Your Ultimate Guide to Sourcing Hydraulic Press

Introduction: Navigating the Global Market for hydraulic press

In today’s fast-paced industrial landscape, hydraulic presses are essential tools that drive efficiency and precision across various manufacturing sectors. By utilizing hydraulic fluid to generate substantial force, these machines facilitate complex processes such as forging, stamping, and material shaping. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, understanding the role and selection of hydraulic presses is crucial for enhancing operational capabilities and product quality.

This comprehensive guide aims to equip buyers with the knowledge needed to navigate the diverse offerings in the hydraulic press market. It covers the various types of hydraulic presses—including C-frame, H-frame, and customized solutions—alongside the materials they can process and the intricacies of manufacturing and quality control. Buyers will also gain insights into evaluating potential suppliers, understanding cost structures, and analyzing market trends that impact procurement decisions.

By leveraging this resource, B2B buyers can make informed sourcing choices, optimizing their operations while mitigating risks associated with machinery investments. This guide is not merely an informational tool; it is a strategic asset designed to empower businesses to harness the full potential of hydraulic technology, driving innovation and growth in a competitive global market.

Understanding hydraulic press Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic C-Frame Press | Compact design, open front for easy access | Bending, forming, punching | Pros: Versatile, space-efficient; Cons: Limited capacity compared to H-frame. |

| Hydraulic H-Frame Press | Sturdy “H” design for enhanced stability | Heavy-duty metal forming, straightening | Pros: High force capacity, excellent stability; Cons: Larger footprint, higher cost. |

| Hydraulic Four-Column Press | Four vertical columns for balanced force | High-precision applications, automotive parts | Pros: Uniform pressure distribution, suitable for large workpieces; Cons: More complex setup and maintenance. |

| Hydraulic Shop Press | Simple design, often portable | General workshop tasks, light assembly | Pros: Affordable, easy to use; Cons: Limited to lighter applications, lower precision. |

| Customized Hydraulic Press | Tailored configurations for specific needs | Specialized manufacturing processes | Pros: Fully adaptable to unique requirements; Cons: Potentially longer lead times and higher initial costs. |

Hydraulic C-Frame Press

C-frame hydraulic presses are designed for accessibility and efficiency, making them ideal for tasks such as bending, forming, and punching. Their compact structure allows for easy integration into smaller workspaces, a crucial factor for many businesses in regions where space is at a premium. Buyers should consider the specific tasks and materials involved, as the C-frame press may not support heavier applications due to its limited pressure capacity compared to larger models.

Hydraulic H-Frame Press

The H-frame hydraulic press is characterized by its robust design, which provides enhanced stability and force distribution. This type is particularly suited for heavy-duty applications, including metal forming and straightening, making it a preferred choice for industries requiring high force capacities. While the initial investment may be higher and the footprint larger, the durability and performance of H-frame presses can lead to long-term savings through improved operational efficiency.

Hydraulic Four-Column Press

Four-column hydraulic presses are known for their ability to apply uniform pressure across large workpieces, making them suitable for high-precision applications such as automotive part manufacturing. The four-column design enhances stability, allowing for intricate tasks that demand accuracy. Buyers should be prepared for a more complex setup and maintenance process, but the investment can pay off in terms of product quality and operational capabilities.

Hydraulic Shop Press

Hydraulic shop presses offer a straightforward, portable solution for general workshop tasks and light assembly. They are often more affordable and user-friendly, making them an excellent option for small businesses or those new to hydraulic pressing. However, their limitations in handling heavier materials and achieving high precision should be considered when evaluating their suitability for specific applications.

Customized Hydraulic Press

Customized hydraulic presses provide tailored solutions for businesses with unique operational requirements. By adapting configurations to fit specific manufacturing processes, these presses can significantly enhance productivity and product quality. However, potential buyers should weigh the benefits of customization against the longer lead times and higher initial costs, ensuring that the investment aligns with their operational goals and budget constraints.

Related Video: What are Transformer Models and how do they work?

