw

When selecting materials for conveyor screws, international B2B buyers must consider various factors such as the specific application, environmental conditions, and regulatory compliance. Here, we analyze four common materials used in the manufacturing of conveyor screws, focusing on their properties, advantages, disadvantages, and considerations for different regions, particularly Africa, South America, the Middle East, and Europe.

Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and durability. It typically has a temperature rating up to 400°F (204°C) and can handle moderate pressure. However, it is susceptible to corrosion, which can be mitigated through coatings or galvanization.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness and availability. It is relatively easy to manufacture and can be tailored for various applications. On the downside, its susceptibility to rust and corrosion in humid or wet environments can lead to increased maintenance costs and reduced lifespan.

Impact on Application:

Carbon steel is suitable for conveying dry bulk materials like grains and powders. However, it is less ideal for corrosive or high-moisture applications unless adequately treated.

Considerations for International Buyers:

Buyers in Europe and the Middle East should ensure compliance with standards such as ASTM A36 or DIN 17100. In Africa and South America, local sourcing may affect availability and cost.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance due to its chromium content. It can withstand higher temperatures (up to 1500°F or 815°C) and is suitable for high-pressure applications.

Pros & Cons:

The key advantage of stainless steel is its durability and resistance to corrosion, making it ideal for food processing and chemical handling. However, it is significantly more expensive than carbon steel and can be more challenging to machine.

Impact on Application:

Stainless steel is particularly well-suited for applications involving corrosive materials or where hygiene is critical, such as in the food and pharmaceutical industries.

Considerations for International Buyers:

Buyers should look for compliance with standards like ASTM A240 and JIS G4303. In Europe, adherence to EU regulations regarding food safety may also be necessary.

Alloy Steel

Key Properties:

Alloy steel combines carbon steel with other elements like chromium, nickel, or molybdenum to enhance properties such as strength and toughness. It typically has a temperature rating similar to stainless steel but offers improved hardness.

Pros & Cons:

The main advantage of alloy steel is its enhanced performance in high-stress applications, making it suitable for heavy-duty environments. However, it tends to be more expensive and requires specialized manufacturing processes.

Impact on Application:

Alloy steel is ideal for applications involving abrasive materials or where high strength is required, such as mining or heavy industrial operations.

Considerations for International Buyers:

Compliance with standards such as ASTM A387 or DIN 1.7225 is crucial. Buyers should also consider the availability of alloy steel in their region, as it may not be as commonly stocked as carbon or stainless steel.

Plastic (Polymer)

Key Properties:

Plastics, particularly high-density polyethylene (HDPE) and polypropylene, offer excellent resistance to corrosion and can operate effectively in a wide range of temperatures (up to 200°F or 93°C).

Pros & Cons:

The primary advantage of using plastic is its lightweight nature and resistance to chemical corrosion, making it suitable for a variety of materials. However, plastics may not be as durable as metals in high-stress applications and can be prone to wear over time.

Impact on Application:

Plastics are ideal for conveying materials that are sensitive to contamination or require a non-corrosive environment, such as in food processing or chemical handling.

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards such as FDA regulations for food-grade materials. In Europe, adherence to REACH regulations regarding chemical safety may be necessary.

Summary Table

| Material | Typical Use Case for conveyor screw | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Conveying dry bulk materials | Cost-effective and widely available | Susceptible to corrosion | Low |

| Stainless Steel | Food processing and chemical handling | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Alloy Steel | Heavy-duty industrial applications | Enhanced strength and toughness | More expensive and requires specialized manufacturing | Medium |

| Plastic (Polymer) | Food processing and chemical handling | Lightweight and corrosion-resistant | Less durable under high-stress conditions | Medium |

This comprehensive analysis provides international B2B buyers with the necessary insights to make informed decisions regarding material selection for conveyor screws, ensuring optimal performance and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor screw

The manufacturing processes and quality assurance protocols for conveyor screws are crucial for ensuring that these essential components operate efficiently across various industries. Understanding these processes can help B2B buyers from Africa, South America, the Middle East, and Europe make informed decisions when sourcing conveyor screws. Below is a comprehensive overview of the manufacturing stages, quality control measures, and standards that buyers should consider.

