Your Ultimate Guide to Sourcing Dc Electric Engine

Introduction: Navigating the Global Market for dc electric engine

In the ever-evolving landscape of industrial technology, the DC electric engine stands out as a pivotal component that drives efficiency and innovation across various sectors. From powering manufacturing equipment to facilitating electric vehicles, these engines are integral to modern operations. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of DC electric engines is crucial for making informed sourcing decisions that can significantly impact performance and profitability.

This comprehensive guide delves into the critical aspects of DC electric engines, offering insights into various motor types, essential materials, manufacturing processes, and quality control standards. It also addresses key considerations for selecting reliable suppliers, analyzing cost factors, and identifying market trends. By providing actionable information and practical tips, this guide empowers businesses to navigate the global marketplace effectively.

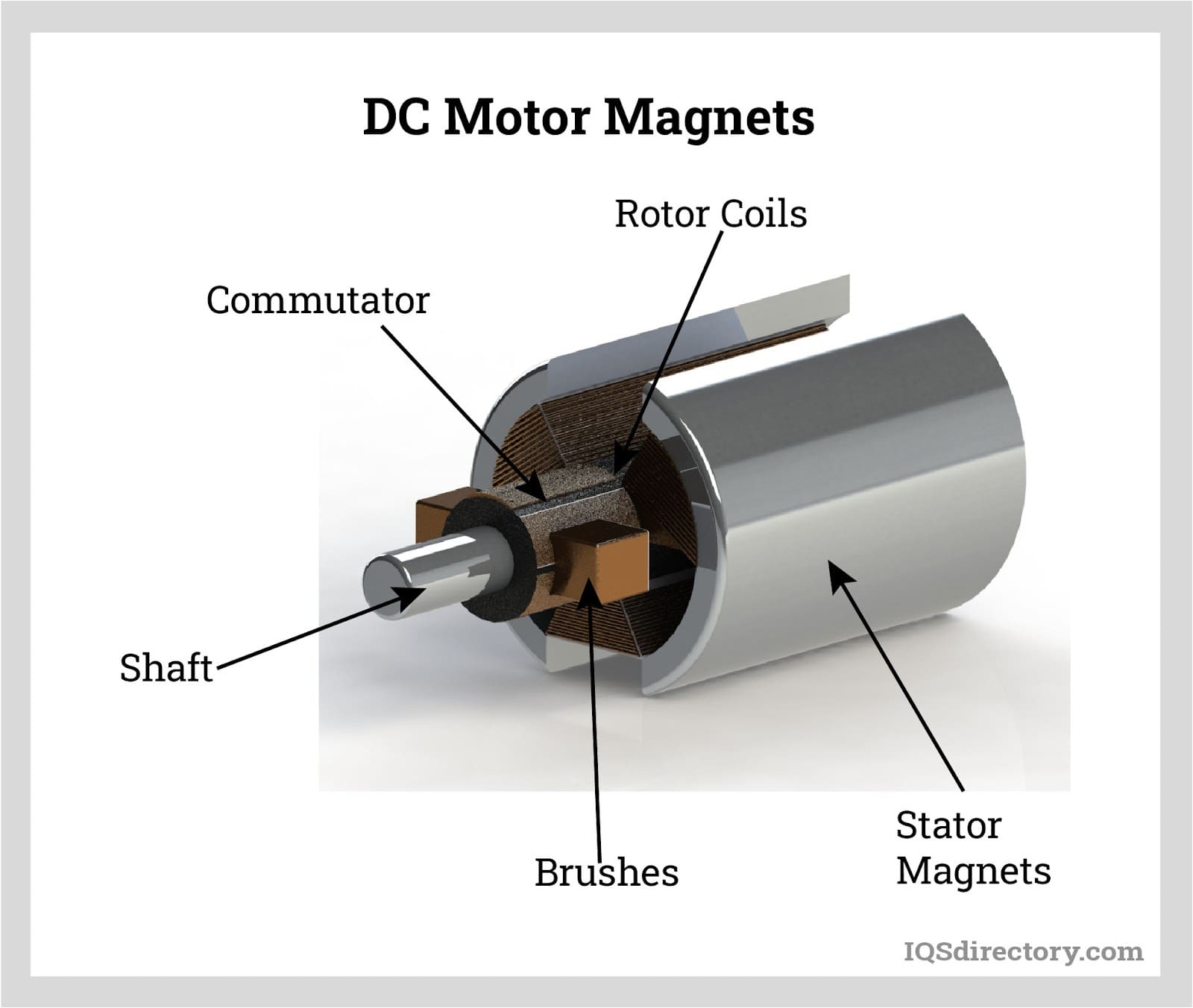

Illustrative Image (Source: Google Search)

As buyers from diverse regions seek to optimize their procurement strategies, this resource serves as an invaluable tool. It not only enhances operational capabilities but also fosters sustainable practices that align with contemporary business demands. By leveraging the insights presented here, you can ensure that your sourcing decisions are not only strategic but also contribute to a competitive edge in your respective markets.