Key Industrial Applications of hydraulic press

| Industry/Sector | Specific Application of Hydraulic Press | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Stamping and forming of metal parts | High precision and efficiency in mass production | Look for presses with high pressure capacity and automation features to enhance productivity. |

| Metal Fabrication | Bending and shaping of metal sheets | Improved material handling and reduced waste | Consider the size and workspace requirements, ensuring the press fits operational needs. |

| Aerospace | Component assembly and forming of lightweight materials | Enhanced structural integrity and weight reduction | Focus on presses that offer high precision and safety features, critical in aerospace applications. |

| Construction | Pre-stressing concrete components | Increased durability and strength of construction materials | Evaluate after-sales support for maintenance and service, ensuring long-term reliability. |

| Electronics | Enclosure forming and component assembly | Streamlined production processes and improved quality control | Assess compatibility with various materials and the need for programmable controls for precision. |

Automotive Manufacturing

In the automotive sector, hydraulic presses are essential for stamping and forming metal parts, such as body panels and structural components. These machines deliver high pressure to shape materials accurately, resulting in consistent quality across mass production runs. International buyers should prioritize presses with advanced automation capabilities to enhance efficiency and reduce labor costs. Additionally, understanding local regulations regarding machine safety and emissions is crucial for compliance.

Metal Fabrication

Hydraulic presses are widely used in metal fabrication for bending and shaping metal sheets into desired forms. This application is vital for creating components used in various industries, including construction and machinery. Buyers in this sector should consider the press’s size and capacity to handle the specific types of metal they work with. Investing in a press with a robust design can help minimize downtime and improve production efficiency, particularly in regions with high demand for fabricated metal products.

Aerospace

In aerospace manufacturing, hydraulic presses are utilized for the assembly and forming of lightweight materials, such as composites and aluminum alloys. These presses contribute to enhancing the structural integrity of components while ensuring weight reduction, which is critical for aircraft performance. Buyers should focus on sourcing presses that provide high precision and incorporate safety features, as the aerospace industry has stringent quality standards. Furthermore, understanding the supply chain dynamics in different regions can help buyers make informed decisions.

Construction

Hydraulic presses play a crucial role in pre-stressing concrete components, which enhances the durability and strength of construction materials. This application is particularly important in regions experiencing rapid urbanization and infrastructure development. Buyers should evaluate the after-sales support offered by manufacturers, as regular maintenance is essential for ensuring the longevity of hydraulic presses in demanding construction environments. Additionally, considering local material availability can influence the choice of press specifications.

Electronics

In the electronics industry, hydraulic presses are used for enclosure forming and component assembly, allowing for efficient production of devices with high-quality standards. These presses streamline production processes and ensure consistent quality control, which is vital in a competitive market. Buyers should assess the compatibility of hydraulic presses with various materials and prioritize those with programmable controls for enhanced precision. Understanding the technological landscape in their region can also aid buyers in selecting the right press to meet their production needs.

Related Video: Converting a hydraulic press from manual to electric. FOR 40 DOLLARS?

Strategic Material Selection Guide for hydraulic press

When selecting materials for hydraulic presses, international B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. Here, we analyze four common materials used in hydraulic press construction: Steel, Aluminum, Cast Iron, and Composite Materials. Each material has unique properties that can significantly impact the operational efficiency and suitability for specific applications.

Steel

Key Properties: Steel is known for its high tensile strength and excellent durability, making it suitable for high-pressure applications. It typically has a temperature rating of up to 500°F (260°C) and can withstand significant loads without deformation.

Pros & Cons: The advantages of steel include its robustness and ability to handle heavy-duty tasks, which is essential for industries such as automotive and aerospace. However, steel can be prone to corrosion if not properly treated or coated, which may lead to increased maintenance costs over time.

Impact on Application: Steel’s compatibility with various hydraulic fluids and its ability to withstand high pressures make it ideal for heavy manufacturing processes. However, buyers in humid or corrosive environments should consider protective coatings or alternative materials.

Considerations for International Buyers: Compliance with international standards such as ASTM A36 or DIN 17100 is crucial. Buyers should also be aware of local regulations regarding material sourcing and environmental impact, especially in regions like Africa and South America, where regulations may vary.

Aluminum

Key Properties: Aluminum is lightweight and has a high strength-to-weight ratio, making it an excellent choice for applications requiring mobility and ease of handling. It typically has a temperature rating of around 400°F (204°C) and is resistant to corrosion.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which allows for easier installation and transport. However, it may not be suitable for extremely high-pressure applications due to its lower tensile strength compared to steel.

Impact on Application: Aluminum hydraulic presses are often used in industries like electronics and light manufacturing, where lower weight and corrosion resistance are more critical than high pressure.

