Your Ultimate Guide to Sourcing Gears Plastic

Introduction: Navigating the Global Market for gears plastic

Navigating the global market for plastic gears presents a wealth of opportunities for B2B buyers looking to enhance their product offerings. As industries increasingly shift towards lightweight, durable, and cost-effective solutions, plastic gears are becoming essential components in sectors ranging from automotive to consumer electronics. Their ability to reduce weight while maintaining performance makes them an attractive option for manufacturers striving for efficiency and innovation.

This guide provides a comprehensive overview of the plastic gear market, covering critical aspects such as types of plastic gears, materials used, and manufacturing and quality control processes. It also explores supplier options, cost considerations, and current market trends. Each section is designed to empower international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, to make informed sourcing decisions.

Understanding the nuances of plastic gears can significantly influence procurement strategies and operational efficiency. By leveraging insights from this guide, businesses can better navigate supplier landscapes, assess material specifications, and ultimately select the most suitable gears for their applications. Whether you are a seasoned professional or new to sourcing plastic gears, this resource aims to equip you with the knowledge needed to thrive in a competitive global marketplace.

Understanding gears plastic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nylon Gears | High strength, wear resistance, self-lubricating | Automotive, industrial machinery | Pros: Durable, low friction. Cons: Can absorb moisture, affecting dimensions. |

| Acetal Gears | Excellent dimensional stability, low friction | Robotics, consumer electronics | Pros: High rigidity, good chemical resistance. Cons: More expensive than nylon. |

| Polycarbonate Gears | High impact resistance, transparent, lightweight | Medical devices, safety equipment | Pros: Tough, good optical clarity. Cons: Less resistant to chemicals than other plastics. |

| Polypropylene Gears | Good fatigue resistance, low density | Packaging machinery, automotive | Pros: Cost-effective, resistant to moisture. Cons: Lower strength compared to nylon or acetal. |

| PTFE Gears | Extremely low friction, high chemical resistance | Chemical processing, food industry | Pros: Non-stick, stable across a wide temperature range. Cons: High cost, lower strength. |

Nylon Gears

Nylon gears are well-known for their high strength and durability, making them suitable for demanding applications in automotive and industrial machinery. Their self-lubricating properties reduce friction, leading to less wear and tear over time. However, buyers should be cautious as nylon can absorb moisture, which may impact the gear’s dimensional stability. When purchasing, consider the environmental conditions to ensure optimal performance.

Acetal Gears

Acetal, or polyoxymethylene (POM), gears are favored for their excellent dimensional stability and low friction characteristics. They are widely used in robotics and consumer electronics where precision is crucial. While acetal gears offer high rigidity and good chemical resistance, they tend to be more expensive than nylon options. Buyers should weigh the cost against the performance benefits, especially in high-precision applications.

Polycarbonate Gears

Polycarbonate gears stand out due to their high impact resistance and transparency, making them suitable for medical devices and safety equipment. Their lightweight nature and toughness make them a viable option in applications where breakage could pose safety risks. However, buyers should note that polycarbonate is less resistant to chemicals compared to other plastic types, which could limit its use in certain environments. Ensuring compatibility with the intended application is vital.

Polypropylene Gears

Polypropylene gears are known for their good fatigue resistance and low density, making them a cost-effective choice for packaging machinery and automotive applications. They offer reasonable moisture resistance, but their strength is lower compared to nylon or acetal. Buyers should consider the trade-off between cost and performance, particularly in applications where high strength is not a primary requirement.

