Your Ultimate Guide to Sourcing Creative Assembly Systems

Introduction: Navigating the Global Market for creative assembly systems

In today’s increasingly interconnected global market, creative assembly systems have emerged as pivotal components for businesses striving for efficiency and innovation. These systems encompass a diverse range of tools and fasteners that facilitate the assembly process, ensuring high-quality production across various industries including automotive, construction, and manufacturing. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe (notably Poland and Egypt), understanding the nuances of creative assembly systems is essential for optimizing procurement strategies.

This guide provides a comprehensive exploration of creative assembly systems, covering critical aspects such as types of systems available, materials used, manufacturing and quality control processes, and supplier networks. Additionally, it delves into cost considerations and current market trends, equipping buyers with the insights needed to make informed decisions.

With a focus on frequently asked questions, this resource empowers buyers to navigate the complexities of sourcing assembly systems effectively. By leveraging this knowledge, businesses can enhance operational efficiency, reduce costs, and ultimately drive profitability. Whether you are seeking innovative solutions or reliable suppliers, this guide is your key to mastering the global landscape of creative assembly systems.

Understanding creative assembly systems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rivet Nut Tools | Versatile for multiple materials, adjustable settings | Automotive, appliance assembly | Pros: High efficiency, cost-effective; Cons: Requires training for optimal use. |

| Lockbolt Tools | Heavy-duty, designed for structural applications | Heavy machinery, aerospace, construction | Pros: Robust, reliable under stress; Cons: Higher initial investment. |

| Blind Rivet Tools | Compact design, ideal for tight spaces | Electronics, furniture manufacturing | Pros: Space-saving, easy to use; Cons: Limited to specific applications. |

| Cutting & Grinding Tools | Diverse range for various materials and applications | Metal fabrication, construction, automotive | Pros: Versatile, essential for production; Cons: Regular maintenance needed. |

| Anchors & Fasteners | Wide variety for different substrates and loads | Construction, HVAC, plumbing | Pros: Strong hold, diverse options; Cons: Selection complexity can lead to errors. |

Rivet Nut Tools

Rivet nut tools are designed to create threaded holes in thin materials, allowing for secure fastening. Their versatility makes them suitable for various applications in the automotive and appliance industries. When purchasing, buyers should consider the tool’s range of materials it can handle and whether it fits their production needs. Training is essential for operators to maximize efficiency and minimize errors.

Illustrative Image (Source: Google Search)

Lockbolt Tools

Lockbolt tools are engineered for heavy-duty applications, particularly in structural settings like aerospace and construction. These tools provide a strong, permanent fastening solution that can withstand significant stress. Buyers should evaluate the specific load requirements of their projects and the tool’s compatibility with different fasteners. While they offer exceptional reliability, the initial investment may be higher compared to standard fasteners.

Blind Rivet Tools

Ideal for applications where space is limited, blind rivet tools allow for fastening from one side of the material. Commonly used in electronics and furniture manufacturing, these tools are compact and user-friendly. B2B buyers should assess the tool’s pulling force and the range of rivet sizes it can accommodate. The ease of use is a significant advantage, but the tool’s limitations in specific applications should be kept in mind.

Cutting & Grinding Tools

A comprehensive range of cutting and grinding tools is essential for various manufacturing processes, particularly in metal fabrication and automotive sectors. These tools must be selected based on the specific materials being processed and the required precision. Buyers should prioritize quality and durability, as well as the availability of replacement parts. Regular maintenance is crucial to ensure optimal performance and longevity.

Anchors & Fasteners

Anchors and fasteners come in various types to suit different substrates and load requirements, making them indispensable in construction and plumbing. Their strength and reliability are crucial for ensuring safety and structural integrity. B2B buyers should focus on the specific needs of their projects, including load capacity and environmental factors. The complexity of selecting the right type can pose challenges, so thorough research and consultation with suppliers are recommended to avoid costly mistakes.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of creative assembly systems

| Industry/Sector | Specific Application of Creative Assembly Systems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Riveting of body panels and structural components | Enhanced assembly speed and structural integrity | Quality certifications, local availability of tools, and support services |

| Heavy Truck | Installation of fasteners in chassis assembly | Increased durability and reduced maintenance costs | Compatibility with existing systems and compliance with regional standards |

| Appliance Manufacturing | Assembly of appliance casings and components | Improved production efficiency and reduced labor costs | Customization options and reliable supply chain management |

| Material Handling Equipment | Fastening of conveyor systems and racks | Enhanced operational reliability and safety | Technical support for installation and ongoing maintenance |

| Aerospace | Installation of fasteners in aircraft components | Compliance with strict safety standards and weight reduction | Sourcing from certified manufacturers with aerospace experience |

