Your Ultimate Guide to Sourcing Hardware Cloth

Introduction: Navigating the Global Market for hardware cloth

Navigating the global market for hardware cloth is essential for B2B buyers looking to enhance their projects with durable and versatile materials. Hardware cloth, a woven mesh product, serves a multitude of applications across various industries, including construction, agriculture, pest control, and HVAC. Its importance cannot be overstated; it provides essential solutions for fencing, sieving, filtration, and even architectural aesthetics.

This comprehensive guide explores the diverse types of hardware cloth, examining the various materials, manufacturing processes, and quality control standards that impact product performance. Buyers will find valuable insights into the different grades of wire, such as stainless and galvanized steel, and how these choices affect durability and application suitability. Additionally, the guide highlights key suppliers and market dynamics, including pricing strategies and procurement tips tailored for international buyers from regions such as Africa, South America, the Middle East, and Europe, including UAE and Spain.

Armed with this knowledge, B2B buyers can make informed sourcing decisions that align with their specific project needs. By understanding the nuances of hardware cloth, businesses can enhance operational efficiency, reduce costs, and improve overall project outcomes. This guide empowers buyers to navigate the complexities of the hardware cloth market confidently, ensuring they select the right products for their unique applications.

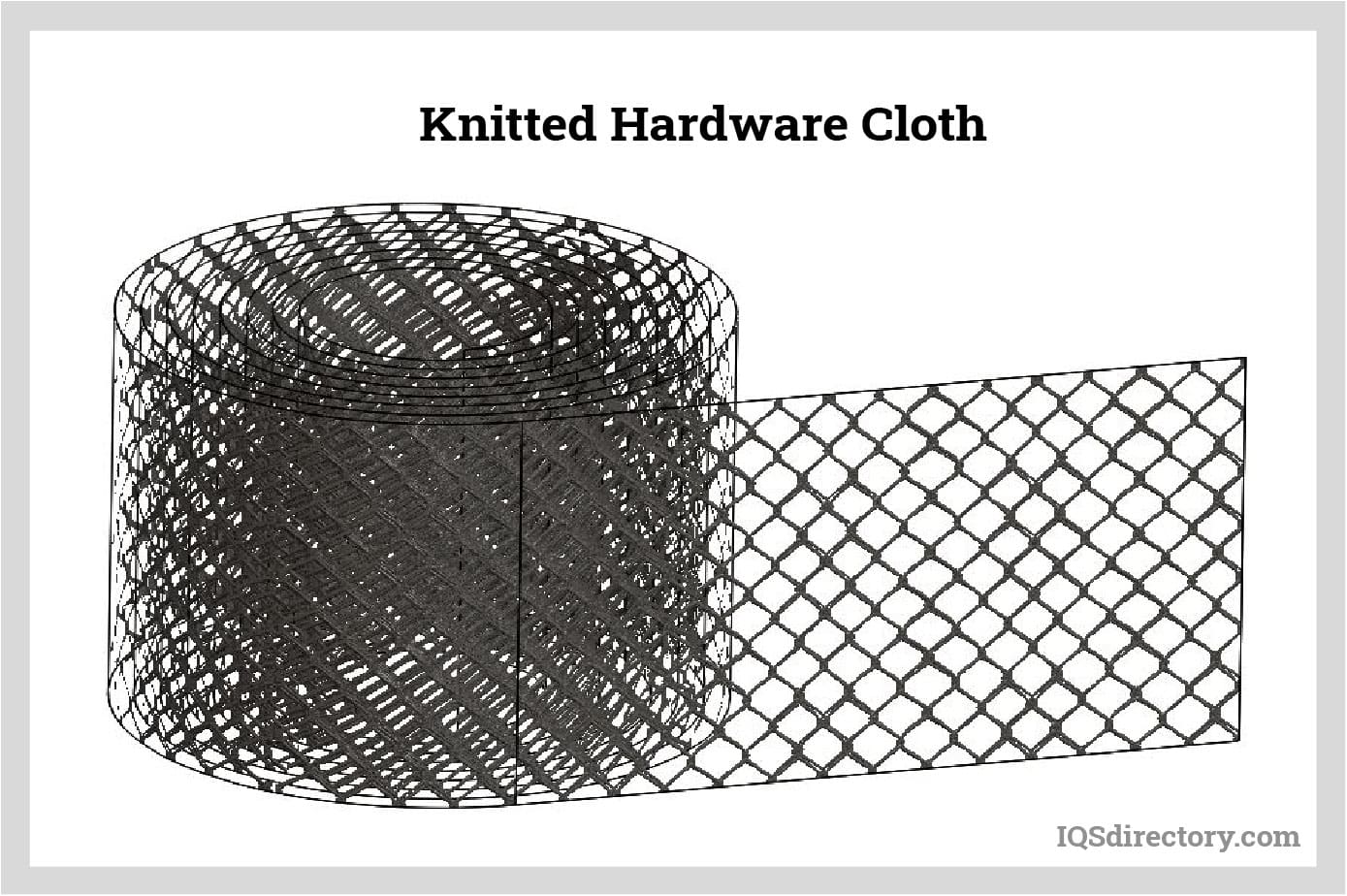

Illustrative Image (Source: Google Search)

Understanding hardware cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Hardware Cloth | Coated with zinc for corrosion resistance | Fencing, animal enclosures, garden use | Pros: Cost-effective, durable. Cons: Can rust if coating is damaged. |

| Stainless Steel Hardware Cloth | High corrosion resistance, available in various grades | Food processing, chemical handling, HVAC | Pros: Long-lasting, strong. Cons: Higher initial cost. |

| Welded Wire Mesh | Rigid structure, welded at intersections | Construction, safety barriers, industrial use | Pros: Stronger, uniform openings. Cons: Less flexible than woven types. |

| Woven Wire Cloth | Flexible, interlaced wire structure | Filtration, sieving, agricultural uses | Pros: Adaptable, good for various applications. Cons: Less structural support. |

| Vinyl Coated Hardware Cloth | PVC coating for added durability and aesthetics | Garden fencing, decorative projects | Pros: Attractive finish, weather-resistant. Cons: Higher cost than galvanized. |

Galvanized Hardware Cloth

Galvanized hardware cloth is the most commonly used type due to its cost-effectiveness and durability. The zinc coating provides a significant level of corrosion resistance, making it ideal for outdoor applications such as fencing, animal enclosures, and gardening. B2B buyers should consider the environmental conditions of their projects; while galvanized cloth is robust, any damage to the zinc layer can lead to rusting.

Stainless Steel Hardware Cloth