Considerations for International Buyers: Buyers should ensure that aluminum components meet standards such as ASTM B221 or JIS H4000. Additionally, sourcing aluminum from suppliers with sustainable practices can enhance corporate responsibility, particularly in Europe and the Middle East.

Cast Iron

Key Properties: Cast iron offers excellent compressive strength and stability, making it suitable for heavy-duty applications. It can withstand temperatures up to 1,200°F (649°C) and has good vibration-damping properties.

Pros & Cons: The durability and stability of cast iron make it ideal for high-performance hydraulic presses. However, it is relatively brittle and can crack under excessive stress or impact, leading to potential failures.

Impact on Application: Cast iron is often used in applications requiring high precision and stability, such as in the automotive and aerospace industries. Its ability to dampen vibrations enhances the quality of the pressing process.

Considerations for International Buyers: Buyers should be aware of the need for compliance with standards like ASTM A48 or DIN 1691. Additionally, understanding the local availability of cast iron and potential import tariffs is essential for cost management.

Composite Materials

Key Properties: Composite materials combine various materials to enhance performance characteristics, such as weight reduction and corrosion resistance. They can withstand temperatures up to 300°F (149°C) and offer excellent chemical resistance.

Pros & Cons: The main advantage of composites is their versatility and ability to be tailored for specific applications. However, they can be more expensive to manufacture and may require specialized knowledge for maintenance and repair.

Impact on Application: Composites are particularly useful in applications where weight and corrosion resistance are critical, such as in the aerospace and marine industries.

Considerations for International Buyers: Buyers must ensure that composite materials comply with relevant standards such as ASTM D3039. Additionally, understanding the supply chain for composites is vital, as sourcing may be more complex than traditional materials.

| Material | Typical Use Case for hydraulic press | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty manufacturing | High tensile strength | Prone to corrosion | Medium |

| Aluminum | Light manufacturing | Lightweight and easy to handle | Lower pressure tolerance | Medium |

| Cast Iron | Precision applications | Excellent stability and durability | Brittle, can crack under stress | High |

| Composite Materials | Aerospace and marine applications | Corrosion resistant and versatile | Higher manufacturing costs | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions that align with operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic press

The manufacturing processes and quality assurance for hydraulic presses are critical components that influence their performance, longevity, and overall value to businesses. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can lead to better purchasing decisions and enhanced operational efficiency.

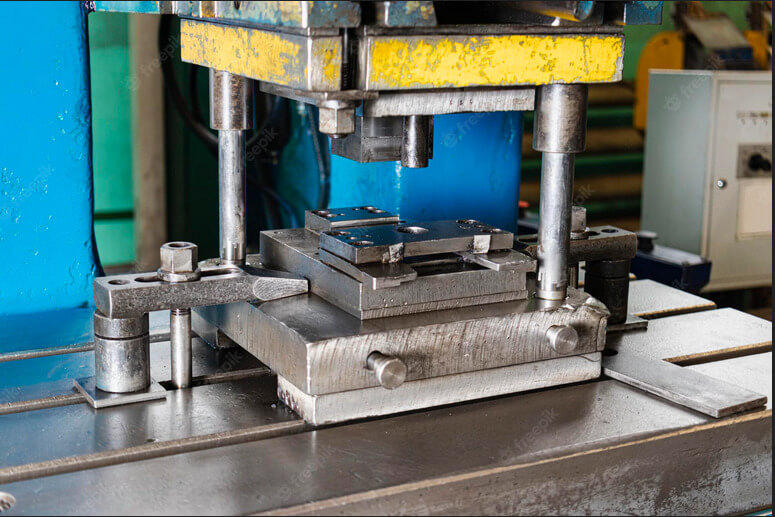

Illustrative Image (Source: Google Search)

Manufacturing Processes for Hydraulic Presses

The production of hydraulic presses involves several key stages, each requiring precision and attention to detail. Below are the main stages of manufacturing, along with important techniques used in the process.

1. Material Preparation

The first step in manufacturing hydraulic presses is material preparation. High-quality raw materials, typically steel or alloy, are sourced based on the specifications required for the press’s intended application. The selection of materials is crucial, as they must withstand significant pressure and stress during operation.

- Material Selection: Buyers should look for suppliers who utilize high-grade steel that complies with international standards to ensure durability and reliability.

