Your Ultimate Guide to Sourcing Gear Drive

Introduction: Navigating the Global Market for gear drive

In today’s competitive global marketplace, gear drives are indispensable components that enhance the efficiency and functionality of various mechanical systems. These intricate systems not only facilitate power transmission but also enable torque multiplication, making them vital across industries such as automotive, manufacturing, and robotics. For international B2B buyers from regions including Africa, South America, the Middle East, and Europe, understanding the nuances of gear drives is crucial for optimizing operations and achieving a sustainable competitive edge.

This comprehensive guide will explore the diverse types of gear drives, including spur, helical, and bevel gears, while delving into the materials used in their manufacturing. We will also discuss critical manufacturing and quality control processes that ensure the reliability and longevity of these components. Furthermore, the guide will provide insights into supplier selection, cost considerations, and emerging market trends, equipping buyers with the knowledge necessary to make informed sourcing decisions.

By navigating the complexities of the gear drive market, B2B buyers can identify the right solutions tailored to their specific operational needs. This guide serves as a vital resource, empowering businesses to enhance production efficiency, reduce costs, and foster innovation in their respective sectors. Prepare to dive deep into the world of gear drives and unlock the potential for increased performance and reliability in your operations.

Understanding gear drive Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spur Gear | Straight teeth, parallel shafts | Industrial machinery, automotive | Simple design, high load capacity; noisy operation at high speeds |

| Helical Gear | Angled teeth for smoother engagement | Gearboxes, conveyor systems | Quieter operation, higher efficiency; more complex to manufacture |

| Bevel Gear | Conical shape for angle changes | Automotive differentials, power transmission | Compact design; potential for misalignment issues |

| Worm Gear | Screw-like design for high torque | Lifts, conveyors, robotics | High torque in a compact space; lower efficiency, potential for wear |

| Rack and Pinion | Linear motion conversion via a circular gear | Steering systems, linear actuators | Simple mechanism, precise motion; limited to linear applications |

Spur Gear

Spur gears are widely recognized for their straight teeth and parallel alignment, making them a staple in various applications, including industrial machinery and automotive systems. Their straightforward design allows for efficient power transmission and high load capacity. B2B buyers should be mindful of their noisy operation at high speeds, which may necessitate additional noise reduction measures in sensitive environments. Cost-effectiveness and reliability are key purchasing considerations when sourcing spur gears.

Helical Gear

Helical gears are distinguished by their angled teeth, which facilitate smoother engagement and quieter operation compared to spur gears. This makes them particularly suitable for gearboxes and conveyor systems where efficiency is paramount. While they offer higher load capacity and reduced vibrations, the complexity of their manufacturing can drive up costs. International buyers should evaluate the trade-off between performance benefits and production expenses when considering helical gears for their applications.

Bevel Gear

Bevel gears are designed with a conical shape, allowing them to transmit power between shafts that intersect at various angles. They are commonly used in automotive differentials and power transmission systems, making them ideal for applications with space constraints. Buyers should consider the importance of precise alignment, as misalignment can lead to increased wear and inefficiency. When sourcing bevel gears, assess the specific angle requirements to ensure compatibility with existing systems.

