Your Ultimate Guide to Sourcing Hardwire Cloth

Introduction: Navigating the Global Market for hardwire cloth

In the ever-evolving landscape of global commerce, hardware cloth has emerged as a vital component across various industries, from agriculture and construction to manufacturing and pest control. This versatile woven mesh product, crafted from a range of metals including stainless steel and galvanized wire, is essential for applications such as fencing, filtration, and structural support. Understanding the nuances of hardware cloth is critical for B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe, where diverse market demands and environmental conditions drive the need for tailored solutions.

This comprehensive guide aims to empower international buyers by providing in-depth insights into the various types of hardware cloth, their manufacturing processes, quality control standards, and the key suppliers in the market. By exploring the different materials and gauges available, buyers can make informed decisions that align with their specific project requirements and budget constraints. Additionally, the guide addresses common FAQs, helping to demystify the complexities of sourcing hardware cloth effectively.

By navigating this guide, you will be equipped with the knowledge necessary to enhance your sourcing strategy, ensuring that you select the right type of hardware cloth for your needs. This not only optimizes your supply chain but also enhances operational efficiency, ultimately contributing to your business’s success in a competitive global market.

Understanding hardwire cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Hardware Cloth | Coated with zinc for corrosion resistance, available in various gauges | Fencing, animal enclosures, construction | Pros: Cost-effective, strong; Cons: Limited longevity in extreme conditions. |

| Stainless Steel Hardware Cloth | High corrosion resistance, available in various grades (304, 316) | Food processing, chemical handling, outdoor applications | Pros: Durable, long-lasting; Cons: Higher upfront cost. |

| Welded Hardware Cloth | Rigid structure due to welded intersections, uniform openings | Industrial applications, security fencing, HVAC systems | Pros: Strong, secure; Cons: Less flexible for certain applications. |

| Woven Hardware Cloth | Flexible mesh created through interlacing wires, customizable openings | Gardening, pest control, decorative applications | Pros: Versatile, easy to handle; Cons: May not offer the same strength as welded types. |

| Vinyl Coated Hardware Cloth | Additional vinyl coating for UV protection and aesthetic appeal | Landscaping, decorative fencing, animal enclosures | Pros: Enhanced durability, attractive; Cons: Higher cost, potential for fading over time. |