- Cutting and Shaping: Raw materials are cut into required shapes and sizes using techniques such as laser cutting or plasma cutting. This ensures precise dimensions that are critical for the subsequent stages.

2. Forming

The forming stage involves shaping the components of the hydraulic press. This can include the frame, columns, and other structural parts that must bear the load during operation.

- Techniques Used:

- Hydraulic Forming: This technique uses hydraulic pressure to shape materials into the desired forms. It is particularly effective for creating complex shapes.

- Stamping and Forging: These methods are often used for manufacturing parts that require significant strength and durability.

3. Assembly

Once the individual components are formed, they are assembled into the final hydraulic press unit. This stage is critical as it determines the machine’s overall integrity and performance.

- Assembly Techniques:

- Welding: Components are often welded together to ensure a strong and stable structure.

- Bolting and Fastening: In some cases, bolts and fasteners are used to allow for easier disassembly and maintenance.

4. Finishing

The finishing stage enhances the hydraulic press’s appearance and protects it from corrosion and wear.

- Surface Treatment: Techniques like powder coating, galvanizing, or painting are employed to provide a protective layer and improve aesthetics.

- Quality Checks: Before moving to the quality assurance phase, the finished product undergoes initial inspections to ensure it meets design specifications.

Quality Assurance in Hydraulic Press Manufacturing

Quality assurance is paramount in the production of hydraulic presses, ensuring that each machine meets both performance standards and safety regulations. For B2B buyers, understanding the quality assurance process can provide confidence in their purchasing decisions.

International and Industry-Specific Standards

Compliance with recognized standards is essential for ensuring the quality and safety of hydraulic presses. Key standards include:

- ISO 9001: This international standard outlines the criteria for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For presses used in oil and gas applications, the American Petroleum Institute (API) provides standards that ensure equipment safety and reliability.

Quality Control Checkpoints

The quality control process involves several checkpoints throughout the manufacturing process to ensure that each hydraulic press meets established standards:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specifications and quality standards.

- In-Process Quality Control (IPQC): Inspections are conducted during the manufacturing process to identify and rectify issues before the final assembly.

- Final Quality Control (FQC): After assembly, the complete hydraulic press undergoes thorough testing and inspection to verify its performance and safety.

Common Testing Methods

To ensure the hydraulic press meets operational standards, several testing methods are employed:

- Hydraulic Testing: The press is tested under actual working conditions to verify its pressure capacity and functionality.

- Load Testing: This involves applying maximum loads to the press to ensure it can handle the specified weight without failure.

- Performance Testing: Tests are conducted to evaluate the machine’s efficiency, speed, and precision in operation.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring they receive a reliable product. Here are some effective strategies:

- Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices. Look for audits that assess compliance with ISO and other relevant standards.

- Reviewing Quality Reports: Request access to quality control reports and certificates that demonstrate compliance with international standards.

- Third-Party Inspections: Engage independent third-party inspectors to evaluate the manufacturing facility and the hydraulic presses produced. This can provide an unbiased assessment of quality and safety.

Quality Control Nuances for International Buyers

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control:

- Regulatory Compliance: Different regions may have varying regulations regarding machinery safety and operation. Understanding local laws is essential for compliance.

- Cultural Factors: Different cultural attitudes toward quality can affect production practices. Buyers should consider suppliers’ cultural contexts when assessing their commitment to quality.

- Logistics and Supply Chain: The complexity of international logistics can introduce risks related to quality. Ensure that your supplier has robust quality control measures throughout their supply chain.

In conclusion, understanding the manufacturing processes and quality assurance protocols for hydraulic presses is vital for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside a robust quality assurance framework, buyers can make informed decisions that enhance operational efficiency and product quality. Prioritizing suppliers who adhere to international standards and demonstrate strong quality control practices will ultimately lead to successful procurement and long-term satisfaction.

Related Video: Hydraulic Press Deep Drawing Process

Comprehensive Cost and Pricing Analysis for hydraulic press Sourcing

Understanding the cost structure and pricing of hydraulic presses is essential for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The following analysis provides insights into the key cost components, price influencers, and practical tips for negotiating and optimizing procurement strategies.

