Your Ultimate Guide to Sourcing Gasketing Material

Introduction: Navigating the Global Market for gasketing material

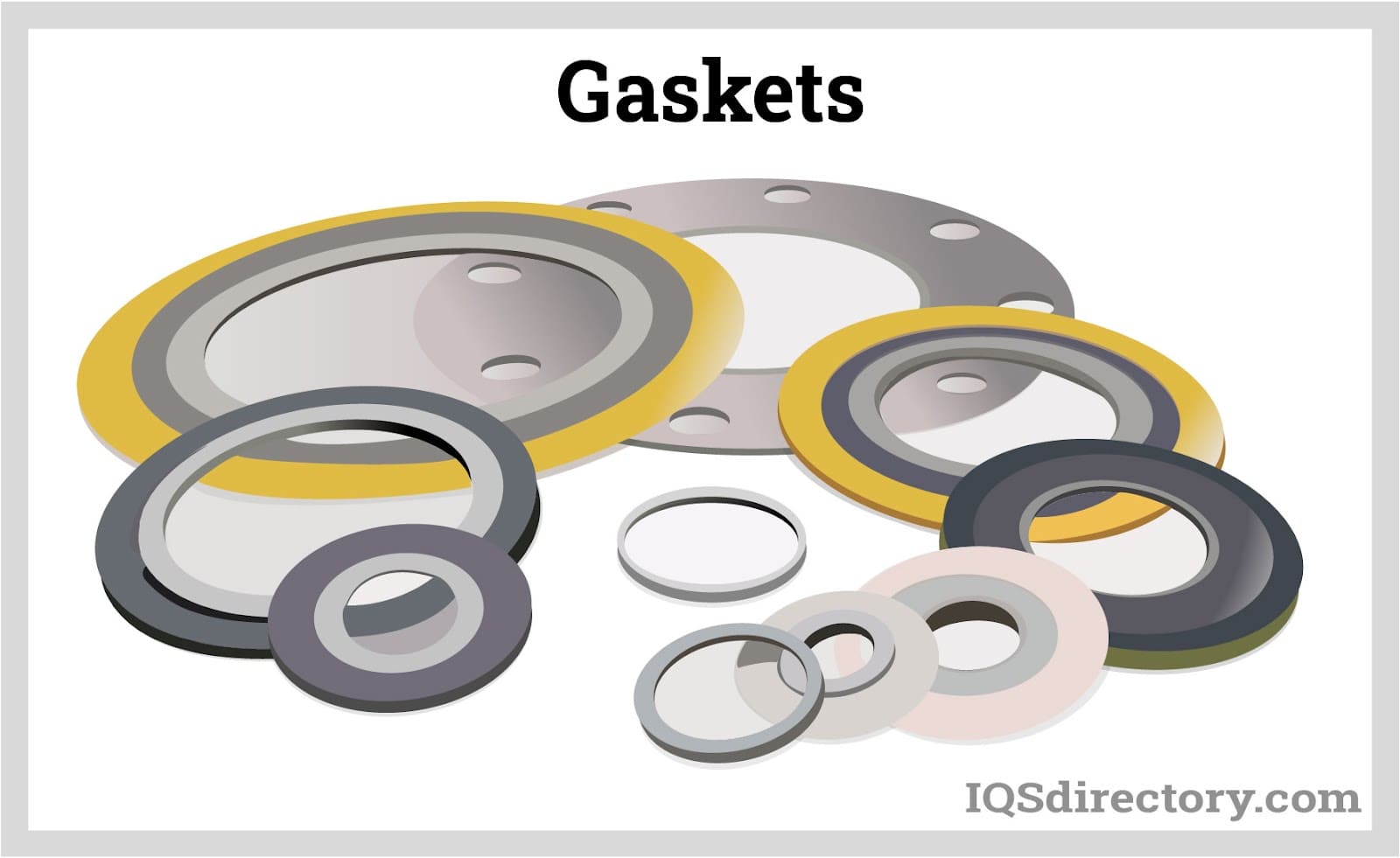

Every industrial operation, from the oil fields of Nigeria to the manufacturing plants of Germany, relies on the unyielding performance of gasketing materials. These essential components serve as barriers against leaks, protect sensitive machinery, and ensure operational safety, making them a critical investment for any business. With the global market for gasketing materials projected to surpass $18 billion by 2030, international B2B buyers face both significant opportunities and intricate challenges in sourcing these vital products.