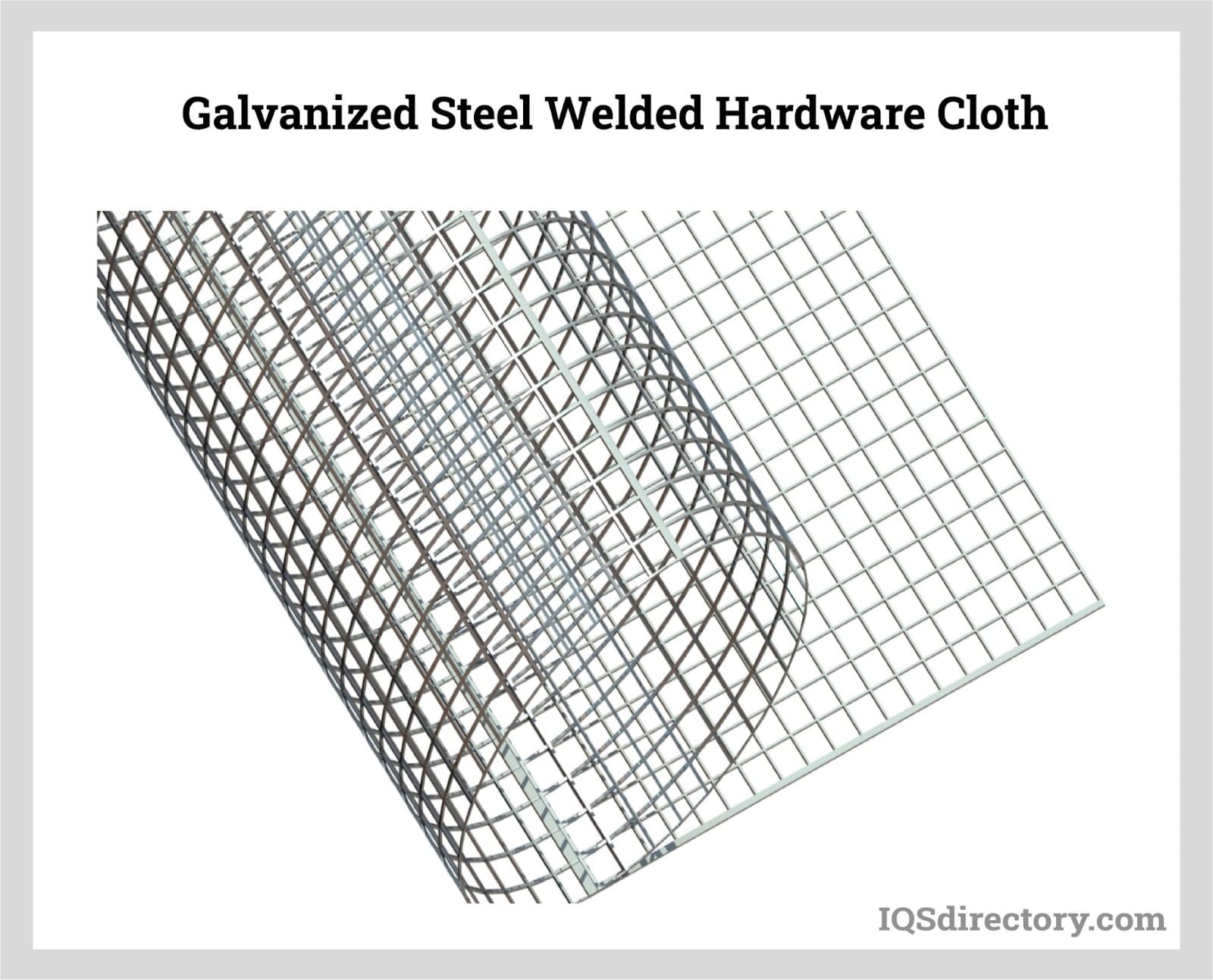

Galvanized Hardware Cloth

Galvanized hardware cloth is a popular choice due to its affordability and durability. The zinc coating protects the wire from rust and corrosion, making it suitable for outdoor applications like fencing and animal enclosures. When purchasing, buyers should consider the gauge of the cloth; lower gauges indicate thicker wire, providing greater strength. While it is cost-effective, its longevity may be compromised in extremely harsh environments.

Illustrative Image (Source: Google Search)

Stainless Steel Hardware Cloth

Renowned for its exceptional corrosion resistance, stainless steel hardware cloth is ideal for demanding environments, particularly in food processing and chemical handling. Available in various grades, such as 304 and 316, this type offers excellent mechanical strength. B2B buyers should weigh the higher initial investment against the long-term benefits of durability and resistance to harsh conditions. This makes it a preferred choice for industries requiring stringent hygiene standards.

Welded Hardware Cloth

Welded hardware cloth features a rigid structure due to the welding process at wire intersections. This results in a strong, secure mesh that is widely used in industrial applications, security fencing, and HVAC systems. Buyers should consider the specific strength requirements of their projects when selecting this type. Although it offers enhanced stability, the lack of flexibility may limit its use in applications requiring custom shapes.

Woven Hardware Cloth

Woven hardware cloth is created by interlacing wires, resulting in a flexible and versatile mesh. It is commonly used in gardening, pest control, and decorative applications. B2B buyers appreciate its ease of handling and customization options, particularly for smaller projects. However, it may not provide the same level of strength as welded types, so it’s essential to assess the specific application needs when making a purchase.