Understanding dc electric engine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Brushed DC Motor | Utilizes brushes and commutators for current delivery | Automotive, small appliances | Pros: Simple control, cost-effective; Cons: Requires maintenance, generates noise. |

| Brushless DC Motor | No brushes, offering higher efficiency and longevity | Drones, electric vehicles | Pros: Low maintenance, high efficiency; Cons: Higher initial cost, complex controllers. |

| Step-Up DC Motor | Increases voltage while maintaining current flow | Battery chargers, power supplies | Pros: Efficient voltage regulation; Cons: May require additional components for operation. |

| Step-Down DC Motor | Decreases voltage while maintaining current flow | LED lighting, electronic devices | Pros: Ideal for low-voltage applications; Cons: Limited output current. |

| Permanent Magnet DC Motor | Uses permanent magnets for rotor magnetism | Robotics, conveyor systems | Pros: High efficiency, compact size; Cons: More expensive, limited to lower power applications. |

Brushed DC Motor

Brushed DC motors are popular for their straightforward design, which includes brushes and commutators to deliver current. This simplicity makes them cost-effective and easy to control, making them suitable for automotive applications and small appliances. However, B2B buyers should consider the maintenance required due to brush wear and the noise generated during operation. When sourcing, evaluate the expected lifespan and maintenance costs to ensure alignment with operational budgets.

Brushless DC Motor

Brushless DC motors eliminate the need for brushes, resulting in greater efficiency and lower maintenance requirements. They are increasingly used in high-tech applications such as drones and electric vehicles. While they offer significant advantages in terms of longevity and performance, the initial investment can be higher, and the integration of complex controllers may pose challenges. B2B buyers should assess the total cost of ownership, including potential savings on maintenance, when considering this motor type.

Step-Up DC Motor

Step-up DC motors are designed to increase voltage while maintaining current flow, making them ideal for applications such as battery chargers and power supplies. Their efficiency in voltage regulation is a key selling point. However, these motors may require additional components for optimal operation, which could affect overall system costs. Buyers should carefully evaluate their voltage requirements and the compatibility of these motors with existing systems before making a purchase.

Step-Down DC Motor

Step-down DC motors are utilized to decrease voltage while maintaining current flow, commonly found in LED lighting and various electronic devices. They are particularly suitable for low-voltage applications but have limitations in output current. B2B buyers should consider the specific voltage requirements of their applications and ensure that the motor’s capabilities align with their needs. Understanding the balance between performance and cost is essential when sourcing these motors.

Permanent Magnet DC Motor

Permanent magnet DC motors leverage permanent magnets for rotor magnetism, providing high efficiency and compact design. They are well-suited for robotics and conveyor systems due to their effective performance in low-power applications. However, their higher cost and limitations in power output may be a concern for some buyers. When evaluating these motors, businesses should consider the trade-off between efficiency and upfront investment to ensure they meet their operational needs effectively.

Related Video: How does an Electric Motor work? DC Motor explained

Key Industrial Applications of dc electric engine

| Industry/Sector | Specific Application of dc electric engine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric vehicles (EVs) | Enhanced efficiency and lower emissions | Supplier reliability, battery compatibility, local regulations |

| Aerospace | Actuation systems in drones | Precision control and lightweight design | Compliance with aviation standards, weight considerations, durability |

| Manufacturing | Conveyor systems | Increased automation and productivity | Motor torque specifications, maintenance support, energy efficiency |

| Agriculture | Irrigation systems | Resource efficiency and operational savings | Water resistance, power supply needs, local sourcing options |

| Renewable Energy | Solar tracking systems | Maximized energy capture and sustainability | Integration with solar panels, environmental durability, cost-effectiveness |

Automotive

DC electric engines are pivotal in the automotive sector, particularly in electric vehicles (EVs). They provide a reliable power source that enables smooth acceleration and energy efficiency, significantly reducing greenhouse gas emissions compared to traditional combustion engines. International buyers, especially from regions like South Africa and Brazil, should consider battery compatibility and supplier reliability, as local regulations may impact sourcing decisions. Ensuring that the engine meets the specific torque and power requirements of the vehicle is also crucial for performance and safety.