This comprehensive guide is tailored for decision-makers in Africa, South America, the Middle East, and Europe, offering a deep dive into the world of gasketing materials. It encompasses a wide range of topics, including:

- Types of Gaskets: Detailed insights into various gasket types and their specific applications across industries.

- Material Selection: Guidance on choosing materials based on regional conditions and operational requirements.

- Manufacturing and Quality Control: Best practices to ensure reliability and consistency from suppliers.

- Supplier Profiles: Evaluative criteria to help identify reputable partners, including cost structures and post-purchase support.

- Market Trends and FAQs: Essential information that aids in strategic planning and informed decision-making.

By equipping buyers with actionable knowledge, this guide empowers them to mitigate procurement risks, optimize sourcing strategies, and enhance their operational value in a dynamic global marketplace. Whether you’re navigating complex supply chains or seeking compliance with regional standards, understanding gasketing materials is pivotal to your success.

Understanding gasketing material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Die-Cut Gaskets | Precision-cut from flat materials, customizable shapes | Automotive, HVAC, electronics, machinery | Pros: Cost-effective for volume; Cons: Limited 3D sealing capabilities. |

| Molded Gaskets | Formed in custom molds for complex shapes | Oil & gas, medical, pumps, chemical | Pros: Excellent for irregular profiles; Cons: Higher initial setup costs. |

| Spiral Wound Gaskets | Composite construction for high-pressure resistance | Petrochemical, power generation, pipelines | Pros: Superior sealing under pressure; Cons: Requires careful installation. |

| Rubber O-Rings | Circular seals with various elastomer compounds | Food processing, hydraulics, water treatment | Pros: Simple and standardized; Cons: Limited in complex sealing applications. |

| Compressed Non-Asbestos | Non-asbestos fibers combined with rubber for performance | General manufacturing, automotive, HVAC | Pros: Better temperature and pressure performance; Cons: May be less available than traditional options. |

Die-Cut Gaskets

Die-cut gaskets are crafted by stamping or cutting flat sheet materials, such as rubber or cork, into precise shapes. This method is ideal for high-volume production, particularly in industries like automotive and HVAC, where specific shapes are needed for seals and insulation. When purchasing, buyers should consider the compatibility of materials with the intended application, as well as potential volume discounts that can significantly reduce costs.

Molded Gaskets

Molded gaskets are produced using elastomers injected or compressed into custom molds, allowing for intricate designs and variable thicknesses. They are particularly suited for applications in oil and gas, medical devices, and pump housings, where complex geometries are common. While the initial tooling costs can be high, the long-term benefits of reliability and consistency make them a worthwhile investment for B2B buyers, especially when anticipating large order volumes.

Spiral Wound Gaskets

Spiral wound gaskets consist of alternating layers of metal and filler materials, providing robust sealing capabilities under extreme pressure and temperature conditions. They are commonly used in petrochemical plants and power generation facilities. Buyers must ensure proper installation to maximize performance and may benefit from suppliers who offer technical support and compliance with international standards to mitigate risks associated with improper handling.

Rubber O-Rings

Rubber O-rings are circular seals made from various elastomers, widely used in static and dynamic applications across industries like food processing and hydraulics. Their simplicity and broad chemical compatibility make them a staple in many applications. Buyers should prioritize selecting the appropriate elastomer to meet regulatory requirements and environmental resistance, ensuring a reliable supply chain for consistent product availability.

Compressed Non-Asbestos

Compressed non-asbestos gaskets are made from non-asbestos fibers mixed with rubber, enhancing their performance in terms of temperature and pressure resistance. These gaskets are increasingly used in general manufacturing and automotive applications. B2B buyers should consider the availability of these materials, as they may not be as widely stocked as traditional asbestos alternatives, but they provide a safer and often more reliable sealing solution.

