Your Ultimate Guide to Sourcing Flat Belt And Pulley

Introduction: Navigating the Global Market for flat belt and pulley

In today’s competitive landscape, flat belt and pulley systems serve as critical components in various industrial applications, ranging from manufacturing to logistics. These systems are essential for efficient power transmission, enabling machinery to operate smoothly and reliably. With the globalization of supply chains, understanding the nuances of sourcing these components becomes paramount for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe.

This comprehensive guide delves into the various types and materials of flat belts and pulleys, providing insights into their applications across different industries. We will explore the manufacturing processes and quality control measures that ensure product reliability, as well as introduce you to a curated list of trusted suppliers from around the globe. Additionally, we will provide a detailed analysis of cost factors and market trends, empowering you to make informed purchasing decisions.

Our aim is to equip you with the knowledge necessary to navigate the complexities of the global market for flat belt and pulley systems. By the end of this guide, you will have the tools to optimize your sourcing strategies, enhance operational efficiency, and ultimately drive profitability in your business. Whether you’re based in Turkey, Vietnam, or anywhere in between, this guide is your roadmap to effective procurement in the ever-evolving international marketplace.

Understanding flat belt and pulley Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Flat Belt | Simple design, made of fabric or rubber | Manufacturing, Agriculture | Pros: Cost-effective, easy to install. Cons: Limited power transmission capacity. |

| V-Belt | Trapezoidal shape, fits into pulley grooves | Automotive, HVAC systems | Pros: High power transmission, efficient. Cons: More complex installation, higher cost. |

| Multi-V Belt | Multiple V-shaped ribs for increased load capacity | Heavy machinery, industrial equipment | Pros: Higher load capacity, reduced slippage. Cons: Requires precise alignment, can be more expensive. |

| Timing Belt | Teeth on the belt for precise movement | Robotics, CNC machines | Pros: Accurate timing, minimal slip. Cons: Sensitive to misalignment, can be noisy. |

| Flat Wire Belt | Made from flat wire, offers strength and flexibility | Food processing, packaging | Pros: Durable, easy to clean. Cons: Higher initial investment, may require custom solutions. |

Standard Flat Belt

Standard flat belts are commonly made from fabric or rubber and are characterized by their simple design. They are widely used in manufacturing and agricultural applications for their cost-effectiveness and ease of installation. However, buyers should consider their limited power transmission capacity, which may not be suitable for high-load applications.

V-Belt

V-belts feature a trapezoidal shape that allows them to fit snugly into pulley grooves, providing efficient power transmission. They are prevalent in automotive and HVAC systems. While V-belts are capable of handling higher power loads, their installation can be more complex, and they tend to be more expensive than standard flat belts.

Multi-V Belt

Multi-V belts consist of multiple V-shaped ribs, enhancing their load capacity and reducing slippage. These belts are ideal for heavy machinery and industrial equipment where high performance is crucial. Buyers should be aware that while they offer significant advantages, precise alignment during installation is necessary, and they can be pricier than standard options.

Timing Belt

Timing belts are distinguished by their toothed design, which allows for precise movement and timing in applications such as robotics and CNC machines. Their ability to minimize slip makes them ideal for tasks requiring accuracy. However, buyers must consider their sensitivity to misalignment and potential noise during operation, which may necessitate additional maintenance.

Flat Wire Belt

Flat wire belts are made from flat wire, providing both strength and flexibility, making them suitable for food processing and packaging industries. Their durability and ease of cleaning are significant advantages for B2B buyers. However, the initial investment can be higher, and buyers may need to consider custom solutions to fit specific operational needs.

