Your Ultimate Guide to Sourcing Hydrolic Press Machine

Introduction: Navigating the Global Market for hydrolic press machine

In the rapidly evolving landscape of global manufacturing, hydraulic press machines stand out as essential tools for a variety of industries, from automotive to aerospace. These machines utilize the principles of hydraulic power to exert tremendous force, enabling precise manipulation of materials for tasks such as forming, bending, and assembling components. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the intricacies of hydraulic presses is crucial for making informed sourcing decisions that can significantly impact production efficiency and product quality.

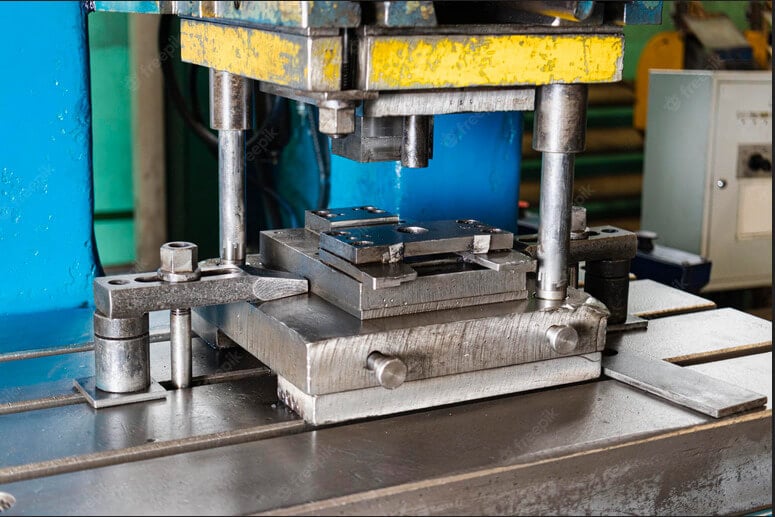

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the diverse types of hydraulic press machines, including C-frame and H-frame models, and explores their specific applications across different sectors. Additionally, it covers critical considerations such as material compatibility, manufacturing and quality control standards, supplier selection, and cost factors. By providing insights into market trends and supplier capabilities, this guide empowers buyers to navigate the complexities of sourcing hydraulic press machines effectively.

As you explore the detailed sections ahead, you will gain a nuanced understanding of hydraulic press technologies, enabling you to select the right equipment tailored to your operational needs. Whether you are looking to enhance production capabilities, ensure compliance with industry standards, or optimize your procurement strategy, this guide serves as a vital resource for making strategic decisions in the global market.

Understanding hydrolic press machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic C-Frame Presses | Compact design, single vertical frame, versatile access | Bending, forming, punching | Pros: Space-efficient, versatile. Cons: Limited force compared to larger frames. |

| Hydraulic H-Frame Presses | Robust structure, horizontal beam, high stability | Heavy-duty metal forming, straightening | Pros: High stability, uniform force distribution. Cons: Takes up more floor space. |

| Custom Hydraulic Presses | Tailored designs, specialized tooling, unique features | Specialized manufacturing processes | Pros: Meets specific needs, enhances productivity. Cons: Higher initial investment, longer lead times. |

| Hydraulic Power Presses | Operates on fluid dynamics, precise control over force | Automotive, aerospace, and metalworking | Pros: High precision, adaptable to various tasks. Cons: Requires regular maintenance of hydraulic components. |

| Mechanical Power Presses | Uses mechanical systems, high-speed operation | High-volume production environments | Pros: Fast cycle times, lower maintenance needs. Cons: Less precise control, potential for uneven force application. |

Hydraulic C-Frame Presses

Hydraulic C-frame presses are characterized by their compact design and accessibility, making them ideal for a variety of applications such as bending, forming, and punching. They are particularly suitable for operations where space is limited, allowing for efficient use of the shop floor. When purchasing, buyers should consider the machine’s tonnage, speed, and the types of tooling required for their specific tasks.

Hydraulic H-Frame Presses

With a robust structure and a horizontal beam that connects two vertical columns, hydraulic H-frame presses offer increased stability and are well-suited for heavy-duty applications like metal forming and straightening. Their design allows for a uniform distribution of force, which is critical in producing high-quality parts. Buyers should assess the machine’s capacity, dimensions, and the materials they will be working with to ensure compatibility with their production needs.