Related Video: Gasketing Application Tips: Permatex Tech Tip Series

Key Industrial Applications of gasketing material

| Industry/Sector | Specific Application of gasketing material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Sealing in pipelines and valves | Prevents leaks, ensuring operational safety and compliance | Material compatibility with harsh chemicals; certifications for safety standards |

| Pharmaceuticals | Sealing in processing equipment | Maintains product integrity and regulatory compliance | FDA-approved materials; ability to withstand sterilization processes |

| Automotive | Engine and transmission gaskets | Enhances performance and durability of vehicles | Temperature and pressure resistance; custom shapes for specific models |

| Power Generation | Gaskets for turbines and boilers | Improves efficiency and minimizes downtime | High-temperature resistance; compliance with international standards |

| Food and Beverage | Seals in processing and packaging machinery | Ensures hygiene and prevents contamination | Compliance with food safety regulations; material compatibility with various food products |

In the Oil & Gas sector, gasketing materials are essential for sealing pipelines and valves. These components prevent leaks, which can lead to environmental hazards and significant financial losses. Buyers must consider material compatibility with corrosive chemicals and ensure that suppliers provide products that meet safety certifications. This is particularly critical in regions with stringent environmental regulations, such as Europe and parts of the Middle East.

In Pharmaceuticals, gasketing materials are used in processing equipment to create airtight seals that prevent contamination. This is vital for maintaining the integrity of sensitive products and adhering to regulatory compliance. Buyers in this sector should prioritize materials that are FDA-approved and capable of withstanding sterilization processes, particularly in markets like Brazil and South Africa where regulatory standards are rigorous.

The Automotive industry relies heavily on gasketing materials for engine and transmission gaskets. These gaskets play a crucial role in enhancing the performance and durability of vehicles by preventing fluid leaks. Buyers should focus on sourcing materials that can withstand high temperatures and pressures, and consider custom shapes tailored to specific vehicle models, which is particularly important in competitive markets like Mexico and Germany.

In Power Generation, gaskets are critical in applications such as turbines and boilers, where they improve efficiency and minimize downtime due to leaks. International buyers must ensure that the selected gasketing materials can endure high temperatures and comply with international standards, as these factors are essential for operational reliability in diverse environments across Africa and Europe.

Finally, in the Food and Beverage sector, gasketing materials are vital for sealing processing and packaging machinery to ensure hygiene and prevent contamination. Buyers should ensure that the materials used comply with food safety regulations and are compatible with various food products. This is especially relevant in rapidly growing markets in South America and Africa, where food safety standards are increasingly prioritized.

Related Video: Uses Of Polymers | Organic Chemistry | Chemistry | FuseSchool

Strategic Material Selection Guide for gasketing material

When selecting gasketing materials, international B2B buyers must consider various factors that can significantly affect performance, compliance, and cost. Below is an analysis of four common gasketing materials, including their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

Rubber Gaskets

Key Properties:

Rubber gaskets are versatile and can be formulated to withstand a range of temperatures and pressures, typically rated from -40°F to 250°F (-40°C to 121°C) depending on the specific type of rubber used. They also exhibit good chemical resistance, making them suitable for various applications.

Pros & Cons:

Rubber gaskets are generally cost-effective and easy to manufacture, allowing for quick production times. However, they may not perform well under extreme temperatures or in highly corrosive environments, which could lead to premature failure.

Impact on Application:

These gaskets are commonly used in hydraulic systems, automotive applications, and food processing. Their compatibility with different media, including oils and water, makes them a popular choice.

Considerations for International Buyers:

Buyers should ensure that the rubber compounds meet local regulatory standards, such as FDA compliance for food-grade applications. Understanding the specific rubber grades available in the region is also crucial, as sourcing may vary.

Spiral Wound Gaskets

Key Properties:

Spiral wound gaskets are designed for high-pressure and high-temperature applications, often rated for temperatures up to 1,000°F (538°C) and pressures exceeding 2,000 psi. Their unique construction allows them to accommodate flange movement and thermal cycling.

Pros & Cons:

The primary advantage of spiral wound gaskets is their superior sealing capability in extreme conditions. However, they require precise installation and handling to ensure effectiveness, which can complicate the manufacturing process.