Manufacturing Processes

Material Preparation

The first stage in the manufacturing of conveyor screws involves the selection and preparation of raw materials. Common materials include carbon steel, stainless steel, and specialized alloys, which are chosen based on the application’s requirements—such as corrosion resistance or strength.

- Material Selection: Buyers should assess material grades (e.g., ASTM, EN standards) to ensure they meet the necessary specifications for their operational environment.

- Cutting and Shaping: Raw materials are cut into appropriate lengths and shapes, often utilizing CNC (Computer Numerical Control) machines to ensure precision.

Forming

The forming stage involves creating the helical screw shape, which is critical for the conveyor’s functionality.

- Helicoid and Sectional Flights: The screw can be formed as a helicoid (continuous spiral) or sectional (discrete sections). The choice between these designs affects the screw’s efficiency and capacity.

- Welding and Fabrication: For sectional flights, welding techniques are employed to assemble parts. Advanced welding techniques like TIG (Tungsten Inert Gas) welding are often used for high-quality joints.

Assembly

After forming, the individual components are assembled into a complete conveyor screw system.

- Integration of Components: This includes the attachment of flights to the central shaft, along with the installation of bearings and other necessary components.

- Alignment and Calibration: Proper alignment is crucial for minimizing wear and tear during operation. Specialized tools are used to ensure that all components are correctly calibrated.

Finishing

The finishing stage enhances the durability and appearance of the conveyor screw.

- Surface Treatment: Common treatments include powder coating, galvanization, or passivation, which provide protection against corrosion and wear.

- Final Inspection: Before packaging, each conveyor screw undergoes a final inspection to ensure it meets design specifications and quality standards.

Quality Assurance Protocols

Quality assurance is integral to the manufacturing process, ensuring that the conveyor screws produced meet both international and industry-specific standards.

International Standards

Adherence to recognized international standards is essential for ensuring product quality and safety.

- ISO 9001: This standard outlines requirements for a quality management system, emphasizing consistent quality and customer satisfaction.

- CE Marking: For products sold in the European Union, CE marking indicates compliance with health, safety, and environmental protection standards.

Industry-Specific Standards

Certain industries may have additional requirements that manufacturers must meet.

- API Standards: For applications in the oil and gas sector, manufacturers should comply with API standards to ensure reliability under extreme conditions.

- CEMA Standards: The Conveyor Equipment Manufacturers Association (CEMA) provides specifications that enhance safety and performance in conveyor systems.

Quality Control Checkpoints

Quality control checkpoints are established at various stages of the manufacturing process to ensure compliance with standards.

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify that they meet specifications.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor adherence to design specifications and standards.

- Final Quality Control (FQC): The final product undergoes rigorous testing and inspection before shipment to ensure it meets all quality standards.

Common Testing Methods

Various testing methods are employed to verify the integrity and performance of conveyor screws.

- Dimensional Inspection: Utilizing calipers and micrometers to ensure that all dimensions meet specified tolerances.

- Material Testing: This includes hardness testing, tensile strength testing, and corrosion resistance tests to verify the material’s properties.

- Functional Testing: Conducting operational tests to ensure the conveyor screw performs as expected under load conditions.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers.

- Supplier Audits: Conducting regular audits of suppliers’ manufacturing facilities can provide insight into their quality assurance practices.

- Quality Assurance Reports: Requesting detailed QA reports can help buyers understand how a supplier maintains quality throughout the manufacturing process.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control systems and product quality.

Quality Control and Certification Nuances

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding certification nuances is vital.

- Regional Compliance: Ensure that products meet the regulatory requirements specific to your region, which may differ from those in the supplier’s country.

- Documentation: Request complete documentation regarding certifications and compliance for transparency and assurance of product quality.

- Cultural Considerations: Understanding cultural differences in business practices can enhance communication and expectations regarding quality assurance and standards.

By comprehensively understanding the manufacturing processes and quality assurance measures associated with conveyor screws, international B2B buyers can make informed sourcing decisions that align with their operational needs and compliance requirements. This knowledge fosters stronger supplier relationships and promotes the procurement of high-quality equipment that enhances productivity and safety.

Related Video: Precision manufacturing|Screw conveyor spiral production process

Comprehensive Cost and Pricing Analysis for conveyor screw Sourcing

Understanding the cost structure and pricing dynamics of conveyor screws is crucial for international B2B buyers, especially those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe. The costs associated with conveyor screw sourcing can be dissected into several components, and various factors can influence pricing.