Related Video: Pulley & Types of Pulley | Grade 4 & 5 | Science | TutWay

Key Industrial Applications of flat belt and pulley

| Industry/Sector | Specific Application of flat belt and pulley | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhances material handling efficiency | Look for durable materials and customizable sizes for specific needs. |

| Food Processing | Packaging and Sorting Machines | Increases speed and accuracy in operations | Ensure compliance with food safety standards and easy cleaning features. |

| Mining and Quarrying | Material Transport Systems | Reduces downtime and operational costs | Seek high-strength belts that can withstand harsh environments. |

| Agriculture | Irrigation Systems | Improves water distribution efficiency | Consider weather-resistant materials and compatibility with existing systems. |

| Textile Industry | Spinning and Weaving Machines | Boosts production rates and reduces waste | Evaluate the flexibility and tensile strength of belts for specific machinery. |

Manufacturing

In the manufacturing sector, flat belt and pulley systems are integral to conveyor systems that transport materials between different stages of production. These systems significantly enhance material handling efficiency by minimizing manual labor and reducing the time taken to move products. For international buyers, especially those in Africa and South America, sourcing durable and customizable belts that can adapt to varying load requirements and environmental conditions is crucial to ensure operational reliability and longevity.

Food Processing

In food processing, flat belts are commonly used in packaging and sorting machines. These systems improve the speed and accuracy of operations, ensuring that products are packaged efficiently and meet high-quality standards. Buyers in the Middle East and Europe should prioritize suppliers who offer belts compliant with food safety regulations, featuring materials that are easy to clean and resistant to contamination, to maintain hygiene in production lines.

Mining and Quarrying

The mining and quarrying industries utilize flat belt and pulley systems for material transport, which are essential for moving heavy loads over long distances. These systems help reduce downtime and operational costs by ensuring a continuous flow of materials. Buyers in regions like Africa, where mining is a significant economic activity, should focus on sourcing high-strength belts designed to withstand harsh conditions, including extreme temperatures and abrasive materials.

Agriculture

Flat belts are also pivotal in irrigation systems, where they help in the efficient distribution of water across large fields. This application is vital for improving agricultural productivity, particularly in arid regions. Buyers from South America and the Middle East should consider sourcing weather-resistant materials that ensure durability and compatibility with existing irrigation systems, which can enhance water management and crop yields.

Textile Industry

In the textile industry, flat belts are used in spinning and weaving machines to facilitate the movement of fibers and finished products. This application boosts production rates and minimizes waste, essential for maintaining competitiveness. Buyers in Europe, particularly in countries with a strong textile manufacturing base, should evaluate the flexibility and tensile strength of belts to ensure they meet the specific requirements of their machinery, thereby optimizing production efficiency.

Related Video: Belt and Pulley Basics – EricTheCarGuy

Strategic Material Selection Guide for flat belt and pulley

When selecting materials for flat belts and pulleys, it is crucial to consider their specific properties and applications. The right material can significantly impact performance, durability, and overall cost-effectiveness. Below, we analyze four common materials used in the manufacture of flat belts and pulleys, providing insights tailored for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

1. Rubber

Key Properties:

Rubber belts are known for their excellent flexibility and elasticity, enabling them to operate effectively under varying loads and conditions. They typically have a temperature rating of -30°C to 80°C and exhibit good abrasion resistance.

Pros & Cons:

Rubber is durable and provides high friction, which is beneficial for power transmission. However, it can degrade when exposed to oils and UV light, potentially leading to a shorter lifespan. Manufacturing complexity is moderate, often requiring specialized equipment for molding and curing.

Impact on Application:

Rubber belts are suitable for applications involving moderate tension and where flexibility is essential, such as in conveyor systems. They are not ideal for environments with high temperatures or chemical exposure.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM or DIN. Rubber belts may be subject to regulations regarding environmental impact, especially in regions with strict sustainability mandates.

2. Polyurethane

Key Properties:

Polyurethane belts offer excellent abrasion resistance and can withstand a temperature range of -30°C to 90°C. They also exhibit good chemical resistance, making them suitable for various industrial applications.

Pros & Cons:

The key advantage of polyurethane is its durability and resistance to wear, which can lead to longer service life. However, it is generally more expensive than rubber, and the manufacturing process can be complex due to the need for precise formulations.