Automotive

In the automotive sector, creative assembly systems are crucial for riveting body panels and structural components. These systems enhance assembly speed while ensuring the structural integrity of vehicles. For international buyers, especially in Africa and Europe, sourcing high-quality riveting tools that meet stringent automotive standards is essential. Buyers should consider factors such as tool compatibility with existing assembly lines, availability of local repair services, and adherence to safety regulations.

Heavy Truck

For heavy truck manufacturing, the installation of fasteners in chassis assembly is a critical application of creative assembly systems. These systems provide increased durability, which translates into lower maintenance costs over the vehicle’s lifespan. Buyers from regions like South America and the Middle East should prioritize sourcing tools that can withstand harsh operating conditions. Additionally, understanding local regulations and ensuring compliance with industry standards is vital for effective procurement.

Appliance Manufacturing

In appliance manufacturing, creative assembly systems facilitate the assembly of casings and internal components. This leads to improved production efficiency and reduced labor costs, which are crucial for maintaining competitive pricing. B2B buyers should seek suppliers who offer customizable solutions tailored to specific appliance designs. Furthermore, reliable supply chain management is critical to ensure timely delivery of components, especially in regions with fluctuating market demands.

Material Handling Equipment

Creative assembly systems play a significant role in fastening conveyor systems and racks in material handling equipment. These systems enhance operational reliability and safety, which are paramount in industrial environments. Buyers should consider sourcing from manufacturers that provide technical support for installation and maintenance, ensuring that the systems are optimized for their specific operational needs. It is also important to evaluate the supplier’s ability to deliver spare parts promptly.

Aerospace

In the aerospace industry, the installation of fasteners in aircraft components is a highly specialized application of creative assembly systems. These systems must comply with strict safety standards while also contributing to weight reduction, which is critical for fuel efficiency. International buyers in this sector must focus on sourcing from certified manufacturers with proven aerospace experience. Understanding the certification requirements and maintaining stringent quality control processes are essential for successful procurement in this highly regulated industry.

Related Video: 3D Vision Guided Robotic Assembly

Strategic Material Selection Guide for creative assembly systems

When selecting materials for creative assembly systems, international B2B buyers must consider various factors that influence performance, cost, and compliance with industry standards. Below is an analysis of four common materials used in these systems, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers from diverse regions.

Aluminum

Key Properties:

Aluminum is lightweight, with excellent corrosion resistance and good thermal and electrical conductivity. It typically has a temperature rating up to 150°C (302°F), making it suitable for various applications.

Pros & Cons:

Aluminum’s durability and resistance to rust make it ideal for outdoor and marine environments. However, it can be more expensive than steel and may require additional coatings for enhanced durability. Manufacturing complexity can also be higher due to the need for specialized machining.

Impact on Application:

Aluminum is compatible with various media, including water and oils, but may not be suitable for strong acids or alkalis. Its lightweight nature enhances the performance of assembly systems where weight savings are crucial.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions. In regions like Europe, adherence to EN standards is essential. Additionally, local sourcing may reduce costs and improve supply chain efficiency.

Stainless Steel

Key Properties:

Stainless steel offers high strength, excellent corrosion resistance, and can withstand temperatures up to 800°C (1472°F). It is available in various grades, each suited for specific applications.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to corrosion, making it suitable for harsh environments. However, it is generally more expensive than carbon steel and can be challenging to machine due to its hardness.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive substances, making it ideal for food processing and chemical industries. Its strength ensures structural integrity in demanding applications.

Considerations for International Buyers:

Buyers must consider compliance with standards such as ASTM A240 for stainless steel sheets and plates. In regions like South America and Africa, understanding local regulations regarding food safety and chemical handling is crucial.

Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and affordability. It typically has a temperature rating of around 300°C (572°F) and is widely used in various applications.