Cost Components

- Materials: The choice of materials significantly impacts the overall cost. Common options include carbon steel, stainless steel, and specialized alloys. Each material has different costs associated with raw procurement and treatment processes. For example, stainless steel tends to be more expensive but offers better resistance to corrosion, which may justify the higher price in specific applications.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs vary by region and can be a significant factor. In regions with higher labor costs, such as parts of Europe, the overall manufacturing price may increase. Additionally, skilled labor may be required for custom designs or complex installations, further influencing labor costs.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and general administrative expenses. Efficient manufacturing processes can help reduce overhead, making it a vital consideration for suppliers.

-

Tooling: Custom tooling can incur high initial costs, especially for unique designs or specifications. Standardized tooling can reduce these costs, but buyers may need to compromise on customization.

-

Quality Control (QC): Ensuring that products meet international standards often requires rigorous QC processes. This can involve testing materials, inspecting finished products, and compliance certifications, which add to the overall cost.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and local tariffs. For international buyers, understanding the logistics involved in shipping conveyor screws, including potential delays and customs duties, is essential.

-

Margin: Suppliers typically apply a markup to cover their costs and ensure profitability. This margin can vary depending on market conditions, competition, and the supplier’s reputation.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should consider their capacity to store and manage inventory when negotiating MOQs.

-

Specifications/Customization: Customized conveyor screws, designed for specific applications, can significantly increase costs. Buyers should clearly communicate their needs to avoid unnecessary expenses.

-

Quality/Certifications: Products that come with quality certifications (e.g., ISO, CEMA) may command higher prices but often provide assurances of performance and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of quality may charge more, but the trade-off often includes better service and product assurance.

-

Incoterms: Understanding the Incoterms associated with a purchase can greatly affect the total landed cost. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift responsibilities and costs between buyer and seller.

Buyer Tips

-

Negotiation: Engage in thorough discussions with suppliers to explore price flexibility, especially for larger orders. Building long-term relationships can also yield better pricing.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO) rather than just initial purchase price. Consider maintenance, operational efficiency, and lifespan when assessing value.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should account for currency fluctuations, local taxation, and import duties when calculating costs.

-

Disclaimer for Indicative Prices: Prices can fluctuate based on market conditions, raw material availability, and geopolitical factors. Always seek updated quotes from suppliers to ensure accuracy in budgeting.

By understanding these components and leveraging the outlined tips, international B2B buyers can make informed decisions when sourcing conveyor screws, ensuring they achieve the best possible value for their investments.

Spotlight on Potential conveyor screw Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘conveyor screw’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for conveyor screw

When considering the procurement of conveyor screws, understanding essential technical properties and industry terminology is crucial for making informed purchasing decisions. Below, we outline critical specifications and common jargon that B2B buyers should be aware of.

Key Technical Properties

-

Material Grade

– Definition: The quality of the material used in manufacturing conveyor screws, typically categorized by its chemical composition and mechanical properties.

– Importance: Selecting the right material grade, such as carbon steel or stainless steel, impacts the conveyor’s durability, resistance to corrosion, and suitability for specific applications, especially in industries dealing with harsh environments. -

Diameter

– Definition: The width of the screw, usually measured in inches, which can vary depending on the design and application.

– Importance: The diameter affects the capacity and efficiency of the conveyor system. A larger diameter generally allows for higher material throughput, which is essential for businesses looking to optimize their production processes. -

Pitch

– Definition: The distance between adjacent flights of the screw.

– Importance: The pitch influences the rate of material flow. A smaller pitch is suitable for denser materials requiring more control, while a larger pitch is effective for lighter, bulk materials. Buyers must select the appropriate pitch to match their material characteristics and handling requirements. -

Tolerance

– Definition: The permissible limit of variation in dimensions and specifications during manufacturing.

– Importance: Precise tolerances ensure proper fitting and operation of the screw within the conveyor system. Inaccurate tolerances can lead to operational inefficiencies and increased wear, resulting in higher maintenance costs. -

Capacity

– Definition: The volume of material that the conveyor screw can transport, typically expressed in cubic feet per hour.