Aerospace

In the aerospace industry, DC electric engines are utilized in actuation systems for drones and other unmanned aerial vehicles. These engines offer precise control and lightweight designs, which are critical for flight performance and efficiency. Buyers from the Middle East and Europe must prioritize compliance with aviation standards, as well as the durability of components due to the challenging operational environments. Additionally, weight considerations play a significant role in the selection process, as reducing weight can enhance flight range and payload capacity.

Manufacturing

Manufacturing facilities leverage DC electric engines in automated conveyor systems, enhancing operational efficiency and productivity. By integrating these motors, businesses can achieve smoother operation and reduced downtime due to fewer mechanical failures. Buyers in Africa and South America should focus on sourcing motors that meet specific torque requirements for their applications, as well as ensuring robust maintenance support from suppliers. Energy efficiency is also a key consideration, given the rising costs of electricity and the push for sustainable operations.

Agriculture

In agriculture, DC electric engines are essential for driving irrigation systems, allowing farmers to optimize water usage and reduce operational costs. These engines can be integrated into various irrigation technologies, enabling precision farming practices that improve crop yields while conserving resources. Buyers should consider the water resistance of the motors and their power supply needs, particularly in regions with variable climates. Local sourcing options can also enhance supply chain resilience, ensuring timely access to replacement parts and maintenance services.

Renewable Energy

DC electric engines play a crucial role in solar tracking systems, which adjust the angle of solar panels to maximize energy capture throughout the day. This technology is vital for enhancing the efficiency of solar energy systems, making them more viable as a sustainable energy source. International buyers should focus on the integration capabilities of these motors with existing solar panel technologies, as well as their durability in harsh environmental conditions. Cost-effectiveness is also a significant factor, as businesses seek to maximize return on investment in renewable energy initiatives.

Related Video: How does an Electric Motor work? (DC Motor)

Strategic Material Selection Guide for dc electric engine

When selecting materials for DC electric engines, it is crucial to consider properties that directly impact performance, durability, and overall application suitability. Here, we analyze four common materials used in the construction of DC electric engines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and corrosion resistance. It operates effectively in a wide temperature range, making it suitable for various environmental conditions.

Pros & Cons: The primary advantage of copper is its high conductivity, which leads to improved efficiency in electric engines. However, copper is relatively expensive compared to other materials and can be prone to oxidation if not properly coated.

Impact on Application: Copper is ideal for windings and connectors in DC electric engines due to its superior electrical properties. However, it may not be suitable for environments with extreme corrosion unless adequately protected.

Considerations for Buyers: International buyers should ensure compliance with standards such as ASTM B170 for copper wire and consider the availability of copper in their region, as fluctuations in market prices can impact overall costs.

Aluminum

Key Properties: Aluminum is lightweight, has good electrical conductivity (though not as high as copper), and offers excellent corrosion resistance, especially when anodized.

Pros & Cons: The lightweight nature of aluminum makes it an attractive option for applications where weight reduction is critical. However, its lower conductivity compared to copper can lead to increased energy loss in some applications.

Impact on Application: Aluminum is often used in the housing and structural components of DC electric engines, where weight savings can enhance performance. It is particularly effective in environments where corrosion resistance is essential.

Considerations for Buyers: Buyers should be aware of the relevant standards, such as ASTM B221 for aluminum extrusions, and ensure that the suppliers can provide materials that meet these specifications.

Steel

Key Properties: Steel is known for its high strength, durability, and ability to withstand high temperatures and pressures. It is also magnetic, which can be advantageous in certain motor applications.

Pros & Cons: The strength of steel makes it suitable for structural components, but it is heavier than aluminum or copper. Additionally, steel can be susceptible to rust and corrosion unless treated or coated.

Impact on Application: Steel is commonly used for the frames and casings of DC electric engines, providing necessary structural integrity. However, its weight may affect the overall efficiency of lightweight applications.

Considerations for Buyers: Buyers must ensure that steel components meet international standards, such as DIN 17100 or JIS G3101, and consider the implications of weight on their specific applications.

