Your Ultimate Guide to Sourcing Graphite Crucibles

Introduction: Navigating the Global Market for graphite crucibles

In the ever-evolving global market, graphite crucibles serve as a cornerstone in various industries, particularly metallurgy, foundry operations, and precious metal refining. Their ability to withstand extreme temperatures and resist chemical reactions makes them indispensable for melting non-ferrous metals such as gold, silver, and aluminum. As international B2B buyers, understanding the nuances of graphite crucibles is crucial for optimizing sourcing strategies and ensuring operational efficiency.

This guide offers a comprehensive exploration of the graphite crucible market, detailing the different types and materials available, alongside insights into manufacturing processes and quality control standards. Buyers will also find valuable information on reputable suppliers across Africa, South America, the Middle East, and Europe, including Germany and Spain, enabling them to make informed decisions when selecting partners.

Additionally, the guide addresses key factors influencing cost structures and provides answers to frequently asked questions, empowering buyers to navigate the complexities of the market. By leveraging the insights provided, international B2B buyers can enhance their procurement processes, reduce risks, and capitalize on opportunities in the graphite crucible market. In an industry where quality and reliability are paramount, this guide will serve as your essential resource for successful sourcing and supplier engagement.

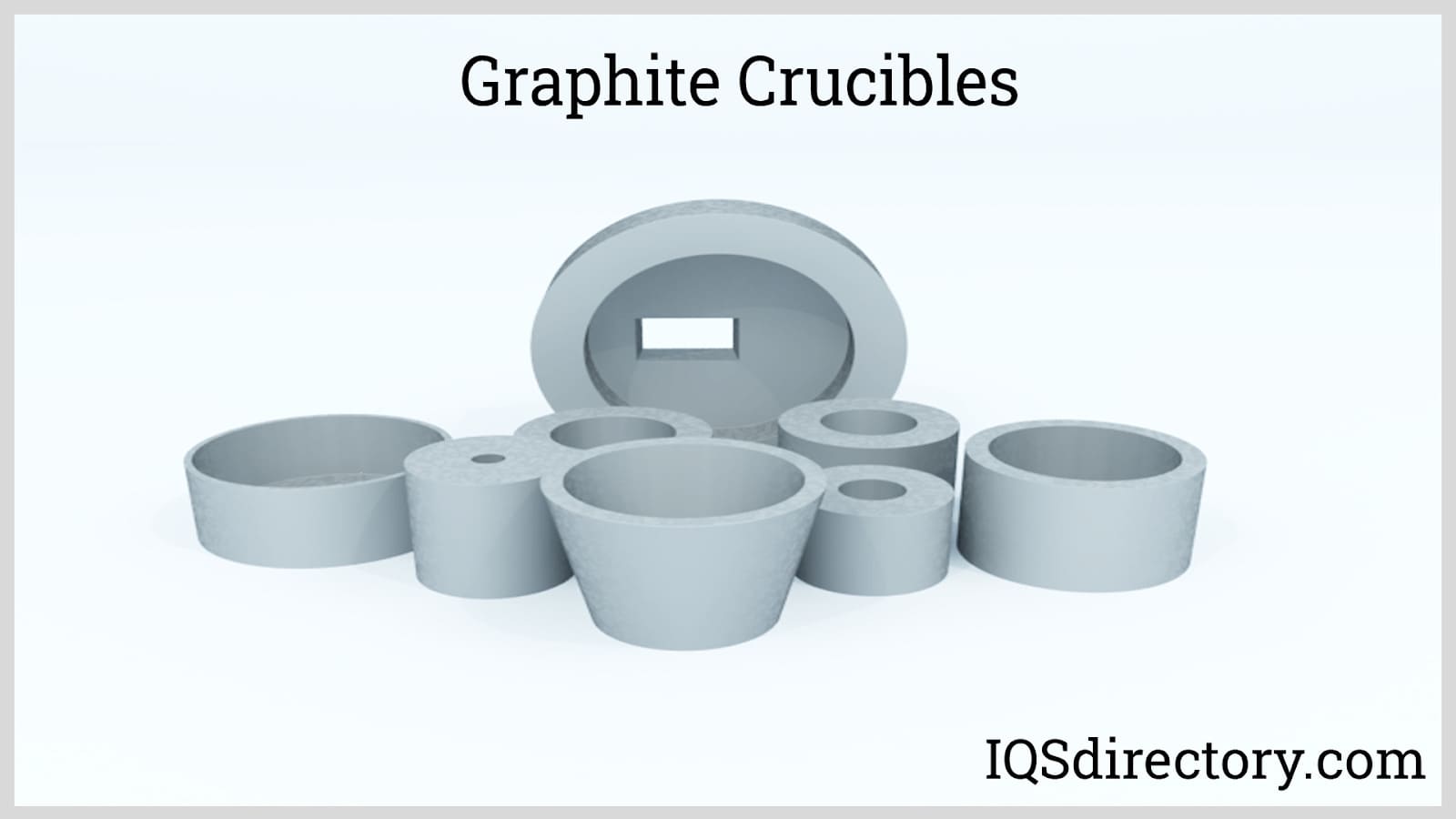

Understanding graphite crucibles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clay Graphite Crucibles | High thermal resistance, blends clay with graphite | Foundries, metal casting | Pros: Durable, cost-effective; Cons: Limited to lower melting point metals. |

| High-Purity Graphite Crucibles | Made from high-purity graphite, low porosity | Jewelry making, semiconductor production | Pros: Excellent thermal conductivity; Cons: Higher cost due to material quality. |

| Silicon Carbide Crucibles | Exceptional thermal shock resistance, lightweight | Glass production, metal fabrication | Pros: High durability, suitable for extreme conditions; Cons: Can be brittle under certain conditions. |

| Isostatic Graphite Crucibles | Uniform density, high strength, tailored shapes | Research and development, high-tech applications | Pros: Customizable, precise dimensions; Cons: Longer lead times for custom orders. |

| Coarse Extruded Graphite Crucibles | Cost-effective, good for general applications | General metal melting, large-scale operations | Pros: Affordable, easy to produce; Cons: Not suitable for high-purity applications. |

Clay Graphite Crucibles

Clay graphite crucibles are a staple in foundries due to their ability to withstand high temperatures while providing good thermal resistance. They combine clay and graphite, making them durable and cost-effective for melting non-ferrous metals like aluminum and brass. When purchasing, consider the specific melting points of the metals you will be working with, as these crucibles are not ideal for materials requiring extremely high temperatures.