– Importance: Understanding the capacity helps buyers assess whether a particular screw conveyor can meet their production demands. Insufficient capacity can bottleneck operations and affect overall productivity. -

Incline Angle

– Definition: The angle at which the screw conveyor is positioned relative to horizontal.

– Importance: The incline angle can significantly affect the material flow and the type of materials that can be conveyed. Selecting the correct incline angle is vital for maintaining efficiency and preventing material spillage.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM products is essential for buyers looking for reliable and compatible components for their conveyor systems. Engaging with OEMs often ensures quality and standardized parts. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is crucial for budgeting and inventory management. Buyers should ensure that their order volumes meet the supplier’s MOQ to avoid additional costs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a quote on specific products or services.

– Relevance: Issuing an RFQ allows buyers to compare prices and terms from different suppliers, facilitating informed purchasing decisions. -

Incoterms

– Definition: International commercial terms that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, insurance, and costs, minimizing risks associated with international procurement. -

CEMA (Conveyor Equipment Manufacturers Association)

– Definition: An industry association that provides standards and guidelines for conveyor systems.

– Relevance: Buyers should consider CEMA standards when selecting conveyor screws to ensure compliance with industry best practices and enhance system reliability. -

Lead Time

– Definition: The time taken from placing an order to its delivery.

– Relevance: Knowing the lead time is essential for project planning and operational scheduling. Longer lead times can impact production timelines, making it vital for buyers to clarify this with suppliers.

By understanding these technical properties and industry terms, B2B buyers can make more strategic decisions when sourcing conveyor screws, leading to optimized operations and improved supply chain efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the conveyor screw Sector

Market Overview & Key Trends

The conveyor screw sector is experiencing significant growth driven by various global factors. The increasing demand for efficient bulk material handling in industries such as agriculture, food processing, and mining is a primary catalyst. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for automation and mechanization to enhance productivity. Innovations in technology, such as IoT-enabled monitoring systems and advanced materials, are shaping the future of screw conveyor systems, making them smarter and more efficient.

Emerging sourcing trends highlight a shift towards modular designs that allow for easy customization and rapid deployment. Buyers are favoring suppliers who offer extensive inventories of standard parts and modular packages, facilitating quicker replacements and reduced downtime. Furthermore, sustainability is becoming a crucial factor; buyers are now prioritizing manufacturers who utilize eco-friendly materials and practices, reflecting a broader industry trend towards greener operations.

As market dynamics evolve, buyers should remain vigilant about regional variations in demand and supply chain logistics. For instance, while Europe may push for higher energy efficiency standards, African and South American markets may focus more on cost-effectiveness and rugged designs suitable for local conditions. Understanding these nuances is essential for international buyers aiming to optimize their sourcing strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of purchasing decisions in the conveyor screw sector. The environmental impact of manufacturing and operating conveyor systems is under scrutiny, leading buyers to seek suppliers who demonstrate a commitment to sustainable practices. This includes the use of recycled materials, energy-efficient production processes, and waste reduction strategies.

Ethical sourcing is equally important. Companies are increasingly aware of the need for transparent supply chains that do not exploit labor or harm local ecosystems. Buyers should look for suppliers who are certified by recognized organizations, such as ISO 14001 for environmental management or Fair Trade certifications. These certifications not only ensure compliance with international standards but also enhance the brand reputation of the buyer.

Moreover, the adoption of ‘green’ materials, such as corrosion-resistant alloys and biodegradable lubricants, is gaining traction. These materials not only contribute to sustainability but also improve the longevity and performance of screw conveyors, ultimately leading to cost savings for businesses in the long run.

Brief Evolution/History

The concept of the screw conveyor dates back to ancient times, attributed to the Greek engineer Archimedes. Initially used for irrigation, the design evolved over centuries to accommodate various bulk materials. The industrial revolution marked a significant turning point; screw conveyors became integral in manufacturing and agricultural sectors, revolutionizing the way materials were transported.

In recent decades, advancements in engineering and materials science have transformed screw conveyors into highly efficient and customizable systems. Modern applications now include everything from food processing to waste management, reflecting the versatility and adaptability of screw conveyor technology. As global industries continue to innovate, the conveyor screw sector will likely witness further enhancements, underscoring its importance in contemporary supply chains.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor screw

-

What key factors should I consider when vetting suppliers for conveyor screws?