Impact on Application:

These gaskets are ideal for use in petrochemical and power generation industries, where they prevent leaks in critical systems. Their ability to handle aggressive media, including acids and hydrocarbons, makes them indispensable.

Considerations for International Buyers:

Buyers must ensure compliance with international standards such as ASME and API. Additionally, technical support from suppliers is essential to facilitate proper installation and maintenance.

Compressed Non-Asbestos Gaskets

Key Properties:

Compressed non-asbestos gaskets are made from a blend of non-asbestos fibers and rubber, providing excellent temperature and pressure resistance, typically up to 500°F (260°C) and 1,500 psi.

Pros & Cons:

These gaskets offer a good balance between performance and cost, making them suitable for various applications. However, they may not be as durable as metal gaskets in extreme conditions and can degrade over time in highly aggressive media.

Impact on Application:

Commonly used in automotive and industrial applications, these gaskets are effective for sealing fluids and gases. Their flexibility allows for a tight seal in irregular surfaces.

Considerations for International Buyers:

Buyers should verify that the materials meet local environmental regulations, especially in regions with strict guidelines against asbestos. Understanding the specific composition and certifications is critical for compliance.

Cork Gaskets

Key Properties:

Cork gaskets are known for their compressibility and flexibility, with temperature ratings typically between -20°F and 200°F (-29°C to 93°C). They are resistant to oils and solvents, making them suitable for various applications.

Pros & Cons:

The main advantage of cork gaskets is their ability to form a tight seal, especially in irregular surfaces. However, they can be less durable than synthetic materials and may require replacement more frequently.

Impact on Application:

These gaskets are often used in automotive applications and machinery where oil resistance is necessary. Their natural properties make them suitable for sealing against fuels and lubricants.

Considerations for International Buyers:

Buyers should ensure that cork gaskets are sourced from reputable suppliers that adhere to quality standards. Additionally, understanding the specific blends available in different regions can impact performance.

Summary Table

| Material | Typical Use Case for gasketing material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber Gaskets | Hydraulic systems, automotive | Cost-effective and versatile | Limited performance in extreme conditions | Low |

| Spiral Wound Gaskets | Petrochemical, power generation | Superior sealing in extreme conditions | Requires precise installation | High |

| Compressed Non-Asbestos Gaskets | Automotive, industrial applications | Good balance of performance and cost | Less durable in aggressive media | Medium |

| Cork Gaskets | Automotive, machinery | Excellent compressibility and flexibility | Less durable than synthetic materials | Medium |

This strategic material selection guide provides actionable insights for B2B buyers to make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for gasketing material

Understanding Manufacturing Processes for Gasketing Material

Manufacturing gaskets involves a series of well-defined stages that ensure the final product meets the specific requirements of various industries. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes is crucial for making informed sourcing decisions.

Main Stages of Manufacturing

-

Material Preparation

– The first step involves selecting the appropriate raw materials based on the desired properties of the gasket. Common materials include rubber, cork, and compressed non-asbestos fibers. Each material has its unique characteristics that affect performance in different environments.

– Raw materials are often subject to initial quality checks to ensure they meet industry standards. This includes verifying specifications such as thickness, density, and chemical resistance. -

Forming

– Die-Cutting: This technique is prevalent for producing flat gaskets. The material is cut into specified shapes using precision dies. Die-cut gaskets are ideal for high-volume production due to their cost-effectiveness.

– Molding: For complex shapes, molding techniques such as compression and injection molding are employed. This process allows manufacturers to create intricate designs that enhance sealing capabilities, particularly in high-pressure applications.

– Spiral Winding: For high-performance gaskets, spiral wound gaskets are created by layering metal and filler materials. This technique is essential for applications requiring superior sealing under fluctuating pressures. -

Assembly

– In some cases, gaskets may require additional components, such as adhesives or metal reinforcements, to enhance their performance. This assembly stage must be meticulously executed to ensure durability and reliability.

– The assembly may also include the application of coatings or treatments to improve chemical resistance or temperature tolerance. -

Finishing

– The final stage involves trimming, surface treatment, and packaging. Proper finishing ensures that gaskets meet dimensional tolerances and surface quality requirements.