Impact on Application:

Polyurethane is ideal for high-load applications and environments where chemical exposure is a concern, such as food processing or pharmaceuticals. Its compatibility with various media enhances its versatility.

Considerations for International Buyers:

Buyers should verify that the polyurethane used meets relevant safety and quality standards. Additionally, understanding the supply chain for sourcing high-quality polyurethane is essential, particularly in regions with limited local production.

3. Nylon

Key Properties:

Nylon belts are characterized by their high tensile strength and low friction properties. They can operate effectively at temperatures up to 120°C and have good resistance to abrasion and wear.

Pros & Cons:

Nylon is lightweight and offers excellent performance in high-speed applications. However, it can absorb moisture, which may affect its dimensional stability and lead to swelling. The manufacturing process can be more complex due to the need for precise machining.

Impact on Application:

Nylon belts are suitable for high-speed conveyor systems and applications requiring lightweight yet strong materials. They are less effective in humid environments unless treated for moisture resistance.

Considerations for International Buyers:

Buyers should consider the availability of nylon materials in their region and the potential need for moisture-resistant treatments. Compliance with international standards for nylon products is also crucial.

4. Steel

Key Properties:

Steel pulleys provide high strength and durability, with a temperature tolerance that can exceed 200°C. They are resistant to deformation and have excellent load-bearing capabilities.

Pros & Cons:

The primary advantage of steel is its strength and longevity, making it suitable for heavy-duty applications. However, steel can be prone to corrosion, necessitating protective coatings, which can add to manufacturing complexity and cost.

Impact on Application:

Steel is ideal for applications requiring high load capacities, such as in mining or heavy machinery. However, its weight can be a disadvantage in systems where weight reduction is critical.

Considerations for International Buyers:

International buyers must ensure compliance with local and international standards for steel products, including corrosion resistance specifications. Understanding the local market for steel sourcing, including potential tariffs and import regulations, is also essential.

Summary Table

| Material | Typical Use Case for flat belt and pulley | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Conveyor systems | High flexibility and elasticity | Degrades under oils and UV exposure | Medium |

| Polyurethane | Food processing, pharmaceuticals | Excellent abrasion and chemical resistance | Higher cost and complex manufacturing | High |

| Nylon | High-speed conveyor systems | Lightweight with high tensile strength | Moisture absorption can affect stability | Medium |

| Steel | Heavy machinery, mining | High strength and durability | Prone to corrosion | Medium to High |

This guide provides a comprehensive overview of material selection for flat belts and pulleys, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for flat belt and pulley

Flat belts and pulleys are essential components in various industrial applications, enabling efficient power transmission and movement. Understanding the manufacturing processes and quality assurance measures for these products is crucial for B2B buyers, especially those sourcing from international suppliers. This section will outline the typical manufacturing stages, quality control standards, and verification methods that can aid buyers in making informed decisions.

Manufacturing Processes

The manufacturing of flat belts and pulleys typically involves several key stages:

1. Material Preparation

- Selection of Materials: The choice of materials is foundational. Common materials for flat belts include rubber, polyurethane, or leather, while pulleys are often made from metals such as aluminum, steel, or plastic composites. The properties of these materials affect durability, flexibility, and weight.

- Processing Raw Materials: For rubber or polyurethane belts, raw materials may undergo chemical treatments to enhance performance characteristics. Metals may require cutting, shaping, or alloying to achieve desired specifications.

2. Forming

- Belt Formation: This stage involves the extrusion or molding of the belt material into the desired shape. Techniques such as die-cutting or calendering may be employed, depending on the material and design requirements.

- Pulley Fabrication: Pulleys are typically machined using CNC (Computer Numerical Control) techniques, which ensure precision in dimensions and surface finishes. This process may include turning, milling, and drilling to create the pulley profile.