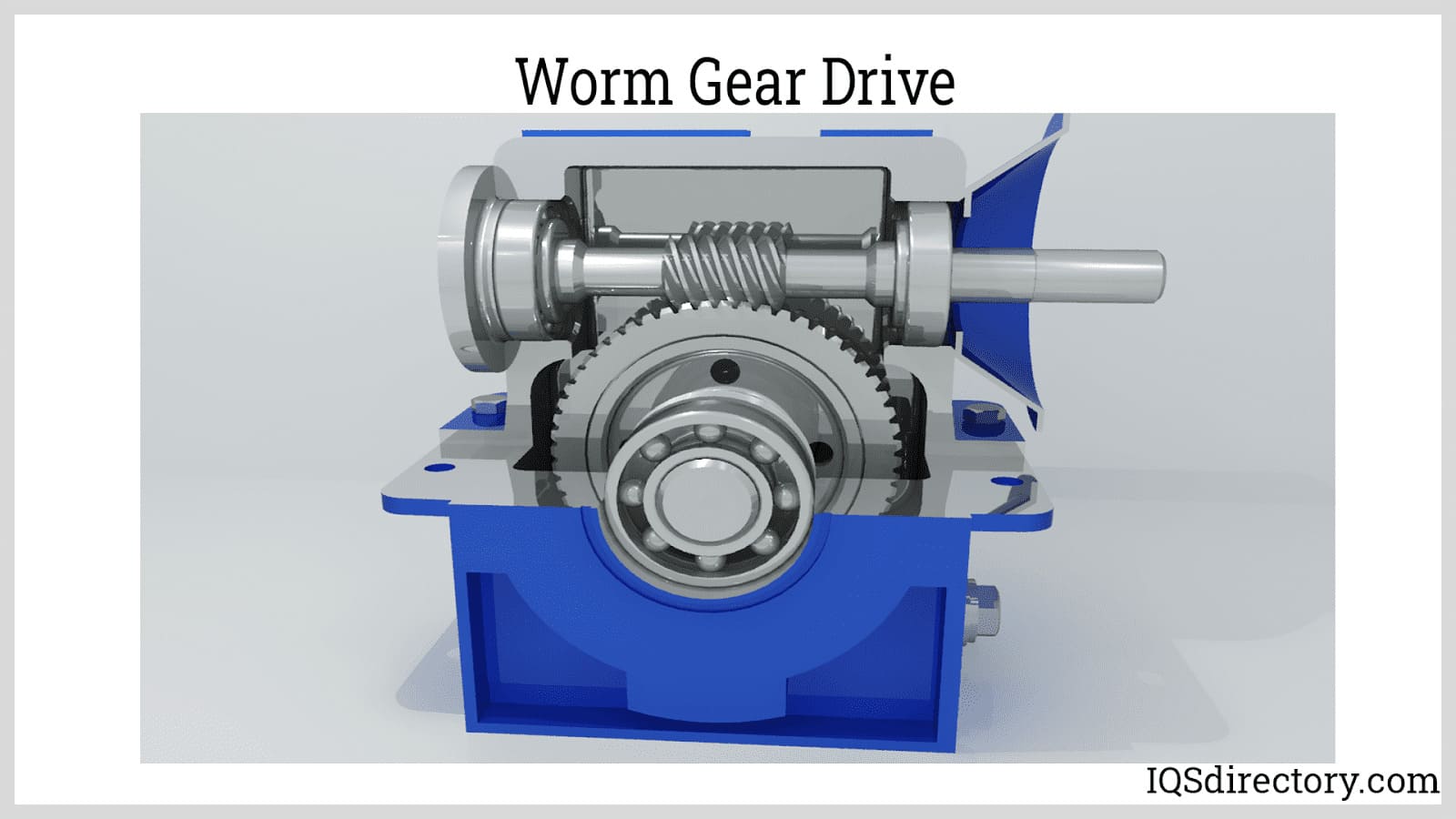

Worm Gear

Worm gears feature a unique screw-like design that excels in high torque applications, often found in lifts, conveyors, and robotics. Their compact nature allows for effective torque transmission in limited spaces. However, buyers should be cautious of their lower efficiency and potential for wear over time, which can affect long-term operational costs. Proper maintenance and lubrication are essential factors to consider when selecting worm gears to ensure optimal performance.

Rack and Pinion

Rack and pinion systems convert rotational motion into linear movement, making them ideal for applications such as steering systems and linear actuators. Their simple and effective design provides precise motion control, which is crucial in many industrial settings. However, their limitation to linear applications may restrict versatility. When sourcing rack and pinion systems, buyers should ensure material robustness to withstand operational stresses and assess compatibility with their specific applications.

Related Video: Gear Types, Design Basics, Applications and More – Basics of Gears

Key Industrial Applications of gear drive

| Industry/Sector | Specific Application of gear drive | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Transmission systems | Enhanced power transfer, improved fuel efficiency | Compatibility with vehicle models, material quality, and durability |

| Manufacturing | Conveyor systems | Increased operational efficiency and reliability | Load capacity, maintenance needs, and integration with existing systems |

| Renewable Energy | Wind turbines | Efficient energy conversion and reduced costs | Compliance with environmental standards, durability against weather conditions |

| Mining | Haul trucks and drilling machinery | Enhanced productivity and reduced downtime | Robustness under extreme conditions, supplier reliability, and after-sales support |

| Agriculture | Tractors and harvesting equipment | Improved productivity and operational efficiency | Precision engineering, adaptability to various terrains, and service availability |

Automotive Applications

In the automotive industry, gear drives are integral to transmission systems, enabling effective power transfer and enhancing fuel efficiency. They help optimize engine performance by adjusting torque and speed as required during operation. For international buyers, particularly from regions like Africa and the Middle East, sourcing high-quality gear drives that are compatible with various vehicle models is critical. Buyers must also consider material durability to withstand harsh driving conditions and ensure longevity.