Pros & Cons:

The main advantage of carbon steel is its cost-effectiveness and ease of manufacturing. However, it is prone to corrosion and may require protective coatings, which can increase overall costs.

Impact on Application:

Carbon steel is suitable for applications where strength is essential, but it may not be ideal for environments exposed to moisture or corrosive substances. Proper surface treatment is necessary to enhance its lifespan.

Considerations for International Buyers:

Buyers should be aware of compliance with standards such as ASTM A36 for structural steel. In regions like the Middle East, where humidity can be high, additional protective measures may be needed.

Composite Materials

Key Properties:

Composite materials, such as fiberglass or carbon fiber, offer lightweight properties and high strength-to-weight ratios. They can withstand a range of temperatures, depending on the resin used.

Pros & Cons:

The key advantage of composites is their ability to be molded into complex shapes, allowing for innovative designs. However, they can be more expensive and may require specialized manufacturing processes.

Impact on Application:

Composites are ideal for applications requiring lightweight components, such as in aerospace and automotive industries. Their resistance to corrosion makes them suitable for various environmental conditions.

Considerations for International Buyers:

Buyers should consider compliance with standards like ASTM D3039 for tensile properties of composites. In Europe, adherence to EN standards is critical, especially in industries with strict safety regulations.

| Material | Typical Use Case for creative assembly systems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight structural components | Excellent corrosion resistance | Higher cost than steel | Medium |

| Stainless Steel | Food processing and chemical applications | High strength and durability | Expensive and hard to machine | High |

| Carbon Steel | General structural applications | Cost-effective and strong | Prone to corrosion | Low |

| Composite Materials | Aerospace and automotive components | Lightweight and moldable | High cost and specialized processes | High |

In-depth Look: Manufacturing Processes and Quality Assurance for creative assembly systems

The manufacturing processes and quality assurance protocols for creative assembly systems are critical for ensuring product reliability, performance, and compliance with international standards. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must understand these processes to make informed procurement decisions. Below is an in-depth exploration of the typical manufacturing stages, key techniques employed, and the quality assurance measures relevant to this sector.

Manufacturing Processes

1. Material Preparation

The first stage of manufacturing involves sourcing and preparing the raw materials. This can include metals, plastics, and composites, which are selected based on the specific requirements of the fasteners and assembly systems. Key considerations in this phase include:

- Material Selection: Choosing high-grade materials that meet the mechanical and thermal properties required for the end product.

- Pre-treatment: Materials may undergo processes such as cleaning, degreasing, or surface treatment to enhance adhesion and performance.

2. Forming

In this stage, raw materials are shaped into components using various techniques. Common forming methods include:

- Stamping: Utilized for producing flat parts like washers and brackets, where sheets of metal are cut and shaped into desired forms.

- Machining: Involves processes such as turning, milling, and drilling to achieve precise dimensions and surface finishes.

- Injection Molding: For plastic components, materials are heated and injected into molds to create complex shapes.

3. Assembly

The assembly phase combines the manufactured components into a final product. This may involve:

- Mechanical Assembly: Using fasteners, rivets, and bolts to join parts together.

- Automated Assembly: Employing robotic systems for high-volume production, ensuring precision and reducing human error.

- Manual Assembly: In some cases, skilled labor is necessary for intricate assemblies that require a high level of craftsmanship.

4. Finishing

The final stage of manufacturing includes processes that enhance the appearance and functionality of the products. Finishing techniques may involve:

- Coating: Application of protective layers such as paint, powder coating, or plating to improve corrosion resistance.

- Heat Treatment: Used to alter the physical properties of metals, enhancing strength and durability.

- Quality Inspection: Conducted at various points to ensure that each component meets specified standards.

Quality Assurance

Quality assurance is vital in maintaining product integrity and compliance with international standards. Below are the key elements of QC processes in creative assembly systems.

1. Relevant International Standards

To ensure quality, manufacturers often adhere to various international standards, including:

- ISO 9001: This standard focuses on quality management systems and is essential for organizations aiming to enhance customer satisfaction through effective processes.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for the oil and gas industry, these standards ensure that products meet rigorous safety and performance criteria.

2. Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during production to identify and rectify issues in real-time.

- Final Quality Control (FQC): Comprehensive testing and inspection of finished products before they are shipped to ensure they meet all specifications.