When vetting suppliers, prioritize their industry experience, customer reviews, and quality certifications such as ISO 9001. Assess their manufacturing capabilities, including technology and materials used, as this impacts the durability and efficiency of the conveyor screws. It’s also essential to request samples to evaluate product quality firsthand. Consider suppliers who offer customization options to meet specific needs and have a robust after-sales support system to address potential issues. -

Can conveyor screws be customized for specific applications?

Yes, many manufacturers offer customization options for conveyor screws to fit unique applications. You can specify dimensions, materials, and flight configurations based on the type of material being transported and the operational environment. Common customizations include varying pitch, length, and diameter, as well as using corrosion-resistant materials for harsh conditions. Discuss your requirements with the supplier to ensure they can deliver a tailored solution that enhances your operational efficiency. -

What are the typical minimum order quantities (MOQ) and lead times for conveyor screws?

MOQs for conveyor screws can vary significantly by supplier and the complexity of the order. Standard products often have lower MOQs, while customized solutions may require higher quantities. Lead times typically range from 4 to 12 weeks, depending on the manufacturer’s production capacity and the specifics of your order. To avoid delays, it’s advisable to confirm these details upfront and factor in additional time for shipping, especially for international orders. -

What payment terms and options should I expect when sourcing conveyor screws internationally?

Payment terms can vary widely between suppliers. Common options include advance payment, letter of credit, or payment upon delivery, depending on the supplier’s policy and your negotiation. Be aware of potential currency exchange risks and consider using secure payment platforms that provide buyer protection. Establishing clear payment terms in the contract can help avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure quality assurance and certifications for conveyor screws?

Ensure the supplier has relevant quality assurance certifications, such as ISO 9001, which indicates a commitment to quality management systems. Request documentation of their testing processes, including materials testing and performance standards. Many suppliers also conduct third-party inspections to verify product quality. It’s beneficial to establish a clear quality agreement, outlining the acceptable quality levels (AQL) and procedures for managing defects. -

What logistics considerations should I keep in mind when importing conveyor screws?

Logistics play a crucial role in international sourcing. Consider shipping methods (air vs. sea), customs clearance processes, and potential tariffs or duties that may apply. Collaborate with a freight forwarder familiar with your supplier’s location to streamline the shipping process. Confirm the delivery timeline and ensure that the supplier provides all necessary documentation, such as packing lists and certificates of origin, to facilitate customs clearance. -

How can I handle disputes with suppliers effectively?

To manage disputes effectively, establish clear communication channels and document all agreements and changes made during negotiations. Include a dispute resolution clause in your contract, specifying preferred methods such as mediation or arbitration, to avoid lengthy legal processes. In case of a disagreement, approach the supplier professionally, aiming to resolve issues amicably. If necessary, escalate the matter to higher management or consider involving a third-party mediator. -

What are the common challenges when sourcing conveyor screws internationally, and how can I mitigate them?

Common challenges include language barriers, cultural differences, and logistical complexities. To mitigate these issues, engage with suppliers who have experience in international trade and understand your market. Utilize clear and concise communication, employing professional translators if necessary. Establish a robust project management approach to track orders and timelines, and consider visiting the supplier’s facility to build rapport and ensure alignment on quality expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for conveyor screw

The strategic sourcing of conveyor screws is crucial for optimizing operational efficiency and reducing costs in material handling systems. As outlined, the versatility of screw conveyors allows for the transportation of a wide range of bulk materials, making them a preferred choice across various industries. Leveraging high-quality components, whether standard or custom-engineered, ensures reliability and longevity, which translates to reduced maintenance and downtime.

Key Takeaways for B2B Buyers:

– Adaptability: Choose screw conveyors that can be tailored to specific material types and operational requirements.

– Cost Efficiency: Consider the total cost of ownership, including installation, maintenance, and energy consumption, when selecting conveyor systems.

– Local Support: Engage with suppliers who provide robust after-sales service and support, especially in your region, to ensure quick response times and effective solutions.

Looking ahead, international B2B buyers from Africa, South America, the Middle East, and Europe should prioritize strategic partnerships with manufacturers that offer innovative solutions and sustainable practices. As industries evolve, embracing advanced technologies and sustainable sourcing will be key to staying competitive. Explore your options today to enhance your supply chain and drive your business forward.