High-Purity Graphite Crucibles

These crucibles are crafted from high-purity graphite, which minimizes impurities that could contaminate the melted materials. Their low porosity enhances thermal conductivity and thermal shock resistance, making them suitable for sensitive applications such as jewelry making and semiconductor production. Buyers should focus on the purity levels required for their specific applications, as these crucibles tend to be more expensive but offer superior performance.

Silicon Carbide Crucibles

Silicon carbide crucibles are known for their exceptional thermal shock resistance and lightweight nature, making them ideal for extreme conditions in glass production and metal fabrication. They provide high durability but may be brittle under certain stress conditions. Buyers should evaluate the operational environment and potential thermal stresses to ensure these crucibles meet their needs.

Isostatic Graphite Crucibles

Isostatic graphite crucibles feature uniform density and high strength, allowing for tailored shapes that cater to specific applications in research and high-tech industries. Their customizable nature makes them perfect for specialized melting processes. However, buyers should be prepared for longer lead times associated with custom orders and assess whether the precision offered justifies the investment.

Coarse Extruded Graphite Crucibles

These crucibles are a cost-effective option for general metal melting and are produced in larger quantities for extensive operations. While they are affordable and easy to manufacture, they may not be suitable for high-purity applications due to their material properties. B2B buyers should evaluate their melting requirements and budget constraints to determine if these crucibles align with their operational needs.

Related Video: Graphite crucible making procedure | How Graphite crucibles are made

Key Industrial Applications of graphite crucibles

| Industry/Sector | Specific Application of graphite crucibles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Foundry and Casting | Melting and pouring non-ferrous metals (e.g., aluminum, brass) | High thermal resistance reduces downtime and increases efficiency. | Ensure high purity and low porosity to prevent contamination. |

| Jewelry Making | Refining precious metals (e.g., gold, silver) | Enhances quality and purity of metals, vital for luxury markets. | Look for suppliers with strict quality control measures. |

| Glass Production | Melting glass materials | Consistent thermal properties ensure uniform glass quality. | Assess crucible compatibility with specific glass types. |

| Semiconductor Industry | Melting materials for semiconductor fabrication | High thermal stability supports precise manufacturing processes. | Consider lead times and customization options for specific needs. |

| Research and Development | Analyzing and melting various experimental materials | Facilitates innovation and development of new materials. | Prioritize suppliers with R&D capabilities and flexible orders. |