Vinyl Coated Hardware Cloth

Vinyl coated hardware cloth offers an additional layer of protection against UV rays and enhances aesthetic appeal, making it suitable for landscaping and decorative fencing. This type is particularly valued for its durability and resistance to fading, although it typically comes at a higher cost compared to uncoated variants. Buyers should evaluate the balance between aesthetics and functionality when considering this option, especially for long-term outdoor use.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of hardwire cloth

| Industry/Sector | Specific Application of hardwire cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Animal enclosures and fencing | Provides durable barriers to protect livestock and crops from predators and pests. | Consider local climate conditions for material selection, and gauge thickness for security needs. |

| Construction | Reinforcement in concrete and masonry | Enhances structural integrity, preventing cracking and increasing longevity of structures. | Ensure compliance with local building regulations and standards; gauge and type of wire matter. |

| Manufacturing | Filtration systems for liquids and gases | Improves product quality by filtering contaminants effectively, reducing waste. | Assess compatibility with the materials being filtered; consider corrosion resistance for longevity. |

| HVAC | Ventilation and air filtration | Ensures efficient airflow while preventing debris ingress, enhancing system performance. | Evaluate mesh size to meet airflow requirements; consider coating options for corrosion resistance. |

| Pest Control | Screens and barriers for pest management | Protects crops and buildings from insect invasions, reducing the need for chemical treatments. | Source materials that are safe for food contact if used in agricultural settings; consider local pest types for mesh size. |

Agriculture

In agriculture, hardwire cloth serves as an essential component for animal enclosures and fencing. It effectively protects livestock from predators and prevents pest infestations in crops. For international B2B buyers, particularly in regions like Africa and South America, it’s crucial to choose materials that can withstand local climate conditions. Buyers should consider the gauge thickness of the wire to ensure adequate security and durability against environmental factors.

Construction

Within the construction industry, hardwire cloth is frequently used for reinforcement in concrete and masonry applications. It enhances structural integrity by preventing cracking and extending the lifespan of buildings and infrastructure. Buyers from Europe and the Middle East must ensure that the selected materials comply with local building codes and standards. Additionally, the gauge and type of wire used are critical for meeting specific load-bearing requirements.

Manufacturing

In manufacturing, hardwire cloth is integral to filtration systems for liquids and gases. It plays a vital role in improving product quality by filtering out contaminants, which, in turn, reduces waste and operational costs. International buyers should assess the compatibility of the hardwire cloth with the materials being filtered, particularly in industries with stringent quality standards. Corrosion resistance is another important factor, especially in humid or chemically aggressive environments.

HVAC

The HVAC sector utilizes hardwire cloth in ventilation and air filtration systems. It ensures efficient airflow while preventing debris from entering, thereby enhancing system performance and longevity. Buyers should evaluate the mesh size to meet specific airflow requirements and consider coating options for added corrosion resistance. This is particularly important in regions with high humidity or exposure to corrosive substances.

Pest Control

In pest control applications, hardwire cloth is used to create screens and barriers that protect crops and buildings from insect invasions. This not only reduces the reliance on chemical treatments but also promotes sustainable practices. For B2B buyers in agricultural sectors, sourcing materials that are safe for food contact is essential. Additionally, understanding local pest types will help determine the appropriate mesh size to effectively block unwanted intruders.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for hardwire cloth

When selecting hardwire cloth for various applications, international B2B buyers must consider the material properties, advantages, and limitations of each option. The following analysis covers four common materials used in hardwire cloth, providing insights for buyers from regions such as Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel hardware cloth is renowned for its exceptional corrosion resistance and mechanical strength. It can withstand high temperatures and is often rated for use in environments that experience moisture and chemicals.

Pros & Cons: The primary advantage of stainless steel is its durability and longevity, making it suitable for demanding applications like filtration and construction. However, it tends to be more expensive than other materials, which could be a limiting factor for budget-sensitive projects.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it ideal for chemical processing and food industries.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for quality assurance. In regions like Europe, stainless steel grades must meet specific regulatory requirements for safety and environmental impact.