3. Common Testing Methods

Testing methods vary based on the component and industry requirements but typically include:

- Dimensional Inspection: Verifying that components meet specified dimensions and tolerances using tools like calipers and micrometers.

- Functional Testing: Assessing the performance of fasteners and assembly systems under simulated operating conditions.

- Destructive Testing: Conducting tests that lead to the failure of a component to determine its limits and safety factors.

Verifying Supplier Quality Control

International B2B buyers must adopt a proactive approach to verify supplier quality control practices. Here are actionable strategies:

- Conduct Audits: Regular audits of suppliers can reveal insights into their manufacturing processes and adherence to quality standards.

- Request Quality Reports: Suppliers should provide documentation of quality control measures, including test results and compliance certifications.

- Engage Third-Party Inspectors: Employing independent inspectors can provide an unbiased assessment of supplier practices and product quality.

Quality Control Nuances for International Buyers

Buyers from diverse regions should be aware of specific nuances in quality control that may impact their procurement decisions:

- Cultural Differences: Attitudes towards quality can vary significantly across regions; understanding these differences can aid in building stronger supplier relationships.

- Regulatory Compliance: Different regions may have unique regulatory requirements that affect product specifications and quality standards.

- Logistical Challenges: International shipping can introduce risks; therefore, ensuring that suppliers have robust QC processes in place can mitigate these risks.

In conclusion, understanding the manufacturing processes and quality assurance measures associated with creative assembly systems is crucial for international B2B buyers. By focusing on detailed material preparation, effective forming techniques, thorough assembly, and rigorous finishing processes, buyers can ensure they select suppliers who maintain high standards of quality and reliability.

Related Video: Mercedes C-Class CAR FACTORY – HOW IT’S MADE Assembly Production Line Manufacturing Making of

Comprehensive Cost and Pricing Analysis for creative assembly systems Sourcing

When sourcing creative assembly systems, understanding the comprehensive cost structure is crucial for international B2B buyers. This section delves into the key cost components, price influencers, and actionable buyer tips that can help optimize procurement strategies.

Cost Components

-

Materials: The cost of raw materials constitutes a significant portion of the overall expense. Prices can fluctuate based on global market conditions, availability, and quality. Buyers should consider sourcing from suppliers who offer a diverse range of materials to mitigate risks associated with price volatility.

-

Labor: Labor costs vary widely depending on the geographic location of manufacturing facilities. Regions like Africa and South America may present lower labor costs, but it’s essential to assess the skill level and training of the workforce to ensure product quality.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility management. Efficient manufacturers will have optimized processes that can reduce overhead costs, translating to lower prices for buyers.

-

Tooling: The initial investment in tooling can be substantial, especially for customized assembly systems. Buyers should inquire about tooling costs and explore options for shared tooling to reduce upfront expenses.

-

Quality Control (QC): Implementing robust QC measures is critical in ensuring the reliability of assembly systems. Although this incurs additional costs, it can prevent costly defects and returns in the long run.

-

Logistics: Transportation and warehousing costs significantly impact the final price. Buyers should consider the total shipping distance, mode of transport, and any potential tariffs or duties when evaluating logistics expenses.

-

Margin: Supplier margins vary based on market positioning and competitiveness. Understanding a supplier’s pricing strategy can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: Larger order volumes often lead to discounts. Establishing a minimum order quantity (MOQ) can benefit both buyers and suppliers, fostering a long-term relationship.

-

Specifications/Customization: Custom solutions typically incur higher costs due to the additional engineering and development required. Buyers should weigh the benefits of customization against its impact on pricing.

-

Materials and Quality/Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but also enhance product reliability. Buyers should assess whether the additional expense aligns with their quality requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to perceived quality, while emerging suppliers may offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect pricing and responsibilities in shipping.

Buyer Tips

-

Negotiation: Effective negotiation can lead to better pricing. Buyers should prepare by understanding market prices and the supplier’s cost structure to create a compelling case for lower rates.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A lower purchase price may not always lead to overall savings if operational costs are high.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and their potential impact on pricing. Establishing contracts in stable currencies can mitigate risks.

-

Local Market Conditions: Buyers from regions like Africa and South America should consider local market dynamics, such as demand and supply constraints, which can influence costs and availability.