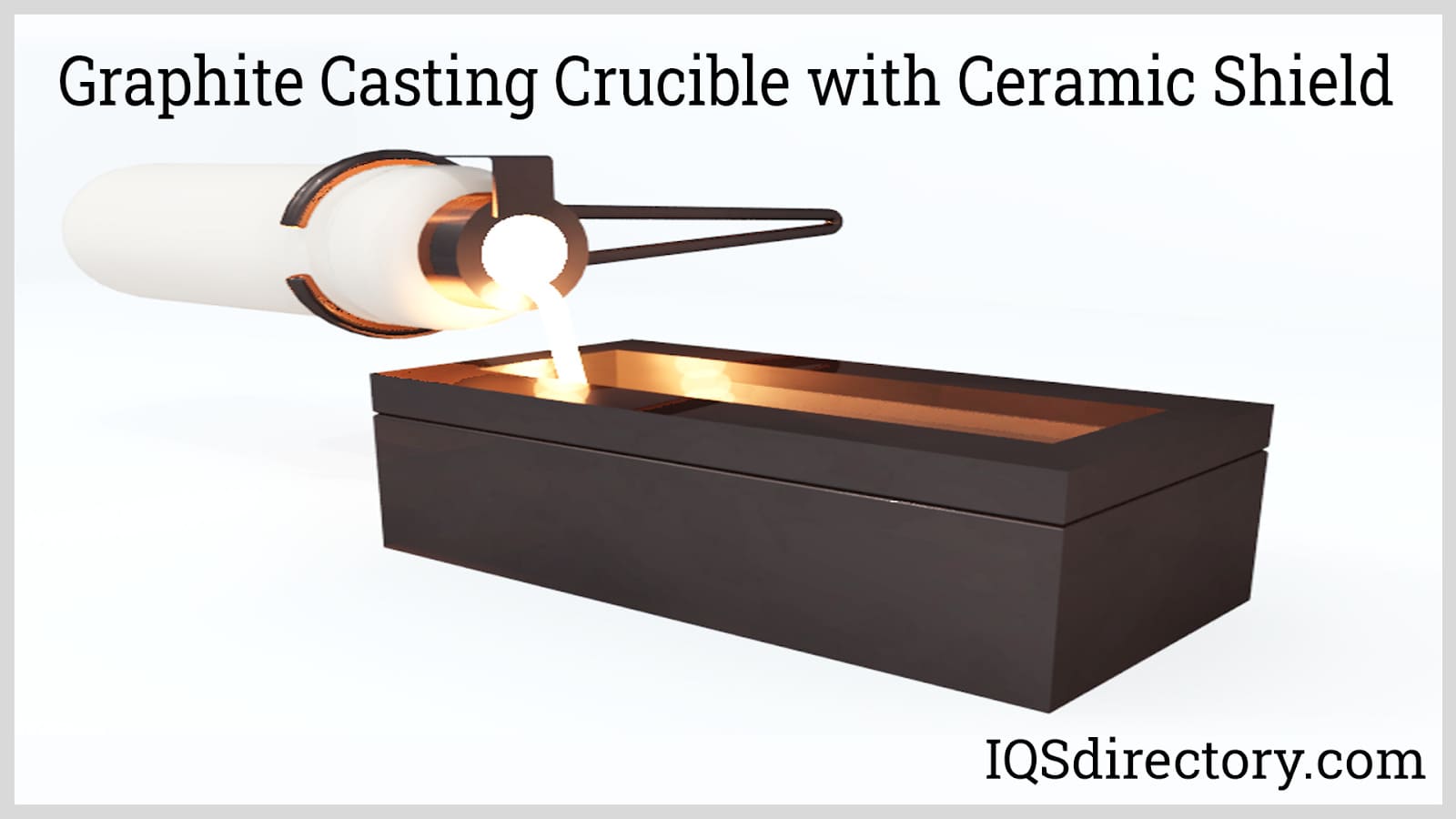

Foundry and Casting

In the foundry and casting sector, graphite crucibles are essential for melting non-ferrous metals such as aluminum and brass. Their high thermal resistance allows for efficient melting processes, significantly reducing downtime associated with equipment failure. For international buyers, especially in Africa and South America, sourcing crucibles that maintain high purity and low porosity is critical to prevent contamination of the molten metal, ensuring high-quality final products.

Jewelry Making

Graphite crucibles are widely used in the jewelry industry for refining precious metals like gold and silver. The high purity of the crucibles directly impacts the quality and value of the refined metals, making them indispensable in luxury markets. Buyers from Europe, particularly Germany and Spain, should prioritize suppliers with stringent quality control to guarantee that the crucibles meet the necessary standards for precious metal processing.