Manufacturing Applications

In manufacturing, gear drives are widely used in conveyor systems to facilitate the movement of materials and products through production lines. They enhance operational efficiency by enabling smooth and reliable transport, which minimizes downtime. Buyers should focus on the load capacity of gear drives and maintenance requirements to ensure seamless integration with existing systems. Additionally, understanding the local supply chain dynamics in regions like South America is essential for timely delivery and support.

Renewable Energy Applications

Wind turbines utilize gear drives for efficient energy conversion, transforming mechanical energy from wind into electrical energy. This application is critical in reducing operational costs and maximizing energy output. International buyers must ensure that the gear drives comply with environmental standards and can withstand various weather conditions prevalent in their regions. Sourcing from reputable suppliers with a track record in renewable energy applications is crucial for maintaining system reliability.

Mining Applications

In the mining sector, gear drives are essential in haul trucks and drilling machinery, significantly enhancing productivity and reducing downtime. These gear systems must operate efficiently under extreme conditions, including heavy loads and harsh environments. International buyers should prioritize robustness and reliability when sourcing gear drives, as well as the supplier’s ability to provide after-sales support and maintenance services, particularly in remote areas.

Agricultural Applications

Tractors and harvesting equipment heavily rely on gear drives to improve productivity and operational efficiency in the agricultural sector. These systems allow for precise control of power and speed, essential for various farming tasks. Buyers need to consider the precision engineering of gear drives to ensure adaptability to different terrains and conditions. Additionally, the availability of service and support in regions like Europe and Africa can significantly influence the sourcing decision, ensuring minimal disruption in operations.

Related Video: Gears and the Principles of Gear Systems

Strategic Material Selection Guide for gear drive

When selecting materials for gear drives, international B2B buyers must consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in gear drive applications, focusing on their properties, advantages and disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Steel

Steel is one of the most widely used materials for gear drives due to its excellent mechanical properties. It typically exhibits high tensile strength, good wear resistance, and the ability to withstand high temperatures and pressures. Steel gears can be treated with various heat treatments to enhance their hardness and durability.

Pros & Cons:

Steel gears are known for their durability and strength, making them suitable for heavy-duty applications. However, they can be prone to corrosion if not properly treated, which may require additional coatings or treatments, increasing manufacturing complexity and costs.

Impact on Application:

Steel gears are compatible with a wide range of media, including oils and greases, making them versatile for different applications. However, their weight can be a disadvantage in applications where weight reduction is critical.

Considerations for Buyers:

B2B buyers should ensure compliance with international standards such as ASTM or DIN for steel grades. Additionally, they should consider the local availability of treated steel to reduce lead times and costs.

Aluminum

Aluminum is another popular material for gear drives, particularly in applications where weight savings are essential. It is lightweight, has good corrosion resistance, and can be anodized to enhance its surface properties.

Pros & Cons:

The primary advantage of aluminum gears is their low weight, which contributes to overall system efficiency. However, they are generally less durable than steel and may not perform well under high-load conditions, limiting their use in heavy-duty applications.

Impact on Application:

Aluminum gears are suitable for applications where weight is a critical factor, such as in aerospace or automotive industries. They are also compatible with various lubricants, although care must be taken to avoid galvanic corrosion when used with dissimilar metals.

Considerations for Buyers:

Buyers should verify that aluminum gears meet relevant standards such as JIS for quality assurance. Additionally, they should assess the local market for aluminum alloys that offer the required strength and corrosion resistance.

Plastic (Polymer)

Plastic gears, often made from polymers such as nylon or acetal, offer unique advantages in specific applications. They are lightweight, resistant to corrosion, and can operate quietly, making them ideal for applications requiring low noise.

Pros & Cons:

Plastic gears are cost-effective and easy to manufacture, allowing for complex shapes and designs. However, they generally have lower load-bearing capacity and may not withstand high temperatures, limiting their use in demanding environments.

Impact on Application:

Plastic gears are commonly used in consumer products, medical devices, and applications where lubrication is limited. Their chemical resistance makes them suitable for environments with aggressive media, but they may not be suitable for high-torque applications.

Considerations for Buyers:

International buyers should ensure that the selected plastic materials comply with relevant safety and quality standards. They should also consider the environmental impact of plastic materials and whether recyclable options are available.

Cast Iron

Cast iron is a traditional material used in gear drives, particularly in heavy machinery. It offers excellent wear resistance and can absorb vibrations, making it suitable for applications involving heavy loads.

Pros & Cons:

The main advantage of cast iron gears is their durability and ability to withstand high loads without deforming. However, they are relatively heavy and can be brittle, which may lead to failure under impact loads.