In conclusion, a comprehensive understanding of cost structures and pricing dynamics is essential for international B2B buyers of creative assembly systems. By leveraging this knowledge and following the outlined tips, buyers can enhance their procurement strategies and optimize their sourcing decisions. Always remember that indicative prices can vary widely based on specific circumstances, so conducting thorough market research is crucial before finalizing any agreements.

Spotlight on Potential creative assembly systems Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘creative assembly systems’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for creative assembly systems

Key Technical Properties of Creative Assembly Systems

Understanding the essential technical properties of creative assembly systems is crucial for international B2B buyers to make informed purchasing decisions. Here are several critical specifications that should be considered:

-

Material Grade

Material grade refers to the classification of materials based on their mechanical properties, such as strength and durability. For instance, steel fasteners may have grades like ASTM A325 or A490, which indicate their tensile strength and suitability for specific applications. Buyers should prioritize high-grade materials to ensure reliability and longevity in their assembly systems, particularly in demanding environments. -

Tolerance

Tolerance defines the permissible limit of variation in a physical dimension of a part. In the context of assembly systems, tight tolerances ensure that components fit together correctly, which is vital for maintaining the integrity and performance of the final product. For instance, a tolerance of ±0.01 mm might be critical in high-precision applications, while looser tolerances may suffice for less critical uses. -

Pulling Force

This specification measures the maximum force that a tool can exert to secure fasteners, such as rivets or lockbolts. For example, tools like the Big Blue series can exert pulling forces of up to 3,800 lbs. Understanding pulling force is essential for buyers to match the right tools with their assembly requirements, ensuring efficiency and safety during operation. -

Operating Pressure

This refers to the air pressure required for pneumatic tools to function optimally, typically measured in psi (pounds per square inch). For example, many rivet tools operate effectively within a range of 85-100 psi. Buyers must ensure their air supply systems can meet these requirements to avoid operational inefficiencies or equipment failures. -

Weight

The weight of tools and equipment can significantly impact operator fatigue and overall productivity. Lightweight tools, such as the Power Micro rivet tool, which weighs only 2.4 lbs, can facilitate easier handling and reduce worker strain. Buyers should consider the weight of tools in relation to their use-case scenarios, especially for high-volume production environments. -

Durability Rating

Durability ratings indicate how well a tool or component can withstand wear, pressure, and impact. Buyers should look for tools with robust construction, such as those made from forged aluminum or high-quality alloys, to ensure they can withstand rigorous operational demands over time.

Common Trade Terminology

Familiarizing oneself with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some commonly used terms in the creative assembly systems market:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure they are sourcing genuine parts that meet quality and compatibility standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory costs and avoid overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on specific products or services. It typically includes detailed specifications, quantities, and terms. Buyers should prepare comprehensive RFQs to receive accurate and competitive pricing. -

Incoterms

International Commercial Terms (Incoterms) are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and customs duties. Understanding Incoterms can help buyers mitigate risks and avoid misunderstandings in cross-border trade. -

Lead Time

Lead time is the amount of time that elapses from placing an order to receiving it. Buyers should consider lead times when planning production schedules to avoid delays that could impact their operations. -

Supply Chain Management (SCM)

SCM involves overseeing and managing the flow of goods, information, and finances as products move from origin to consumption. Effective SCM can enhance efficiency, reduce costs, and improve customer satisfaction, making it a critical focus area for B2B buyers in the creative assembly systems sector.

By understanding these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing creative assembly systems more effectively, ensuring they meet their operational needs while optimizing costs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the creative assembly systems Sector

Market Overview & Key Trends

The creative assembly systems sector is currently experiencing dynamic shifts driven by various global factors. The rise in automation and advanced manufacturing technologies is reshaping sourcing trends, particularly in regions such as Africa, South America, the Middle East, and Europe. B2B buyers are increasingly leveraging Industry 4.0 technologies, which include IoT, AI, and machine learning, to enhance production efficiency and reduce downtime. This trend is essential for businesses looking to streamline their operations and improve their competitive edge.