Glass Production

In glass production, graphite crucibles are employed to melt raw materials, ensuring consistent thermal properties that lead to uniform glass quality. The ability to withstand high temperatures without degrading is vital in this application. International buyers should evaluate crucible compatibility with various glass types and assess the supplier’s ability to provide customized solutions tailored to specific production requirements.

Semiconductor Industry

The semiconductor industry utilizes graphite crucibles to melt materials that are integral to the fabrication of semiconductor devices. The thermal stability and resistance to corrosive materials make graphite crucibles ideal for this high-precision sector. Buyers need to consider lead times and the ability of suppliers to customize crucibles to fit specific manufacturing processes, ensuring seamless integration into their operations.

Research and Development

In research and development environments, graphite crucibles are utilized for melting and analyzing experimental materials. Their versatility allows researchers to explore new compositions and processes, driving innovation. B2B buyers in this sector should prioritize suppliers that offer robust R&D capabilities and flexible ordering options, enabling them to adapt to the evolving demands of their projects.

Strategic Material Selection Guide for graphite crucibles

When selecting graphite crucibles, the choice of material significantly impacts performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of graphite crucibles, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Clay Graphite

Key Properties: Clay graphite crucibles are composed of a mixture of clay and graphite, providing excellent thermal resistance and mechanical strength. They typically withstand temperatures up to 1,600°C (2,912°F) and have good thermal shock resistance.

Pros & Cons: The major advantage of clay graphite crucibles is their durability and ability to handle high temperatures, making them suitable for melting metals like aluminum and brass. However, they can be heavier and more expensive than other options, which may affect shipping costs for international buyers.

Impact on Application: These crucibles are ideal for foundry applications where high thermal stability is required. They are compatible with non-ferrous metals, but their performance may degrade when used with highly reactive metals.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial for buyers from Europe and the Middle East. Additionally, understanding local regulations regarding material sourcing and environmental impact is essential, especially in regions like Africa and South America.

2. High-Purity Graphite

Key Properties: High-purity graphite crucibles are made from fine-grain graphite, offering superior thermal conductivity and low porosity. They can typically withstand temperatures up to 3,000°C (5,432°F) in inert atmospheres.

Pros & Cons: The main advantage is their exceptional thermal shock resistance and low contamination risk, making them ideal for high-precision applications such as semiconductor manufacturing. However, they tend to be more costly due to the high-quality materials used in their production.

Impact on Application: These crucibles are particularly suitable for applications requiring high purity, such as precious metal refining and glass production. Their low porosity minimizes the risk of contamination, which is critical in sensitive processes.

Considerations for International Buyers: Buyers should ensure that suppliers adhere to international quality standards and certifications. The higher cost may be justified in applications where purity is paramount, especially in developed markets like Germany and Spain.

3. Silicon Carbide (SiC) Composite

Key Properties: Silicon carbide crucibles are known for their high thermal conductivity and excellent chemical resistance. They can withstand temperatures up to 1,600°C (2,912°F) and are particularly resistant to oxidation.

Pros & Cons: The key advantage of SiC crucibles is their durability and resistance to thermal shock. They are less prone to cracking compared to traditional graphite crucibles. However, they can be more brittle and may require careful handling during transport and use.

Impact on Application: These crucibles are well-suited for melting metals and alloys that are reactive or have high melting points. They are compatible with a wide range of materials, making them versatile for various industrial applications.

Considerations for International Buyers: Compliance with safety and environmental regulations is critical, especially in regions with stringent manufacturing standards. Buyers should also consider the potential for higher shipping costs due to the weight and fragility of these crucibles.

4. Molded Graphite

Key Properties: Molded graphite crucibles are produced by compressing graphite powder into molds, resulting in a uniform structure. They can withstand temperatures up to 2,500°C (4,532°F) and offer good thermal shock resistance.

Pros & Cons: One of the main advantages is their cost-effectiveness and ease of manufacturing. They can be produced in various shapes and sizes, tailored to specific applications. However, they may not perform as well under extreme conditions compared to high-purity or SiC crucibles.

Impact on Application: Molded graphite crucibles are commonly used in metal casting and jewelry making. They are suitable for non-ferrous metals but may not be ideal for high-precision applications.

Considerations for International Buyers: Buyers should evaluate the manufacturing processes and material sourcing to ensure compliance with international standards. Cost considerations are also vital, particularly for buyers in developing regions where budget constraints may influence material choices.

