Your Ultimate Guide to Sourcing Dc Power Source

Introduction: Navigating the Global Market for dc power source

In an era where the demand for reliable and efficient power solutions is paramount, DC power sources have emerged as critical components across various industries. From powering electronic devices and laboratory equipment to supporting industrial machinery and renewable energy systems, the versatility of DC power supplies cannot be overstated. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of the DC power source market is essential for ensuring operational continuity and competitive advantage.

This comprehensive guide is designed to equip B2B buyers with the insights needed to navigate the complex landscape of DC power sources. It delves into the various types of DC power supplies, detailing their applications and suitability for different business needs. Additionally, the guide examines essential factors such as material quality, manufacturing processes, and quality control standards, enabling buyers to evaluate potential suppliers effectively.

Furthermore, it provides a clear framework for assessing cost structures and understanding market dynamics, ensuring that buyers can make informed decisions that align with their strategic objectives. Common FAQs are also addressed, clarifying typical concerns and enhancing buyers’ confidence in their sourcing choices. Armed with this knowledge, B2B buyers can not only secure reliable power solutions but also foster long-term partnerships that drive innovation and growth in their respective markets.

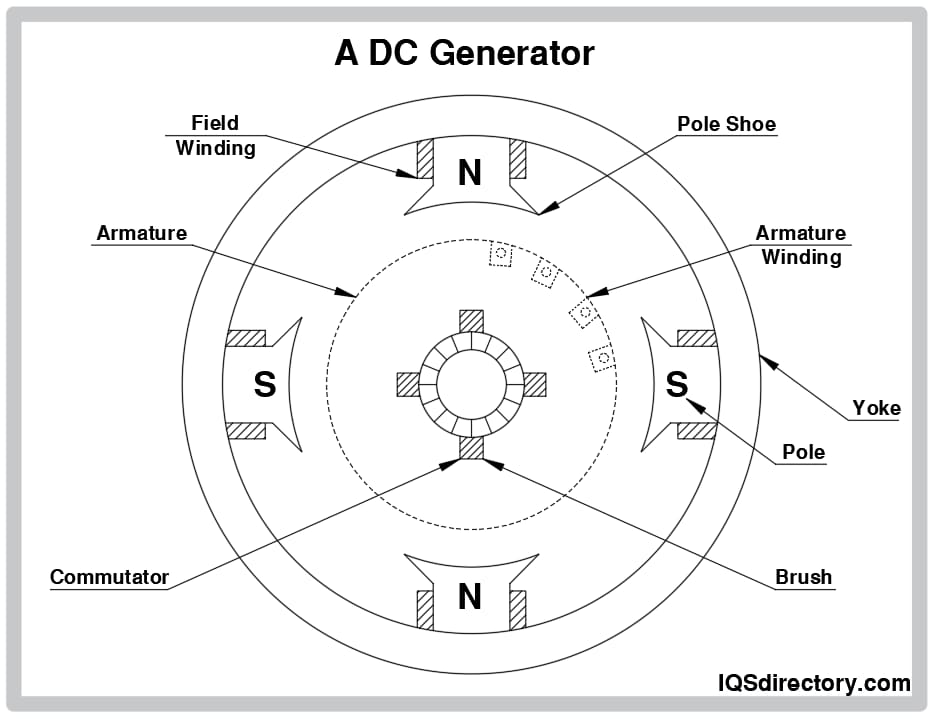

Understanding dc power source Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Linear Power Supplies | Simple design; stable output voltage; less efficient | Laboratory equipment, audio devices | Reliable performance; bulkier and less energy-efficient |

| Switching Power Supplies | High efficiency; compact size; versatile voltage outputs | Telecommunications, industrial machinery | Lightweight and efficient; potential electromagnetic interference |

| Programmable DC Power Supplies | Adjustable voltage/current; remote control capabilities | R&D labs, testing environments | Flexibility for testing; higher cost compared to fixed models |

| Battery Chargers | Converts AC to DC; provides charging for batteries | Electric vehicles, consumer electronics | Essential for energy storage; varying charging speeds |

| Solar DC Power Systems | Utilizes solar panels; renewable energy source | Off-grid installations, remote telecommunications | Sustainable energy; dependent on sunlight availability |

Linear Power Supplies

Linear power supplies are characterized by their straightforward design, providing a stable output voltage. They are commonly used in laboratory equipment and audio devices where reliability is crucial. However, they tend to be bulkier and less energy-efficient compared to other types. For B2B buyers, key considerations include space requirements, energy costs, and the specific voltage stability needed for sensitive applications.