3. Assembly

- Joining Components: For systems requiring multiple components, assembly techniques such as adhesive bonding, mechanical fastening, or welding may be utilized. Ensuring proper alignment and fit is critical for performance.

- Integration of Features: Features such as grooves for belt engagement or keyways for shaft locking are integrated during this stage to enhance functionality.

4. Finishing

- Surface Treatments: Finishing processes, including polishing, coating, or painting, are applied to improve appearance and protect against environmental factors. For belts, surface texturing can enhance grip and reduce slippage.

- Final Inspection: Before packaging, a final inspection is performed to ensure that the products meet specified dimensions and surface quality.

Quality Assurance

Quality assurance is pivotal in ensuring that flat belts and pulleys meet industry standards and customer expectations. Here are the key elements involved in the QC process:

International and Industry-Specific Standards

- ISO 9001: This widely recognized standard focuses on quality management systems. Compliance indicates that a manufacturer has established a systematic approach to quality assurance.

- CE Marking: In Europe, products must meet safety, health, and environmental protection standards. CE marking signifies compliance with EU legislation.

- API Standards: For applications in the oil and gas sector, API (American Petroleum Institute) standards may apply, ensuring equipment meets industry-specific safety and performance criteria.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This involves the inspection of raw materials and components upon arrival. Buyers should ensure that suppliers have robust IQC processes to prevent defects from entering the production line.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are conducted to monitor production quality. This includes measuring dimensions, testing material properties, and ensuring compliance with specifications.

- Final Quality Control (FQC): A comprehensive review of the finished products is conducted before shipping. This includes functional testing and visual inspections to identify any defects.

Common Testing Methods

- Tensile Testing: This method assesses the strength and elasticity of flat belts, ensuring they can withstand operational loads.

- Durability Testing: Pulleys may undergo fatigue and wear tests to evaluate their longevity under continuous operation.

- Dimensional Inspection: Precision measuring tools are used to confirm that products meet specified tolerances.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are effective methods:

Audits

- On-Site Audits: Conducting audits at the supplier’s facility allows buyers to assess production processes, quality control measures, and overall operational capabilities.

- Third-Party Audits: Engaging independent auditors can provide an objective evaluation of a supplier’s compliance with international standards.

Quality Reports

- Requesting Documentation: Buyers should request detailed quality reports that outline testing results, certifications, and compliance with industry standards. This documentation serves as a critical reference for assessing supplier reliability.

Third-Party Inspection

- Engaging Inspection Services: Utilizing third-party inspection services before shipment can help ensure that products meet quality expectations. These services can perform random inspections and provide reports verifying compliance.

Considerations for International Buyers

When sourcing flat belts and pulleys from suppliers in Africa, South America, the Middle East, and Europe, buyers should consider the following nuances:

- Cultural Differences: Understanding cultural norms and business practices can facilitate smoother negotiations and interactions with suppliers.

- Regulatory Compliance: Different regions may have varying regulations regarding product safety and quality. Buyers must ensure that suppliers are compliant with local and international laws.

- Logistics and Supply Chain: Consider the implications of shipping, customs clearance, and potential delays. Establishing clear communication with suppliers can mitigate issues arising from international logistics.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for flat belts and pulleys is essential for B2B buyers. By focusing on key manufacturing stages, adhering to quality standards, and implementing effective verification methods, buyers can ensure they source reliable, high-quality products that meet their operational needs.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for flat belt and pulley Sourcing

When sourcing flat belts and pulleys, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This knowledge not only aids in budget planning but also enhances negotiation strategies with suppliers. Here’s a breakdown of the key components influencing costs and pricing.

Cost Components

-

Materials: The primary cost driver in flat belt and pulley production is the materials used. Common materials include rubber, polyurethane, and various metals, each with varying cost implications based on market fluctuations and availability. Buyers should consider sourcing high-quality materials that meet their operational requirements to avoid additional costs in the long run.