Summary Table

| Material | Typical Use Case for graphite crucibles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clay Graphite | Melting non-ferrous metals | Excellent thermal resistance | Heavier and more expensive | Medium |

| High-Purity Graphite | Semiconductor manufacturing | Superior thermal shock resistance | Higher cost due to quality materials | High |

| Silicon Carbide | Melting reactive metals | High durability and chemical resistance | Brittle and requires careful handling | Medium |

| Molded Graphite | Metal casting, jewelry making | Cost-effective and easy to manufacture | Lower performance under extreme conditions | Low |

This strategic material selection guide provides crucial insights for international B2B buyers, helping them make informed decisions based on application needs, compliance requirements, and cost considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for graphite crucibles

The manufacturing of graphite crucibles involves several critical stages that ensure the production of high-quality products suitable for diverse applications, from metal melting to semiconductor manufacturing. Understanding these processes and the associated quality assurance protocols is essential for international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe.

Manufacturing Process of Graphite Crucibles

1. Material Preparation

The manufacturing process begins with the careful selection and preparation of raw materials. The primary components used in graphite crucibles are high-purity graphite and clay.

- Graphite Selection: High-purity graphite is essential as it minimizes impurities that could negatively affect performance. Buyers should inquire about the source and purity level of the graphite used.

- Clay Addition: Clay acts as a binding agent that enhances the structural integrity of the crucible. The ratio of graphite to clay is critical and varies based on the desired properties of the final product.

2. Forming

Once the materials are prepared, they undergo forming processes, which can include methods such as:

- Molding: The mixture is placed into molds to create the desired shape. This can involve both manual and automated processes.

- Pressing: The mixture is subjected to high pressure to ensure uniform density and eliminate air pockets, which can lead to weaknesses in the crucible.

3. Assembly

In some cases, graphite crucibles may require assembly if they consist of multiple parts or components. This stage involves:

- Joining: Various parts of the crucible are connected, often using adhesives or additional graphite materials.

- Alignment: Ensuring that all components are precisely aligned to maintain the structural integrity and performance of the crucible.

4. Finishing

The finishing stage is crucial for enhancing the crucible’s performance characteristics. This includes:

- Machining: Precision machining processes, such as CNC machining, are employed to achieve tight tolerances and smooth surfaces. This is vital for applications where consistency and thermal conductivity are paramount.

- Surface Treatment: Additional treatments may be applied to improve resistance to thermal shock and corrosion, further enhancing the crucible’s lifespan.

Quality Assurance in Manufacturing

Quality assurance is a fundamental aspect of the manufacturing process, ensuring that graphite crucibles meet international standards and customer specifications.

Relevant International Standards

B2B buyers should be aware of various international standards that govern the quality of graphite crucibles:

- ISO 9001: This standard focuses on quality management systems and is crucial for manufacturers aiming to provide consistent quality. Buyers should request ISO 9001 certification to ensure that suppliers adhere to systematic quality processes.

- CE Marking: For buyers in Europe, CE marking indicates compliance with EU safety and health regulations. This is particularly relevant for products used in high-stakes environments.

- API Standards: In specific industries like oil and gas, adherence to API (American Petroleum Institute) standards may be necessary. Buyers should verify that manufacturers comply with relevant API specifications.

Quality Control Checkpoints

To ensure adherence to quality standards, manufacturers implement several key quality control (QC) checkpoints throughout the production process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for quality and purity before they enter the manufacturing process.

- In-Process Quality Control (IPQC): During production, continuous monitoring and testing are performed to identify any deviations from specifications.

- Final Quality Control (FQC): After production, the finished crucibles undergo rigorous testing for dimensional accuracy, thermal conductivity, and resistance to thermal shock.

Common Testing Methods

Several testing methods are employed to ensure the performance and quality of graphite crucibles:

- Thermal Conductivity Testing: Measures the crucible’s ability to conduct heat, which is critical for melting applications.

- Thermal Shock Resistance Testing: Assesses how well the crucible can withstand sudden temperature changes without cracking.

- Dimensional Inspection: Utilizes precision measuring tools to ensure that the crucibles meet specified dimensions and tolerances.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality assurance processes of their suppliers, especially when sourcing from international manufacturers.

Supplier Audits

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. Buyers should consider:

- On-site Inspections: Visiting the manufacturing facility can provide insights into the production process and quality management systems in place.

- Document Review: Requesting documentation related to QC processes, including inspection reports and certifications, can help buyers gauge reliability.

Third-party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. This is particularly beneficial when dealing with suppliers from regions with varying standards.

