Your Ultimate Guide to Sourcing Directory Of Manufacturers

Introduction: Navigating the Global Market for directory of manufacturers

In today’s dynamic global marketplace, the ability to efficiently source products and services is crucial for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. A well-curated directory of manufacturers serves as an invaluable tool, enabling businesses to connect with trusted suppliers across various industries. By leveraging these directories, buyers can streamline their procurement processes, reduce costs, and ensure high-quality production standards.

This comprehensive guide delves into the multifaceted world of manufacturing directories, covering essential aspects such as types of directories, material specifications, manufacturing and quality control processes, supplier evaluations, and cost considerations. It also addresses frequently asked questions, providing insights that empower buyers to make informed decisions.

Understanding the nuances of different suppliers and manufacturers not only enhances negotiation power but also fosters long-term partnerships that can lead to competitive advantages. Whether you’re sourcing advanced electronics in Europe or raw materials in South America, this guide equips international B2B buyers with the knowledge and resources necessary to navigate the complexities of global sourcing. With the right directory at your fingertips, the path to identifying reliable partners and maximizing supply chain efficiency becomes significantly clearer.

Understanding directory of manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| General Manufacturer Directories | Comprehensive listings across various industries; often searchable by product or service. | Sourcing suppliers, market research, networking. | Pros: Wide range of options; easy to navigate. Cons: May lack detailed insights on specific manufacturers. |

| Niche Industry Directories | Focused on specific sectors (e.g., electronics, textiles); often include detailed product specifications. | Targeted sourcing, specialized procurement. | Pros: In-depth information; tailored search capabilities. Cons: Limited to specific industries; may miss broader options. |

| Local Manufacturer Directories | Listings organized by geographic location; often include local business ratings and reviews. | Regional sourcing, local partnerships. | Pros: Supports local economies; easier logistics. Cons: May have fewer options compared to national directories. |

| Online Marketplaces | Platforms that connect buyers directly with manufacturers; often include user reviews and ratings. | Direct purchasing, bidding for contracts. | Pros: Transparent pricing; user feedback available. Cons: Quality control may vary; potential for scams. |

| Export/Import Directories | Focused on international trade; often feature manufacturers that cater to export markets. | Global sourcing, finding overseas suppliers. | Pros: Access to international markets; diverse supplier base. Cons: Language barriers; different regulatory standards. |

General Manufacturer Directories

General manufacturer directories offer a wide-ranging overview of suppliers across various sectors. They are typically searchable by product or service, making it easy for B2B buyers to find potential partners. These directories are particularly useful for market research and networking opportunities. However, while they provide a vast array of options, they may not always include detailed insights about individual manufacturers, which can be a drawback for buyers seeking specific qualifications or capabilities.

Niche Industry Directories

Niche industry directories focus on specific sectors, such as electronics or textiles, and often provide detailed product specifications. These directories are ideal for businesses looking to source specialized materials or components. The depth of information available allows buyers to make informed decisions tailored to their industry needs. However, the limitation lies in their scope, as they might not encompass broader options available in general directories.

Local Manufacturer Directories

Local manufacturer directories organize listings by geographic location, facilitating connections with nearby suppliers. They often include business ratings and reviews, which can help buyers assess the reliability of potential partners. These directories are particularly advantageous for businesses aiming to foster regional partnerships and reduce logistical challenges. However, the trade-off may be a more limited selection compared to national directories, potentially restricting options for buyers.

Online Marketplaces

Online marketplaces serve as platforms that connect buyers directly with manufacturers, often featuring user reviews and ratings. They are beneficial for direct purchasing and bidding on contracts, providing transparency in pricing and supplier performance. While these platforms can enhance buyer confidence through feedback, there may be concerns regarding quality control and the risk of encountering fraudulent suppliers, necessitating careful vetting.