– Gaskets are often marked with relevant certifications or batch numbers for traceability.

Quality Assurance Protocols

Quality assurance (QA) is a critical component in the manufacturing of gasketing materials. For B2B buyers, understanding the QA processes can help mitigate risks associated with sourcing inferior products.

Relevant International Standards

- ISO 9001: This widely recognized standard outlines the requirements for a quality management system (QMS). Manufacturers certified to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- Industry-Specific Certifications: Depending on the application, additional certifications may be necessary:

- CE Marking: Required for products sold within the European Economic Area (EEA), ensuring compliance with health, safety, and environmental protection standards.

- API Spec Q1/Q2: Essential for suppliers in the oil and gas industry, ensuring that products meet stringent quality and safety requirements.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Raw materials are inspected upon arrival to verify compliance with specifications. This includes dimensional checks and material composition analysis. -

In-Process Quality Control (IPQC)

– During manufacturing, regular checks are conducted at various stages. This can include monitoring machine performance, verifying process parameters, and conducting intermediate inspections to catch defects early. -

Final Quality Control (FQC)

– Before shipment, finished gaskets undergo a comprehensive inspection. This typically involves dimensional verification, performance testing (such as pressure testing), and visual inspections for defects.

Common Testing Methods

- Pressure Testing: Essential for ensuring that gaskets can withstand the required pressure without leaking.

- Chemical Resistance Testing: Assesses how well the gasket material holds up against various chemicals, which is critical for applications in the oil and gas, and chemical processing industries.

- Thermal Cycling Tests: Evaluate the gasket’s ability to maintain integrity under extreme temperature variations.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control practices of potential suppliers is paramount. Here are some actionable steps:

- Conduct Audits: Regular audits of suppliers can help assess their manufacturing processes and adherence to quality standards. This can include facility inspections and review of their QMS documentation.

- Request Quality Reports: Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC stages. These reports offer insights into their quality assurance processes and product reliability.

- Third-Party Inspection: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. This is particularly beneficial for buyers in regions with varying industrial standards.

Quality Control Nuances for International Buyers

Navigating the complexities of quality control can be particularly challenging for buyers in different regions. Here are some considerations:

- Regulatory Compliance: Understanding the regulatory landscape in your region is essential. For instance, buyers in the EU must ensure that products comply with CE marking requirements.

- Cultural Differences: Different countries may have varying approaches to quality assurance. Building strong relationships with suppliers and understanding their quality philosophies can bridge these gaps.

- Supply Chain Dynamics: Buyers should be aware of potential disruptions in the supply chain, particularly in regions experiencing political or economic instability. Establishing relationships with multiple suppliers can mitigate risks.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols for gasketing materials is vital for international B2B buyers. By focusing on supplier quality, adhering to relevant standards, and implementing rigorous verification practices, buyers can ensure they procure high-quality gaskets that meet their operational needs.

Related Video: How 1 Million Chocolate Bars Are Made in Factory | Surprising Chocolate Production Process

Comprehensive Cost and Pricing Analysis for gasketing material Sourcing

When sourcing gasketing materials, understanding the cost structure and pricing dynamics is crucial for making informed procurement decisions. This section breaks down the key components of costs, the factors influencing prices, and offers actionable tips for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of gasket material—rubber, cork, or compressed non-asbestos—significantly affects cost. Specialty materials, such as Viton or silicone, tend to be more expensive due to their enhanced properties, such as chemical resistance or high-temperature tolerance.

-

Labor: Labor costs vary by region and the complexity of the gasket manufacturing process. Automated production may lower labor costs, while custom or low-volume orders often require skilled labor, increasing overall expenses.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production facilities, utilities, and equipment maintenance. Suppliers with higher operational efficiencies may offer more competitive pricing.

-

Tooling: Custom gaskets typically require specialized tooling, which can be a significant upfront cost. Tooling expenses are amortized over the production run, so larger orders can reduce the per-unit cost.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but add to manufacturing costs. Certifications (e.g., ISO, FDA) can also increase costs, but they may be essential for compliance, especially in regulated industries.