PTFE Gears

PTFE gears, commonly known for their non-stick properties, exhibit extremely low friction and high chemical resistance, making them ideal for use in chemical processing and food industries. Their stability across a wide temperature range is a significant advantage. However, the high cost and lower strength compared to other plastic gears may deter some buyers. It is essential to evaluate the specific needs of the application to justify the investment in PTFE gears.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of gears plastic

| Industry/Sector | Specific Application of Gears Plastic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Transmission systems | Lightweight components improving fuel efficiency | Material compatibility, temperature resistance, and precision manufacturing capabilities. |

| Consumer Electronics | Robotics in smart devices | Enhanced durability and reduced noise levels | Customization options, compliance with safety standards, and rapid prototyping services. |

| Medical Devices | Surgical tools and equipment | Biocompatibility and precision in critical applications | Regulatory compliance, sterilization compatibility, and high-performance material selection. |

| Industrial Machinery | Gearboxes in conveyor systems | Lower maintenance costs and improved operational efficiency | Supplier reliability, material strength, and resistance to wear and tear. |

| Aerospace | Actuation systems in aircraft components | Weight reduction leading to fuel savings | Certification standards, precision engineering, and long-term performance guarantees. |

Automotive Applications

In the automotive sector, plastic gears are increasingly utilized in transmission systems. These components are designed to be lightweight, contributing to overall vehicle efficiency and fuel savings. International buyers must consider the material’s compatibility with high temperatures and its ability to withstand mechanical stress. Sourcing from manufacturers with proven precision engineering capabilities is crucial to ensure the longevity and reliability of these gears in demanding automotive environments.

Consumer Electronics

Plastic gears play a vital role in the robotics of smart devices, such as automated vacuum cleaners and drones. Their enhanced durability and reduced noise levels make them ideal for consumer products. B2B buyers should prioritize suppliers that offer customization options and adhere to safety standards, ensuring that the gears meet specific operational requirements. Rapid prototyping services can also facilitate quicker product development cycles.

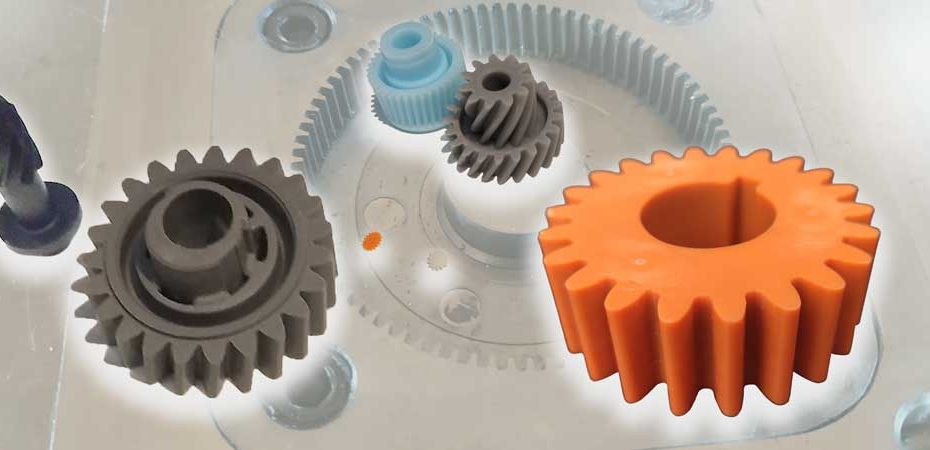

Illustrative Image (Source: Google Search)

Medical Device Applications

In the medical industry, plastic gears are essential for surgical tools and equipment, where biocompatibility and precision are paramount. These gears must not only meet stringent regulatory compliance but also be compatible with sterilization processes. Buyers should focus on sourcing high-performance materials that ensure reliability in critical applications, as well as suppliers who understand the complexities of medical device manufacturing.

Industrial Machinery

Plastic gears are commonly found in gearboxes used within conveyor systems in industrial machinery. Their use leads to lower maintenance costs and improved operational efficiency. When sourcing, businesses should evaluate the reliability of suppliers, the strength of materials used, and the gears’ resistance to wear and tear. These considerations are vital for ensuring uninterrupted operations in high-demand industrial environments.

Aerospace Applications

In the aerospace sector, plastic gears are used in actuation systems for various aircraft components. The weight reduction benefits significantly contribute to fuel savings, an essential factor in modern aviation. Buyers should ensure that their suppliers meet certification standards and can provide precision-engineered components. Long-term performance guarantees are also a critical consideration, given the rigorous operational demands in aerospace applications.