Export/Import Directories

Export/import directories are designed for international trade, highlighting manufacturers that cater to export markets. They are invaluable for businesses looking to expand their sourcing capabilities globally. These directories provide access to a diverse supplier base, which can enhance competitive advantage. However, buyers should be mindful of potential language barriers and differing regulatory standards, which can complicate transactions and require additional due diligence.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of directory of manufacturers

| Industry/Sector | Specific Application of directory of manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Sourcing raw materials and components | Streamlines procurement processes, reducing costs | Supplier reliability, lead times, and material certifications |

| Construction | Finding subcontractors and specialized service providers | Enhances project efficiency and timely completion | Licensing, project experience, and geographical proximity |

| Automotive | Identifying parts manufacturers and suppliers | Ensures quality and compliance with safety standards | Quality assurance, industry certifications, and delivery timelines |

| Electronics | Locating PCB and component suppliers | Facilitates innovation and product development | Technological capabilities, customization options, and support services |

| Food & Beverage | Sourcing packaging and processing equipment | Improves product safety and shelf life | Compliance with health regulations, sustainability practices |

Manufacturing

In the manufacturing sector, directories of manufacturers are invaluable for sourcing raw materials and components. B2B buyers can quickly identify suppliers that meet their specific needs, ensuring a streamlined procurement process. This reduces costs and minimizes delays, which is crucial for maintaining production schedules. International buyers, particularly from regions like Africa and South America, should prioritize supplier reliability, lead times, and necessary material certifications to ensure compliance with local and international standards.

Construction

For the construction industry, directories serve as a vital resource for finding subcontractors and specialized service providers. By accessing a comprehensive list of qualified professionals, buyers can enhance project efficiency and ensure timely completion. This is particularly important in emerging markets where skilled labor may be scarce. Buyers should consider licensing, project experience, and geographical proximity when selecting subcontractors to mitigate risks associated with delays or compliance issues.

Automotive

In the automotive sector, identifying parts manufacturers and suppliers is essential for maintaining quality and compliance with safety standards. Directories of manufacturers help buyers locate reputable suppliers who can deliver high-quality components on time. For international B2B buyers, particularly those in Europe and the Middle East, it’s crucial to evaluate quality assurance practices, industry certifications, and delivery timelines to ensure that the supply chain remains robust and efficient.

Electronics

The electronics industry relies heavily on locating suppliers for printed circuit boards (PCBs) and other components. Directories provide access to manufacturers that can facilitate innovation and support product development. Buyers should focus on technological capabilities, customization options, and support services offered by suppliers. This is particularly relevant for international buyers in regions like Africa and South America, where access to advanced technology may be limited.

Food & Beverage

In the food and beverage sector, sourcing packaging and processing equipment is critical for ensuring product safety and extending shelf life. Directories of manufacturers assist buyers in finding suppliers that comply with health regulations and sustainability practices. International buyers should prioritize suppliers with a strong track record of compliance and quality to avoid costly recalls and reputational damage.

Related Video: Industrial Control Panel Basics

Strategic Material Selection Guide for directory of manufacturers

When selecting materials for manufacturing, international B2B buyers must consider several factors that can significantly impact product performance and compliance with regional standards. Below are analyses of four common materials, including their properties, pros and cons, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Steel

Key Properties: Steel is known for its high tensile strength, durability, and versatility. It can withstand high temperatures and pressures, making it suitable for a wide range of applications.

Pros & Cons:

– Advantages: Steel is highly durable and resistant to wear and tear. It is relatively cost-effective compared to other metals and can be easily fabricated.

– Disadvantages: Steel is susceptible to corrosion unless treated, which can increase maintenance costs. It is also heavier than some alternatives, which may not be suitable for all applications.

Impact on Application: Steel is often used in construction, automotive, and machinery industries. Its compatibility with various media, including water and chemicals, is essential for applications requiring structural integrity.

Considerations for International Buyers: Compliance with standards like ASTM or DIN is crucial. Buyers should also consider local availability and sourcing options to minimize lead times and costs.

2. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal and electrical conductivity. It is also non-magnetic and can be easily machined.