-

Logistics: Shipping and handling expenses can vary based on distance, shipping method, and delivery timelines. Buyers should consider Incoterms (e.g., FOB, CIF) to understand who bears these costs and risks.

-

Margin: Suppliers typically build in a profit margin, which can vary widely depending on market demand, competition, and supplier positioning.

Price Influencers

Several factors can influence pricing in the gasketing material market:

-

Volume/MOQ: Larger orders often lead to volume discounts. Buyers should assess their actual needs to avoid excess inventory while capitalizing on bulk pricing.

-

Specifications/Customization: Custom gaskets tailored to specific applications can incur additional costs. Buyers should balance the need for customization with standard options to optimize pricing.

-

Quality/Certifications: Higher-quality materials and certifications may lead to increased costs but can enhance product performance and longevity, ultimately reducing total lifecycle costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven quality and service, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of delivery can significantly impact overall costs. Buyers should negotiate terms that minimize their liabilities while ensuring timely and cost-effective delivery.

Buyer Tips

-

Negotiation: Engage suppliers in discussions regarding pricing and payment terms. Building long-term relationships can lead to better pricing and service terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and potential downtime. Opt for materials that minimize long-term expenses, even if they have a higher upfront cost.

-

Pricing Nuances: Be aware of regional pricing differences. Suppliers in emerging markets might offer lower prices, but ensure they meet the necessary quality and certification standards.

-

Market Research: Regularly monitor market trends and pricing shifts to stay informed about competitive rates and new materials that could enhance your operations.

Disclaimer

Prices for gasketing materials can vary widely based on the factors discussed. The information provided here is indicative and should not be considered as fixed pricing. It is essential for buyers to obtain quotes from multiple suppliers and perform due diligence to ensure the best procurement decisions.

Spotlight on Potential gasketing material Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘gasketing material’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for gasketing material

Critical Specifications of Gasketing Material

When sourcing gasketing materials, understanding key technical properties is essential for making informed purchasing decisions. Below are several critical specifications that B2B buyers should consider:

-

Material Grade

The material grade defines the quality and performance characteristics of the gasket. Common materials include rubber, cork, and compressed non-asbestos composites, each offering unique properties suitable for specific applications. For instance, Viton® is known for its high-temperature resistance, making it ideal for automotive applications. Selecting the correct material grade ensures compliance with operational demands and regulatory standards, ultimately safeguarding equipment and processes. -

Tolerance

Tolerance refers to the allowable variation in dimensions and is crucial for ensuring a proper fit in assemblies. Tight tolerances are often necessary in high-pressure applications to prevent leaks and maintain system integrity. Buyers must ensure that suppliers can meet the required tolerances, as insufficient precision can lead to operational failures and costly downtimes. -

Temperature Resistance

This property indicates the gasket’s ability to withstand extreme temperatures without degrading. Different applications, such as those in oil refineries or food processing plants, may expose gaskets to high heat or extreme cold. Understanding the temperature range of the gasket material helps in selecting a product that can maintain performance over time, ensuring longevity and reliability. -

Chemical Compatibility

Gaskets often come into contact with various fluids and chemicals, making compatibility a critical factor. Materials like Nitrile (NBR) are suitable for oil-based environments, while EPDM is favored for water and steam applications. Assessing chemical compatibility helps prevent gasket failure due to chemical degradation, which can lead to leaks and safety hazards. -

Compression Set

This property measures a material’s ability to return to its original shape after being compressed. A low compression set indicates a gasket can maintain a tight seal over time, reducing the risk of leaks. For B2B buyers, understanding this property is vital for applications where long-term performance is required, such as in automotive or aerospace industries. -

Sealability

Sealability refers to the material’s effectiveness in preventing the passage of fluids or gases. This characteristic is crucial in applications involving high pressures or volatile substances. Buyers should inquire about the sealability ratings of potential gasket materials to ensure they meet the specific requirements of their applications.