Related Video: Gear Types, Design Basics, Applications and More – Basics of Gears

Strategic Material Selection Guide for gears plastic

When selecting materials for plastic gears, international B2B buyers must consider various factors that impact product performance, manufacturing processes, and application suitability. Below is an analysis of four common materials used in the production of plastic gears, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Acetal (POM)

Key Properties:

Acetal, also known as polyoxymethylene (POM), offers excellent mechanical strength, low friction, and high wear resistance. It operates effectively in a temperature range of -40°C to 100°C and has good chemical resistance, particularly to hydrocarbons and alcohols.

Pros & Cons:

The primary advantage of acetal is its durability and dimensional stability, making it suitable for precision applications. However, it can be more expensive than other plastics and may require specialized machining processes, which can increase manufacturing complexity.

Impact on Application:

Acetal is ideal for applications involving high-speed operations and moderate loads, such as in automotive and consumer electronics. Its compatibility with lubricants makes it suitable for gear applications where reduced friction is critical.

Considerations for International Buyers:

Buyers should ensure compliance with ASTM and ISO standards for mechanical properties. Acetal’s higher cost may be a consideration for budget-sensitive projects, particularly in developing regions.

2. Nylon (Polyamide)

Key Properties:

Nylon is known for its toughness, flexibility, and resistance to abrasion. It operates effectively in temperatures up to 120°C and has good chemical resistance, although it can absorb moisture, which may affect its mechanical properties.

Pros & Cons:

Nylon gears are generally less expensive than acetal and offer good impact resistance. However, moisture absorption can lead to dimensional changes, which may be a concern for precision applications.

Impact on Application:

Nylon is suitable for applications requiring flexibility and resistance to wear, such as in household appliances and industrial machinery. Its ability to withstand high loads makes it a popular choice for various gear applications.

Considerations for International Buyers:

Buyers should be aware of the potential need for moisture control in applications. Compliance with standards such as DIN and JIS is essential, particularly for buyers in Europe and Asia.

3. Polycarbonate (PC)

Key Properties:

Polycarbonate is known for its high impact resistance and transparency. It can withstand temperatures up to 135°C and has good dimensional stability and resistance to UV light.

Pros & Cons:

The main advantage of polycarbonate is its strength and toughness, making it suitable for high-impact applications. However, it is more expensive than other plastics and can be prone to scratching unless treated.

Impact on Application:

Polycarbonate is often used in applications where visibility is important, such as in transparent gear housings or protective covers. Its strength makes it suitable for safety-critical applications in automotive and aerospace industries.

Considerations for International Buyers:

Buyers should consider the higher cost and ensure that polycarbonate meets relevant safety and performance standards. Its UV resistance is particularly beneficial for applications in sunny regions, such as parts of Africa and the Middle East.

4. Polypropylene (PP)

Key Properties:

Polypropylene is lightweight, flexible, and resistant to chemical exposure. It can operate effectively in temperatures up to 100°C and has moderate impact resistance.

Pros & Cons:

The primary advantage of polypropylene is its low cost and ease of processing. However, it has lower mechanical strength compared to other materials, which may limit its use in high-load applications.

Impact on Application:

Polypropylene is suitable for applications where weight savings are critical, such as in consumer products and packaging. Its chemical resistance makes it ideal for applications in the food and beverage industry.

Considerations for International Buyers:

Buyers should ensure compliance with food safety standards when using polypropylene in food-related applications. Its cost-effectiveness may appeal to buyers in developing markets looking for budget-friendly solutions.

| Material | Typical Use Case for gears plastic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acetal (POM) | Automotive and consumer electronics gears | High durability and low friction | Higher cost and manufacturing complexity | High |

| Nylon (Polyamide) | Household appliances and industrial machinery | Good impact resistance and flexibility | Moisture absorption affects dimensions | Medium |

| Polycarbonate (PC) | Transparent gear housings and safety applications | High impact resistance | Prone to scratching and higher cost | High |

| Polypropylene (PP) | Consumer products and packaging gears | Low cost and easy processing | Lower mechanical strength | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, facilitating informed decisions based on performance, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for gears plastic

The manufacturing of plastic gears involves several critical stages, each designed to ensure the final product meets specific performance and quality standards. Understanding these processes is vital for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Manufacturing Processes for Plastic Gears

-

Material Preparation

– Selection of Materials: High-performance engineering plastics such as polycarbonate, nylon, and acetal are commonly used for manufacturing gears. These materials are chosen for their strength, durability, and resistance to wear.