Plastic Composites

Key Properties: Plastic composites offer excellent insulation properties, are lightweight, and can be molded into complex shapes. They are resistant to many chemicals and moisture.

Pros & Cons: The primary advantage of plastic composites is their insulation capabilities, which enhance safety in electric engines. However, they may not withstand high temperatures as effectively as metals, and their mechanical strength can be lower.

Impact on Application: Plastic composites are often used for insulating components and housings in DC electric engines, making them suitable for applications where electrical insulation is critical.

Considerations for Buyers: Buyers should ensure that the composites meet relevant safety and performance standards, such as UL 94 for flammability, and consider the environmental impact of plastic materials in their sourcing decisions.

| Material | Typical Use Case for dc electric engine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings and connectors | High electrical conductivity | Expensive and prone to oxidation | High |

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Steel | Frames and casings | High strength and durability | Heavy and susceptible to corrosion | Medium |

| Plastic Composites | Insulating components and housings | Excellent insulation properties | Lower mechanical strength and heat resistance | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for dc electric engine

The manufacturing process for DC electric engines involves several critical stages, each designed to ensure high quality and performance standards. International B2B buyers should be familiar with these processes and the associated quality control measures to make informed sourcing decisions.

Manufacturing Process

1. Material Preparation

– Selection of Materials: The first step involves selecting high-quality materials such as copper for windings, silicon steel for laminations, and various alloys for the rotor and stator components. The choice of materials directly impacts the engine’s efficiency and longevity.

– Material Inspection: Incoming materials undergo rigorous inspection to ensure compliance with specified standards. This includes checking for purity, dimensions, and mechanical properties to avoid defects in the final product.

2. Forming

– Machining: Components are shaped using precision machining techniques. This may involve CNC (Computer Numerical Control) milling and turning, which ensure that parts are manufactured to exact specifications.

– Winding: The winding process is critical for the efficiency of DC motors. It involves wrapping copper wire around the rotor and stator to create magnetic fields. Automated winding machines are often used to enhance precision and reduce labor costs.

3. Assembly

– Component Assembly: After forming, the components are assembled. This typically involves placing the rotor within the stator, securing windings, and installing brushes and commutators. Each assembly stage is conducted under strict supervision to maintain quality.

– Integration of Electronics: Modern DC engines may incorporate electronic controllers or drives. This integration requires specialized knowledge to ensure compatibility and optimal performance.

4. Finishing

– Coating and Treatment: Components may undergo surface treatments such as coating or anodizing to enhance corrosion resistance and improve aesthetic appeal. This step is vital for ensuring the durability of the motor in various operating environments.

– Final Assembly and Testing: The final assembly includes all electronic components and additional features like sensors. Once assembled, the motor undergoes rigorous testing to confirm operational efficiency.

Quality Assurance

Implementing robust quality assurance processes is essential for ensuring that DC electric engines meet international standards and customer expectations.

International Standards

– ISO 9001: This quality management system standard ensures that manufacturers maintain consistent quality in their processes. Compliance with ISO 9001 indicates a commitment to continuous improvement and customer satisfaction.

– CE Marking: For products sold in the European Union, obtaining CE marking is crucial as it signifies conformity with health, safety, and environmental protection standards.

– API Certification: For motors used in the petroleum and natural gas industry, API certification ensures that products meet specific standards for performance and safety.

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they enter the manufacturing process. It helps prevent defects from the outset.

– In-Process Quality Control (IPQC): During manufacturing, real-time checks are performed at various stages to monitor compliance with specifications. This may include dimensional checks, visual inspections, and functional tests.

– Final Quality Control (FQC): Once assembly is complete, the final product undergoes comprehensive testing to verify performance under load, efficiency, and safety. This stage may involve simulated operational conditions.

Common Testing Methods

– Electrical Testing: This includes insulation resistance tests, winding resistance tests, and performance tests under load to ensure the motor operates within specified parameters.

– Thermal Testing: Evaluating the motor’s thermal performance under different operating conditions helps assess heat dissipation and the effectiveness of cooling mechanisms.

– Vibration Analysis: This method identifies potential mechanical issues by analyzing vibration patterns during operation. Unusual vibrations can indicate misalignment or imbalance.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers should take proactive steps:

- Supplier Audits: Conducting audits of potential suppliers helps verify their manufacturing processes, quality control measures, and compliance with international standards. It also allows buyers to assess the supplier’s capabilities firsthand.