Impact on Application:

Cast iron gears are often used in industrial machinery and automotive applications where strength and durability are paramount. Their ability to absorb vibrations can enhance the longevity of the entire system.

Considerations for Buyers:

B2B buyers should ensure compliance with international standards such as ASTM for cast iron grades. Additionally, they should consider the availability of cast iron in their region to avoid delays in procurement.

Summary Table

| Material | Typical Use Case for gear drive | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial machinery | High strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | Aerospace and automotive | Lightweight and corrosion-resistant | Less durable under high loads | Medium |

| Plastic | Consumer products and medical devices | Cost-effective and quiet | Lower load-bearing capacity | Low |

| Cast Iron | Industrial machinery | Excellent wear resistance | Heavy and brittle under impact | Medium |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when sourcing gear drive components, ensuring compatibility with their specific applications and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for gear drive

In the competitive landscape of gear drive manufacturing, understanding the processes and quality assurance measures is crucial for B2B buyers. This section outlines the typical manufacturing stages, key techniques, and quality control practices relevant to international buyers, particularly those from Africa, South America, the Middle East, and Europe.

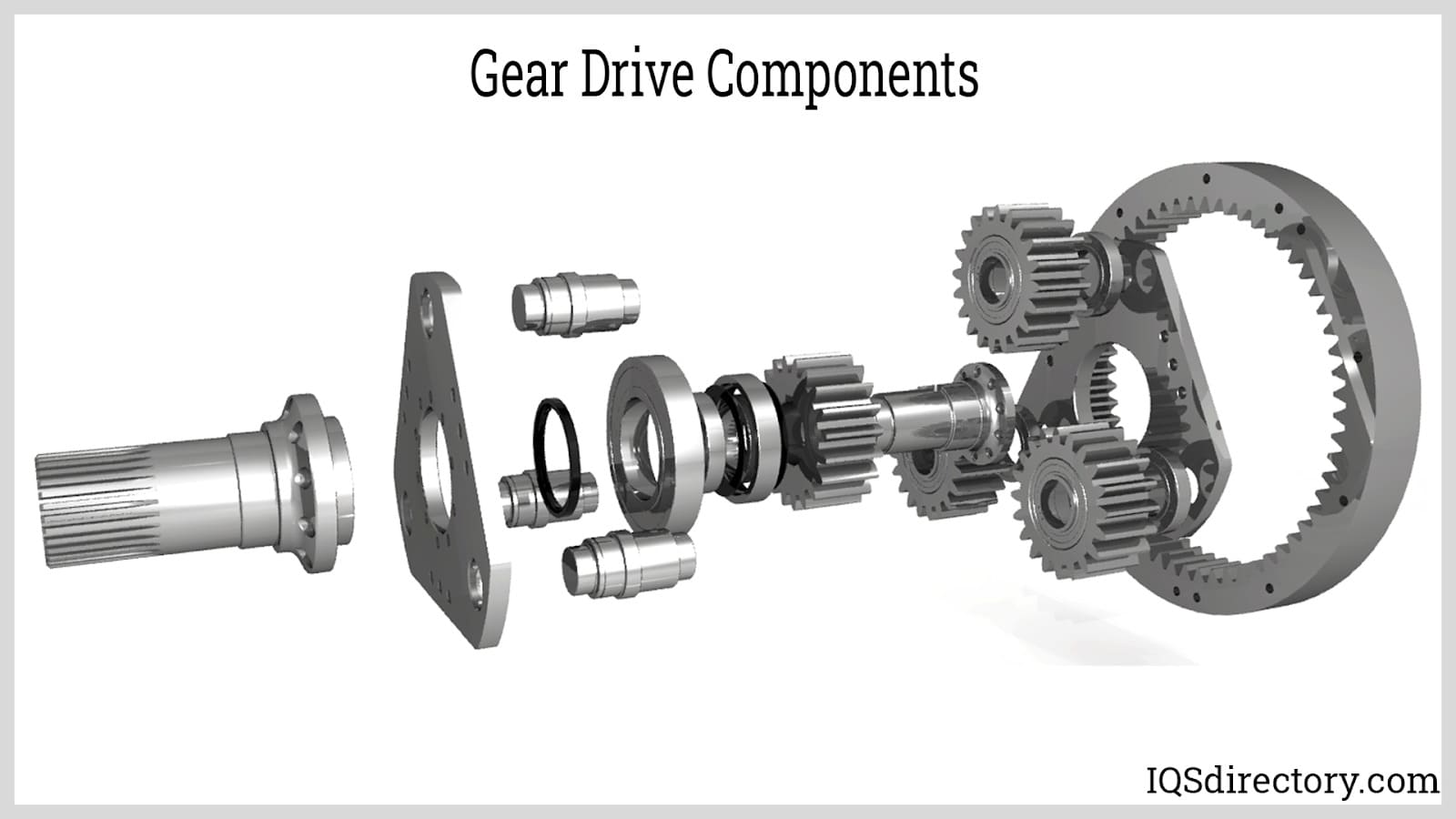

Manufacturing Processes for Gear Drives

The manufacturing of gear drives involves several stages, each critical to ensuring the final product meets the required specifications and performance standards. The main stages include:

1. Material Preparation

The choice of materials is fundamental to the performance of gear drives. Common materials include:

- Steel: Offers high strength and durability.

- Aluminum: Lightweight and corrosion-resistant, often used in lower-load applications.

- Plastic and Composite Materials: Used for specific applications where weight reduction is essential.

During the material preparation phase, raw materials are sourced, inspected for quality, and cut to size. Buyers should seek suppliers who adhere to international material standards (e.g., ASTM, ISO) to ensure the quality of the materials used.

2. Forming

The forming process involves shaping the material into gear blanks. Common techniques include:

- Casting: Suitable for complex shapes; involves pouring molten material into molds.

- Forging: Involves shaping metal using compressive forces, resulting in a denser and stronger product.

- Machining: Precision cutting of gear shapes from solid blocks, often using CNC machines for high accuracy.

The choice of forming technique affects the mechanical properties of the gear drive, including strength, toughness, and wear resistance. B2B buyers should consider the manufacturing capabilities of their suppliers, ensuring they can produce gears that meet specific engineering requirements.

3. Assembly

Once the individual components are formed, they are assembled into complete gear drives. This stage may involve:

- Gear Pairing: Ensuring correct meshing and alignment between gears.