Pros & Cons:

– Advantages: The lightweight nature of aluminum makes it ideal for applications where weight is a concern, such as aerospace and automotive. Its resistance to corrosion reduces maintenance needs.

– Disadvantages: Aluminum is generally more expensive than steel and may not be as strong under high-stress conditions. It can also be prone to deformation under excessive load.

Impact on Application: Aluminum is commonly used in packaging, transportation, and construction. Its compatibility with various environmental conditions makes it a preferred choice for outdoor applications.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades and their compliance with international standards. Understanding local recycling regulations can also impact material selection.

3. Plastic (Polymer)

Key Properties: Plastics are lightweight, resistant to corrosion, and can be engineered for specific applications. They offer good insulation properties and can be produced in various forms.

Pros & Cons:

– Advantages: Plastics are highly versatile and can be molded into complex shapes, making them suitable for a wide range of applications. They are generally cost-effective and lightweight.

– Disadvantages: Plastics can have lower strength compared to metals and may degrade under UV exposure unless treated. They are also less environmentally friendly unless recycled.

Impact on Application: Plastics are widely used in consumer goods, automotive parts, and packaging. Their chemical resistance makes them suitable for applications involving various media.

Considerations for International Buyers: Compliance with environmental regulations and standards such as ISO is essential. Buyers should also consider the availability of recycled plastic options to meet sustainability goals.

4. Composite Materials

Key Properties: Composites combine two or more materials to achieve superior properties, such as enhanced strength-to-weight ratios and improved durability. They can be tailored for specific applications.

Pros & Cons:

– Advantages: Composites offer exceptional strength while remaining lightweight, making them ideal for aerospace and automotive applications. They can also be designed for specific environmental conditions.

– Disadvantages: The manufacturing process can be complex and costly. Additionally, composites may require specialized disposal methods at the end of their lifecycle.

Impact on Application: Composites are increasingly used in industries such as aerospace, automotive, and construction due to their high performance and durability.

Considerations for International Buyers: Understanding the specific composite materials and their certifications is critical. Buyers should also be aware of local manufacturing capabilities and compliance with international standards.

Summary Table

| Material | Typical Use Case for directory of manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, automotive, machinery | High durability and strength | Susceptible to corrosion | Medium |

| Aluminum | Aerospace, packaging, transportation | Lightweight and corrosion-resistant | Higher cost than steel | High |

| Plastic (Polymer) | Consumer goods, automotive parts, packaging | Versatile and cost-effective | Lower strength compared to metals | Low |

| Composite Materials | Aerospace, automotive, construction | Exceptional strength-to-weight ratio | Complex manufacturing process | High |

This guide provides a foundational understanding of material selection for B2B buyers, enabling informed decision-making that aligns with their specific industry needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for directory of manufacturers

Manufacturing Processes

Understanding the manufacturing processes is crucial for international B2B buyers looking to source products effectively. The manufacturing journey typically encompasses several key stages: material preparation, forming, assembly, and finishing. Each stage is critical for ensuring that the final product meets quality and performance specifications.

-

Material Preparation

This initial stage involves selecting and preparing raw materials based on product specifications. Common techniques include:

– Cutting and Shaping: Raw materials, such as metals or plastics, are cut into manageable sizes.

– Surface Treatment: Processes like cleaning and coating may be employed to enhance material properties.

– Mixing: For composite materials, mixing different raw components is essential to achieve desired characteristics. -

Forming

This phase is where raw materials are transformed into their desired shapes. Techniques include:

– Casting: Molten material is poured into molds to create complex shapes.

– Molding: Used primarily for plastics, this involves injecting material into molds.

– Machining: This subtractive manufacturing process involves cutting away material to achieve precise dimensions.

-

Assembly

After forming, components are assembled into the final product. This can involve:

– Mechanical Assembly: Using screws, bolts, or adhesives to join parts.