Custom Hydraulic Presses

Custom hydraulic presses can be tailored to meet specific operational requirements, including specialized tooling and control systems. This type of press is particularly beneficial for companies with unique manufacturing processes that require specialized solutions. While they can enhance productivity and efficiency, buyers must weigh the higher initial investment and longer lead times against the potential gains in operational effectiveness.

Hydraulic Power Presses

Hydraulic power presses operate on the principles of fluid dynamics, providing precise control over force application. They are commonly used in industries such as automotive and aerospace, where accurate forming and shaping of materials are crucial. When considering a hydraulic power press, buyers should focus on the machine’s precision capabilities, maintenance requirements, and the availability of hydraulic components to ensure long-term reliability.

Mechanical Power Presses

Mechanical power presses utilize mechanical systems to deliver high-speed operations, making them ideal for high-volume production environments. While they offer rapid cycle times and lower maintenance needs, buyers should be aware that they may lack the precision of hydraulic presses. It is essential to evaluate the specific production demands, including the types of materials processed and the required accuracy, before investing in this type of press.

Related Video: How To Make Hydraulic Press Machine || DIY Mini Hydraulic Press || Without Welding

Key Industrial Applications of hydrolic press machine

| Industry/Sector | Specific Application of Hydraulic Press Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Metal stamping and forming | Increases production efficiency and part precision | Supplier reliability, customization options, and service support |

| Aerospace | Component fabrication and assembly | Ensures high precision and safety in critical parts | Compliance with industry standards and certifications |

| Construction | Concrete forming and shaping | Enhances structural integrity and reduces waste | Material compatibility and machine adaptability |

| Electronics | PCB pressing and component assembly | Improves product quality and reduces cycle time | Precision control features and after-sales support |

| Metalworking | Forging and machining of metal parts | Increases durability and performance of components | Durability of hydraulic components and ease of maintenance |

Automotive Manufacturing

In the automotive sector, hydraulic press machines are integral for metal stamping and forming processes. These machines enable manufacturers to shape and mold metal sheets into complex components, ensuring high precision and repeatability. The main challenges faced include the need for rapid production cycles and consistent quality. International buyers should prioritize suppliers who offer robust customization options and reliable after-sales support to address specific manufacturing needs.

Aerospace

Hydraulic presses are crucial in the aerospace industry for fabricating and assembling components that require extreme precision and reliability. They are utilized for processes such as forming aircraft skins and assembling critical components like wing structures. Given the stringent safety regulations in this sector, buyers must ensure that their suppliers comply with industry standards and possess the necessary certifications to guarantee product safety and performance.

Construction

In construction, hydraulic press machines are used for concrete forming and shaping, allowing for the creation of intricate designs and structural components. This application enhances the structural integrity of buildings while minimizing material waste. Buyers in this sector should consider the machine’s adaptability to various molds and materials, as well as the supplier’s ability to provide ongoing maintenance and support.

Electronics

The electronics industry employs hydraulic presses for pressing printed circuit boards (PCBs) and assembling components. This application significantly enhances product quality and reduces cycle times, which is critical in a fast-paced market. Buyers should focus on sourcing machines with advanced precision control features to ensure high-quality outputs and to look for suppliers who provide comprehensive after-sales service to maintain operational efficiency.

Illustrative Image (Source: Google Search)

Metalworking

In metalworking, hydraulic press machines are essential for forging and machining metal parts. They allow for the production of components with increased durability and performance, which is vital for industries such as manufacturing and heavy machinery. Buyers should evaluate the durability of the hydraulic components and the ease of maintenance when selecting a supplier to ensure long-term reliability and reduced operational downtime.

Strategic Material Selection Guide for hydrolic press machine

When selecting materials for hydraulic press machines, it’s essential to consider the specific properties and performance requirements that will impact the machine’s efficiency and longevity. Below is an analysis of four common materials used in hydraulic press machines, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

Steel

Key Properties:

Steel is known for its high tensile strength, durability, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 300°C and can handle pressures exceeding 2000 psi, depending on the grade.