- Housing Assembly: Incorporating the gears into a housing that protects them and facilitates installation.

Precision during assembly is vital, as misalignment can lead to premature wear and failure. Buyers should inquire about the assembly processes used by potential suppliers, including the use of jigs and fixtures that enhance accuracy.

4. Finishing

The finishing stage enhances the surface quality and performance characteristics of gear drives. Common finishing techniques include:

- Heat Treatment: Increases hardness and strength, improving durability.

- Surface Grinding: Achieves precise dimensions and surface finishes.

- Coating: Applying protective coatings to reduce friction and wear.

Finishing not only impacts the aesthetic appeal of the gear drives but also their operational efficiency. Buyers should ensure that suppliers employ appropriate finishing techniques aligned with the intended application of the gear drives.

Quality Assurance Measures

Quality assurance is paramount in gear drive manufacturing to ensure reliability and performance. Key aspects of QA include adherence to international standards, QC checkpoints, and testing methods.

International Standards

B2B buyers should look for suppliers that comply with recognized quality standards, such as:

- ISO 9001: Focuses on quality management systems, ensuring consistent quality in products and services.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for gear drives used in oil and gas applications, ensuring they meet industry-specific requirements.

Compliance with these standards not only provides assurance of quality but can also facilitate easier access to international markets.

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon receipt to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Conducts checks during various manufacturing stages to identify and rectify defects early.

- Final Quality Control (FQC): Verifies that finished products meet all specifications before shipping.

Establishing these checkpoints helps minimize defects and ensures that only high-quality products reach the customer.

Common Testing Methods

Several testing methods are commonly employed to assess the performance and reliability of gear drives:

- Dimensional Inspection: Ensures that all components meet specified dimensions and tolerances.

- Load Testing: Evaluates the performance of gear drives under expected operating conditions.

- Vibration Analysis: Detects misalignment or imbalance that could lead to premature failure.

B2B buyers should inquire about the specific testing methods utilized by suppliers to ensure thorough evaluation of gear drive performance.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers can undertake several actions:

- Supplier Audits: Conduct audits of potential suppliers to assess their manufacturing processes, quality control measures, and adherence to standards.

- Quality Reports: Request detailed quality reports that outline inspection and testing results, providing insight into the supplier’s quality management practices.

- Third-Party Inspections: Engage independent inspection agencies to evaluate supplier operations and product quality, providing an unbiased assessment.

These verification methods are essential for mitigating risks associated with sourcing gear drives, particularly for international buyers who may face additional challenges related to logistics and compliance.