-

Labor: Labor costs can significantly impact overall pricing, especially in regions with high wage standards. Understanding the local labor market conditions where the production occurs can provide insights into potential cost variations. Regions with lower labor costs, such as parts of Southeast Asia, may offer competitive pricing.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and administrative costs associated with production. Buyers should inquire about overhead allocations when negotiating prices, as these can vary significantly among suppliers.

-

Tooling: Custom tooling for specific belt and pulley designs can add a substantial upfront cost. Buyers should assess whether the long-term benefits of custom solutions outweigh the initial investment.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to manufacturing costs. Suppliers with robust QC systems may charge higher prices but can ultimately save buyers money by reducing defects and returns.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, mode of transport, and any tariffs or duties can significantly affect the total price.

-

Margin: Supplier margins can vary widely based on market conditions and competition. Understanding the typical margins in the industry can help buyers gauge fair pricing.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) can greatly influence pricing. Larger orders often lead to lower per-unit costs. Buyers should evaluate their needs to strike a balance between inventory costs and order size.

-

Specifications/Customization: Custom specifications can lead to increased costs. Buyers should clearly define their requirements upfront to avoid unexpected charges later in the process.

-

Quality/Certifications: Products that meet international quality standards or have certifications may come at a premium. However, investing in certified products can enhance operational efficiency and reduce risks.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but offer better service, quality, and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for cost management. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the total landed cost.