– Material Conditioning: Prior to processing, materials may undergo drying or conditioning to remove moisture, which can affect the molding process and the final properties of the gears. -

Forming Techniques

– Injection Molding: This is the most prevalent technique for producing plastic gears. It involves injecting molten plastic into a mold, where it cools and solidifies into the desired gear shape. This method is efficient for high-volume production and allows for complex geometries.

– 3D Printing: Emerging as a viable option for prototyping and low-volume production, 3D printing can create intricate designs that might be difficult or costly to achieve with traditional methods.

– Machining: For high-precision applications, machining processes such as CNC milling and turning may be employed. This is typically used for custom gears or where tight tolerances are required. -

Assembly

– Integration with Other Components: In some applications, gears may need to be assembled with other parts, such as shafts or housings. This requires careful alignment and securing methods, which can include press-fitting or using adhesives.

– Automation in Assembly: Utilizing automated assembly lines can enhance efficiency and reduce the risk of human error, particularly in high-volume operations. -

Finishing Processes

– Surface Treatment: Depending on the application, surface treatments such as polishing or coating may be applied to enhance performance characteristics, such as reducing friction or improving wear resistance.

– Quality Checks: Before final packaging, gears are often subjected to rigorous quality checks to ensure they meet all specifications and tolerances.

Quality Assurance in Plastic Gear Manufacturing

Quality assurance is paramount in the manufacturing of plastic gears, ensuring that products not only meet specifications but also comply with international standards.

-

International Standards

– ISO 9001: This standard focuses on quality management systems and is applicable across various industries, including gear manufacturing. Adhering to ISO 9001 signifies that a manufacturer consistently provides products that meet customer and regulatory requirements.

– Industry-Specific Certifications: Depending on the application, additional certifications may be necessary. For example, CE marking indicates conformity with health, safety, and environmental protection standards for products marketed in the European Economic Area. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial phase involves checking raw materials for compliance with specifications before they are used in production.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted to ensure that production remains within specified tolerances.

– Final Quality Control (FQC): Once the gears are completed, a final inspection is conducted to verify dimensions, material properties, and overall quality. -

Common Testing Methods

– Dimensional Inspection: Using tools such as calipers and micrometers, manufacturers measure the dimensions of gears to ensure they meet design specifications.

– Functional Testing: Gears may be tested under operational conditions to evaluate performance characteristics such as load-bearing capacity and noise levels.

– Material Testing: Techniques like tensile testing and hardness testing can assess the mechanical properties of the plastic materials used.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from regions with varying standards, verifying a supplier’s quality control processes is crucial. Here are actionable insights:

-

Audits: Conducting on-site audits can provide firsthand insight into a supplier’s manufacturing capabilities and adherence to quality standards. This includes reviewing processes, equipment, and the qualifications of personnel involved in manufacturing.

-

Quality Reports: Requesting detailed quality control reports can help buyers understand how a supplier tracks and manages quality throughout the production process. These reports should include data from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an objective assessment of a supplier’s quality management system. This is particularly beneficial for buyers in regions where local quality assurance practices may differ from international standards.

Quality Control Nuances for International Buyers

International buyers must navigate various challenges related to quality control. Here are some considerations:

- Understanding Regional Standards: Different regions may have specific regulations or standards that must be adhered to. For example, buyers from Europe must ensure compliance with CE marking, while those in the Middle East may have different certification requirements.

- Communication Barriers: Language and cultural differences can affect the clarity of quality expectations. Establishing clear lines of communication and documentation can mitigate misunderstandings.