Galvanized Steel

Key Properties: Galvanized steel is coated with zinc to enhance its corrosion resistance. It typically handles moderate temperatures and pressures well, making it a versatile choice for various applications.

Pros & Cons: The main advantage of galvanized steel is its cost-effectiveness and good durability. However, it may not perform as well in highly corrosive environments compared to stainless steel, which could limit its use in certain applications.

Impact on Application: This material is widely used in agricultural fencing, animal enclosures, and construction due to its balance of strength and affordability.

Considerations for International Buyers: Compliance with local standards is crucial, particularly regarding the thickness of the zinc coating. Buyers in Africa and South America should be aware of the local availability of galvanized products and potential variations in quality.

Carbon Steel

Key Properties: Carbon steel hardware cloth is available in various grades, offering flexibility in strength and ductility. It is generally rated for moderate temperatures and pressures.

Pros & Cons: Carbon steel is praised for its strength and impact resistance, making it suitable for heavy-duty applications. However, it is prone to rusting if not properly coated or maintained, which can be a significant drawback in humid or wet environments.

Impact on Application: This material is commonly used in industrial settings where durability is essential, such as in machinery guards and construction barriers.

Considerations for International Buyers: Buyers should consider the specific grade of carbon steel required for their application and ensure that it meets local standards. In the Middle East, for example, the high humidity may necessitate additional protective coatings.

Vinyl Coated Wire

Key Properties: Vinyl-coated wire cloth combines a metal core with a protective vinyl layer, enhancing its resistance to corrosion and wear. It is suitable for moderate temperature applications.

Pros & Cons: The key advantage of vinyl-coated wire is its aesthetic appeal and additional protection against the elements. However, it may not be as strong as bare metal options, which could limit its use in high-stress environments.

Impact on Application: This material is often used in decorative applications, garden fencing, and light-duty enclosures where aesthetics and moderate strength are required.

Considerations for International Buyers: Buyers should check the quality of the vinyl coating and its compliance with environmental regulations, especially in regions where chemical exposure is a concern.

Summary Table

| Material | Typical Use Case for hardwire cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Filtration, chemical processing | Exceptional corrosion resistance | Higher cost compared to alternatives | High |

| Galvanized Steel | Agricultural fencing, construction | Cost-effective and durable | Limited performance in corrosive environments | Medium |

| Carbon Steel | Machinery guards, heavy-duty barriers | Strong and impact-resistant | Prone to rust without coating | Medium |

| Vinyl Coated Wire | Decorative fencing, light-duty enclosures | Aesthetic appeal and added protection | Weaker than bare metal options | Low |

This guide provides a comprehensive overview of material options for hardwire cloth, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hardwire cloth

Manufacturing processes and quality assurance are critical components for ensuring that hardwire cloth meets the diverse needs of various industries. Understanding these elements can significantly aid B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed purchasing decisions.

Manufacturing Processes of Hardwire Cloth

The production of hardwire cloth involves several key stages, each designed to ensure durability, functionality, and compliance with industry standards.

1. Material Preparation

The first step in the manufacturing process is selecting the appropriate raw materials. Common materials include:

- Stainless Steel: Known for its corrosion resistance and strength, ideal for high-demand environments.

- Carbon Steel: Valued for its ductility and customizable strength properties.

- Galvanized Steel: Offers enhanced corrosion protection and is widely used for outdoor applications.

After selecting the raw materials, they are processed to the required gauge and diameter, which can vary based on the intended application. This stage may involve cutting, straightening, and cleaning the wire to remove any contaminants.

2. Forming

The forming stage involves creating the mesh structure through either welding or weaving:

- Welding: This technique uses specialized machines to fuse wires at their intersections, producing a rigid mesh suitable for applications requiring structural support.

- Weaving: Traditional weaving involves interlacing wires over and under one another to create a flexible mesh with uniform openings. This method is often used for applications that require adaptability.