- Requesting Quality Reports: Buyers should ask for detailed quality control reports, including results from IQC, IPQC, and FQC stages. This documentation provides transparency into the supplier’s quality management practices.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. This is particularly useful for international transactions where buyers may not have direct access to the supplier’s facilities.

Considerations for International B2B Buyers

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must navigate various challenges when sourcing DC electric engines:

- Cultural and Regulatory Differences: Understanding local regulations, import/export requirements, and cultural nuances can significantly impact sourcing decisions. Buyers should ensure that suppliers are compliant with both local and international standards.

- Logistics and Supply Chain Management: Efficient logistics are crucial, especially for buyers in remote locations. Establishing clear communication channels with suppliers can help mitigate delays and ensure timely deliveries.

- Long-Term Relationships: Building strong relationships with suppliers fosters trust and reliability. Regular communication, feedback, and collaboration on quality improvements can lead to better product outcomes and shared success.

By understanding the manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their specific needs for DC electric engines.

Related Video: Electric Cars Motors Production – Electric ENGINE – EV Motor Factory PRODUCTION Assembly Line

Comprehensive Cost and Pricing Analysis for dc electric engine Sourcing

When sourcing DC electric engines, understanding the comprehensive cost structure is crucial for international B2B buyers. This involves dissecting the various components that contribute to the overall pricing, as well as recognizing factors that can influence these costs.

Cost Structure Components

-

Materials: The cost of raw materials is a significant part of the total price. Common materials for DC electric engines include copper (for windings), steel (for the core), and various plastics. Prices of these materials can fluctuate based on global supply and demand, impacting overall costs.

-

Labor: Labor costs vary widely depending on the region where the engine is manufactured. Countries with lower labor costs may offer competitive pricing, but this can also lead to variability in quality. It’s essential to assess the balance between cost and craftsmanship.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment depreciation, and administrative costs. Overhead can be a significant factor, especially for suppliers in regions with higher operational costs.

-

Tooling: Custom tooling for specific engine designs can add to the initial costs. Buyers should consider whether the investment in tooling will yield long-term savings through reduced unit costs.

-

Quality Control (QC): Ensuring that engines meet quality standards often requires additional resources for testing and inspections. Certifications like ISO 9001 can enhance credibility but may also affect pricing due to the costs associated with maintaining these standards.

-

Logistics: Shipping costs, including freight, insurance, and tariffs, play a crucial role in the total cost structure. Buyers should account for these expenses, especially when sourcing from overseas suppliers.

-

Margin: Supplier margins can vary based on market conditions and competition. Understanding the expected margin can help buyers gauge whether a quote is reasonable.

Price Influencers

Several factors influence the pricing of DC electric engines, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Negotiating better rates for larger orders can significantly reduce overall expenditure.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should assess whether the additional features justify the price increase.

-

Materials and Quality Certifications: Engines made with higher quality materials or those that have undergone rigorous testing may command higher prices. Certifications can also imply a quality assurance that may be worth the investment.

-

Supplier Factors: The reputation, reliability, and geographic location of the supplier can impact pricing. Suppliers with a strong track record may charge a premium, but their reliability can save costs in the long run.

-

Incoterms: The chosen Incoterms can affect the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost assessments.

Buyer Tips

-

Negotiation: Always be prepared to negotiate terms and pricing. Having a clear understanding of your needs and the market can empower you during discussions.

-

Cost-Efficiency: Consider the total cost of ownership (TCO), which includes not just purchase price but also operational, maintenance, and disposal costs. Selecting a slightly more expensive engine that is more efficient can result in lower operational costs.

-

Pricing Nuances: Be aware that prices may vary significantly based on geographic location. Buyers from Africa, South America, the Middle East, and Europe should factor in local economic conditions and currency fluctuations when evaluating offers.

-

Disclaimer for Indicative Prices: Always treat indicative prices as a starting point. Final quotes can vary based on real-time material costs, labor rates, and other external factors.

By understanding these components and influencers, buyers can make informed decisions that align with their budgetary constraints while ensuring quality and performance in their DC electric engine sourcing.

Spotlight on Potential dc electric engine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dc electric engine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dc electric engine

Key Technical Properties of DC Electric Engines

Understanding the essential technical properties of DC electric engines is crucial for B2B buyers to ensure the selected motors meet operational requirements. Here are several critical specifications to consider:

-

Voltage Rating

– Definition: The voltage at which the motor operates efficiently.