– Automated Assembly: Robotics and automation can streamline the assembly process, reducing labor costs and increasing precision. -

Finishing

The final stage enhances product performance and aesthetics. Finishing techniques include:

– Painting and Coating: Provides protection and improves appearance.

– Polishing: Enhances surface smoothness and reflects quality.

– Heat Treatment: Alters material properties to improve strength and durability.

Quality Assurance

Quality assurance (QA) is a pivotal aspect of the manufacturing process, especially for B2B buyers who need to ensure that products meet specific standards and regulations. A well-structured QA process not only enhances product reliability but also builds trust with clients.

International Standards

Adhering to internationally recognized standards is essential for manufacturers looking to compete globally. Key standards include:

– ISO 9001: This standard outlines the requirements for a quality management system (QMS), ensuring consistent quality in products and services.

– CE Marking: Indicates that a product meets EU safety, health, and environmental protection standards.

– API Certification: Relevant for manufacturers in the oil and gas sector, ensuring compliance with industry-specific quality standards.

QC Checkpoints

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to identify defects early. Common checkpoints include:

– Incoming Quality Control (IQC): Inspects raw materials and components upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Monitors the manufacturing process to identify issues as they occur.

– Final Quality Control (FQC): Conducts thorough inspections and tests on the finished product before shipment.

Common Testing Methods

To ensure compliance with quality standards, various testing methods are employed, such as:

– Mechanical Testing: Evaluates properties like tensile strength and hardness.

– Chemical Analysis: Assesses material composition and purity.

– Functional Testing: Ensures that the product performs as intended under specified conditions.

Verifying Supplier Quality Control

For international B2B buyers, verifying the QC processes of potential suppliers is vital for mitigating risks associated with product quality. Here are several strategies to ensure suppliers adhere to robust QC standards:

-

Conduct Audits

Regular audits of suppliers’ facilities can provide insights into their manufacturing processes and QC systems. This can include both announced and unannounced visits. -

Request Quality Reports

Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC. These documents should outline any non-conformities and corrective actions taken. -

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality processes. These inspections can be tailored to specific requirements and can include pre-shipment inspections. -

Certifications and Compliance

Verify that suppliers hold necessary certifications relevant to your industry and region. This might include ISO certifications, CE marking, and any other local compliance certifications. -

Sample Testing

Before placing large orders, request samples of products to conduct your testing. This allows you to evaluate the quality firsthand and ensure it meets your standards.

Navigating Quality Control Nuances

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control that may affect their purchasing decisions. Here are some considerations:

- Cultural Differences: Different regions may have varying approaches to quality assurance. Understanding these cultural aspects can enhance communication with suppliers.

- Regulatory Compliance: Each country may have specific regulations governing product quality and safety. Being aware of these regulations is essential to avoid legal issues and ensure product acceptance in the target market.

- Supply Chain Transparency: In an increasingly interconnected world, maintaining transparency throughout the supply chain is vital. Buyers should seek suppliers who prioritize transparency in their QC processes and are willing to share relevant documentation.

In conclusion, a comprehensive understanding of manufacturing processes and quality assurance practices equips B2B buyers with the tools needed to make informed sourcing decisions. By focusing on these areas, international buyers can establish strong partnerships with manufacturers that prioritize quality and compliance, ultimately leading to successful business outcomes.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for directory of manufacturers Sourcing

When engaging in international B2B sourcing through manufacturer directories, understanding the cost structure and pricing dynamics is crucial for effective decision-making. This analysis will provide insights into the various cost components, price influencers, and practical tips for buyers, particularly those operating in Africa, South America, the Middle East, and Europe.

Cost Components in Manufacturing

-

Materials: The choice of raw materials significantly impacts the overall cost. High-quality materials typically command higher prices, but they can enhance product durability and performance, potentially leading to lower long-term costs.

-

Labor: Labor costs vary widely across regions. In countries with lower labor costs, such as some in Africa and South America, you may find more competitive pricing. However, consider the implications on quality and production capabilities.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and administrative costs. Efficient manufacturers often have lower overhead costs, allowing them to offer more competitive prices.