3. Assembly

Once the mesh is formed, it is cut to size and assembled according to specific project requirements. This may include:

- Trimming: Cutting the mesh to the desired dimensions.

- Reinforcement: Adding edge bindings or frames to enhance durability, especially for larger panels.

4. Finishing

The final stage includes various finishing processes to enhance the performance and appearance of the hardwire cloth:

- Coating: Applying protective coatings such as vinyl or powder to improve corrosion resistance and aesthetics.

- Surface Treatment: Processes like galvanization or passivation may be employed to further protect the wire from environmental factors.

Quality Assurance in Hardwire Cloth Manufacturing

Quality assurance is vital in the production of hardwire cloth to ensure that products meet international standards and customer expectations.

International Standards

B2B buyers should be aware of several international quality standards that manufacturers may adhere to:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: Particularly relevant in Europe, it indicates that products conform to health, safety, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, adherence to American Petroleum Institute standards is essential.

Quality Control Checkpoints

Quality control is typically implemented at several key checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon delivery to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Monitors the production process to identify any deviations from established standards.

- Final Quality Control (FQC): Conducts a thorough inspection of the finished product to ensure it meets all specifications before shipping.

Common Testing Methods

To verify the quality of hardwire cloth, various testing methods may be employed:

- Tensile Testing: Measures the strength of the wire and its ability to withstand pulling forces.

- Corrosion Resistance Testing: Evaluates the material’s resistance to oxidation and rust.

- Mesh Size Verification: Ensures the openings meet the specified dimensions for intended applications.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control measures of potential suppliers:

- Audits: Conducting on-site audits of the manufacturing facility can provide insights into the production processes and quality control systems in place.

- Quality Reports: Requesting detailed quality assurance reports can help assess the supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent inspection services can add an extra layer of assurance that products meet specified standards before shipment.

QC and Certification Nuances for International Buyers

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification processes:

- Regional Standards: Different regions may have varying regulations and standards. Understanding local compliance requirements is essential for smooth importation.

- Documentation: Ensure that suppliers provide all necessary documentation, including certifications, test reports, and compliance with local regulations.

- Cultural Considerations: Be prepared to navigate cultural differences in business practices, which may affect communication and negotiation regarding quality expectations.

By comprehensively understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions and select suppliers that meet their quality expectations for hardwire cloth. This knowledge not only helps in ensuring product reliability but also fosters long-term partnerships with manufacturers who prioritize quality and compliance.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for hardwire cloth Sourcing

When sourcing hardwire cloth, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. This analysis will provide insights into the cost components, price influencers, and practical tips for effective sourcing.

Cost Components

-

Materials: The primary cost driver in hardwire cloth production is the raw materials used, which can include various metals such as stainless steel, carbon steel, or galvanized steel. The choice of material significantly impacts cost; for instance, stainless steel is generally more expensive due to its corrosion resistance and strength.

-

Labor: Labor costs can vary significantly based on geographic location and the complexity of the manufacturing process. Regions with lower labor costs may offer more competitive pricing, but it’s essential to consider the potential trade-offs in quality and craftsmanship.

-

Manufacturing Overhead: This includes costs associated with factory maintenance, utilities, and administration. High overhead can affect pricing, particularly for manufacturers in regions with elevated operational costs.

-

Tooling: The initial investment in molds and machinery necessary for production can influence pricing. Custom tooling for specific designs or specifications typically adds to the overall cost but may yield better long-term returns through increased efficiency.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes is crucial, especially for international buyers who may face additional compliance regulations. Enhanced QC measures can increase production costs but are essential for maintaining product integrity.

-

Logistics: Transportation costs, including shipping and handling, are vital components of the total cost. International shipping can incur significant fees, particularly if the product is being sourced from a distant supplier. Additionally, factors such as customs duties and taxes must be factored into the logistics budget.