Common Trade Terminology in Gasketing

Familiarity with industry jargon can enhance communication with suppliers and improve procurement strategies. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding whether a gasket supplier is an OEM can provide insights into the quality and reliability of their products, as OEMs often adhere to stringent manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers to assess whether they can meet their procurement needs without overcommitting to large inventories, which can tie up capital. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other details for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process, allowing for better comparisons among suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and obligations associated with the delivery of gasketing materials.

-

Lead Time

Lead time is the time taken from placing an order to receiving the goods. Understanding lead times is crucial for inventory management and ensuring that production schedules are met without delays. -

Certification

Certification indicates that a product meets specific industry standards or regulations. For instance, certifications like ISO or FDA compliance are essential for ensuring that gasket materials are safe and reliable for use in sensitive applications.

By grasping these technical specifications and trade terms, B2B buyers can make more informed decisions when sourcing gasketing materials, ensuring alignment with their operational requirements and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gasketing material Sector

Market Overview & Key Trends

The global gasketing material market is on a trajectory of robust growth, driven by several key factors. Industrialization across developing regions, particularly in Africa and South America, is leading to increased demand for high-performance sealing solutions. The ongoing technological advancements in manufacturing processes, such as 3D printing and automation, are enabling the production of more complex and customized gasket designs, enhancing efficiency and reducing lead times.

Illustrative Image (Source: Google Search)

B2B buyers are increasingly focusing on cost-effective sourcing strategies, leveraging global supply chains to minimize procurement costs while ensuring quality and compliance with international standards. Notably, the rise of digital platforms is facilitating more transparent supplier interactions, allowing buyers to compare options and negotiate better terms. Sustainability is also becoming a critical consideration, with buyers looking for suppliers that prioritize eco-friendly materials and processes.

Emerging trends include the shift towards biodegradable and recyclable gasket materials, which align with global environmental goals. Additionally, the integration of IoT in manufacturing is paving the way for smarter quality control measures, ensuring that products meet stringent industry specifications. For international buyers, particularly those in regions like Europe and the Middle East, understanding these dynamics is essential for making informed sourcing decisions that align with both operational needs and corporate sustainability goals.

Sustainability & Ethical Sourcing in B2B

The gasketing material sector is increasingly acknowledging its environmental impact, particularly concerning the sourcing and disposal of materials. As industrial processes evolve, there is a growing emphasis on ethical sourcing and the adoption of sustainable practices throughout the supply chain. B2B buyers are urged to seek suppliers who prioritize green certifications, such as ISO 14001 for environmental management and materials that are certified by recognized bodies.

Recyclable and biodegradable materials are becoming more prevalent in gasket production, offering alternatives to traditional petroleum-based materials. Buyers should consider suppliers that utilize non-toxic and low-VOC (volatile organic compounds) materials, which contribute to a healthier workplace and environment. Furthermore, the adoption of a circular economy approach can enhance brand reputation while meeting regulatory requirements and consumer expectations.

By focusing on sustainable sourcing, international buyers can mitigate risks associated with environmental compliance and enhance their corporate social responsibility (CSR) profiles. This not only improves operational efficiency but also positions companies favorably in the eyes of environmentally-conscious customers and stakeholders.

Brief Evolution/History

The gasketing material sector has evolved significantly over the past century. Initially dominated by simple materials like rubber and cork, advancements in material science and manufacturing technology have led to the introduction of high-performance materials such as PTFE (Teflon) and advanced composites. The shift from traditional production methods to modern manufacturing techniques, including CNC machining and additive manufacturing, has enabled the creation of customized solutions that cater to specific industry needs.

As industries face increasingly stringent regulations regarding safety and environmental impact, the evolution of gasketing materials reflects a broader commitment to innovation and sustainability. This historical context is crucial for B2B buyers, as it informs current market offerings and helps in understanding the trajectory of future developments in the sector.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of gasketing material

-

How can I effectively vet suppliers of gasketing materials?

When vetting suppliers, prioritize their industry experience and expertise in manufacturing the specific type of gasketing material you require. Request samples to assess quality and performance. Verify certifications relevant to your industry, such as ISO or ASTM standards, which indicate adherence to quality management systems. Additionally, check customer reviews and case studies to gauge reliability. Conducting site visits or audits can also provide insights into their operational capabilities and ethical practices, especially for suppliers in different regions. -

What options are available for customizing gasketing materials?