Moreover, the demand for customization and flexibility in assembly systems is on the rise. Buyers are increasingly seeking suppliers who can offer tailored solutions that meet specific manufacturing requirements. This trend is particularly prevalent in the automotive and heavy-duty industries, where the need for bespoke fasteners and assembly tools is critical. Additionally, international buyers are focusing on establishing long-term relationships with suppliers who can provide comprehensive support, including logistics and inventory management, to optimize their supply chains.

In regions like Africa and South America, emerging markets are seeing a surge in infrastructure development, which further drives the demand for creative assembly systems. B2B buyers in these areas should be aware of the local regulatory frameworks and market entry barriers, which may affect sourcing decisions. Overall, understanding these market dynamics and sourcing trends is crucial for international buyers to navigate the evolving landscape effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal concern in the creative assembly systems sector, influencing sourcing decisions across the globe. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmentally friendly practices. This includes the use of sustainable materials, reduction of waste, and adherence to ethical sourcing standards. Buyers are encouraged to seek out suppliers who provide certifications such as ISO 14001, which indicates a commitment to environmental management.

The environmental impact of fasteners and assembly tools is significant, particularly in terms of energy consumption and material waste during production. Buyers should consider suppliers that implement ‘green’ manufacturing processes, such as using recycled materials or reducing emissions in their production lines. Moreover, ethical supply chains are essential to ensure that labor practices meet international standards, thereby mitigating risks associated with human rights violations.

As global awareness of sustainability continues to grow, B2B buyers must align their procurement strategies with sustainable practices. This not only helps to enhance brand reputation but also meets the increasing consumer demand for responsible sourcing. Implementing sustainability measures can lead to long-term cost savings and operational efficiencies, making it a worthwhile investment for businesses in the creative assembly systems sector.

Brief Evolution/History

The creative assembly systems sector has evolved significantly over the past few decades, transitioning from traditional assembly methods to advanced automated solutions. Initially focused on basic fasteners and manual tools, the industry has witnessed a surge in innovation driven by technological advancements. The introduction of pneumatic and hydraulic tools has revolutionized the way assembly tasks are performed, enhancing efficiency and precision.

As manufacturing processes have become more complex, the demand for specialized fasteners and assembly systems has increased. This evolution has been further accelerated by globalization, enabling international collaboration and sourcing of innovative solutions. Today, the sector is characterized by a focus on customization, sustainability, and the integration of cutting-edge technologies, which collectively shape the future of creative assembly systems.

Related Video: Global Trends Chapter 2 | Part 1 | Video Posted!

Frequently Asked Questions (FAQs) for B2B Buyers of creative assembly systems

-

What criteria should I use to vet suppliers of creative assembly systems?

When vetting suppliers, focus on their industry experience, product quality, and customer service reputation. Request references from previous clients and verify their financial stability. Additionally, assess their certifications and compliance with international standards, such as ISO or ASTM. Conduct site visits if possible, and inquire about their supply chain practices to ensure reliability. Consider their ability to provide customization and support for your specific needs, which is crucial for maintaining efficiency in your operations. -

Can I customize creative assembly systems to fit my specific requirements?

Many suppliers offer customization options for creative assembly systems to meet unique project specifications. Discuss your requirements early in the procurement process, including dimensions, materials, and functionality. Ensure that the supplier has the capability to produce bespoke solutions and inquire about any additional costs or lead times associated with customization. Document all agreed-upon specifications to avoid misunderstandings and ensure that the final product aligns with your expectations. -

What are the typical minimum order quantities (MOQs) and lead times for these systems?

Minimum order quantities can vary significantly among suppliers, often depending on the complexity and customization of the assembly systems. Standard MOQs may range from a few dozen to several hundred units. Lead times typically range from 4 to 12 weeks, depending on the supplier’s production capacity and your order size. To optimize your procurement process, discuss your needs upfront and explore options for bulk purchasing or scheduling regular deliveries to manage inventory effectively. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can differ based on the supplier’s policies and your negotiation outcomes. Common arrangements include upfront payments, partial payments with the balance upon delivery, or net terms ranging from 30 to 90 days. Consider using secure payment methods, such as letters of credit or escrow services, especially for large transactions. Ensure that all payment terms are clearly outlined in your purchase agreement to prevent disputes later on. -