-

Tooling: Custom tooling can be a significant upfront investment, particularly for specialized products. However, this cost can be amortized over larger production runs, decreasing per-unit costs.

-

Quality Control (QC): Implementing stringent quality control measures ensures product reliability but adds to the cost. Buyers should assess the balance between QC expenses and the potential costs of defects or returns.

-

Logistics: Transportation and warehousing costs can fluctuate based on distance and shipping methods. Incoterms (International Commercial Terms) play a pivotal role in determining responsibilities for logistics costs.

-

Margin: Manufacturers typically add a margin to cover their costs and ensure profitability. This margin can vary based on market conditions, competition, and the perceived value of the product.

Price Influencers

Several factors can influence pricing strategies in the B2B manufacturing sector:

-

Volume/MOQ: Larger orders often attract better pricing due to economies of scale. Understanding the minimum order quantities (MOQs) can help in negotiating more favorable terms.

-

Specifications/Customization: Custom products or those with specific requirements can lead to higher costs. Clarifying your needs upfront can prevent unexpected expenses later in the process.

-

Quality/Certifications: Products that meet specific quality standards or certifications may carry a premium. Buyers should weigh the benefits of certification against the additional costs.

-

Supplier Factors: The reputation, reliability, and experience of suppliers can influence pricing. Established suppliers may charge higher prices but often provide better service and product assurance.

-

Incoterms: The choice of Incoterms affects cost allocation between buyers and sellers, impacting the final price. Familiarizing yourself with these terms is essential for accurate cost assessments.

Buyer Tips for Cost Efficiency

-

Negotiate: Don’t hesitate to negotiate prices. Suppliers often have some flexibility, especially if you are a repeat customer or can offer larger volumes.

-

Consider Total Cost of Ownership (TCO): Evaluate all costs associated with a product, including purchase price, shipping, tariffs, and maintenance. A lower initial price might not always equate to lower overall costs.

-

Leverage Manufacturer Directories: Utilize platforms like IndustrySelect and Thomasnet to compare suppliers and access verified information, enabling informed decisions.

-

Understand Pricing Nuances: Be aware that pricing can vary based on geopolitical factors, currency fluctuations, and local market conditions. Staying informed on these aspects can enhance your negotiation strategy.

Disclaimer

Pricing structures in manufacturing are indicative and can vary widely based on numerous factors, including market conditions and specific project requirements. It’s advisable to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to your needs.

Spotlight on Potential directory of manufacturers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘directory of manufacturers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for directory of manufacturers

Key Technical Properties for B2B Manufacturing

Understanding the essential technical properties when sourcing products from manufacturers is crucial for international B2B buyers. Here are some critical specifications to consider:

-

Material Grade

– Definition: This refers to the specific quality or classification of a material used in manufacturing, such as stainless steel, aluminum, or plastics.

– Importance: Material grade affects product durability, performance, and cost. Buyers must ensure the material meets their project requirements to avoid costly replacements or failures. -

Tolerance

– Definition: Tolerance specifies the allowable deviation from a standard dimension in manufactured parts. It is often expressed as a range (e.g., ±0.01 mm).

– Importance: Accurate tolerances are vital for parts that must fit together or function correctly. Inconsistent tolerances can lead to assembly issues and increased rejection rates, impacting overall project timelines and costs. -

Surface Finish

– Definition: This describes the texture and smoothness of a product’s surface, which can be specified in terms of roughness (Ra value) or finish type (e.g., polished, anodized).

– Importance: Surface finish can influence a product’s aesthetic appeal and functional properties, such as corrosion resistance or friction. Buyers need to specify the desired finish to meet both functional and visual requirements. -

Load Capacity

– Definition: This refers to the maximum load a product can safely handle without failure, typically expressed in weight units (e.g., pounds or kilograms).