– Importance: Selecting the correct voltage rating is vital for compatibility with existing electrical systems. A mismatch can lead to inefficiency, overheating, or complete failure of the motor. -

Current Draw

– Definition: The amount of current the motor draws during operation.

– Importance: Understanding the current draw helps buyers assess the electrical load on their systems. It also influences the choice of circuit protection and wiring, ensuring safety and performance.

Illustrative Image (Source: Google Search)

-

Torque Rating

– Definition: The rotational force the motor can generate, typically measured in Newton-meters (Nm).

– Importance: Torque ratings are critical in applications requiring specific force output. Buyers must match torque specifications to the operational demands of their machinery to avoid performance issues. -

Speed Rating

– Definition: The rotational speed of the motor, usually expressed in revolutions per minute (RPM).

– Importance: Different applications require different speed outputs. Buyers need to select a motor with a speed rating that aligns with their operational needs to ensure optimal performance. -

Efficiency Rating

– Definition: The ratio of useful power output to the total power input, often expressed as a percentage.

– Importance: Higher efficiency ratings lead to lower energy costs and reduced environmental impact. Buyers should prioritize motors that offer high efficiency to improve sustainability and reduce operational expenses. -

Duty Cycle

– Definition: The duration the motor can operate continuously without overheating.

– Importance: Understanding the duty cycle helps buyers choose a motor that can handle their specific workload without risk of damage, ensuring reliability and longevity in operations.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B sector. Below are several common terms related to DC electric engines:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Buyers often seek OEM components for quality assurance and compatibility with existing systems. Understanding OEM relationships can facilitate sourcing decisions. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for buyers to manage inventory costs and ensure that their purchasing aligns with operational needs. It can influence negotiations and supplier selection. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and other terms for specific products or services.

– Importance: An RFQ allows buyers to compare prices and terms from multiple suppliers, enabling informed decision-making. It is a critical step in the procurement process. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers for the delivery of goods.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks. This knowledge is essential for negotiating contracts and ensuring clarity in international transactions. -

Lead Time

– Definition: The time it takes from placing an order to delivery.

– Importance: Understanding lead times is vital for planning and inventory management. Buyers must account for lead times when scheduling production to avoid delays. -

Tolerances

– Definition: The permissible limit or limits of variation in a physical dimension of a component.

– Importance: Knowledge of tolerances is essential for ensuring that parts fit and function as intended. Buyers need to specify tolerances to maintain quality control in their operations.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing DC electric engines, ensuring they meet both operational and budgetary requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dc electric engine Sector

Market Overview & Key Trends

The global market for DC electric engines is experiencing robust growth, driven by several key factors. Increasing demand for energy-efficient solutions across various industries, such as automotive, aerospace, and manufacturing, is propelling the adoption of DC motors. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate this landscape, they should pay close attention to emerging technologies like Internet of Things (IoT) integration and advanced automation. These technologies enhance the efficiency and performance of DC electric engines, making them increasingly attractive for modern applications.

Another significant trend is the shift towards electrification in transportation, particularly in electric vehicles (EVs). Countries in Europe and regions in South America are investing heavily in EV infrastructure, creating a surge in demand for high-performance DC motors. Additionally, the rise of renewable energy sources, such as solar and wind, is driving the need for efficient motor solutions in energy conversion systems. Buyers should also note the importance of local sourcing as supply chain resilience becomes a priority in a post-pandemic world. Establishing relationships with local suppliers not only reduces lead times but also mitigates risks associated with international shipping.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a trend; it is a critical business imperative. For B2B buyers in the DC electric engine sector, understanding the environmental impact of sourcing decisions is essential. The production and disposal of electric motors can generate significant waste and emissions. Therefore, companies must prioritize suppliers who adhere to sustainable practices, such as using recycled materials and minimizing energy consumption during manufacturing.