Most suppliers offer customization options, including material selection, thickness, shape, and size, to suit specific applications. Discuss your requirements with the supplier to explore available materials—such as rubber, cork, or composite materials—and their performance characteristics under your operating conditions. It’s beneficial to provide detailed specifications, such as temperature ranges and chemical exposure, to ensure the gasket meets your needs. Be prepared for potential additional costs and longer lead times for customized products. -

What are typical minimum order quantities (MOQs) and lead times for gasketing materials?

Minimum order quantities vary by supplier and the complexity of the gasket design. For standard gaskets, MOQs may range from 100 to 500 pieces, while custom gaskets often require higher quantities due to setup costs. Lead times can also differ significantly, generally spanning from 2 to 12 weeks depending on the customization level, supplier location, and production capacity. Discuss your project timeline with potential suppliers to ensure they can meet your deadlines. -

What payment terms should I expect when sourcing gasketing materials internationally?

Payment terms can vary widely among suppliers. Common practices include advance payments, letters of credit, or payment upon delivery. It’s advisable to negotiate terms that protect your interests while providing suppliers with assurance of payment. Consider using escrow services for larger transactions to mitigate risks. Additionally, ensure clarity on currency exchange rates and any potential fees associated with international transactions, which can affect overall costs. -

How can I ensure quality assurance and certifications for gasketing materials?

Request documentation of quality assurance processes from your suppliers, including details on material sourcing, manufacturing methods, and testing protocols. Key certifications to look for include ISO 9001 for quality management and specific industry-related certifications. Suppliers should be willing to provide test results or compliance documentation to verify that their products meet your industry standards. Establishing clear quality expectations in your contracts can help safeguard against discrepancies. -

What logistics considerations should I be aware of when sourcing internationally?

International logistics can be complex, involving customs clearance, tariffs, and shipping regulations. Work with suppliers who have experience in international shipping to navigate these challenges. Discuss shipping options, including freight forwarders and carriers, to determine the best method for cost and time efficiency. Ensure that you understand the incoterms (International Commercial Terms) that dictate responsibilities for shipping costs and risks, which can significantly impact your total landed cost.

Illustrative Image (Source: Google Search)

-

How should I handle disputes with suppliers over gasketing material orders?

To mitigate disputes, establish clear contractual terms regarding quality, delivery timelines, and payment conditions before placing orders. In the event of a dispute, maintain open communication with your supplier to address issues promptly. Document all correspondence and agreements, which can serve as evidence if formal mediation or arbitration becomes necessary. Consider including clauses in your contracts that specify the dispute resolution process, potentially involving third-party mediation to expedite resolution. -

What trends are impacting the international gasketing material market?

Several trends are shaping the gasketing material market, including the growing demand for sustainable materials and eco-friendly production processes. Increased regulation around environmental compliance is prompting suppliers to innovate with biodegradable and recyclable materials. Additionally, advancements in technology are leading to improved manufacturing techniques, allowing for greater customization and faster production times. Staying informed about these trends can help buyers make strategic sourcing decisions that align with industry developments and consumer preferences.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gasketing material

The strategic sourcing of gasketing materials is essential for ensuring operational efficiency and compliance in diverse industrial applications. International B2B buyers must prioritize the selection of materials that align with their specific environmental conditions and regulatory requirements. Key takeaways include the importance of understanding the unique properties of various gasket types—such as die-cut, molded, and spiral wound—as well as their suitability for different applications across industries.

Moreover, fostering strong relationships with reputable suppliers can enhance procurement processes, ensuring access to high-quality, certified products. Buyers should be proactive in evaluating suppliers based on their manufacturing capabilities, material certifications, and after-sales support to mitigate risks associated with sourcing.

Looking ahead, the global gasketing market is poised for continued growth, driven by innovations in material science and manufacturing techniques. As industries across Africa, South America, the Middle East, and Europe evolve, buyers must stay informed about market trends and advancements. Embrace strategic sourcing today to secure a competitive edge and drive sustainable operational value in your business.