-

Margin: The supplier’s profit margin will vary based on market competition and product demand. High demand for specific types of hardwire cloth may lead to increased margins, whereas a saturated market could lead to lower prices.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Bulk orders typically lead to lower per-unit costs. Buyers should negotiate MOQs that align with their needs while ensuring cost-efficiency.

-

Specifications and Customization: Custom designs or specific material requirements can significantly impact pricing. Buyers should be clear about their needs and consider whether off-the-shelf options might be more economical.

-

Quality and Certifications: Products meeting specific industry standards or certifications often command higher prices. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers with a track record of quality may charge a premium, but the assurance of reliability can justify the cost.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) can impact overall costs. Buyers should clarify these terms to avoid unexpected expenses.

Buyer Tips

-

Negotiation: Effective negotiation is key to securing favorable pricing. Engage suppliers in discussions about volume discounts, payment terms, and potential for long-term contracts.

-

Cost-Efficiency: Assess the total cost of ownership, including not just the purchase price but also maintenance and operational costs. This holistic view can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa and South America should be aware of currency fluctuations and their potential impact on costs. Additionally, understanding local market conditions and competitor pricing can provide leverage in negotiations.

-

Research and Benchmarking: Conducting thorough market research and benchmarking against similar suppliers can help in identifying competitive pricing and ensuring value for money.

-

Consider Local Suppliers: Where feasible, sourcing from local manufacturers can reduce logistics costs and lead times, enhancing overall supply chain efficiency.

Disclaimer

Pricing for hardwire cloth can vary widely based on the factors mentioned above. Buyers are encouraged to obtain multiple quotes and conduct comprehensive market analysis to determine indicative prices that reflect current market conditions.

Spotlight on Potential hardwire cloth Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘hardwire cloth’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for hardwire cloth

When sourcing hardwire cloth for industrial applications, understanding its technical properties and trade terminology is crucial for making informed purchasing decisions. This section outlines key specifications and terms that international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be familiar with.

Key Technical Properties of Hardwire Cloth

-

Material Grade

– Hardwire cloth can be made from various materials, including stainless steel, carbon steel, and galvanized steel. The choice of material impacts corrosion resistance, strength, and durability. For example, stainless steel is ideal for environments with high moisture levels, while galvanized steel offers good protection against rust for outdoor applications. -

Wire Gauge

– The wire gauge indicates the thickness of the wire used in the cloth. A lower gauge number signifies a thicker wire, which generally provides greater strength and durability. Common gauges range from 16 to 27; for instance, a gauge of 16 is robust and suitable for heavy-duty applications, while higher gauges like 27 may be used for more delicate tasks. -

Mesh Opening Size

– This specification refers to the size of the openings created by the woven or welded wires. Smaller openings are used for applications requiring filtration or pest control, while larger openings are suitable for fencing or enclosures. Understanding mesh sizes helps buyers select the right product for their specific needs. -

Finish

– The finish of hardwire cloth can vary and includes options like galvanized, vinyl-coated, or powder-coated. Each finish offers different levels of protection against environmental factors. For example, vinyl-coated cloth provides additional corrosion resistance and aesthetic appeal, making it suitable for decorative or exposed applications. -

Tolerance

– Tolerance indicates the permissible variation in dimensions of the wire mesh. Precise tolerances are critical in applications where fit and performance are essential, such as in machinery or filtration systems. Suppliers typically provide tolerance specifications, allowing buyers to ensure compatibility with their projects. -

Weld Type

– Hardwire cloth can be produced through welding or weaving. Welded wire cloth is more rigid and suitable for structural applications, while woven cloth offers flexibility and is often used for enclosures. Understanding the differences in weld types helps buyers choose the right product for their intended use.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM can help buyers identify reliable suppliers and assess product quality in their sourcing decisions. -

MOQ (Minimum Order Quantity)

– This term indicates the smallest quantity of a product that a supplier is willing to sell. Recognizing MOQs is essential for budgeting and inventory planning, particularly for international buyers managing shipping and storage costs. -