- Logistical Challenges: Shipping products across borders introduces potential quality control issues. Ensuring proper handling and storage during transit is essential to maintain product integrity.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing plastic gears, ensuring they receive high-quality products that meet their operational needs.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for gears plastic Sourcing

When sourcing plastic gears for industrial applications, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will provide insights into the various components that contribute to the total cost and highlight factors that influence pricing, especially for buyers from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of plastic material significantly impacts cost. Common materials include nylon, acetal, and polycarbonate, each offering different performance characteristics and price points. High-performance materials may carry a premium but can offer better durability and efficiency.

-

Labor: Labor costs vary by region and supplier. In countries with lower labor costs, such as some in South America and Africa, manufacturing expenses can be reduced. However, labor skill level and availability can affect production timelines and quality.

-

Manufacturing Overhead: This includes costs associated with factory operation, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, impacting the final pricing.

-

Tooling: Tooling costs are incurred for the creation of molds and dies specific to the gear design. Custom gears will require higher tooling costs, which should be amortized over production runs to understand the per-unit cost effectively.

-

Quality Control (QC): Implementing robust QC processes ensures product reliability and compliance with industry standards. QC costs can vary based on the complexity of testing and certification processes, impacting overall pricing.

-

Logistics: Shipping and handling costs can be significant, especially for international buyers. Factors like distance, shipping mode (air vs. sea), and customs duties must be considered in the total cost.

-

Margin: Suppliers typically build in a profit margin, which can vary widely based on competition, market demand, and the supplier’s pricing strategy.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing significantly. Larger orders often lead to bulk discounts, whereas smaller quantities may incur higher per-unit costs.

-

Specifications/Customization: Custom designs and specifications typically incur additional costs for tooling and production. Buyers should balance the need for customization with the associated costs.

-

Materials: The choice of material not only affects the performance but also the cost. Opting for standard materials can reduce expenses, while specialized materials may enhance performance but at a higher price.

-

Quality/Certifications: Gears that meet specific industry standards or certifications may command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Relationship with suppliers, their location, and their reputation can influence pricing. Reliable suppliers may charge a premium but can offer better service and quality assurance.

-

Incoterms: The agreed-upon Incoterms can significantly affect logistics costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost estimation.

Buyer Tips

-

Negotiation: Engage in discussions with suppliers to negotiate pricing based on volume, long-term contracts, or loyalty discounts. Leverage competition among suppliers to achieve better pricing.

-

Cost-Efficiency: Consider the total cost of ownership (TCO) rather than just the initial purchase price. Factors like durability, maintenance, and energy efficiency can lead to significant savings over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can affect the final cost. Establish clear communication with suppliers regarding pricing terms and conditions to avoid unexpected costs.

-

Disclaimer for Indicative Prices: Pricing can fluctuate based on market conditions, material availability, and supplier capabilities. Always request updated quotes and clarify all terms before finalizing purchases.

By understanding these components and influences, international B2B buyers can make informed decisions when sourcing plastic gears, ensuring both cost-effectiveness and quality in their procurement processes.

Spotlight on Potential gears plastic Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘gears plastic’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for gears plastic

When sourcing plastic gears for industrial applications, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. Below are key specifications and commonly used terms that will aid B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in navigating this specialized market.

Key Technical Properties

-

Material Grade

– Definition: This refers to the specific type of plastic used in the manufacturing of gears, such as Nylon, Acetal, or Polycarbonate.

– Importance: The material grade affects the gear’s strength, durability, and wear resistance. Buyers should select the appropriate grade based on the application, such as high-stress environments or exposure to chemicals. -

Tolerance

– Definition: Tolerance specifies the allowable variation in the dimensions of the gear, which is critical for proper fit and function.

– Importance: Precise tolerances ensure that gears mesh correctly, minimizing wear and prolonging lifespan. Inaccurate tolerances can lead to gear failure and increased maintenance costs. -

Load Capacity

– Definition: This property indicates the maximum load that a gear can handle without failing.

– Importance: Understanding load capacity is essential for selecting gears that will operate efficiently under specified conditions. Buyers must consider both static and dynamic loads to prevent premature wear. -

Coefficient of Friction

– Definition: This is a measure of how much resistance the gear experiences when in contact with another surface.