Cost Components

-

Materials: The primary material costs include steel, hydraulic cylinders, pumps, and seals. The choice of materials directly impacts the durability and efficiency of the hydraulic press. High-quality materials may lead to higher upfront costs but can result in significant long-term savings through reduced maintenance and longer service life.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembling, and testing the hydraulic press. Skilled labor is essential for ensuring high-quality production standards, and labor costs can vary significantly based on geographical location and local wage standards.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and equipment depreciation. Effective management of manufacturing overhead can enhance overall cost efficiency.

-

Tooling: Tooling costs are related to the specialized tools and fixtures required for manufacturing hydraulic presses. Custom tooling can significantly increase initial costs but may be necessary for producing specialized or high-precision equipment.

-

Quality Control (QC): Implementing stringent QC measures ensures that the hydraulic presses meet safety and performance standards. While this may add to the cost, it is crucial for maintaining product quality and minimizing warranty claims.

-

Logistics: Transportation and shipping costs can vary widely depending on the supplier’s location and the buyer’s delivery requirements. International shipping may involve additional tariffs and duties, which should be factored into the total cost.

-

Margin: Suppliers typically include a profit margin that varies based on market conditions, competition, and the perceived value of the hydraulic press. Understanding the margin can help buyers gauge whether the price is competitive.

Price Influencers

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to maximize savings.

-

Specifications/Customization: Custom features can significantly affect the price. Buyers should clearly define their needs to avoid unexpected costs and ensure they receive the desired specifications.

-

Materials: The choice of materials influences both the price and the performance of the hydraulic press. Buyers should consider the trade-offs between cost and quality.

-

Quality/Certifications: Presses that meet international quality standards and certifications may command higher prices. However, investing in certified equipment can mitigate risks associated with safety and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but often provide better support and warranties.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define the responsibilities of buyers and sellers in shipping and logistics. This knowledge can help buyers manage costs effectively.

Buyer Tips

-

Negotiation: Leverage competitive quotes from multiple suppliers to negotiate better pricing. Being transparent about your budget and requirements can foster a collaborative approach to pricing.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes purchase price, maintenance, and operational costs over the machine’s lifespan. This perspective can reveal long-term savings.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and shipping costs that can affect pricing. Establishing relationships with local suppliers may help mitigate these risks.

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and industry standards. This information can empower buyers to make informed decisions and avoid overpaying.

In conclusion, navigating the cost structure and pricing of hydraulic presses involves understanding various components and influencers. By employing strategic purchasing practices and leveraging negotiation techniques, international B2B buyers can optimize their sourcing efforts and secure high-quality hydraulic presses that meet their operational needs.

Spotlight on Potential hydraulic press Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘hydraulic press’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for hydraulic press

Key Technical Properties of Hydraulic Presses

When selecting a hydraulic press, understanding its technical specifications is crucial for ensuring optimal performance and suitability for your production needs. Here are some essential properties to consider:

-

Pressure Capacity

This refers to the maximum force the hydraulic press can exert, typically measured in tons or kilonewtons. Pressure capacity is critical because it determines the type and size of materials that can be processed. For instance, heavy-duty applications in metal forming will require presses with higher pressure ratings. -

Working Area Size

The dimensions of the press’s working area dictate the maximum size of the components that can be processed. A larger working area allows for more versatility in applications, but it can also require more floor space. Buyers should assess their workspace and the typical size of the materials they handle to make an informed decision. -

Stroke Length

Stroke length is the distance the ram travels when compressing materials. This parameter is important for applications requiring specific depths or heights during pressing. A longer stroke allows for more extensive operations, while a shorter stroke may suffice for simpler tasks. -

Material Grade

The materials used in the construction of the hydraulic press significantly impact its durability and longevity. Common grades include structural steel and alloy steels, which provide strength and resistance to deformation. Buyers should inquire about the material specifications to ensure that the press can withstand the demands of their specific applications. -

Tolerance

Tolerance refers to the allowable variation in dimensions during the pressing process. High precision in tolerance is vital for industries like automotive manufacturing, where even minor deviations can lead to product failure. Understanding the tolerance levels of a hydraulic press ensures that it meets quality standards and operational requirements.

- Automation Features

Many modern hydraulic presses come equipped with automation capabilities, including programmable controls and sensor technology. These features enhance precision and efficiency, allowing for higher production rates and reduced manual intervention. Buyers should consider whether these features align with their operational goals.