This type is favored in industries that require high corrosion resistance and mechanical strength, such as food processing and chemical handling. Available in various grades, including 304 and 316, stainless steel hardware cloth is suitable for demanding environments exposed to moisture or chemicals. Buyers should be prepared for a higher initial investment, but the long-term durability often offsets the cost, making it a smart choice for critical applications.

Welded Wire Mesh

Welded wire mesh is characterized by its rigid structure, with wires fused at their intersections. This type is particularly strong and is often used in construction, safety barriers, and industrial applications. B2B buyers should consider the specific strength requirements of their projects, as welded wire mesh offers superior structural integrity but is less flexible than woven wire options. It is ideal for applications where uniformity and durability are paramount.

Woven Wire Cloth

Woven wire cloth is made from interlaced wires, resulting in a flexible and versatile mesh. This type is commonly used in filtration and agricultural applications where adaptability is essential. For B2B buyers, the key consideration is the balance between flexibility and the required strength for specific applications. While woven wire cloth can be used in various contexts, it may not provide the same level of structural support as welded options.

Vinyl Coated Hardware Cloth

Vinyl coated hardware cloth features a PVC coating that enhances durability and provides an aesthetically pleasing finish. This type is particularly popular in garden fencing and decorative projects, where appearance is as important as function. Buyers should weigh the benefits of enhanced weather resistance against the higher cost compared to galvanized options. Vinyl coated cloth is an excellent choice for projects that require both functionality and visual appeal.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of hardware cloth

| Industry/Sector | Specific Application of hardware cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Pest Control Fencing | Protects crops from pests, reducing loss and increasing yield. | Ensure durability and resistance to weather conditions. |

| Construction | Reinforcement in Concrete | Enhances structural integrity of concrete, preventing cracks and failures. | Select appropriate gauge and material for specific loads. |

| Food Processing | Filtration Screens | Ensures purity and quality of food products by filtering contaminants. | Prioritize food-grade materials and corrosion resistance. |

| HVAC | Air Filtration Mesh | Improves air quality and system efficiency, reducing energy costs. | Focus on mesh size and material compatibility with systems. |

| Mining and Quarrying | Screening for Mineral Separation | Increases efficiency in separating valuable minerals from waste. | Consider abrasion resistance and mesh size for specific minerals. |

Agriculture: Pest Control Fencing

In agriculture, hardware cloth is extensively used for pest control fencing. This application prevents rodents and other pests from damaging crops, leading to significant yield increases. Buyers in this sector should prioritize durable materials that can withstand various weather conditions, ensuring long-lasting protection. Galvanized or stainless steel options are recommended for enhanced corrosion resistance, especially in humid climates found in parts of Africa and South America.