– Importance: A lower coefficient of friction indicates smoother operation, which is crucial for energy efficiency and reducing heat generation. This is particularly important in high-speed applications.

Illustrative Image (Source: Google Search)

- Temperature Resistance

– Definition: This property defines the maximum temperature at which the gear can operate effectively without deforming or losing its mechanical properties.

– Importance: Buyers must assess the operational environment to ensure that selected gears can withstand the temperature ranges they will encounter, particularly in industries like automotive and aerospace.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships helps buyers identify quality sources and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their purchases and manage inventory efficiently, especially in regions where stock availability may be limited. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to solicit pricing and terms for specific products or services.

– Relevance: Submitting an RFQ allows buyers to compare offers from multiple suppliers, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost allocation, critical for international trade. -

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Relevance: Understanding lead times is essential for project planning and inventory management, particularly for buyers operating in fast-paced industries. -

Customization

– Definition: The ability to tailor the design and specifications of gears to meet specific application requirements.

– Relevance: Customization options can significantly enhance performance in specialized applications, making it a critical factor for buyers looking for unique solutions.

By familiarizing themselves with these technical properties and industry terms, B2B buyers can make more informed decisions, ensuring that they select the right plastic gears for their applications while effectively managing costs and logistics.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gears plastic Sector

Market Overview & Key Trends

The global plastic gears market is experiencing dynamic growth, driven by advancements in material science, increasing automation, and the rising demand for lightweight and corrosion-resistant components across various industries. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial for effective sourcing and procurement strategies.

Key Drivers:

– Technological Advancements: Innovations in manufacturing processes, such as 3D printing and CNC machining, are enabling the production of highly customized plastic gears. This flexibility allows buyers to meet specific application requirements while reducing lead times.

– Cost Efficiency: Compared to traditional metal gears, plastic gears offer lower manufacturing costs and reduced weight, which can lead to savings in energy and transportation costs, particularly significant for buyers in emerging markets.

– Industry Applications: The automotive, aerospace, and consumer electronics sectors are increasingly integrating plastic gears into their products, emphasizing the need for B2B buyers to stay updated on industry-specific requirements and standards.

Emerging Trends:

– Smart Manufacturing: The adoption of IoT and AI in manufacturing is enhancing predictive maintenance and quality control, enabling buyers to source products that meet higher standards of reliability.

– Global Supply Chains: As companies seek to diversify their supply chains post-pandemic, B2B buyers are encouraged to consider local suppliers in their regions while also leveraging global networks for specialized needs.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal concern in the gears plastic sector, influencing purchasing decisions among international B2B buyers. The environmental impact of plastic production and disposal is significant, prompting a shift toward more sustainable practices.

Importance of Ethical Supply Chains:

– Environmental Impact: The production of plastic materials is often associated with high carbon emissions and waste generation. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their environmental footprint.

– Consumer Demand: As end-users become more environmentally conscious, B2B buyers must align their sourcing strategies with sustainability goals to maintain competitiveness.

Green Certifications and Materials:

– Biodegradable Plastics: Sourcing gears made from biodegradable materials can significantly reduce environmental impact. Buyers should seek suppliers offering products certified as compostable or recyclable.

– Sustainable Certifications: Look for suppliers with certifications such as ISO 14001, which indicates adherence to environmental management standards. This can assure buyers of ethical practices and sustainability in the supply chain.

Brief Evolution/History

The evolution of plastic gears can be traced back to the mid-20th century when advancements in polymer science began to unlock new potential for engineering applications. Initially, plastic gears were seen as an inferior alternative to metal, primarily used in low-load applications. However, as material properties improved—offering enhanced strength, durability, and wear resistance—plastic gears gained traction across various industries.

Today, they are integral to high-performance applications, from medical devices to automotive systems, reflecting a broader trend towards lightweight and energy-efficient solutions. This historical perspective is essential for B2B buyers as it highlights the ongoing innovation and adaptability of plastic gear technology, ensuring they are well-equipped to make informed sourcing decisions in a rapidly changing market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of gears plastic

-

What factors should I consider when vetting suppliers for plastic gears?