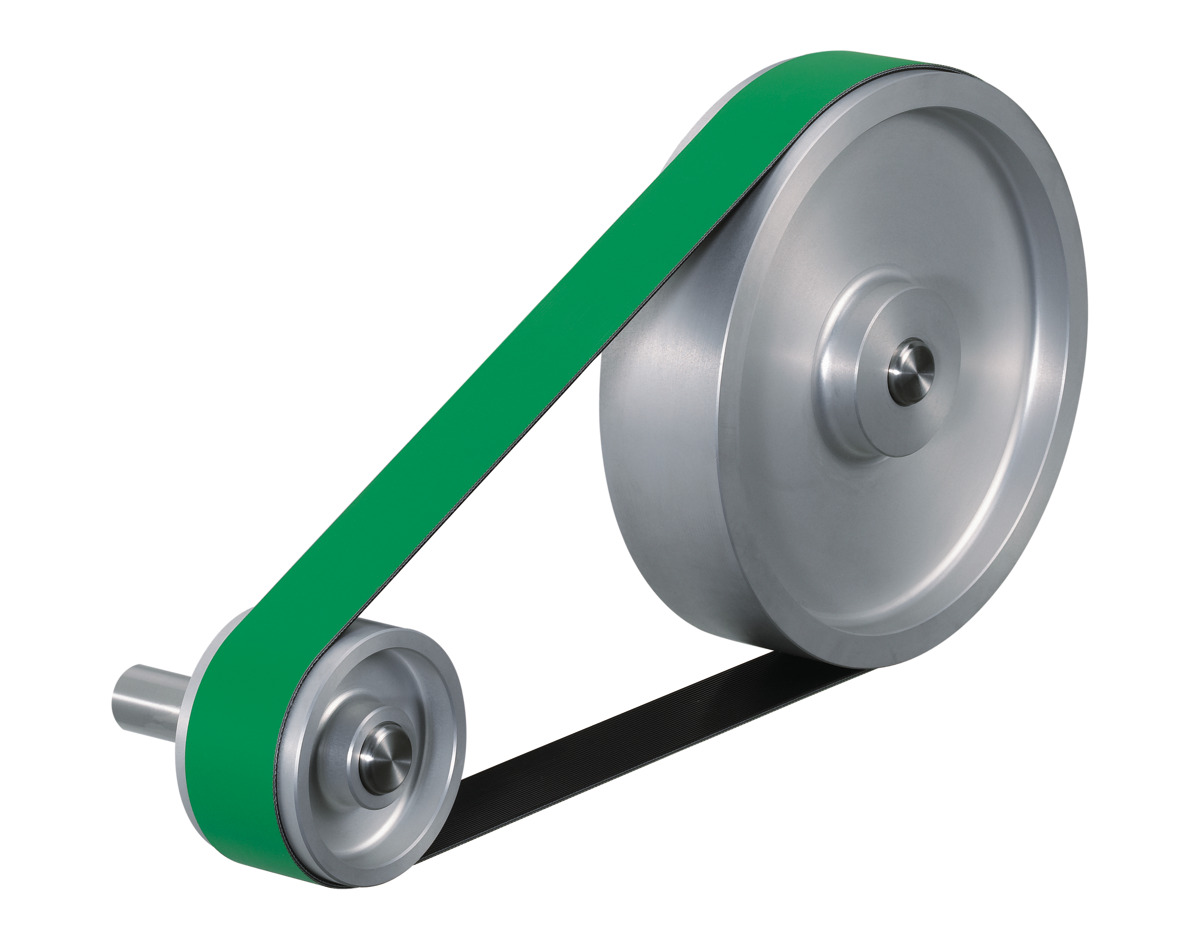

Illustrative Image (Source: Google Search)

Buyer Tips

-

Negotiation: Leverage knowledge of cost components and market trends during negotiations. Be prepared to discuss the rationale behind pricing and seek discounts for larger volumes.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Consider maintenance, lifespan, and operational efficiency when evaluating options.

-

Pricing Nuances: International buyers should be aware of regional pricing trends. For example, sourcing from Europe may yield higher initial prices but could offer superior quality and reliability compared to lower-cost suppliers in other regions.

In conclusion, navigating the cost and pricing landscape for flat belts and pulleys requires a strategic approach. By understanding the components that contribute to pricing and leveraging negotiation tactics, international buyers can optimize their sourcing decisions. Always remember that prices can fluctuate based on market conditions, so obtaining multiple quotes and staying informed is crucial.

Spotlight on Potential flat belt and pulley Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘flat belt and pulley’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for flat belt and pulley

When engaging in the procurement of flat belts and pulleys, understanding the essential technical properties and trade terminology is crucial for making informed decisions. This section outlines key specifications and common industry terms that international B2B buyers should be familiar with.

Key Technical Properties

-

Material Grade

– Flat belts and pulleys can be made from various materials, including rubber, polyurethane, and PVC. The choice of material affects durability, flexibility, and resistance to wear and tear. For instance, polyurethane belts are often favored for their strength and longevity in high-tension applications. Selecting the right material grade is vital to ensure optimal performance and lifespan, reducing the need for frequent replacements. -

Width and Thickness

– The width and thickness of flat belts directly influence their load-bearing capacity and the fit with pulleys. Common widths range from 10 mm to over 300 mm, with thicknesses varying accordingly. It is important for buyers to match these specifications with the requirements of their machinery to avoid slippage or excessive wear, which can lead to operational inefficiencies.

-

Belt Tension

– Proper tension is crucial for the effective operation of flat belt systems. Insufficient tension can cause slippage, while excessive tension can lead to premature wear of both the belt and the pulleys. Buyers should consider the recommended tension specifications provided by manufacturers, as these can vary based on the application and design of the system. -

Temperature and Environmental Resistance

– Flat belts and pulleys must often operate in varying environmental conditions. Buyers should consider the temperature range and resistance to chemicals, oils, and other substances that may be present in their operating environment. Selecting products with suitable resistance properties can prevent degradation and ensure consistent performance. -

Tolerance

– Tolerance specifications refer to the allowable deviation from the nominal dimensions of the belts and pulleys. Tight tolerances are essential for applications requiring precision, such as in automated machinery. Buyers should assess the tolerance levels that manufacturers can provide to ensure compatibility with their systems.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is essential for buyers looking to procure components that will fit seamlessly into existing systems. -

MOQ (Minimum Order Quantity)

– This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for smaller businesses or those looking to test new products. -

RFQ (Request for Quotation)

– An RFQ is a formal request sent to suppliers to obtain price quotes for specific products or services. Buyers should prepare detailed RFQs to ensure they receive accurate and comparable quotations, which can aid in effective supplier selection. -

Incoterms (International Commercial Terms)

– These are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is vital for negotiating shipping costs and responsibilities, ensuring clarity on who bears the risk at each stage of the shipping process. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is critical for planning production schedules and maintaining inventory levels, particularly in industries with tight deadlines.