Pros & Cons:

Steel offers excellent durability and is relatively cost-effective. However, it is susceptible to corrosion, which can be a significant drawback in humid or corrosive environments. Manufacturing complexity can vary based on the specific steel alloy used, with some requiring specialized treatments.

Impact on Application:

Steel’s compatibility with various hydraulic fluids makes it suitable for diverse applications, including metal forming and assembly. However, its corrosion susceptibility means that protective coatings or regular maintenance may be necessary.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A36 or DIN 17100. Additionally, understanding local environmental conditions is crucial for selecting the right steel grade.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating of around 150°C. It can withstand moderate pressures, typically up to 1500 psi.

Pros & Cons:

The main advantage of aluminum is its lightweight nature, which can lead to reduced energy consumption during operation. However, it is less durable than steel and can be more expensive, particularly for high-strength alloys. Manufacturing processes for aluminum can also be more complex.

Impact on Application:

Aluminum is ideal for applications requiring lightweight components, such as in automotive and aerospace industries. Its corrosion resistance makes it suitable for environments where exposure to moisture is a concern.

Considerations for International Buyers:

Buyers should be aware of compliance with standards like ASTM B221. In regions with high humidity, aluminum’s benefits may outweigh its costs, making it a preferred choice.

Cast Iron

Key Properties:

Cast iron exhibits excellent compressive strength and can withstand high temperatures, typically rated up to 400°C. It is also highly resistant to wear and deformation under heavy loads.

Pros & Cons:

The durability and stability of cast iron make it a preferred choice for heavy-duty applications. However, it is brittle and can crack under sudden impact or stress, which limits its use in dynamic applications. Additionally, cast iron is generally more expensive than steel.

Impact on Application:

Cast iron is particularly suitable for applications requiring high stability and resistance to wear, such as in heavy machinery. Its ability to dampen vibrations can enhance operational efficiency.

Considerations for International Buyers:

Buyers should consider compliance with standards such as ASTM A48. In regions with stringent safety regulations, the structural integrity of cast iron components can be an advantage.

Composite Materials

Key Properties:

Composite materials, such as carbon fiber reinforced polymers, offer high strength-to-weight ratios and excellent corrosion resistance. They can operate effectively at temperatures up to 200°C and pressures around 1000 psi.

Pros & Cons:

The primary advantage of composites is their lightweight nature combined with high strength, making them suitable for specialized applications. However, they can be significantly more expensive than traditional materials and may require advanced manufacturing techniques.

Impact on Application:

Composites are ideal for applications where weight reduction is critical, such as in aerospace and automotive sectors. Their resistance to corrosion makes them suitable for harsh environments.

Considerations for International Buyers:

Buyers should be aware of the need for compliance with specific standards related to composite materials, such as ASTM D3039. Understanding the local market for composites and their availability can also influence purchasing decisions.

Summary Table

| Material | Typical Use Case for hydraulic press machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Metal forming, assembly | High durability and cost-effectiveness | Susceptible to corrosion | Medium |

| Aluminum | Lightweight components in automotive | Lightweight, good corrosion resistance | Less durable and more expensive | High |

| Cast Iron | Heavy-duty machinery | Excellent stability and wear resistance | Brittle and can crack under stress | High |

| Composite Materials | Aerospace and specialized applications | High strength-to-weight ratio | Expensive and requires advanced manufacturing | High |

This strategic material selection guide provides valuable insights for international B2B buyers, ensuring informed decisions that align with their operational needs and local conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for hydrolic press machine

Manufacturing Processes for Hydraulic Press Machines

The manufacturing of hydraulic press machines involves several critical stages, each contributing to the overall performance and reliability of the final product. Understanding these stages can help international B2B buyers make informed decisions when sourcing hydraulic presses.

1. Material Preparation

The first step in the manufacturing process is material selection and preparation. High-quality materials, such as high-strength steel or alloyed metals, are crucial for ensuring durability and performance. This stage includes:

- Material Sourcing: Establishing relationships with reliable suppliers who can provide certified raw materials that meet international standards.

- Cutting and Shaping: Materials are cut to required dimensions using techniques such as laser cutting or waterjet cutting, ensuring precision.