Switching Power Supplies

Switching power supplies are known for their high efficiency and compact size, making them suitable for a variety of applications, including telecommunications and industrial machinery. They can adjust output voltage dynamically, which adds versatility. B2B buyers should evaluate the potential for electromagnetic interference, which can affect nearby sensitive equipment, and ensure compatibility with their operational environment.

Programmable DC Power Supplies

These supplies offer adjustable voltage and current levels, often with remote control capabilities. They are particularly useful in research and development labs and testing environments where precise power control is essential. While they provide flexibility, they typically come at a higher cost compared to fixed-output models. Buyers should consider their testing needs and budget when selecting programmable options.

Battery Chargers

Battery chargers convert alternating current (AC) to direct current (DC) to recharge batteries, playing a vital role in electric vehicles and consumer electronics. They vary in charging speeds and efficiency, which can impact operational productivity. B2B buyers need to assess the compatibility of chargers with their battery types, charging time requirements, and overall energy consumption.

Solar DC Power Systems

Solar DC power systems harness renewable energy from solar panels, making them an eco-friendly option for off-grid installations and remote telecommunications. While they contribute to sustainability goals, their performance is highly dependent on sunlight availability. Buyers should evaluate the initial investment against long-term energy savings and consider local climate conditions when opting for solar solutions.

Related Video: Linear vs Switching DC Power Supplies – What’s the Difference?

Key Industrial Applications of dc power source

| Industry/Sector | Specific Application of dc power source | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Powering telecom base stations and equipment | Ensures continuous communication services | Reliability of power supply, local regulations, and backup solutions |

| Manufacturing | Operation of automated machinery and robotics | Increases production efficiency and reduces operational costs | Equipment compatibility, scalability, and energy efficiency |

| Healthcare | Operation of medical devices and imaging equipment | Critical for patient care and diagnostic accuracy | Compliance with health standards, reliability, and maintenance support |

| Renewable Energy | Integration in solar power systems and energy storage | Enhances energy efficiency and sustainability | System compatibility, local energy policies, and installation support |

| Automotive | Electric vehicle (EV) charging stations | Supports the growing EV market and infrastructure development | Location suitability, power capacity, and regulatory compliance |

Telecommunications

DC power sources are essential for powering telecommunications base stations and related equipment. They provide a stable and reliable power supply necessary for uninterrupted communication services, particularly in remote areas where grid power may be inconsistent. International B2B buyers should consider the reliability of power supply, local regulations regarding telecommunications infrastructure, and the availability of backup solutions to mitigate potential outages.

Manufacturing

In the manufacturing sector, DC power sources are utilized to operate automated machinery and robotics. This application enhances production efficiency and reduces operational costs by ensuring that machinery runs smoothly and continuously. Buyers in this sector should focus on equipment compatibility, scalability of power solutions, and energy efficiency to optimize their manufacturing processes while minimizing downtime.

Healthcare

Healthcare facilities depend on DC power sources for the operation of critical medical devices and imaging equipment. A reliable power supply is crucial for patient care, ensuring that diagnostic and treatment technologies function correctly without interruption. B2B buyers in the healthcare industry must prioritize compliance with health standards, the reliability of power systems, and ongoing maintenance support to safeguard patient welfare.

Renewable Energy

DC power sources play a significant role in renewable energy applications, particularly in solar power systems and energy storage solutions. They enhance energy efficiency and sustainability by converting and storing energy generated from renewable sources. Buyers should evaluate system compatibility with existing infrastructure, local energy policies that may impact installation, and the availability of technical support for seamless integration.

Automotive

In the automotive sector, particularly with the rise of electric vehicles (EVs), DC power sources are vital for charging stations. These stations support the growing EV market and contribute to the development of necessary infrastructure. B2B buyers should assess location suitability for charging stations, the power capacity required to meet demand, and adherence to regulatory compliance to ensure successful implementation.