Common Trade Terminology in the Hydraulic Press Industry

Familiarity with industry jargon can significantly enhance communication and negotiation with suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment or components that are used in another company’s end product. Understanding OEM relationships is crucial for buyers looking for specific hydraulic press models or parts, as it can affect warranty and support services. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For hydraulic presses, knowing the MOQ can help buyers manage their inventory and budget effectively. This is particularly relevant for small businesses or startups that may not need large quantities. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific products or services. In the context of hydraulic presses, an RFQ helps buyers compare offers from different suppliers, ensuring they make cost-effective decisions. -

Incoterms (International Commercial Terms)

These are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international buyers from Africa, South America, the Middle East, and Europe to avoid misunderstandings and ensure smooth transactions. -

Lead Time

Lead time is the amount of time from placing an order to receiving the product. For hydraulic presses, longer lead times can impact production schedules, so buyers should clarify this with suppliers to align their operations accordingly. -

After-Sales Support

This term encompasses the services provided by the manufacturer or supplier after the sale, including installation, maintenance, and customer service. Strong after-sales support is critical for ensuring the longevity and optimal performance of hydraulic presses, making it a key consideration for buyers.

Understanding these technical properties and terms will empower B2B buyers to make informed decisions when investing in hydraulic presses, ultimately enhancing their production efficiency and product quality.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hydraulic press Sector

Market Overview & Key Trends

The hydraulic press market is experiencing robust growth, driven by increasing demand across various manufacturing sectors, including automotive, aerospace, and metalworking. Key global drivers include the rise of automation in manufacturing processes, the demand for high-precision components, and the expansion of industries in emerging markets. For international B2B buyers from Africa, South America, the Middle East, and Europe, recognizing these dynamics is crucial for optimizing sourcing strategies.

Current trends indicate a significant shift toward smart hydraulic presses integrated with IoT technology, enabling real-time monitoring and predictive maintenance. This technological advancement not only enhances operational efficiency but also minimizes downtime and reduces maintenance costs. Furthermore, buyers are increasingly prioritizing flexibility in sourcing, looking for suppliers who can provide customized solutions that cater to specific operational requirements.

Another emerging trend is the focus on supply chain resilience. With geopolitical tensions and disruptions caused by global events, businesses are seeking to diversify their supplier networks. This trend is particularly relevant for buyers in regions like Africa and South America, where local sourcing initiatives can mitigate risks and promote regional economic growth. Additionally, understanding the cost structures associated with hydraulic presses, including initial investment and long-term operational costs, will empower buyers to make informed purchasing decisions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the hydraulic press sector, reflecting a broader shift toward environmentally responsible manufacturing practices. The environmental impact of hydraulic presses, particularly concerning energy consumption and hydraulic fluid disposal, necessitates the adoption of greener technologies. Buyers should seek suppliers that prioritize energy-efficient models and sustainable manufacturing practices, reducing their overall carbon footprint.

Ethical sourcing is also gaining traction among B2B buyers. Establishing a transparent supply chain that adheres to ethical standards is essential for fostering trust and ensuring compliance with international regulations. Buyers should look for suppliers that hold green certifications, such as ISO 14001, which denotes adherence to environmental management standards, and those that use recyclable materials in their hydraulic presses.

Moreover, engaging with suppliers committed to ethical labor practices and community development can enhance a company’s reputation and align with the growing consumer demand for corporate social responsibility. By integrating sustainability and ethical sourcing into their procurement strategies, international buyers can not only contribute to environmental preservation but also drive long-term business success.

Brief Evolution/History

The hydraulic press has evolved significantly since its inception in the 18th century, when Joseph Bramah patented the first hydraulic press in 1795. Initially used for simple tasks such as metal shaping, advancements in hydraulic technology have transformed these machines into sophisticated tools capable of performing complex operations with high precision. The introduction of hydraulic systems revolutionized manufacturing processes, allowing for increased force application and automation.

Today, hydraulic presses are integral to various industries, reflecting innovations in design and technology. The shift towards automation, digital monitoring, and energy efficiency represents the latest chapter in the hydraulic press’s evolution, emphasizing the importance of adaptability for international B2B buyers seeking competitive advantages in their markets.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic press

-

How do I vet potential suppliers for hydraulic presses?