RFQ (Request for Quote)

– A document that buyers send to suppliers to request pricing for specific products or services. An RFQ outlines product specifications and quantities, allowing suppliers to provide accurate quotes. This process is vital for securing competitive pricing in B2B transactions. -

Incoterms (International Commercial Terms)

– A set of predefined international trade terms that clarify the responsibilities of buyers and sellers in a transaction. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery responsibilities, which are critical in international trade. -

Lead Time

– The amount of time it takes from placing an order to receiving it. Lead times can vary based on production schedules and shipping methods. Buyers should consider lead times when planning projects to avoid delays. -

Certification

– Refers to compliance with industry standards or regulations, such as ISO or ASTM. Certifications can provide assurance of product quality and performance, making them an important consideration for buyers focused on reliability and safety.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing hardwire cloth, ensuring that they select the best products for their specific applications and requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hardwire cloth Sector

Market Overview & Key Trends

The hardwire cloth market is experiencing robust growth driven by several global factors. Increasing urbanization, infrastructure development, and the rising demand for protective barriers in agriculture and construction are pushing the need for versatile materials like hardwire cloth. In particular, regions such as Africa and South America are witnessing rapid industrialization, leading to a surge in construction projects that require durable wire mesh solutions.

Emerging trends in B2B sourcing include the integration of advanced manufacturing technologies such as automation and digital supply chain management. These technologies are enhancing production efficiency and reducing lead times, allowing suppliers to meet the rising demand for customized solutions. Additionally, the rise of e-commerce platforms for industrial supplies is changing the landscape, enabling international buyers to access a broader range of products and suppliers, streamlining the procurement process.

Market dynamics are also influenced by fluctuating raw material prices, particularly for steel and other metals. Buyers must stay informed about market conditions to negotiate favorable terms. Furthermore, as environmental regulations become more stringent, the demand for sustainable materials is increasing. This trend is particularly relevant for B2B buyers in Europe and the Middle East, where green compliance is often a prerequisite for procurement decisions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central focus in the hardwire cloth sector as environmental impact and ethical sourcing gain prominence. The production of hardware cloth can involve significant resource consumption and emissions; therefore, companies are increasingly seeking materials that minimize ecological footprints. Buyers should prioritize suppliers that utilize recycled metals or employ energy-efficient manufacturing processes to reduce their overall environmental impact.

Illustrative Image (Source: Google Search)

Ethical supply chains are crucial, particularly for international buyers who must navigate various regulatory landscapes. Ensuring that suppliers adhere to labor and environmental standards not only protects a company’s reputation but also fosters long-term relationships built on trust. Certifications such as ISO 14001 (Environmental Management) and the ResponsibleSteel standard can serve as reliable indicators of a supplier’s commitment to sustainability.

Additionally, the use of ‘green’ materials, such as polymer-coated wires that reduce corrosion and extend product life, is gaining traction. These materials not only enhance durability but also contribute to lower maintenance costs over time, aligning with the sustainability goals of many organizations.

Brief Evolution/History

The concept of hardware cloth dates back to ancient civilizations, where woven metal meshes were used for various practical applications. However, its modern evolution began in the late 19th century with the advent of industrialization, leading to advanced manufacturing techniques. Initially utilized primarily for agricultural fencing and animal enclosures, the applications of hardware cloth have expanded significantly over the decades.

Today, it serves a wide array of industries, including construction, HVAC, and filtration systems, reflecting its versatility and adaptability. The ongoing advancements in material science and manufacturing processes continue to shape the future of hardwire cloth, positioning it as a vital component in sustainable industrial practices. For international B2B buyers, understanding this evolution can provide insights into selecting the right products that meet current market demands and sustainability standards.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of hardwire cloth

-

How can I effectively vet suppliers for hardwire cloth?