Related Video: 220V AC to 12V DC Converter Power Supply Using Diodes, Capacitors, Resistors, & Transformers

Strategic Material Selection Guide for dc power source

When selecting materials for DC power sources, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of common materials used in DC power supplies, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and corrosion resistance. It typically operates effectively in a temperature range of -200°C to 200°C and can withstand moderate pressure.

Pros & Cons: Copper’s high conductivity makes it ideal for electrical connections, ensuring minimal energy loss. However, it is relatively expensive compared to alternatives like aluminum, and it can be prone to corrosion in harsh environments. Manufacturing processes can be complex, particularly when forming intricate shapes or components.

Impact on Application: Copper is highly compatible with a range of media, including water and various oils, making it versatile for different applications. However, its susceptibility to corrosion in saline or acidic environments may limit its use in certain geographical areas.

Specific Considerations: Buyers in regions like Saudi Arabia and coastal areas of South America should consider the impact of humidity and salt on copper components. Compliance with standards such as ASTM B170 for copper wire may also be necessary.

Aluminum

Key Properties: Aluminum is lightweight and exhibits good electrical conductivity, though not as high as copper. It has a temperature rating of approximately -50°C to 150°C and is resistant to corrosion due to its natural oxide layer.

Pros & Cons: The primary advantage of aluminum is its low cost and lightweight nature, making it ideal for applications where weight is a critical factor. However, it has lower conductivity than copper, which may necessitate larger cross-sectional areas for conductors, potentially increasing manufacturing complexity.

Impact on Application: Aluminum’s corrosion resistance makes it suitable for outdoor applications, especially in humid environments. Its compatibility with various media is generally good, but care must be taken with certain chemicals that can degrade aluminum.

Specific Considerations: In Europe, compliance with EN 60228 standards for conductors is essential. Buyers should also assess local availability and pricing fluctuations, particularly in South America, where aluminum production is significant.

Steel

Key Properties: Steel, particularly stainless steel, offers high strength and durability, with temperature ratings typically ranging from -40°C to 400°C. It has moderate electrical conductivity, which can vary based on the alloy used.

Pros & Cons: The durability of steel makes it suitable for structural components in DC power systems. However, its electrical conductivity is lower than that of copper and aluminum, which can lead to increased energy losses. Additionally, the weight of steel can be a disadvantage in portable applications.

Impact on Application: Steel is often used in enclosures and frames for DC power supplies, providing robust protection against physical damage. Its compatibility with various media is generally good, but it may require protective coatings in corrosive environments.

Specific Considerations: Buyers in the Middle East should be aware of the need for corrosion-resistant coatings to protect steel components from harsh environmental conditions. Compliance with ASTM A240 for stainless steel may also be relevant.

Polycarbonate

Key Properties: Polycarbonate is a thermoplastic polymer known for its high impact resistance and transparency. It can withstand temperatures from -40°C to 120°C and is resistant to UV radiation.

Pros & Cons: The lightweight nature and excellent impact resistance of polycarbonate make it ideal for protective covers and housings in DC power supplies. However, it has lower thermal stability compared to metals and can be susceptible to scratching.

Impact on Application: Polycarbonate is compatible with various media, including oils and fuels, making it suitable for diverse applications. Its transparency allows for visual inspection of components housed within.

Specific Considerations: Buyers from Europe should ensure compliance with RoHS and REACH regulations regarding the use of polycarbonate in electrical applications. Additionally, understanding local recycling regulations is crucial for sustainability.

| Material | Typical Use Case for dc power source | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections | Excellent conductivity | High cost, prone to corrosion | High |

| Aluminum | Conductors in lightweight designs | Low cost, lightweight | Lower conductivity than copper | Medium |

| Steel | Structural components | High strength and durability | Lower conductivity, heavier weight | Medium |

| Polycarbonate | Protective housings | Impact resistance, lightweight | Lower thermal stability, scratches | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for dc power source

The manufacturing processes and quality assurance protocols for DC power sources are crucial for ensuring reliability and performance in various applications. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can help in making informed sourcing decisions. This section delves into the typical manufacturing stages, key techniques, international standards, and the quality control measures that are essential for verifying supplier capabilities.

Manufacturing Processes

The production of DC power sources involves several critical stages, each contributing to the overall quality and functionality of the final product.