Construction: Reinforcement in Concrete

In the construction industry, hardware cloth serves as reinforcement in concrete applications. It helps maintain the structural integrity of concrete structures, preventing cracks and structural failures. International buyers, particularly from Europe and the Middle East, must consider the specific gauge and material type to match the load-bearing requirements of their projects. Opting for welded hardware cloth can provide additional strength and stability.

Food Processing: Filtration Screens

The food processing industry utilizes hardware cloth for filtration screens, ensuring the purity and quality of food products by filtering out contaminants. This application is crucial for maintaining food safety standards. Buyers should focus on sourcing food-grade materials that meet regulatory requirements and possess high corrosion resistance, especially in humid environments. Stainless steel is often the preferred choice due to its durability and ease of cleaning.

HVAC: Air Filtration Mesh

In HVAC systems, hardware cloth is employed as air filtration mesh, significantly improving air quality and system efficiency. By filtering out dust and particulates, it helps reduce energy costs associated with system overwork. Buyers should pay attention to the mesh size and material compatibility with their specific HVAC systems to ensure optimal performance and longevity. Polymeric coatings can enhance durability in corrosive environments.

Mining and Quarrying: Screening for Mineral Separation

In the mining and quarrying sectors, hardware cloth is essential for screening and separating valuable minerals from waste material. This application increases operational efficiency and recovery rates of minerals. Buyers should consider the abrasion resistance of the mesh and select appropriate mesh sizes tailored to the specific minerals being processed. High-carbon steel options may be ideal for heavy-duty applications in rugged environments.

Strategic Material Selection Guide for hardware cloth

When selecting hardware cloth, the choice of material is crucial for ensuring optimal performance and suitability for specific applications. Here, we analyze four common materials used in hardware cloth: stainless steel, galvanized steel, carbon steel, and vinyl-coated wire. Each material has unique properties, advantages, and limitations that international B2B buyers should consider, particularly those in Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties:

Stainless steel hardware cloth is highly resistant to corrosion, making it ideal for environments with moisture or exposure to chemicals. It typically comes in various grades, such as 304 and 316, which offer different levels of corrosion resistance and strength.

Pros & Cons:

The primary advantage of stainless steel is its durability and longevity, which reduces the need for frequent replacements. However, it tends to be more expensive than other materials, which can impact budget considerations for large-scale projects. Manufacturing processes can also be complex, potentially leading to longer lead times.

Impact on Application:

Stainless steel is particularly suitable for applications requiring high strength and corrosion resistance, such as filtration systems in chemical processing or food production.

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards like ASTM A313 for wire rope and consider local regulations regarding the use of stainless materials in construction and manufacturing.

Galvanized Steel

Key Properties:

Galvanized steel is coated with a layer of zinc to enhance corrosion resistance. This material is often used in outdoor applications due to its ability to withstand the elements.

Pros & Cons:

The key advantage of galvanized steel is its cost-effectiveness compared to stainless steel while still providing decent corrosion resistance. However, the zinc coating can wear off over time, especially in harsh conditions, leading to rust.

Impact on Application:

Galvanized hardware cloth is commonly used in agricultural settings for fencing and animal enclosures, where exposure to moisture is a concern but not as severe as in industrial applications.

Considerations for International Buyers:

Buyers in regions with high humidity or saline environments should assess the longevity of galvanized products and consider additional protective coatings. Compliance with local standards such as ISO 1461 for hot-dip galvanized coatings is also essential.

Carbon Steel

Key Properties:

Carbon steel hardware cloth offers a range of strength and ductility based on its carbon content. It is available in low, medium, and high carbon grades, allowing for customization based on specific application needs.

Pros & Cons:

The versatility of carbon steel makes it suitable for various applications, from general-purpose to heavy-duty uses. However, it is more susceptible to corrosion compared to stainless and galvanized steel, which may necessitate protective coatings or treatments.

Impact on Application:

Carbon steel is often used in construction and industrial applications where strength is paramount, such as in machinery guards and heavy-duty fencing.