Moreover, ethical sourcing is gaining traction as buyers increasingly demand transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) can help buyers identify suppliers committed to sustainable practices. Utilizing materials with “green” certifications, such as RoHS (Restriction of Hazardous Substances), ensures that the components used in DC electric engines are environmentally friendly and safe. By aligning sourcing strategies with sustainability goals, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

Brief Evolution/History

The evolution of DC electric engines dates back to the late 19th century, with Thomas Edison and Nikola Tesla playing pivotal roles in their development. Initially used in industrial applications, these motors have undergone significant advancements over the years. The introduction of brushless technology in the late 20th century improved efficiency and reduced maintenance needs, making DC motors suitable for a broader range of applications, including robotics and electric vehicles. Today, the focus is on integrating smart technology and enhancing energy efficiency, positioning DC electric engines at the forefront of modern manufacturing and transportation solutions. Understanding this historical context allows B2B buyers to appreciate the technological advancements that can influence their purchasing decisions and operational strategies.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of dc electric engine

-

What factors should I consider when vetting suppliers of DC electric engines?

When vetting suppliers, prioritize their reputation, production capabilities, and quality certifications (e.g., ISO 9001). Verify their experience in your specific industry and request client references. Additionally, assess their capacity to meet your volume demands and delivery schedules. Engage in discussions about their manufacturing processes and quality control measures to ensure they align with your standards. -

Can I customize my DC electric engine order?

Many suppliers offer customization options based on your specific application needs. Customization may include modifications in size, power ratings, or operational features. Discuss your requirements with potential suppliers early in the negotiation process to understand their capabilities. Ensure that they have the technical expertise and resources to accommodate your customization requests without significantly increasing lead times. -

What are the typical minimum order quantities (MOQ) and lead times for DC electric engines?

MOQs can vary significantly depending on the supplier, the complexity of the engines, and your specific requirements. Generally, MOQs can range from a few units to hundreds. Lead times also depend on factors such as customization, supplier location, and production schedules, typically ranging from a few weeks to several months. Always clarify these terms upfront to align your procurement timelines with your operational needs. -

What quality assurance measures and certifications should I look for?

Essential quality assurance measures include adherence to international standards such as ISO 9001 and IEC standards. Request documentation that verifies these certifications and inquire about the supplier’s testing protocols for their DC electric engines. Additionally, consider suppliers who offer warranties and after-sales support, which can be indicative of their commitment to quality. -

How should I handle logistics and shipping when sourcing DC electric engines internationally?

When sourcing internationally, work closely with suppliers to determine the best shipping methods and terms (e.g., FOB, CIF). Consider the total landed cost, including shipping, duties, and taxes. It’s crucial to collaborate with experienced logistics providers who understand the regulations of your importing country. Establish clear communication with your supplier regarding packaging and documentation to avoid delays. -

What steps can I take to resolve disputes with suppliers?

To effectively resolve disputes, maintain open and transparent communication with your supplier. Document all agreements and correspondence to refer back to in case of issues. If a dispute arises, attempt to negotiate a solution directly. If that fails, consider mediation or arbitration, as these methods can be less costly and time-consuming than litigation. Familiarize yourself with the dispute resolution terms outlined in your contract. -

What payment terms are common in international B2B transactions for DC electric engines?

Common payment terms include upfront deposits (typically 30-50%), with the balance due upon delivery or prior to shipping. Some suppliers may offer letter of credit arrangements for added security. Evaluate the payment terms based on your cash flow and the supplier’s reliability. Always ensure that payment terms are clearly defined in the contract to avoid misunderstandings. -

What should I do if the delivered DC electric engines do not meet my specifications?

Upon delivery, inspect the engines immediately to ensure they conform to the agreed specifications. If discrepancies are identified, document them with photos and detailed notes. Contact the supplier promptly to discuss the issue and provide evidence of the deviation. Most reputable suppliers will work with you to resolve the issue, whether through replacement, repair, or financial compensation, depending on the terms of your agreement.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dc electric engine

In summary, strategic sourcing of DC electric engines is crucial for international B2B buyers aiming to enhance operational efficiency and maintain competitiveness in their respective markets. By understanding the various motor types, evaluating supplier capabilities, and considering factors such as quality, price, and delivery timelines, businesses can make informed purchasing decisions.

Key takeaways include:

– Clearly define your requirements before engaging with suppliers to streamline the sourcing process.

– Thoroughly research potential suppliers to ensure they meet your quality standards and can deliver on time.

– Maintain strong supplier relationships to facilitate ongoing support and innovation.

As markets continue to evolve, especially in regions such as Africa, South America, the Middle East, and Europe, the demand for efficient and reliable DC electric engines will only grow. Buyers are encouraged to leverage these insights to enhance their sourcing strategies and adopt technologies that drive sustainability and performance. The future of electric engines is promising; engage with suppliers who can help you navigate this dynamic landscape and position your business for success.