– Importance: Knowing load capacity is crucial for structural components and machinery. Underestimating this can lead to catastrophic failures, safety risks, and financial losses. -

Certifications and Compliance

– Definition: Certifications indicate that a product meets specific industry standards (e.g., ISO, CE, RoHS).

– Importance: Compliance with regulations is essential for international trade. Buyers should verify that products meet necessary certifications to avoid legal issues and ensure product safety and reliability.

Common Trade Terminology in B2B Manufacturing

Familiarity with industry jargon is essential for effective communication and negotiation with manufacturers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify the source of components and assess quality standards. -

MOQ (Minimum Order Quantity)

– Definition: This term refers to the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is critical for budgeting and inventory management. Buyers should negotiate MOQs to align with their purchasing capabilities. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting a quote for specific products or services.

– Importance: Issuing an RFQ helps buyers compare pricing and terms across multiple suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: These are standardized international trade terms that define the responsibilities of buyers and sellers for shipping and delivery.

– Importance: Understanding Incoterms is essential for managing shipping costs and responsibilities, reducing the risk of disputes during international transactions.

Illustrative Image (Source: Google Search)

- Lead Time

– Definition: Lead time refers to the amount of time it takes from placing an order until the product is delivered.

– Importance: Buyers must consider lead time in their planning to ensure timely project completion. Longer lead times can impact supply chain efficiency and customer satisfaction.

Illustrative Image (Source: Google Search)

- Supply Chain Transparency

– Definition: This term describes the extent to which information about the supply chain is accessible and clear to buyers.

– Importance: Transparency is vital for trust and risk management. It allows buyers to understand sourcing practices and ethical considerations, essential for maintaining brand integrity in global markets.

By understanding these technical properties and trade terms, international B2B buyers can enhance their procurement strategies, ensuring they source high-quality products that meet their specific needs while navigating the complexities of global manufacturing.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the directory of manufacturers Sector

Market Overview & Key Trends

The global landscape for manufacturers is evolving rapidly, driven by factors such as technological advancements, changing consumer preferences, and geopolitical shifts. Digital transformation is a cornerstone of this evolution, with technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and blockchain reshaping how manufacturers operate and engage with B2B buyers. For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, leveraging these technologies can enhance sourcing efficiency and transparency.