Considerations for International Buyers:

Buyers should be aware of the potential need for protective coatings in humid or corrosive environments and ensure compliance with relevant standards like ASTM A653 for hot-dip galvanized steel.

Vinyl-Coated Wire

Key Properties:

Vinyl-coated hardware cloth consists of a wire mesh that has been coated with a layer of vinyl for added protection against corrosion and UV damage.

Pros & Cons:

The vinyl coating enhances durability and provides aesthetic appeal, making it a popular choice for residential applications. However, it may not be as strong as uncoated metal options, and the coating can wear off over time.

Impact on Application:

Vinyl-coated wire is ideal for decorative fencing and garden applications where both appearance and functionality are important.

Considerations for International Buyers:

Buyers should ensure that the vinyl coating meets local environmental regulations and standards for outdoor use, particularly in regions with extreme weather conditions.

Summary Table

| Material | Typical Use Case for hardware cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Filtration systems, food production | Exceptional corrosion resistance | Higher cost and complex manufacturing | High |

| Galvanized Steel | Agricultural fencing, outdoor enclosures | Cost-effective with decent durability | Zinc coating can wear off | Medium |

| Carbon Steel | Machinery guards, heavy-duty fencing | Customizable strength and ductility | Susceptible to corrosion | Low |

| Vinyl-Coated Wire | Decorative fencing, garden applications | Enhanced durability and aesthetics | Weaker than uncoated options | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on application needs, environmental conditions, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hardware cloth

Manufacturing hardware cloth involves several critical stages that ensure the final product meets the required specifications for strength, durability, and versatility. Understanding these processes is essential for international B2B buyers looking to source hardware cloth for various applications.

Manufacturing Process

1. Material Preparation

The initial step in hardware cloth manufacturing is selecting the appropriate wire material. Common choices include:

- Stainless Steel: Known for its corrosion resistance and strength, ideal for environments exposed to moisture or chemicals.

- Carbon Steel: Valued for its ductility; different grades (low, medium, high, and very high carbon) offer varying strengths and applications.

- Galvanized Steel: Provides an additional layer of protection against rust, making it suitable for outdoor uses.

Once the material is chosen, the wires are cut to the required lengths and cleaned to remove any impurities that could affect the final product’s quality.

2. Forming

This stage involves creating the mesh structure. Two primary techniques are employed:

- Welding: In this method, wires are fused at their intersection points using specialized machines. The result is a rigid, sturdy mesh suitable for applications requiring high structural support.

- Weaving: Traditional weaving techniques interlace the wires over and under each other, creating a flexible mesh. This type is often used where uniform openings and flexibility are required.

The choice between welding and weaving significantly impacts the mesh’s characteristics, including strength and flexibility.

3. Assembly

After forming the mesh, the next step is to assemble it into the desired dimensions. This may involve cutting the mesh to size or rolling it onto spools for easier transport and handling. At this stage, manufacturers may also prepare the mesh for additional treatments, such as coating or finishing.

4. Finishing

Finishing processes enhance the mesh’s performance and aesthetics. Common finishing techniques include:

- Galvanization: A coating of zinc to prevent rust and enhance durability.

- Polymer Coating: Applied to improve chemical resistance and provide additional protection against environmental factors.

- Electroplating: Involves depositing a layer of metal onto the surface to improve corrosion resistance.

These finishing touches are crucial for ensuring that the hardware cloth meets specific environmental and application requirements.

Quality Assurance

Quality assurance (QA) is vital in the manufacturing process to ensure that the hardware cloth produced meets international standards and customer expectations.

International Standards

B2B buyers should be aware of relevant quality standards, including:

- ISO 9001: A widely recognized standard for quality management systems that ensures consistent quality in manufacturing processes.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for products used in the oil and gas industry, ensuring they meet specific performance and safety requirements.

These certifications signal a commitment to quality and can help buyers make informed sourcing decisions.

Quality Control Checkpoints

Quality control (QC) in hardware cloth manufacturing typically includes several checkpoints throughout the process:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A comprehensive review of the finished product before shipment, ensuring it adheres to quality standards.

Common Testing Methods

To ensure the reliability of hardware cloth, manufacturers often employ various testing methods, including:

- Tensile Testing: Measures the strength and elasticity of the wire.

- Corrosion Resistance Testing: Evaluates how well the material withstands environmental factors.

- Mesh Opening Verification: Ensures that the openings meet specified dimensions for the intended application.