1. Material Preparation

The manufacturing process begins with the careful selection and preparation of raw materials. High-quality components such as semiconductors, capacitors, inductors, and printed circuit boards (PCBs) are sourced from reputable suppliers. During this stage, materials undergo testing for electrical properties and physical integrity. B2B buyers should prioritize suppliers that demonstrate a robust supply chain management process, ensuring that materials meet industry standards and specifications.

2. Forming

In the forming stage, the prepared materials are shaped into their required configurations. This includes processes like die-casting for metal components, injection molding for plastic parts, and PCB fabrication. Techniques such as surface mount technology (SMT) are commonly employed for assembling electronic components onto PCBs. Buyers should assess the manufacturer’s capabilities in using advanced forming technologies, as this can significantly influence the performance and reliability of the power source.

3. Assembly

The assembly stage involves integrating various components into a complete unit. This process is often automated to enhance precision and efficiency. Key techniques include robotic assembly and manual soldering for components that require special handling. Quality control at this stage is paramount, as improper assembly can lead to failures. Buyers should inquire about the manufacturer’s assembly techniques and the training provided to personnel involved in the process.

4. Finishing

Finishing processes include testing, coating, and packaging the DC power sources. Testing is critical to ensure that each unit meets the specified performance criteria, such as output voltage and current stability. Coatings may be applied to protect against environmental factors, which is particularly important in harsh operating conditions. Buyers should look for manufacturers that have rigorous finishing processes to guarantee that their products are robust and reliable.

Illustrative Image (Source: Google Search)

Quality Assurance

Quality assurance is a systematic process that ensures the products meet required standards and specifications. For international B2B buyers, understanding these practices is essential for mitigating risks associated with sourcing.

International Standards

The adherence to international quality standards is a vital aspect of the manufacturing process. Key standards include:

- ISO 9001: This standard focuses on quality management systems, ensuring that organizations consistently provide products that meet customer and regulatory requirements.

- CE Marking: This certification indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Particularly relevant for DC power sources used in the oil and gas industry, these standards ensure that products are suitable for harsh environments.

Buyers should confirm that their suppliers are certified and maintain compliance with these international standards, as this provides assurance of quality and reliability.

Quality Control Checkpoints

Quality control checkpoints are integral to the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, reducing waste and ensuring product integrity.

- Final Quality Control (FQC): The final inspection ensures that the completed DC power sources meet all performance specifications and regulatory requirements before shipment.

B2B buyers should ensure that suppliers have established and documented procedures for these quality control checkpoints.

Common Testing Methods

Testing methods for DC power sources can include:

- Load Testing: Evaluating the performance under various load conditions to ensure stability and reliability.

- Thermal Testing: Assessing the unit’s performance under extreme temperatures to ensure it operates effectively in different environments.

- Electrical Testing: Measuring voltage, current, and resistance to confirm that the product meets electrical specifications.

These testing methods are crucial for validating the performance of the power sources. Buyers should request testing reports and certifications from suppliers to verify compliance with specified standards.

Verifying Supplier Quality Control

For international buyers, verifying a supplier’s quality control processes is essential. Strategies include:

- Supplier Audits: Conducting regular audits of the supplier’s facilities and processes can provide insights into their quality control practices and adherence to standards.

- Requesting Quality Reports: Buyers should ask for detailed quality assurance reports, including results from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Engaging independent third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control measures.

Quality Control Nuances for International Buyers

International B2B buyers must be aware of regional nuances in quality control. For instance, different countries may have varying regulations and certifications that affect product quality. Buyers from regions such as Africa and South America may encounter challenges related to logistics and communication with suppliers, making thorough due diligence essential.

Illustrative Image (Source: Google Search)

In Europe and the Middle East, where regulatory compliance is stringent, buyers should prioritize suppliers who demonstrate a clear understanding of local standards and can provide documentation to support compliance. Additionally, cultural differences may impact communication styles and expectations, necessitating a tailored approach to supplier engagement.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for DC power sources is vital for international B2B buyers. By prioritizing suppliers that adhere to established standards, implementing robust quality control measures, and maintaining clear communication, buyers can secure reliable and high-performing power sources that meet their operational needs. Investing time in evaluating these aspects will not only enhance procurement decisions but also foster long-term partnerships that drive business success.