Conclusion

Understanding the manufacturing processes and quality assurance measures for gear drives is vital for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, alongside robust quality control practices, buyers can ensure they source high-quality gear drives that meet their operational needs. Establishing clear communication with suppliers regarding their manufacturing capabilities and quality standards will further enhance the procurement process, supporting long-term business success in a competitive market.

Related Video: Mercedes C-Class CAR FACTORY – HOW IT’S MADE Assembly Production Line Manufacturing Making of

Comprehensive Cost and Pricing Analysis for gear drive Sourcing

In the sourcing of gear drives, understanding the comprehensive cost structure and pricing dynamics is critical for international B2B buyers. This analysis will highlight the key components of costs, influential pricing factors, and actionable tips for buyers to optimize their sourcing strategies.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost of gear drives. Common materials include steel, aluminum, and plastics, each with varying costs based on market fluctuations. Higher-grade materials may offer better durability and performance but will elevate the initial price.

-

Labor: Labor costs are influenced by the complexity of the gear drive design and the location of manufacturing. Skilled labor is essential for precision machining, and regions with higher labor costs may result in increased pricing. Understanding local labor markets can help buyers anticipate these expenses.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and administrative expenses. Overhead can vary significantly based on the manufacturing facility’s location and efficiency, which is crucial for buyers to consider when evaluating supplier proposals.

-

Tooling: The costs associated with the creation of molds, dies, or specific tools for manufacturing gear drives can be substantial, especially for custom designs. Buyers should inquire about tooling costs, as these can be amortized over larger production runs, reducing the unit price.

-

Quality Control (QC): Ensuring the reliability and performance of gear drives necessitates investment in quality control processes. This includes testing and inspection protocols that can add to the overall cost but are essential for maintaining product standards.

-

Logistics: Shipping and handling costs play a significant role, particularly for international transactions. Factors such as distance, transport mode, and freight terms can all affect logistics costs. Buyers should evaluate their supply chain options to minimize these expenses.

-

Margin: Suppliers will typically include a margin that reflects their business model and market competition. Understanding the competitive landscape can help buyers negotiate better pricing.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Pricing is often more favorable at higher volumes. Establishing a long-term relationship with suppliers can lead to negotiated discounts.

-

Specifications/Customization: Customized gear drives incur additional costs related to design and production. Buyers should balance the need for custom features with cost implications.

-

Material Selection: The choice of materials not only affects performance but also the price. Buyers should consider lifecycle costs versus initial costs when selecting materials.

-

Quality and Certifications: Products that meet specific international quality standards may have higher upfront costs. However, investing in certified products can lead to lower failure rates and reduced maintenance expenses.

-

Supplier Factors: Factors such as supplier reputation, reliability, and support can influence pricing. Buyers should conduct thorough assessments of potential suppliers before making sourcing decisions.

-

Incoterms: Understanding shipping terms and conditions can help buyers anticipate additional costs. Incoterms dictate who is responsible for various logistics costs and risks, which can significantly affect the final price.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing. Highlighting long-term relationships and potential bulk orders can lead to better terms.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, operational costs, and potential downtime associated with gear drives.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of local economic factors, currency fluctuations, and import duties that can affect overall costs.

-

Disclaimer for Indicative Prices: Pricing for gear drives can vary widely based on the factors mentioned above. It is essential for buyers to obtain specific quotes from suppliers to get accurate pricing for their unique requirements.

By comprehensively understanding these cost and pricing components, international B2B buyers can make informed decisions that align with their operational needs and financial constraints.

Spotlight on Potential gear drive Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘gear drive’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for gear drive

Understanding the technical properties and terminology associated with gear drives is crucial for B2B buyers, particularly in international markets. This knowledge not only aids in making informed purchasing decisions but also ensures that the selected gear systems meet operational requirements effectively.

Key Technical Properties

-

Material Grade

– Definition: The material grade refers to the specific type and quality of material used in the manufacturing of gear drives, commonly steel, aluminum, or plastic composites.

– B2B Importance: Different applications require varying levels of strength, weight, and corrosion resistance. Understanding material grades allows buyers to select gear drives that can withstand operational demands and environmental conditions, which is particularly critical in diverse climates across Africa, South America, and the Middle East. -

Tooth Profile

– Definition: The tooth profile describes the shape and dimensions of the gear teeth, which can significantly affect performance.

– B2B Importance: Selecting the correct tooth profile, such as involute or cycloidal, influences gear efficiency, noise levels, and load capacity. Buyers must consider the operational speed and load conditions to ensure optimal performance. -

Tolerance

– Definition: Tolerance refers to the allowable variation in the dimensions of gear components, ensuring proper meshing and function.