When vetting suppliers for plastic gears, focus on their experience and expertise in your specific industry. Verify their certifications, such as ISO 9001, to ensure they adhere to quality management standards. Request samples to assess material quality and manufacturing precision. Additionally, inquire about their production capacity, lead times, and whether they have a history of on-time deliveries. It’s also beneficial to check references or reviews from previous clients, particularly those in your region, to gauge their reliability and service quality. -

Can I get custom plastic gears tailored to my specific needs?

Yes, many manufacturers offer customization options for plastic gears. When discussing your requirements, provide detailed specifications including dimensions, material type, and performance criteria. Be clear about your application to ensure the design meets functional demands. Customization might involve higher costs and longer lead times, so it’s essential to discuss Minimum Order Quantities (MOQs) and production timelines upfront to align expectations. -

What are typical lead times and MOQs for ordering plastic gears?

Lead times for plastic gears can vary significantly based on customization and the supplier’s capacity. Generally, standard gears may be available within 2-4 weeks, while custom designs could take 6-12 weeks or more. MOQs often depend on the complexity of the gear and the supplier’s policies; some may require a minimum order of 100 pieces, while others might accommodate lower quantities. Always clarify these details during initial discussions to avoid potential delays. -

What payment options are commonly accepted by plastic gear suppliers?

Payment options for plastic gear suppliers typically include bank transfers, letters of credit, and credit terms depending on the supplier’s policies and your relationship with them. International buyers should also consider currency exchange rates and transaction fees. Establishing trust through initial smaller orders can sometimes lead to more flexible payment arrangements in future transactions. Always ensure that payment terms are documented in the purchase agreement to avoid disputes later. -

How can I ensure quality assurance for my plastic gears?

To ensure quality assurance, request a detailed quality control plan from your supplier. This should outline their inspection processes, testing methods, and compliance with industry standards. It’s advisable to ask for certifications related to quality management and material safety. Consider conducting an on-site inspection or third-party audit, especially for large orders. Additionally, request samples before full-scale production to verify that the gears meet your specifications and performance requirements. -

What certifications should I look for in plastic gear suppliers?

Look for suppliers that hold relevant industry certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Depending on your industry, additional certifications like FDA approval for medical applications or UL certification for electrical components may be necessary. These certifications demonstrate a commitment to quality and compliance with regulatory standards, which is crucial for international trade. -

How do logistics and shipping impact the procurement of plastic gears?

Logistics and shipping play a critical role in the procurement process, especially for international buyers. Consider the shipping methods available (air, sea, or land) and their associated costs and transit times. Discuss with your supplier who will be responsible for shipping and customs clearance. It’s also wise to factor in potential delays due to customs regulations in your country. Establishing a reliable logistics partner can help ensure timely delivery and minimize disruptions. -

What should I do if there’s a dispute with my plastic gear supplier?

In the event of a dispute, first, refer to the terms outlined in your purchase agreement. Open a line of communication with the supplier to address the issue directly, as many disputes can be resolved through discussion. If necessary, escalate the matter to a higher authority within the company. For unresolved issues, consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming. Always keep thorough documentation of all communications and agreements to support your position.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gears plastic

As we conclude this exploration of plastic gears and their strategic sourcing, it is vital to recognize their transformative potential across various industries. By leveraging custom plastic gears, businesses can enjoy significant advantages such as reduced weight, lower manufacturing costs, and increased design flexibility. These factors are especially crucial for international B2B buyers seeking to optimize production processes while maintaining quality.

Strategic sourcing plays a pivotal role in enhancing supply chain efficiency and fostering strong relationships with suppliers. Buyers from regions like Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers that emphasize innovation and sustainability. This approach not only reduces operational risks but also aligns with global trends toward eco-friendly manufacturing practices.

Looking ahead, the market for plastic gears is poised for growth, driven by advancements in material science and manufacturing technologies. International buyers are encouraged to stay informed about emerging trends and to actively engage with industry events and educational resources. By doing so, they can make informed decisions that will position their businesses for future success in the evolving landscape of mechanical components. Engage with suppliers today to unlock the full potential of plastic gears in your applications.