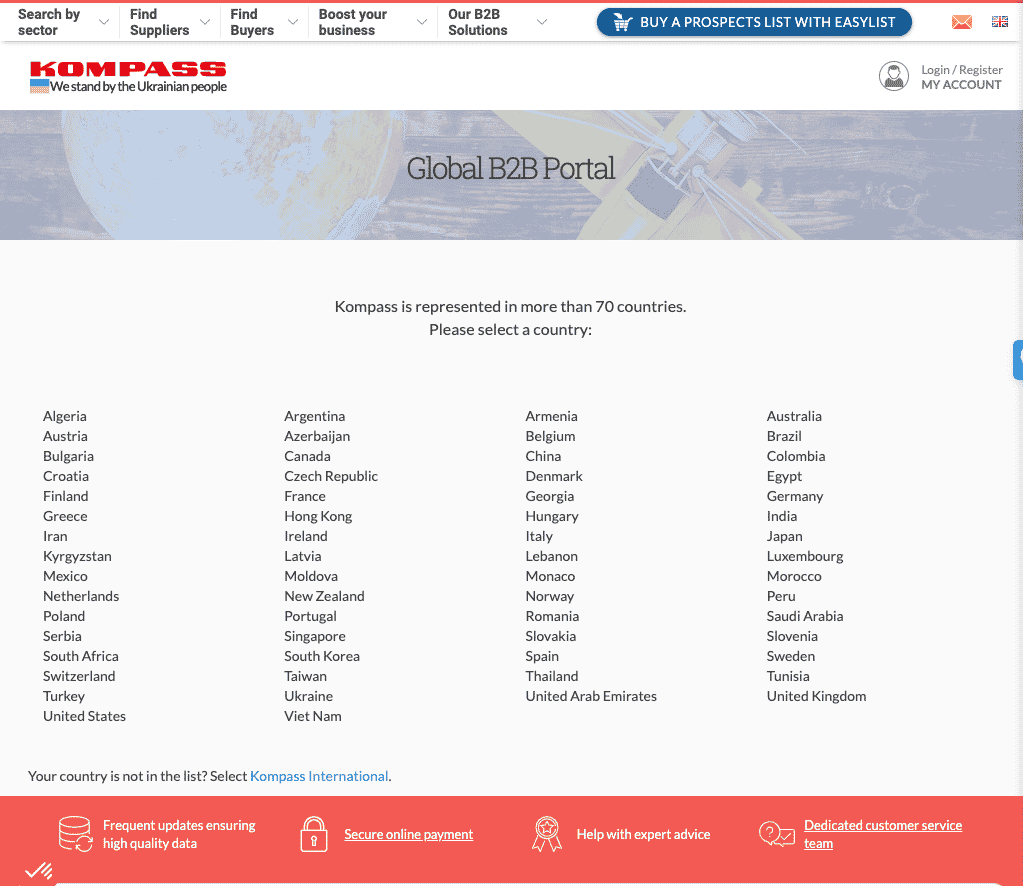

Emerging sourcing trends include a shift towards data-driven decision-making. Buyers are increasingly utilizing comprehensive databases and platforms like IndustrySelect and Thomasnet to identify and connect with potential suppliers based on specific criteria such as location, industry, and certifications. This trend is particularly advantageous for B2B buyers from developing markets, who can now access a broader range of manufacturers and service providers than ever before.

Additionally, localization is gaining traction as companies seek to mitigate supply chain risks exacerbated by global disruptions. By sourcing from local or regional manufacturers, buyers can reduce lead times and costs while supporting local economies. This trend is especially relevant in the context of post-pandemic recovery, where resilience and sustainability have become paramount.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere buzzword; it is a critical component of modern supply chain strategy. International buyers are increasingly prioritizing ethical sourcing practices that minimize environmental impact and promote social responsibility. This shift reflects a growing awareness of the importance of sustainable practices in enhancing brand reputation and customer loyalty.

Ethical supply chains are characterized by transparency, fairness, and adherence to environmental regulations. Buyers should look for manufacturers that hold certifications such as ISO 14001 (Environmental Management) or those that utilize green materials and processes. These certifications not only demonstrate a commitment to sustainability but also provide buyers with assurance regarding the ethical standards upheld throughout the supply chain.

Moreover, the demand for eco-friendly products is on the rise, with consumers increasingly favoring brands that prioritize sustainability. This trend creates opportunities for B2B buyers to collaborate with manufacturers that align with these values, thereby enhancing their market competitiveness. By integrating sustainability into sourcing strategies, companies can drive innovation and foster long-term relationships with responsible manufacturers.

Brief Evolution/History

The directory of manufacturers has its roots in the early industrial revolution, when businesses began to recognize the need for organized supplier information to facilitate trade. Initially, these directories were physical books, compiling lists of manufacturers and their products. With the advent of the internet, the directory model evolved significantly, transitioning to online platforms that offered real-time access to extensive databases of manufacturers and suppliers.

Today, platforms like IndustrySelect and Thomasnet serve as comprehensive resources for B2B buyers, providing not only manufacturer listings but also valuable insights and tools for effective sourcing. This evolution has democratized access to information, enabling international buyers from diverse regions to connect with manufacturers worldwide, fostering a more interconnected global economy.

Related Video: Made in the world: Better understanding global trade flows

Frequently Asked Questions (FAQs) for B2B Buyers of directory of manufacturers

-

How can I effectively vet suppliers from a manufacturer directory?

To vet suppliers, start by checking their certifications, industry reputation, and customer reviews. Utilize directories that provide detailed company profiles, including executive contact information and financial stability indicators. Look for third-party audits or quality certifications like ISO, which can assure reliability. Engaging in direct communication with suppliers can also help gauge their responsiveness and willingness to share references. Consider requesting samples of their products to evaluate quality before making larger commitments. -

Are there options for customizing products when sourcing from manufacturers?