Quality Reports

Regular quality reports from suppliers can keep buyers informed about production quality and any issues encountered during manufacturing. Buyers should establish expectations for reporting frequency and content.

Conclusion

Understanding the manufacturing processes and quality assurance measures for graphite crucibles is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, as well as adhering to rigorous QC protocols, buyers can ensure they source high-quality products that meet their specific needs. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers that demonstrate compliance with international standards, maintain robust quality control processes, and are open to audits and inspections. This diligence will help mitigate risks and enhance the overall purchasing experience.

Comprehensive Cost and Pricing Analysis for graphite crucibles Sourcing

Understanding the cost structure and pricing dynamics for sourcing graphite crucibles is crucial for international B2B buyers. The overall cost and pricing can significantly impact the bottom line, especially for companies operating in diverse regions like Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver for graphite crucibles is the quality and type of raw materials used. High-purity graphite is often more expensive but essential for applications requiring minimal contamination. Clay and other additives also contribute to the material costs.

-

Labor: Labor costs vary significantly by region and can affect the overall pricing of crucibles. In countries with higher labor costs, such as Germany and Spain, the manufacturing expenses may be higher than in regions with lower labor costs, such as some parts of Africa and South America.

-

Manufacturing Overhead: This includes utilities, facility costs, and other indirect expenses associated with production. Companies with advanced manufacturing techniques may have higher overhead costs due to investments in technology and infrastructure.

-

Tooling: Custom tooling for specific crucible designs can add to the initial costs. Buyers should consider whether they require standard or custom designs, as custom tooling often leads to higher upfront costs but can result in better fit for specific applications.

-

Quality Control (QC): Ensuring that the crucibles meet specific quality and performance standards adds to the cost. Rigorous testing and certification processes are essential, particularly for buyers in industries such as metallurgy and semiconductor manufacturing.

-

Logistics: Transportation costs can fluctuate based on the origin of the materials, shipping methods, and destination. International shipping, customs duties, and local distribution should be factored into the total cost.

-

Margin: Suppliers will typically build a profit margin into their pricing. Understanding the margin expectations of different suppliers can help buyers negotiate better deals.

Price Influencers

Several factors can influence the pricing of graphite crucibles:

-

Volume/MOQ: Bulk purchases often result in lower per-unit costs. Buyers should consider negotiating minimum order quantities (MOQs) to take advantage of volume discounts.

-

Specifications/Customization: Custom specifications can lead to higher prices. Buyers need to weigh the benefits of custom products against potential cost increases.

-

Materials: Different grades of graphite and clay will have varying prices. Higher-quality materials may lead to improved performance but at a higher cost.

-

Quality/Certifications: Suppliers that can provide certifications for their products (e.g., ISO, ASTM) may charge a premium, but this can be a worthwhile investment for critical applications.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can affect pricing. Suppliers in regions with more established manufacturing capabilities may offer better pricing and quality assurance.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) can impact overall costs. Buyers should clarify responsibilities and costs associated with transportation and insurance.

Buyer Tips

-

Negotiation: Engage in discussions with multiple suppliers to compare prices and negotiate terms. Leverage your volume needs to secure better pricing.

-

Cost Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial purchase price, shipping, storage, and potential replacement costs. A higher upfront cost may be justified by lower long-term maintenance costs.

Illustrative Image (Source: Google Search)

-

Pricing Nuances: Be aware of seasonal fluctuations in pricing and global market trends that can affect the cost of graphite and related materials.

-

Regional Considerations: Buyers from Africa and South America may need to consider logistics and import duties more heavily, while European buyers might focus on quality certifications and local sourcing to mitigate risks.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and terms over time. Consider establishing contracts that include favorable pricing structures for ongoing purchases.

Disclaimer

Prices mentioned in discussions and quotations may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes and consider all cost components when evaluating suppliers.

Spotlight on Potential graphite crucibles Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘graphite crucibles’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for graphite crucibles

Graphite crucibles are essential tools in various industries, especially metallurgy and foundry applications. Understanding their technical properties and trade terminology is crucial for B2B buyers to make informed purchasing decisions. Below are the key specifications and common terms that define the landscape of graphite crucibles.

Critical Technical Properties

-

Material Grade

– Definition: Graphite crucibles are typically made from either clay-graphite or high-purity graphite. The material grade affects the crucible’s thermal properties and its ability to withstand high temperatures.

– Importance: Choosing the right material grade ensures that the crucible can handle the specific melting temperatures of the metals being processed, which is vital for maintaining product quality and operational efficiency. -

Tolerance

– Definition: Tolerance refers to the allowable deviation in the dimensions of the crucible. It is critical for ensuring that the crucible fits seamlessly into the existing equipment.