These tests are essential for verifying the durability and functionality of the hardware cloth.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are some actionable steps:

- Request Documentation: Ask for quality assurance reports, certifications, and compliance documents.

- Conduct Audits: If possible, perform on-site audits of the manufacturing facilities to assess their QC processes firsthand.

- Third-Party Inspections: Engage third-party inspection services to conduct independent assessments of the supplier’s products and processes.

- Evaluate Past Performance: Review customer testimonials and case studies to gauge the supplier’s reliability and quality over time.

Quality Control Nuances for International Buyers

When sourcing hardware cloth globally, buyers must consider regional differences in standards and regulations. For instance:

- Local Regulations: Be aware of specific requirements in your region (e.g., the EU’s REACH regulations) that may impact material selection and safety compliance.

- Cultural Differences: Understand the supplier’s business practices and communication styles, which can affect the purchasing process and negotiations.

By being informed and proactive, international B2B buyers can ensure they select high-quality hardware cloth that meets their specific needs while minimizing risks associated with global sourcing.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for hardware cloth Sourcing

Understanding Cost Structure and Pricing Influencers for Hardware Cloth Sourcing

When sourcing hardware cloth, international B2B buyers must navigate a complex cost structure that comprises several key components. Understanding these elements is crucial for making informed purchasing decisions and achieving cost-efficiency.

Cost Components

-

Materials: The type of wire used (stainless steel, carbon steel, or galvanized steel) significantly impacts the base material costs. Stainless steel, while more expensive, offers superior corrosion resistance, making it ideal for demanding environments. Galvanized steel is a cost-effective alternative for outdoor applications but may not provide the same durability.

-

Labor: Labor costs vary by region and manufacturing methods (welded vs. woven). Regions with lower labor costs may offer more competitive pricing, but this could also affect quality. It’s important to balance cost with the craftsmanship and expertise of the workforce.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, equipment maintenance, and factory management. Buyers should consider suppliers who optimize their manufacturing processes to reduce overhead, which can lead to lower prices.

-

Tooling: The initial setup costs for producing custom hardware cloth can be significant, especially for unique specifications or large orders. Buyers should inquire about tooling costs and whether these are amortized over the order volume.

-

Quality Control (QC): Effective QC processes ensure that the hardware cloth meets required specifications. Suppliers who invest in robust QC may charge more upfront but can ultimately save buyers from costly errors or rejections down the line.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and Incoterms. Buyers should consider the total logistics costs, including duties, taxes, and potential delays at customs, especially when importing from distant suppliers.

-

Margin: Supplier profit margins can vary based on market competition and product demand. Understanding the typical margins in your specific region can aid in negotiations.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volumes typically lead to better unit prices, but buyers should assess their actual needs to avoid overcommitting.

-

Specifications and Customization: Custom specifications (gauge, mesh size, coating) can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses while ensuring the product meets their requirements.

-

Quality and Certifications: Products with certifications (e.g., ISO standards) may command higher prices but offer assurance of quality. Buyers should weigh the benefits of certifications against their specific project needs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but often provide better service and consistency.

-

Incoterms: The choice of Incoterms can affect the total landed cost. For instance, “FOB” (Free On Board) indicates that the buyer assumes responsibility for shipping costs once the goods are on board the vessel, while “CIF” (Cost, Insurance, and Freight) includes shipping and insurance costs in the price.

Buyer Tips

-

Negotiation: Leverage volume commitments to negotiate better prices. Establishing long-term relationships with suppliers can also yield favorable terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. Sometimes investing more upfront in higher-quality materials can reduce long-term expenses.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional market trends and currency fluctuations that can impact pricing. Understanding local demand and supply dynamics can provide leverage in negotiations.

Disclaimer on Pricing

Prices for hardware cloth can vary significantly based on the factors outlined above. It is advisable for buyers to request quotes from multiple suppliers to obtain a clearer picture of the market and to ensure they are making cost-effective purchasing decisions.

Spotlight on Potential hardware cloth Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘hardware cloth’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for hardware cloth

Key Technical Properties of Hardware Cloth

When sourcing hardware cloth, international B2B buyers should be well-versed in its critical specifications, as these properties directly impact product performance and suitability for various applications.

-

Material Grade: The grade of metal used in hardware cloth significantly influences its durability and resistance to corrosion. Common materials include galvanized steel, known for its rust resistance, and stainless steel, which offers enhanced corrosion resistance, making it ideal for harsh environments. Understanding material grades helps buyers select the right product for specific conditions.