When vetting suppliers, consider their industry reputation, certifications, and production capabilities. Look for suppliers with experience in exporting to your region, as they will better understand the regulatory and logistical challenges. Request references from previous clients and check online reviews. Additionally, consider visiting the supplier’s facility or conducting a virtual tour to assess their operations and quality control processes. -

Can I customize the specifications of hardwire cloth?

Yes, many suppliers offer customization options for hardwire cloth, including wire gauge, mesh size, and material type. Be clear about your project requirements and discuss these with potential suppliers. Provide detailed specifications in your request for quotes (RFQ) to ensure accurate quotes and timely production. Custom orders may require longer lead times, so plan accordingly to avoid delays in your project timeline. -

What are the typical minimum order quantities (MOQs) and lead times for hardwire cloth?

MOQs can vary significantly based on the supplier and the specific product. Generally, you may expect MOQs ranging from 100 square meters to several thousand, depending on the customization required. Lead times typically range from 2 to 6 weeks after order confirmation, but this can fluctuate based on order complexity and supplier workload. Always confirm these details during the negotiation process to align your expectations. -

What payment terms should I expect when sourcing hardwire cloth internationally?

Payment terms can differ widely among suppliers. Common practices include partial payment upfront (30-50%) with the balance due upon shipment or delivery. It’s advisable to negotiate terms that suit your cash flow needs while ensuring supplier security. Consider using secure payment methods such as letters of credit or escrow services for larger transactions to mitigate risks associated with international trade. -

What quality assurance certifications should I look for in hardwire cloth suppliers?

Look for suppliers that have relevant quality assurance certifications such as ISO 9001, which indicates a commitment to consistent quality management. Additionally, certifications like CE marking for products sold in Europe may be necessary. Verify if the supplier conducts regular quality inspections and testing for their products, ensuring compliance with international standards for durability and safety. -

How should I handle logistics and shipping for hardwire cloth purchases?

When arranging logistics, consider the mode of transport (air, sea, or land) based on your budget and urgency. Collaborate with your supplier to determine the best shipping options and incoterms (like FOB, CIF) that define responsibilities for costs and risks. It’s crucial to work with reliable freight forwarders who understand customs procedures in your country to avoid delays and additional costs upon arrival. -

What steps can I take to resolve disputes with my hardwire cloth supplier?

To effectively resolve disputes, maintain clear communication and document all interactions. Establish a formal dispute resolution process in your contract, which may include mediation or arbitration. If issues arise, try to resolve them amicably through direct negotiation before escalating. Having a legal advisor familiar with international trade laws can help you navigate disputes effectively and protect your interests. -

What are the best practices for inspecting hardwire cloth upon delivery?

Upon delivery, conduct a thorough inspection of the hardwire cloth to ensure it meets your specifications. Check for correct dimensions, wire gauge, and any defects or damage during shipping. Document any discrepancies with photographs and detailed notes. If issues are found, notify the supplier immediately and follow the dispute resolution process outlined in your contract. Implementing a quality control checklist can streamline this inspection process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hardwire cloth

In conclusion, the strategic sourcing of hardware cloth presents significant opportunities for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. Understanding the diverse materials, gauges, and manufacturing processes is essential for selecting the right product tailored to specific applications, whether for construction, agriculture, or industrial uses.

Key takeaways include:

- Material Selection: Choose between galvanized, stainless, and carbon steel based on durability and corrosion resistance needed for your projects.

- Production Methods: Differentiate between welded and woven hardware cloth to align with your structural requirements.

- Supplier Relationships: Establish strong partnerships with reliable suppliers to ensure quality and timely delivery, which can significantly impact your operational efficiency.

As the demand for versatile and durable materials continues to rise globally, now is the time for buyers to refine their sourcing strategies. By investing in high-quality hardware cloth, businesses can enhance their project outcomes while also supporting local economies.

Take action today by evaluating your current supply chain and exploring new supplier partnerships that can help you leverage these insights for competitive advantage in your market.