– Importance: Precise tolerances are essential for maximizing efficiency and minimizing waste. Inaccurate dimensions can lead to operational issues, such as improper heat distribution or difficulty in handling. -

Porosity

– Definition: This property indicates the amount of void space within the crucible material. Low porosity is preferable as it reduces the risk of contamination from the crucible into the molten metal.

– Importance: Low porosity ensures higher purity of the melted material, which is especially important in industries such as jewelry making and semiconductor production where contamination can have severe consequences. -

Thermal Conductivity

– Definition: Thermal conductivity measures how well a material can conduct heat. Graphite has excellent thermal conductivity, which is vital for efficient melting processes.

– Importance: High thermal conductivity allows for uniform heating of the metal, which is crucial for achieving desired properties in the final product. It can also reduce energy costs by minimizing heating times. -

Thermal Shock Resistance

– Definition: This property refers to the ability of the crucible to withstand rapid temperature changes without cracking or deforming.

– Importance: High thermal shock resistance is essential for applications where temperature fluctuations are common, ensuring the longevity and reliability of the crucible.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of graphite crucibles, it refers to suppliers who create custom products for specific clients.

– Importance: Understanding OEM relationships can help buyers identify reliable sources for tailored crucibles that meet unique specifications. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest number of units a supplier is willing to sell. This can vary significantly between manufacturers.

– Importance: Knowing the MOQ is crucial for budgeting and inventory planning. It can affect your purchasing strategy, especially for smaller companies or startups. -

RFQ (Request for Quote)

– Definition: An RFQ is a document sent by a buyer to suppliers to solicit pricing and terms for specific products or services.

– Importance: Utilizing RFQs can lead to better pricing negotiations and ensure that all potential suppliers are on the same page regarding specifications and expectations. -

Incoterms

– Definition: Incoterms are international commercial terms that define the responsibilities of buyers and sellers in global trade, including shipping, insurance, and tariffs.

– Importance: Familiarity with Incoterms helps buyers understand their obligations and risks in the shipping process, which is essential for international transactions. -

Lead Time

– Definition: Lead time refers to the time it takes from placing an order to receiving the product.

– Importance: Knowing the lead time is critical for planning production schedules and ensuring that operations run smoothly without delays.

By understanding these essential technical properties and trade terms, B2B buyers can navigate the complexities of sourcing graphite crucibles more effectively, ensuring that they make informed decisions that align with their operational needs and business goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the graphite crucibles Sector

Market Overview & Key Trends

The global graphite crucibles market is experiencing notable growth, driven by increasing demand across various sectors such as metallurgy, jewelry making, and semiconductor manufacturing. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of key trends shaping this landscape. For instance, the rise of advanced manufacturing technologies, including CNC machining and precision engineering, is enhancing the quality and performance of graphite crucibles.

Moreover, the demand for high-purity graphite crucibles is surging, particularly in applications requiring minimal contamination, such as in the production of precious metals and semiconductors. Emerging markets in Africa and South America are witnessing a shift towards local sourcing, enabling buyers to reduce lead times and shipping costs. This trend is complemented by a growing emphasis on just-in-time inventory systems, which can significantly enhance supply chain efficiency.

Additionally, the increasing adoption of digital platforms for sourcing and procurement is transforming traditional buying processes. B2B buyers can leverage online marketplaces and supplier directories to identify reliable manufacturers and compare product specifications. This digital shift is crucial for buyers from regions like Germany and Spain, where operational efficiency and quality assurance are paramount.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the sourcing of graphite crucibles. The environmental impact of graphite mining and processing cannot be overlooked; hence, buyers should prioritize suppliers that implement sustainable practices. This includes the use of recycled materials in the production of graphite crucibles and adherence to environmental regulations.

Ethical supply chains are equally important. Buyers should seek manufacturers who are transparent about their sourcing practices and demonstrate a commitment to ethical labor standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s dedication to sustainability.

In addition, “green” materials, such as bio-based binders and coatings, are gaining traction in the graphite crucible industry. By opting for suppliers that utilize these innovative materials, international buyers can not only reduce their carbon footprint but also align their procurement strategies with global sustainability goals.

Brief Evolution/History

The use of graphite crucibles dates back to ancient civilizations, where they were primarily employed for melting metals. Over the centuries, advancements in materials science have led to the development of more durable and efficient crucibles. The introduction of clay-graphite formulations in the 20th century marked a significant evolution, enhancing thermal resistance and reducing contamination risks.