Related Video: 18650 Cell Manufacturing Process, Automatic Production Line

Comprehensive Cost and Pricing Analysis for dc power source Sourcing

Understanding the cost structure and pricing dynamics of DC power sources is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This section will explore the key components that influence costs, the factors that affect pricing, and practical tips for buyers to optimize their sourcing strategies.

Cost Components of DC Power Sources

-

Materials: The primary materials used in DC power supplies, such as semiconductors, capacitors, transformers, and circuit boards, significantly impact the overall cost. The choice of materials can also dictate the durability and efficiency of the power source.

-

Labor: Labor costs can vary based on geographical location, skill level required for assembly, and the complexity of the power source design. Regions with a skilled workforce may command higher labor costs, but this can be offset by increased productivity and quality.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses associated with the production process. Efficient manufacturing processes can help reduce overhead, contributing to overall cost savings.

-

Tooling: Initial setup costs for production, including specialized tools and molds, can be substantial, especially for custom designs. Buyers should consider these costs as part of their total investment.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the DC power supplies meet performance and safety standards. While this may increase upfront costs, it helps avoid long-term failures and warranty claims.

-

Logistics: Transporting DC power sources can add significant costs, particularly for international shipments. Factors such as shipping methods, customs duties, and freight insurance should be factored into the overall cost.

-

Margin: Suppliers typically include a profit margin that can vary widely based on market conditions, competition, and demand. Understanding typical margins in different regions can aid in negotiation.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) and bulk purchasing can lead to lower per-unit costs. Buyers should assess their needs and consider consolidating orders to achieve better pricing.

-

Specifications/Customization: Custom specifications can lead to higher costs due to the need for specialized materials and manufacturing processes. However, tailored solutions often provide greater value and performance.

-

Materials: The choice of high-quality materials can increase initial costs but often results in lower maintenance and operational costs over time. Buyers should evaluate the trade-off between upfront investment and long-term savings.

-

Quality/Certifications: Products that meet international standards (such as ISO certifications) may carry a premium price. However, compliance with local regulations and standards can be critical for market entry and operational reliability.

-

Supplier Factors: Supplier reputation, reliability, and service capabilities can influence pricing. Established suppliers with proven track records may command higher prices but can also offer better support and warranty terms.

-

Incoterms: Understanding Incoterms is essential for determining who bears the costs and risks during shipping. Buyers should negotiate terms that minimize their exposure to unforeseen costs.

Buyer Tips for Cost-Efficiency

-

Negotiate Strategically: Leverage bulk purchasing and long-term contracts to negotiate better pricing. Building strong relationships with suppliers can also lead to favorable terms and conditions.

-

Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the long-term operational costs, including energy efficiency, maintenance, and potential downtime costs.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, tariffs, and supply chain dynamics. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand local pricing trends.

-

Request Detailed Quotations: Ensure that suppliers provide detailed breakdowns of costs, including materials, labor, and logistics. This transparency can aid in evaluating the best value proposition.

Disclaimer

Prices and cost structures mentioned are indicative and may vary significantly based on specific circumstances, market conditions, and supplier negotiations. B2B buyers are encouraged to conduct their due diligence and seek multiple quotes to ensure competitive pricing.

Spotlight on Potential dc power source Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dc power source’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dc power source

Understanding the technical properties and trade terminology associated with DC power sources is crucial for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. This knowledge not only facilitates informed purchasing decisions but also enhances negotiations with suppliers and manufacturers.

Essential Technical Properties

-

Voltage Rating

– Definition: The voltage rating indicates the maximum output voltage a DC power source can deliver. Common ratings include 5V, 12V, 24V, and 48V.

– B2B Importance: Selecting the correct voltage rating is essential to ensure compatibility with the intended application. Mismatched voltage can lead to equipment failure or damage, resulting in costly downtime. -

Current Rating

– Definition: This specification refers to the maximum current (measured in amperes) that the power source can supply safely without overheating.

– B2B Importance: Understanding the current requirements of your equipment helps in choosing a power source that can handle peak loads, ensuring reliable operation and longevity of connected devices. -

Efficiency

– Definition: Efficiency is the ratio of output power to input power, expressed as a percentage. Higher efficiency means less energy is wasted in the form of heat.