-

Wire Gauge: The wire gauge indicates the thickness of the wire used in the hardware cloth. A lower gauge number corresponds to a thicker wire, which generally provides greater strength and durability. For example, a gauge of 16 is thicker and more robust than a gauge of 27. This specification is crucial for buyers who need to ensure the cloth can withstand specific environmental stresses or loads.

-

Mesh Size: This refers to the size of the openings in the hardware cloth, which can vary significantly depending on the intended use. Smaller mesh sizes are ideal for applications requiring filtration or pest control, while larger sizes may be used for fencing or structural purposes. Selecting the correct mesh size is essential for achieving the desired performance in applications like gardening, animal enclosures, or industrial filtration.

-

Weld vs. Woven Construction: Hardware cloth can be produced using either welding or weaving techniques. Welded hardware cloth is typically more rigid and suited for applications that require structural integrity, while woven hardware cloth offers flexibility, making it ideal for varied applications. Understanding the construction method helps buyers make informed decisions based on their project’s requirements.

-

Finish Type: The finishing process applied to hardware cloth can affect its resistance to environmental factors. Common finishes include galvanization, which adds a protective zinc layer, and polymer coatings, which can enhance chemical resistance. Buyers should consider finish types when selecting products for outdoor or chemically aggressive environments.

Common Trade Terminology

Understanding industry jargon is essential for effective communication and negotiation in the hardware cloth market. Here are key terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Buyers should recognize OEMs when sourcing custom hardware cloth products that meet specific design or performance criteria.

-

MOQ (Minimum Order Quantity): This indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers to manage inventory effectively and ensure they can meet their production needs without incurring excess costs.

-

RFQ (Request for Quote): An RFQ is a standard business process where buyers request pricing information from suppliers for specific products or services. For hardware cloth procurement, issuing an RFQ can help buyers compare pricing and terms from multiple suppliers, ensuring they receive competitive offers.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk transfers, and cost allocations, which are crucial for international procurement processes.

-

Lead Time: This term refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for planning project timelines and ensuring that materials arrive when needed.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing hardware cloth, ultimately enhancing their procurement strategies and project outcomes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hardware cloth Sector

Market Overview & Key Trends

The global hardware cloth market is witnessing significant growth driven by increasing demand across various sectors such as construction, agriculture, and pest control. Emerging economies in Africa and South America are experiencing a construction boom, leading to heightened requirements for durable materials like hardware cloth. In the Middle East, infrastructural developments and a focus on sustainable building practices further bolster demand.

Illustrative Image (Source: Google Search)

Noteworthy trends influencing B2B sourcing include the rise of digital procurement platforms that streamline supplier selection and order fulfillment. Buyers are increasingly utilizing data analytics to assess supplier performance and optimize inventory management. Additionally, the adoption of advanced manufacturing techniques, such as automated welding and weaving, enhances product consistency and reduces lead times.

For international buyers, particularly in regions like the UAE and Spain, understanding local market dynamics is crucial. Variations in regulations, import tariffs, and currency fluctuations can impact pricing and availability. Buyers should establish strong relationships with local distributors to navigate these complexities effectively. It is also important to keep an eye on emerging materials, such as polymer-coated hardware cloth, which offer enhanced chemical resistance and durability, catering to specialized applications.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal consideration in the hardware cloth sector. The environmental impact of production processes, particularly in metal sourcing and manufacturing, necessitates a focus on eco-friendly practices. Buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainability through responsible sourcing of raw materials and energy-efficient manufacturing processes.

Ethical supply chains are essential, especially for international B2B buyers. Ensuring that suppliers adhere to labor rights and environmental regulations is crucial in maintaining brand reputation and compliance with international standards. Certifications such as ISO 14001 for environmental management and Fair Trade can provide assurance of a supplier’s commitment to sustainable practices.

Moreover, the trend towards ‘green’ materials is gaining traction. Hardware cloth made from recycled metals or featuring eco-friendly coatings can appeal to environmentally conscious buyers. Engaging with suppliers who emphasize sustainability can not only enhance a company’s corporate social responsibility (CSR) profile but also meet the growing consumer demand for environmentally responsible products.