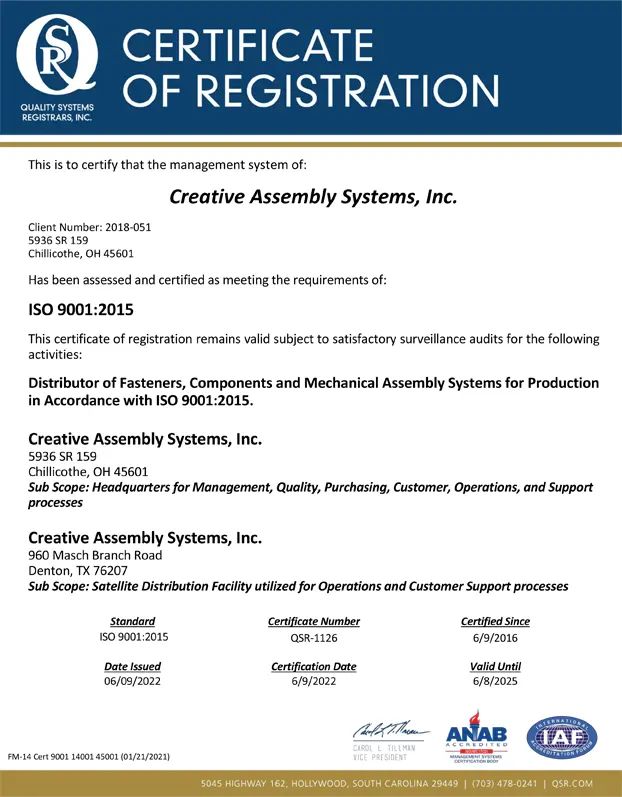

How can I ensure quality assurance and compliance with certifications?

Request detailed information about the supplier’s quality assurance processes, including any certifications they hold, such as ISO 9001. Ask for documentation that demonstrates compliance with industry standards and regulations relevant to your market. Establish a quality control plan that includes product inspections and testing protocols at various stages of production. Regular communication with the supplier and the option for third-party inspections can further enhance quality assurance. -

What logistics considerations should I keep in mind when sourcing internationally?

Logistics play a critical role in international sourcing. Consider factors such as shipping methods, customs regulations, and import duties that may impact delivery timelines and costs. Choose a supplier with experience in handling international shipments and ask about their logistics partners. It may be beneficial to work with a freight forwarder who can navigate the complexities of customs clearance and provide reliable shipping options tailored to your needs. -

How can I resolve disputes with international suppliers effectively?

To manage disputes effectively, establish clear communication channels and document all agreements in writing. Include clauses in your contracts regarding dispute resolution methods, such as mediation or arbitration, to streamline the process. If issues arise, address them promptly and professionally, aiming for a mutually beneficial solution. Involve legal counsel if necessary, especially if the dispute escalates or if significant financial interests are at stake. -

What are the best practices for maintaining long-term relationships with suppliers?

Building strong relationships with suppliers requires consistent communication, transparency, and mutual respect. Provide feedback on products and services, and engage in regular performance reviews to discuss areas for improvement. Consider collaborative initiatives, such as joint product development or supply chain optimization efforts, to foster partnership. Recognizing and rewarding supplier performance can also enhance loyalty and encourage them to prioritize your needs in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for creative assembly systems

Strategic sourcing is essential for optimizing procurement processes, especially for international B2B buyers engaged with creative assembly systems. By leveraging strategic sourcing, businesses can enhance cost efficiency, improve supplier relationships, and streamline operations. The growing demand for high-quality fasteners and assembly tools underscores the importance of selecting reliable partners who can provide not only the products but also support services that boost productivity.

Illustrative Image (Source: Google Search)

For buyers in Africa, South America, the Middle East, and Europe, the strategic sourcing of creative assembly systems can lead to significant competitive advantages. Key takeaways include understanding the diverse product offerings, such as Rivet Nut tools and Lockbolt installation systems, and recognizing the importance of quality assurance and after-sales support. Investing in advanced tools that enhance production capabilities will ultimately lead to better assembly integrity and lower operational risks.

As markets continue to evolve, international B2B buyers are encouraged to adopt a proactive approach in sourcing creative assembly systems. By doing so, they can not only meet current demands but also anticipate future needs, ensuring sustainable growth in an increasingly competitive landscape. Start evaluating your sourcing strategy today to unlock the potential of your assembly operations.