Vetting suppliers is crucial for ensuring reliability and quality. Start by researching their reputation in the industry through reviews and testimonials. Verify their certifications, such as ISO or CE, which indicate compliance with international quality standards. Additionally, request references from previous clients, particularly those in your region. Consider visiting their facilities if feasible, or arrange virtual tours to assess their manufacturing capabilities. Finally, inquire about their after-sales support and service options to ensure they can assist with maintenance and repairs. -

Can hydraulic presses be customized to meet specific needs?

Yes, many manufacturers offer customization options for hydraulic presses. Customization can range from altering dimensions to suit your workspace to modifying features that enhance functionality for specific applications. When seeking customization, clearly outline your requirements and ensure the supplier has experience in producing tailored solutions. Be mindful that customized presses may have longer lead times and higher costs, so factor these into your budget and timeline. -

What are typical minimum order quantities (MOQ) and lead times for hydraulic presses?

Minimum order quantities can vary significantly based on the manufacturer and the complexity of the press. Generally, MOQs may range from one unit for standard models to larger quantities for customized solutions. Lead times can also differ; standard models may take a few weeks, while custom presses can require several months for production. Always clarify these details upfront to manage your expectations and plan your procurement process effectively. -

What quality assurance certifications should I look for in hydraulic presses?

When sourcing hydraulic presses, prioritize suppliers that hold relevant quality assurance certifications. Common certifications include ISO 9001 for quality management systems and CE marking for compliance with European safety standards. Additionally, look for any industry-specific certifications that may apply to your operations. These certifications not only ensure the product meets quality standards but also reflect the supplier’s commitment to continuous improvement and customer satisfaction. -

How should I handle logistics when importing hydraulic presses?

Importing hydraulic presses requires careful logistics planning. First, determine the shipping method that best suits your needs, considering factors like cost, speed, and the press’s size and weight. Engage a reputable freight forwarder with experience in handling heavy machinery to navigate customs regulations and documentation. Additionally, factor in insurance to protect your investment during transit. Establish clear communication with your supplier regarding shipping timelines and responsibilities to ensure a smooth process.

Illustrative Image (Source: Google Search)

-

What steps can I take to resolve disputes with suppliers?

To effectively resolve disputes, establish a clear contract that outlines terms, responsibilities, and expectations. In the event of a disagreement, maintain open communication with the supplier to discuss the issue calmly and professionally. Document all correspondence and agreements related to the dispute. If necessary, involve a neutral third party for mediation. Familiarize yourself with the legal frameworks applicable in your region and the supplier’s location, as this knowledge can guide you in pursuing formal resolutions if needed. -

What payment methods are commonly used in international transactions for hydraulic presses?

Common payment methods for international B2B transactions include wire transfers, letters of credit, and escrow services. Wire transfers are straightforward but require trust in the supplier. Letters of credit provide added security by ensuring payment is made only upon fulfillment of contract terms. Escrow services act as intermediaries, holding funds until both parties meet their obligations. Discuss payment terms upfront to find a method that balances security and convenience for both parties. -

How can I ensure ongoing support and maintenance for my hydraulic press?

Ensuring ongoing support begins with selecting a supplier that offers robust after-sales services, including maintenance and repairs. Inquire about their service agreements, response times, and availability of spare parts. Establish a maintenance schedule to regularly check and service your hydraulic press to prevent costly downtimes. Additionally, consider training your staff on basic troubleshooting and maintenance practices to enhance the longevity and efficiency of your equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hydraulic press

As international B2B buyers evaluate their sourcing strategies for hydraulic presses, several key insights emerge. Understanding your specific operational needs is paramount, whether you require a compact C-frame for lighter tasks or a robust H-frame for heavy-duty applications. Prioritizing quality and after-sales support ensures that your investment translates into long-term operational efficiency and reliability. Additionally, recognizing the importance of cost structures and supplier evaluations will help mitigate risks associated with procurement.

Strategic sourcing is not merely about acquiring equipment; it’s about fostering partnerships that can drive innovation and efficiency within your operations. Investing in the right hydraulic press can significantly enhance your production capabilities, ultimately leading to improved product quality and competitive advantage.

Looking ahead, the landscape for hydraulic press procurement continues to evolve, driven by technological advancements and increasing market demands. Now is the time for buyers from Africa, South America, the Middle East, and Europe to leverage these insights and make informed decisions. Explore your options, engage with reputable suppliers, and position your business for success in an ever-competitive global marketplace.