By familiarizing themselves with these technical properties and industry terms, B2B buyers can enhance their purchasing strategy, ensuring they acquire the right flat belts and pulleys that meet their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the flat belt and pulley Sector

Market Overview & Key Trends

The flat belt and pulley sector is experiencing significant growth driven by industrialization and technological advancements across various regions, particularly in Africa, South America, the Middle East, and Europe. The global shift towards automation and increased demand for efficient power transmission systems are key drivers. Emerging technologies such as IoT and smart manufacturing are transforming traditional operations, leading to the integration of data analytics for predictive maintenance, which enhances efficiency and reduces downtime.

International B2B buyers should be aware of several trends shaping the market. First, there is a growing preference for customized solutions tailored to specific industrial applications. Suppliers that offer modular designs and flexible manufacturing processes are gaining a competitive edge. Second, sustainability is becoming a critical factor; buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental responsibility. Lastly, the market is witnessing a surge in digital platforms facilitating sourcing, enabling buyers to easily compare suppliers and products, which enhances transparency and efficiency in procurement.

Additionally, geopolitical factors and supply chain disruptions due to global events have emphasized the need for strategic sourcing. Companies are diversifying their supplier base to mitigate risks and ensure continuity, particularly in regions vulnerable to political instability or economic fluctuations.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer an option but a necessity in the flat belt and pulley sector. The environmental impact of manufacturing processes, from raw material extraction to production waste, necessitates a shift towards greener practices. Buyers are increasingly scrutinizing suppliers for their sustainability initiatives, such as energy-efficient manufacturing processes and waste reduction strategies.

Ethical sourcing plays a pivotal role in building a responsible supply chain. Buyers should prioritize suppliers who adhere to ethical labor practices and maintain transparency in their operations. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) signal a supplier’s commitment to sustainability and can enhance a company’s reputation in the marketplace.

Moreover, the use of eco-friendly materials and processes, such as recycled plastics and biodegradable lubricants, is gaining traction. Buyers should seek out suppliers who offer ‘green’ certifications for their products, ensuring that their sourcing aligns with their corporate sustainability goals. Implementing these practices not only reduces environmental impact but can also lead to cost savings and improved operational efficiencies.

Brief Evolution/History

The flat belt and pulley systems have evolved significantly since their inception during the Industrial Revolution. Initially, flat belts were primarily made from leather, which provided limited durability and efficiency. Over time, advancements in materials science led to the development of synthetic materials such as rubber and polyester, enhancing the performance and lifespan of these systems.

In the latter half of the 20th century, the introduction of variable-speed pulleys and automated tensioning systems revolutionized the industry, allowing for greater flexibility in power transmission. Today, the focus has shifted towards integrating digital technologies, enabling real-time monitoring and optimization of belt systems. This evolution not only underscores the importance of innovation in the sector but also highlights the growing demand for sustainable practices and ethical sourcing, which are now integral to the modern B2B landscape.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of flat belt and pulley

-

How can I effectively vet suppliers for flat belts and pulleys?

When sourcing flat belts and pulleys, it’s crucial to conduct thorough due diligence. Begin by researching potential suppliers’ reputations through online reviews and industry forums. Request references from previous clients, and verify their manufacturing capabilities by visiting their facilities if possible. Additionally, check for certifications such as ISO 9001, which indicates quality management standards. Engaging a local sourcing agent familiar with the region can also help in assessing the reliability and credibility of suppliers. -

What customization options are typically available for flat belts and pulleys?