– B2B Importance: High-efficiency power supplies reduce operational costs and environmental impact. Buyers should prioritize efficiency ratings to enhance overall system performance and sustainability. -

Ripple Voltage

– Definition: Ripple voltage refers to the AC voltage fluctuations superimposed on the DC output. It’s an important measure of the stability of the power supply.

– B2B Importance: Low ripple voltage is critical for sensitive electronic applications, such as in telecommunications or medical devices, where stable power is necessary to maintain performance and reliability. -

Temperature Coefficient

– Definition: This property measures how the output voltage changes with temperature variations, typically expressed in parts per million per degree Celsius (ppm/°C).

– B2B Importance: Understanding the temperature coefficient is vital for applications in extreme environments. Ensuring the power source operates reliably under varying temperatures can mitigate risks associated with equipment failure.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Recognizing OEMs is crucial for buyers seeking high-quality, reliable components that meet specific industry standards. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQs helps buyers plan their procurement strategies effectively and ensures they do not over-commit financially on inventory that may not be needed. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Importance: Utilizing RFQs enables buyers to compare costs and negotiate better terms with suppliers, ensuring they receive the best possible deal. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of predefined international sales terms that clarify the responsibilities of buyers and sellers in shipping goods.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother international transactions. -

Lead Time

– Definition: Lead time refers to the amount of time it takes from placing an order until the product is delivered.

– Importance: Knowing the lead time is essential for planning and operational efficiency, as delays can impact project timelines and customer satisfaction. -

Customs Duty

– Definition: Customs duty is a tax imposed on goods when they are transported across international borders.

– Importance: Understanding customs duties is vital for budgeting total costs and ensuring compliance with international trade regulations.

By grasping these technical properties and trade terms, B2B buyers can enhance their sourcing strategies, optimize costs, and ensure the reliability and efficiency of their DC power solutions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dc power source Sector

In the rapidly evolving landscape of DC power sources, international B2B buyers are increasingly influenced by various global market drivers. Key trends shaping this sector include the rise of renewable energy sources, advancements in energy storage technologies, and the growing demand for high-efficiency power solutions. In regions like Africa and South America, where access to reliable grid power can be inconsistent, DC power sources provide essential stability for industries ranging from telecommunications to manufacturing.

Moreover, technological innovations such as smart grids and IoT integration are enhancing the functionality and efficiency of DC power systems. For buyers in Europe and the Middle East, regulatory frameworks supporting green energy initiatives are propelling investments in sustainable power solutions. The push for electrification in transportation and the adoption of electric vehicles also contribute to the increasing demand for DC power supplies. As buyers navigate these dynamics, they must prioritize suppliers who not only offer competitive pricing but also demonstrate a commitment to innovation and reliability.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of sourcing strategies in the DC power source sector. As environmental concerns mount, B2B buyers are increasingly scrutinizing the ecological impact of their purchases. This includes evaluating the carbon footprint of manufacturing processes, the lifecycle of products, and the materials used in production. Emphasizing ethical sourcing practices is vital; buyers should seek suppliers who adhere to sustainable practices, ensuring that materials are sourced responsibly and that labor conditions meet international standards.

Certifications such as ISO 14001 for environmental management and adherence to RoHS (Restriction of Hazardous Substances) standards are crucial indicators of a supplier’s commitment to sustainability. Additionally, integrating ‘green’ materials—such as recyclable components and energy-efficient designs—can enhance a company’s marketability and align with consumer expectations for corporate responsibility. Buyers should establish long-term partnerships with suppliers who prioritize transparency in their supply chains, enabling a shared commitment to sustainability goals.

Brief Evolution/History

The evolution of DC power sources can be traced back to the early days of electricity generation, where direct current was the standard. However, the advent of alternating current (AC) systems in the late 19th century overshadowed DC technologies. In recent decades, the resurgence of interest in DC power has been driven by advancements in renewable energy technologies and the proliferation of electronic devices that require stable, low-voltage power. This shift has led to the development of sophisticated DC power supplies tailored for diverse applications, ranging from telecommunications to industrial automation. As the market continues to mature, buyers must remain informed about the historical context to better understand current innovations and future trends in the DC power source sector.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of dc power source

-

What should I consider when vetting suppliers of DC power sources?