Brief Evolution/History

The history of hardware cloth dates back to the early 20th century when it began as a simple woven wire mesh for agricultural applications. Over the decades, technological advancements have transformed its production methods, from manual weaving to automated welding techniques, enhancing strength and durability. The introduction of various materials, such as stainless steel and polymer coatings, has expanded its applications beyond agriculture to include construction, HVAC, and filtration. As industries evolve, hardware cloth continues to adapt, reflecting the growing emphasis on sustainability and innovation in manufacturing.

This evolution underscores the importance for B2B buyers to stay informed about the latest materials and production techniques to ensure they are sourcing products that meet current and future market demands.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of hardware cloth

-

What criteria should I use to vet suppliers of hardware cloth?

When vetting suppliers, consider their industry experience, production capacity, and reputation. Look for certifications such as ISO 9001 to ensure quality management systems are in place. Request samples to assess material quality and gauge customer service responsiveness. Additionally, check references or reviews from other international buyers, particularly those from your region, to validate reliability and trustworthiness. -

Can hardware cloth be customized to meet specific project requirements?

Yes, many manufacturers offer customization options, including specific wire gauges, mesh sizes, and coatings. When discussing customization, provide detailed specifications regarding your application needs, such as environmental conditions and load requirements. Be clear about your expectations for lead times and any additional costs associated with custom orders, as these can vary significantly. -

What are the typical minimum order quantities (MOQs) and lead times for hardware cloth?

MOQs can vary widely depending on the supplier, ranging from small orders for samples to larger quantities for bulk purchases. Generally, expect MOQs to start around 100 square meters for standard products. Lead times also depend on customization and production schedules; standard orders may take 2-4 weeks, while custom orders could take longer. Always confirm these details during negotiations to avoid unexpected delays. -

What payment methods are commonly accepted by hardware cloth suppliers?

Most suppliers accept various payment methods, including bank transfers, credit cards, and letters of credit, especially for international transactions. It’s advisable to discuss payment terms upfront, including deposits and balance payments, to ensure clarity. Be cautious of suppliers requesting full payment in advance, as this can indicate a lack of established trust or financial stability. -

How can I ensure quality assurance and certifications when sourcing hardware cloth?

Request documentation for quality assurance processes, including inspection reports and material certifications. Look for products that meet international standards, such as ASTM or EN specifications, depending on your location. Some suppliers may offer third-party testing to validate their claims. Establishing clear quality expectations in your contract can also mitigate risks associated with product defects. -

What logistics considerations should I keep in mind when importing hardware cloth?

When importing, consider shipping methods, costs, and customs duties. Collaborate with suppliers to understand packaging requirements to minimize damage during transit. Research local import regulations in your country to ensure compliance, as this can affect delivery times and costs. Engaging a freight forwarder can simplify logistics management and help navigate international shipping complexities. -

How should I handle disputes or issues with suppliers?

Establish clear communication channels and document all agreements in writing to prevent misunderstandings. If disputes arise, attempt to resolve them directly with the supplier through dialogue. If necessary, consider mediation or arbitration as a formal dispute resolution process. Having a well-defined contract that outlines dispute resolution procedures can provide a framework for addressing issues effectively. -

What factors should I consider regarding the environmental impact of hardware cloth?

When sourcing hardware cloth, inquire about the materials used and their environmental impact. Opt for suppliers who utilize eco-friendly manufacturing processes and sustainable materials. Additionally, consider the lifecycle of the product, including recyclability and disposal options. Certifications such as LEED or other environmental standards can provide assurance that the products meet sustainability criteria.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hardware cloth

In conclusion, effective strategic sourcing for hardware cloth is pivotal for international B2B buyers aiming to enhance their operational efficiency and product quality. Understanding the diverse types of hardware cloth—ranging from galvanized to stainless steel—and their respective applications allows buyers to make informed decisions tailored to their specific industry needs. The selection of appropriate wire gauge and mesh type not only impacts durability but also influences overall project costs.

Key Takeaways:

- Diversity in Materials: Buyers should assess the benefits of various metals, such as stainless and carbon steel, based on environmental factors and application requirements.

- Manufacturing Methods: Recognizing the differences between welded and woven hardware cloth can significantly affect performance in applications requiring strength versus flexibility.

- Supplier Relationships: Building strong relationships with reliable suppliers ensures access to high-quality materials and timely delivery, which are essential in competitive markets.

As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, a proactive approach to sourcing hardware cloth will be crucial. Embrace the opportunity to innovate and optimize your supply chain—connect with leading manufacturers today to secure the best materials for your projects.