Today, the graphite crucible industry continues to innovate, driven by technological advancements and the increasing demand for high-performance materials. As industries evolve, so too does the need for crucibles that can withstand extreme temperatures and provide consistent performance, making them indispensable in modern manufacturing processes. For international B2B buyers, understanding this historical context can inform better purchasing decisions and foster long-term partnerships with suppliers.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of graphite crucibles

-

What key factors should I consider when vetting suppliers of graphite crucibles?

When vetting suppliers, prioritize their experience in the industry, reputation, and product quality. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, assess their production capabilities, including technology and equipment used. Consider their ability to provide customized solutions based on your specific needs. Finally, check references and customer reviews to gauge the reliability and service quality of the supplier. -

Can I customize graphite crucibles to meet specific requirements?

Yes, many manufacturers offer customization options for graphite crucibles. This can include variations in size, shape, and material composition tailored to your application needs. When discussing customization, provide detailed specifications and any particular performance requirements. Ensure the supplier has a robust design and engineering team that can assist in creating prototypes and make necessary adjustments based on your feedback before final production. -

What are the typical minimum order quantities (MOQs) and lead times for graphite crucibles?

MOQs can vary significantly based on the supplier and the complexity of the order. Generally, MOQs range from a few dozen to several hundred units. Lead times also depend on the customization level and production capacity, typically ranging from 2 to 8 weeks. For urgent needs, some suppliers may offer expedited services, but this often comes with increased costs. Always confirm these details upfront to ensure they align with your project timelines. -

What payment options are available when sourcing graphite crucibles internationally?

Payment options for international purchases usually include wire transfers, letters of credit, and escrow services. It’s crucial to negotiate terms that offer both security and flexibility. Consider using payment methods that protect against fraud and ensure you receive the goods as agreed. Discuss payment terms upfront, including deposits, balance payments, and any conditions tied to milestones in production or delivery. -

How can I ensure quality assurance and certification for the graphite crucibles I purchase?

To guarantee quality, request documentation such as material certifications and test reports demonstrating compliance with relevant industry standards. Many reputable suppliers will conduct third-party inspections and provide certificates of analysis for their products. Establishing a quality assurance protocol during negotiations can also help, ensuring the supplier agrees to specific performance metrics and inspection processes before shipment. -

What logistics considerations should I keep in mind when importing graphite crucibles?

Logistics play a critical role in the timely delivery of your order. Coordinate with your supplier to understand their shipping options, including Incoterms that define responsibilities for shipping, insurance, and customs clearance. Consider using freight forwarders experienced in handling industrial goods to navigate import regulations and optimize shipping costs. Also, factor in potential delays due to customs, especially in regions with stringent import controls. -

What should I do if there are disputes or issues with my graphite crucible order?

Establish clear communication channels with your supplier to address issues promptly. If disputes arise, refer to the terms outlined in your purchase agreement, which should include dispute resolution procedures. Consider mediation or arbitration as potential solutions to avoid lengthy legal battles. Maintaining a professional relationship and open dialogue can often resolve misunderstandings amicably and efficiently. -

Are there specific certifications or standards I should look for when sourcing graphite crucibles?

Yes, look for certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and specific industry standards relevant to your application (e.g., ASTM standards for materials). These certifications indicate that the supplier adheres to recognized quality and environmental practices. Additionally, inquire about any industry-specific certifications that may enhance the crucible’s performance in your particular application, ensuring compliance with regulatory requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for graphite crucibles

In conclusion, strategic sourcing of graphite crucibles presents a pivotal opportunity for international B2B buyers across Africa, South America, the Middle East, and Europe. By focusing on suppliers that offer high-purity materials, tailored solutions, and robust manufacturing processes, businesses can enhance their operational efficiencies and product quality. The ability to secure reliable and cost-effective sourcing channels will not only drive profitability but also foster sustainable growth in competitive markets.

Key takeaways include:

- Quality Assurance: Prioritize suppliers with proven track records in high-quality materials and manufacturing practices.

- Customization: Seek manufacturers that offer flexible production options to meet specific application needs, ensuring optimal performance.

- Logistics and Delivery: Consider suppliers that provide quick turnaround times and efficient logistics to maintain supply chain fluidity.

As the demand for advanced materials continues to rise, investing in strategic sourcing for graphite crucibles will be crucial. Engage with reputable manufacturers, leverage their expertise, and position your business for future success in an evolving marketplace. Now is the time to act—evaluate your sourcing strategies and explore partnerships that can propel your business forward.