– B2B Importance: Tight tolerances are essential for high-performance applications, as they reduce backlash and enhance efficiency. Buyers should be aware of tolerance specifications to avoid operational failures and ensure compatibility with existing machinery. -

Gear Ratio

– Definition: The gear ratio is the relationship between the number of teeth on two meshing gears, affecting the torque and speed output.

– B2B Importance: Understanding gear ratios is vital for buyers to achieve the desired balance between torque and speed for their specific applications. This knowledge helps in optimizing machine performance and energy consumption.

Illustrative Image (Source: Google Search)

- Load Capacity

– Definition: Load capacity indicates the maximum weight or force that a gear drive can handle without failure.

– B2B Importance: Buyers must match the load capacity with the application requirements to ensure safety and reliability. This consideration is particularly important in sectors like automotive and industrial machinery, where failure can lead to significant downtime and costs.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding the OEM relationship helps buyers ensure they are sourcing high-quality components that are compatible with existing systems, which is essential for maintaining operational efficiency. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for buyers to manage inventory costs and production schedules. This is particularly relevant for international buyers who may face additional logistics considerations. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products.

– Importance: Utilizing RFQs effectively allows buyers to compare offers from multiple suppliers, facilitating better negotiation and cost management. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, which is vital for efficient international trade operations. -

Lead Time

– Definition: Lead time refers to the time it takes from placing an order to receiving the product.

– Importance: Buyers must consider lead times to align procurement with production schedules, especially in industries where time-sensitive operations are critical.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing gear drives more effectively, ensuring that their procurement decisions align with their operational needs and market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gear drive Sector

Market Overview & Key Trends

The gear drive sector is experiencing significant growth driven by technological advancements and increasing demand across various industries, including automotive, aerospace, and manufacturing. Globalization has also enhanced supply chain dynamics, allowing international B2B buyers from Africa, South America, the Middle East, and Europe to access a wider range of suppliers and innovative products. Key trends shaping the market include the rise of automation and digitalization, prompting manufacturers to seek gear drives that offer enhanced efficiency and performance.

In recent years, there has been a notable shift towards the adoption of Industry 4.0 technologies, which integrate IoT and AI into manufacturing processes. These technologies allow for real-time monitoring and predictive maintenance, which are critical for optimizing gear drive performance. Furthermore, sustainability is increasingly influencing purchasing decisions, as buyers prioritize suppliers who demonstrate eco-friendly practices and materials.

Emerging markets in Africa and South America present unique opportunities, as local industries seek to modernize equipment and enhance production capabilities. B2B buyers should be aware of the competitive landscape, as suppliers increasingly differentiate themselves through innovation and customer service. Understanding these market dynamics will enable buyers to make informed decisions and secure advantageous sourcing agreements.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of the gear drive sector, with a growing emphasis on minimizing environmental impacts throughout the supply chain. B2B buyers are increasingly scrutinizing their suppliers’ practices, prioritizing those that adopt sustainable manufacturing processes and materials. The environmental footprint of gear drives can be significant, particularly in terms of energy consumption and waste generation. Therefore, suppliers that employ energy-efficient technologies and reduce emissions are more likely to attract discerning buyers.

Ethical sourcing is equally important, as companies face pressure to ensure transparency in their supply chains. Buyers should look for suppliers who adhere to recognized ethical standards and certifications, such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety. Additionally, the use of ‘green’ materials, such as recycled metals and bio-based lubricants, can enhance the sustainability profile of gear drives. By aligning sourcing strategies with sustainability goals, B2B buyers can not only reduce their environmental impact but also improve their brand reputation and customer loyalty.

Brief Evolution/History

The evolution of gear drives reflects significant advancements in engineering and manufacturing technologies. Historically, gears have been utilized since ancient civilizations for tasks such as lifting heavy objects and facilitating water flow. The introduction of gear-cutting machines during the Industrial Revolution marked a pivotal moment, allowing for the production of precise and standardized gears.

In the modern era, the development of computer-aided design (CAD) and CNC machining has further revolutionized gear manufacturing, enabling the creation of complex gear systems with enhanced performance capabilities. As industries continue to evolve, gear drives remain integral to the efficiency of mechanical systems, adapting to new technologies and market demands. This historical context is vital for B2B buyers, as it underscores the importance of selecting suppliers that leverage advanced manufacturing techniques and innovative designs to stay competitive in a rapidly changing market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of gear drive

-

What factors should I consider when vetting suppliers for gear drives?