Many manufacturers offer customization options, but the extent can vary. When using a directory, filter suppliers by those specializing in custom solutions. Clearly outline your requirements during initial discussions to assess their capabilities. Be prepared to discuss design specifications, materials, and any special features you need. Ensure that the manufacturer has experience in your specific industry to facilitate a smoother customization process. -

What are typical minimum order quantities (MOQ) and lead times for international orders?

MOQs can vary significantly between manufacturers based on product type and customization level. It’s essential to inquire about these details upfront. For international orders, lead times can also differ based on shipping methods and customs processing. Generally, expect longer lead times for customized products. Always confirm these details in writing to avoid misunderstandings and to plan your inventory needs accordingly. -

What payment methods are commonly accepted by manufacturers in directories?

Payment methods vary by manufacturer but typically include wire transfers, letters of credit, and online payment platforms. For international transactions, it’s crucial to choose a secure method that offers buyer protection. Discuss payment terms early in negotiations, including deposits and final payment schedules. Consider using escrow services for large transactions to mitigate risks, ensuring funds are only released when both parties meet agreed-upon conditions. -

How do I ensure quality assurance and compliance with certifications?

Quality assurance is critical when sourcing internationally. Request detailed information about the manufacturer’s quality control processes and any relevant certifications (e.g., ISO, CE). Ask for documentation that verifies compliance with local and international standards. Regular audits and inspections can be arranged to ensure ongoing compliance. Consider third-party inspection services before shipment to assess product quality and adherence to specifications. -

What logistics considerations should I keep in mind when importing products?

Logistics can significantly impact your supply chain efficiency. Understand the shipping options available, including air freight for speed or sea freight for cost-effectiveness. Be aware of customs regulations in your country and the exporting country, including tariffs and duties that may apply. Establish a reliable logistics partner who can manage the complexities of international shipping and provide tracking capabilities for better visibility. -

How can I handle disputes with manufacturers sourced from directories?

Dispute resolution should be addressed in your contract before proceeding with an order. Clearly outline the terms for returns, refunds, and exchanges, as well as communication protocols for addressing issues. If a dispute arises, maintain a detailed record of all correspondence and agreements. Mediation and arbitration are often effective ways to resolve disputes without resorting to litigation. If necessary, engage legal counsel experienced in international trade. -

What are the benefits of using a directory of manufacturers for sourcing?

Utilizing a directory provides access to a wide range of verified suppliers, saving time in the sourcing process. You can filter manufacturers by location, industry, and certifications, ensuring you find partners that meet your specific needs. Many directories offer tools for direct communication, quotes, and comparison of supplier capabilities. This centralized approach enhances transparency and allows for better-informed decision-making, ultimately strengthening your supply chain and business relationships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for directory of manufacturers

In today’s global marketplace, strategic sourcing is vital for international B2B buyers seeking competitive advantages. By leveraging comprehensive directories of manufacturers, businesses can identify reliable suppliers tailored to their specific needs. Access to detailed company profiles, including executive contacts and operational capabilities, enables buyers to make informed decisions, streamline procurement processes, and enhance supply chain resilience.

Key takeaways for buyers from Africa, South America, the Middle East, and Europe include the importance of utilizing verified databases to uncover potential partners and the necessity of evaluating suppliers based on certifications and service capabilities. Additionally, the ability to filter suppliers by location and industry can lead to more localized sourcing strategies, reducing lead times and shipping costs.

Looking forward, the trend toward digital transformation in procurement will continue to shape the sourcing landscape. Buyers are encouraged to embrace these tools and technologies to remain agile and responsive to market changes. As you navigate your sourcing journey, consider the insights provided here to foster strategic partnerships that drive growth and innovation in your business. Start exploring your options today—your next successful partnership awaits!