Many suppliers offer customization options for flat belts and pulleys to meet specific operational requirements. Common customizations include variations in material, thickness, width, and length. You can also request specific surface treatments, colors, or branding features. It’s important to communicate your exact specifications clearly to the supplier and inquire about their design capabilities. Ensure that the supplier can provide prototypes or samples before finalizing large orders to verify that the customizations meet your needs. -

What are the typical minimum order quantities (MOQs) and lead times for flat belts and pulleys?

MOQs for flat belts and pulleys can vary widely depending on the supplier and the complexity of the product. Generally, MOQs can range from 100 to 1,000 units. Lead times also depend on the supplier’s location, manufacturing capacity, and whether the products are customized. Standard lead times typically range from 2 to 6 weeks for non-custom orders, while custom orders might take longer. Always clarify these details upfront to align with your project timelines and budget.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when sourcing flat belts and pulleys internationally?

Payment terms can vary depending on the supplier’s policies and your negotiation. Common options include advance payment, a letter of credit, or payment upon delivery. For larger orders, suppliers may offer a 30% deposit with the balance due before shipment. Ensure that you understand the implications of each payment method, including potential fees and risks. It’s advisable to use escrow services for high-value transactions to protect both parties involved. -

What quality assurance measures should I look for when sourcing flat belts and pulleys?

Quality assurance is critical in ensuring that the flat belts and pulleys meet your operational standards. Look for suppliers who have established QA processes, including regular inspections and testing of materials. Request documentation of their quality certifications and ask about their return policy for defective products. Additionally, consider conducting third-party inspections, especially for large orders, to ensure compliance with your specifications before shipment. -

How can I manage logistics effectively when importing flat belts and pulleys?

Effective logistics management is vital for smooth international sourcing. Work with experienced freight forwarders who understand customs regulations in your country and can handle all shipping documentation. Determine the most cost-effective shipping methods based on your timeline and budget. Consider using incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to clarify responsibilities. Ensure that you have a clear understanding of import duties and taxes to avoid unexpected costs. -

What should I do if a dispute arises with a supplier?

In the event of a dispute, first attempt to resolve the issue directly with the supplier through clear and open communication. Document all correspondence and agreements to have a record of your interactions. If resolution is not possible, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration clauses. Engaging a legal advisor experienced in international trade can provide guidance on the best course of action to protect your interests. -

Are there specific certifications that flat belts and pulleys should have for international trade?

Yes, several certifications can enhance the credibility of flat belts and pulleys in international trade. Key certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and CE marking for compliance with European safety standards. Depending on the application, you may also need industry-specific certifications, such as FDA approval for food-grade materials. Always verify that your supplier can provide the necessary documentation to meet regulatory requirements in your target market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for flat belt and pulley

In summary, strategic sourcing of flat belts and pulleys is critical for optimizing operational efficiency and reducing costs across various industries. By focusing on reliable suppliers, conducting thorough market research, and leveraging technology for procurement processes, international B2B buyers can significantly enhance their supply chain resilience. Key takeaways include the importance of understanding local market dynamics, evaluating supplier capabilities, and maintaining flexibility to adapt to changing demands.

As businesses in Africa, South America, the Middle East, and Europe look to innovate and expand, embracing strategic sourcing practices will pave the way for sustainable growth. The ability to source high-quality flat belt and pulley systems not only improves productivity but also fosters long-term partnerships with suppliers that can drive competitive advantages.

Looking ahead, we encourage B2B buyers to actively engage in sourcing discussions and explore new avenues for collaboration. The global marketplace presents unprecedented opportunities; by strategically aligning sourcing strategies with business objectives, companies can position themselves for success in an ever-evolving landscape. Take the next step in your sourcing journey today—your future efficiency depends on it.