When vetting suppliers, prioritize their experience in the DC power sector and their track record in international trade. Verify their certifications for quality assurance, such as ISO 9001, and assess their manufacturing capabilities. It’s crucial to check customer reviews or references from previous clients in your region to gauge reliability. Additionally, consider their ability to provide technical support and customization options tailored to your specific needs, which is especially important for complex projects. -

Can I customize my DC power source according to my specific requirements?

Yes, many suppliers offer customization options to meet unique specifications, including voltage, current ratings, and form factors. When engaging with potential suppliers, clearly communicate your requirements and inquire about their customization capabilities. Consider discussing lead times for custom orders, as these can vary significantly based on the complexity of the modifications and the supplier’s production capacity. -

What are the typical minimum order quantities (MOQs) and lead times for DC power sources?

MOQs can vary widely among suppliers based on their production processes and your customization needs. Generally, larger orders may result in lower unit prices, but it’s essential to balance cost with your actual requirements. Lead times typically range from a few weeks to several months, influenced by factors such as order volume, complexity, and the supplier’s location. Always confirm these details upfront to align your project timelines with supplier capabilities. -

How do I ensure the quality of the DC power sources I am purchasing?

To ensure quality, request detailed product specifications and certifications from suppliers. Look for compliance with international standards such as CE, UL, or RoHS, which indicate adherence to safety and environmental regulations. Additionally, consider asking for samples or conducting factory visits to assess quality control processes firsthand. Establishing a clear quality assurance agreement before placing large orders can also safeguard your interests. -

What payment terms should I expect when sourcing DC power sources internationally?

Payment terms can vary depending on the supplier’s policies and your relationship with them. Common arrangements include upfront payments, partial payments with balance on delivery, or letters of credit for larger orders. It’s crucial to negotiate terms that protect both parties, especially in international transactions where currency fluctuations and shipping delays can impact costs. Make sure to document all agreements clearly to avoid disputes later. -

What logistics considerations should I keep in mind when importing DC power sources?

Logistics play a critical role in the successful import of DC power sources. Ensure you understand the shipping options available, including air freight for speed versus sea freight for cost-effectiveness. Assess the customs regulations in your country and ensure the supplier can provide all necessary documentation, such as invoices, packing lists, and certificates of origin. Partnering with a reliable freight forwarder can help streamline the process and mitigate potential delays. -

How can disputes with suppliers be effectively managed?

To manage disputes effectively, establish clear communication channels and document all agreements and interactions. Consider including a dispute resolution clause in your contracts, specifying mediation or arbitration as preferred methods for resolving conflicts. If issues arise, address them promptly and professionally, aiming for a collaborative solution. Maintaining a positive relationship with suppliers can often help in resolving disputes amicably and preserving future business opportunities. -

What are the key certifications I should look for in DC power sources?

Key certifications to look for include ISO 9001 for quality management systems, CE marking for compliance with European safety standards, and UL certification for safety in North America. Additionally, RoHS compliance ensures that the product meets environmental regulations regarding hazardous substances. These certifications not only ensure product reliability but also facilitate smoother customs clearance when importing goods internationally, particularly in regions with stringent regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dc power source

In conclusion, the strategic sourcing of DC power sources is essential for international B2B buyers aiming to enhance operational resilience and efficiency. By understanding the various types of DC power supplies—such as linear, switching, and programmable options—businesses can make informed decisions that align with their specific applications and needs. It is crucial to evaluate suppliers based on reliability, customization capabilities, and support services, particularly in regions where access to stable power can be a challenge.

Key Takeaways:

- Prioritize suppliers that offer robust technical support and customization options to meet unique operational demands.

- Consider the long-term value of investments in DC power sources, looking beyond initial costs to total lifecycle expenses.

- Stay informed about evolving technologies and market trends to ensure your sourcing strategy remains competitive.

Looking ahead, the global demand for reliable power solutions will only increase, driven by advancements in technology and infrastructure. As you navigate the complexities of sourcing DC power sources, remain proactive in building partnerships that foster innovation and sustainability. Take the next step towards securing your power needs and enhancing your business’s operational capabilities—strategic sourcing is your pathway to success.