When vetting suppliers for gear drives, assess their industry experience, technical capabilities, and reputation. Look for suppliers with certifications like ISO 9001, which indicate quality management systems. Request references from previous clients to gauge reliability and performance. Additionally, consider their production capacity, lead times, and ability to meet your specific requirements, including customization options. Engaging in a site visit or utilizing third-party audits can further ensure the supplier’s operational standards align with your expectations. -

Can gear drives be customized to meet specific operational requirements?

Yes, many suppliers offer customization options for gear drives to cater to unique operational needs. Customization may include alterations in gear ratios, materials, or dimensions. When approaching a supplier, clearly outline your specifications and any performance criteria. It’s essential to discuss the implications of customization on lead times and costs, as bespoke solutions may require additional time for design and manufacturing. Ensure that the supplier has the necessary engineering capabilities to handle your custom requests effectively. -

What are the typical minimum order quantities (MOQs) and lead times for gear drives?

Minimum order quantities (MOQs) for gear drives can vary significantly based on the supplier and the complexity of the gears. Generally, MOQs can range from a few units to hundreds. Lead times can also differ depending on customization, material availability, and production schedules, typically ranging from a few weeks to several months. It’s crucial to clarify these details upfront with suppliers to align your production timelines and inventory management with their capabilities. -

What payment terms are common when sourcing gear drives internationally?

International payment terms for gear drives can include options like letters of credit, wire transfers, or escrow services. Most suppliers prefer upfront payments or a deposit followed by the balance upon delivery. Be aware of potential currency fluctuations and ensure that all payment terms are clearly defined in the purchase agreement to avoid disputes. Familiarize yourself with the supplier’s accepted payment methods and consider discussing payment milestones based on production progress to protect your investment. -

How can I ensure quality assurance (QA) and certifications for gear drives?

To ensure quality assurance for gear drives, request documentation of the supplier’s quality management system and certifications, such as ISO 9001 or specific industry-related certifications. Implement a quality control process that includes inspections at various production stages and final product testing. You may also want to include QA clauses in your contracts that stipulate the standards and testing methods to be used. Conducting third-party inspections or audits can provide additional assurance of product quality and compliance with your specifications. -

What logistical considerations should I keep in mind when sourcing gear drives?

Logistical considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling industrial components to ensure smooth transportation. Understand the import duties and taxes applicable to your region, as these can affect overall costs. Additionally, discuss with your supplier the packaging and handling procedures they use to minimize damage during transit. Establish clear communication channels for tracking shipments to ensure timely delivery and address any potential delays proactively. -

What steps should I take if a dispute arises with a gear drive supplier?

If a dispute arises with a supplier, first attempt to resolve the issue through direct communication. Clearly outline your concerns and seek a mutually agreeable solution. If informal discussions fail, refer to the terms of your contract, including any specified dispute resolution processes. Consider mediation or arbitration as alternative dispute resolution methods to avoid lengthy litigation. It’s advisable to consult legal counsel familiar with international trade law to navigate the complexities of cross-border disputes effectively.

Illustrative Image (Source: Google Search)

- How do I assess the long-term reliability of gear drives from a supplier?

To assess the long-term reliability of gear drives, review the supplier’s track record and customer feedback regarding their products’ durability and performance. Request case studies or testimonials from clients in similar industries. Evaluate the supplier’s commitment to ongoing support, including warranty terms and maintenance services. Additionally, inquire about their production processes and quality control measures to ensure that they adhere to industry standards consistently. Establishing a long-term partnership with a supplier who demonstrates reliability can significantly enhance your operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gear drive

The complexities of sourcing gear drives require a strategic approach to ensure optimal performance and cost efficiency. Understanding the various types of gear drives, such as spur, helical, bevel, and worm gears, enables B2B buyers to select the right components for their specific applications. By considering factors like material durability, efficiency, and compatibility, buyers can mitigate risks associated with misalignment and wear, ultimately enhancing the reliability of their machinery.

Key takeaways include the importance of evaluating suppliers based on quality control measures, pricing structures, and their ability to provide timely support. Additionally, leveraging technology, such as CAD and CNC machining, can improve the precision of gear manufacturing and reduce lead times.

As industries across Africa, South America, the Middle East, and Europe continue to evolve, the demand for efficient and reliable gear drives will only increase. B2B buyers are encouraged to adopt a proactive sourcing strategy that embraces innovation and sustainability. By doing so, they can stay ahead of market trends, improve operational efficiency, and drive competitive advantage in their respective sectors. Embrace the future of gear drive sourcing today for a more resilient and productive tomorrow.