- Heat Treatment: Certain components may undergo heat treatment processes to enhance strength and durability.

2. Forming

The forming stage involves shaping the components of the hydraulic press. This is where the design specifications come into play:

- Hydraulic Cylinder Manufacturing: The heart of the hydraulic press, cylinders are often manufactured through processes like forging or machining. Precision is key, as any defects can lead to operational failures.

- Component Forming: Other parts, such as frames and plates, are shaped using bending, stamping, or welding techniques, ensuring they can withstand the pressure generated during operation.

3. Assembly

Once individual components are ready, the assembly stage begins. This phase is crucial for ensuring that all parts fit and function correctly:

- Sub-Assembly: Smaller components are first assembled into larger units (e.g., assembling the hydraulic system), allowing for easier handling.

- Main Assembly: The hydraulic press is assembled as a whole, incorporating the hydraulic cylinders, frames, and control systems. Special attention is given to alignment and fitting to ensure optimal performance.

4. Finishing

The finishing stage enhances the hydraulic press’s aesthetics and functionality:

- Surface Treatment: Processes such as painting, powder coating, or galvanizing protect against corrosion and wear.

- Final Inspection: A thorough inspection is conducted to verify that all components meet specifications before the machine is packaged for shipment.

Quality Assurance (QA) in Hydraulic Press Manufacturing

Quality assurance is vital to ensure that hydraulic press machines meet the necessary performance and safety standards. B2B buyers should be aware of the following elements of QA in the manufacturing process.

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system, focusing on consistent quality and customer satisfaction. Manufacturers should be certified to ISO 9001 to ensure their processes are standardized and effective.

- CE Marking: In Europe, hydraulic presses must comply with EU safety, health, and environmental protection standards. CE marking indicates that the product meets these requirements.

- API Standards: For manufacturers serving the oil and gas industry, adhering to API (American Petroleum Institute) standards is essential for quality and safety.

Quality Control Checkpoints

Quality control checkpoints are critical in the manufacturing process to ensure each stage meets the required standards:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps detect and rectify issues early.

- Final Quality Control (FQC): A comprehensive inspection of the finished hydraulic press ensures it meets all performance and safety standards before delivery.

Common Testing Methods

Several testing methods are employed to verify the quality and performance of hydraulic press machines:

- Hydraulic Testing: This involves pressurizing the hydraulic system to check for leaks and ensure proper functioning.

- Load Testing: The machine is subjected to maximum load conditions to verify that it can handle operational stress without failure.

- Dimensional Inspection: Precision measurements ensure that all components meet design specifications, reducing the risk of operational issues.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are actionable steps to ensure supplier reliability:

- Audits: Conduct regular audits of suppliers to assess their compliance with international quality standards. This includes reviewing their manufacturing processes and quality control systems.

- Documentation: Request detailed quality control reports and certifications from suppliers to verify their adherence to standards such as ISO 9001 and CE marking.

- Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of the supplier’s processes and products, ensuring they meet your quality requirements.

Quality Control Considerations for International Buyers

International buyers should be aware of specific nuances in quality control when sourcing hydraulic press machines:

- Cultural and Regional Variations: Understanding local manufacturing practices and quality perceptions in regions such as Africa, South America, the Middle East, and Europe can influence your supplier selection.

- Regulatory Compliance: Ensure that suppliers are familiar with the regulatory requirements of your target market, as non-compliance can lead to legal and operational challenges.

- After-Sales Support: Evaluate the supplier’s capability for after-sales service and support, including maintenance and spare parts availability, which are essential for long-term operational success.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can ensure they select reliable hydraulic press machines that meet their operational needs and comply with relevant standards.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for hydrolic press machine Sourcing

Cost Structure of Hydraulic Press Machines

Understanding the cost components involved in sourcing hydraulic press machines is crucial for international B2B buyers. The primary cost elements include:

-

Materials: The quality and type of materials used, such as steel and hydraulic components, significantly influence the cost. High-grade materials enhance durability but increase expenses.

-

Labor: Labor costs vary by region, with developed countries typically having higher wages. Skilled labor is essential for manufacturing precision machinery, impacting overall pricing.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tooling for specific applications can add to the initial investment but may be necessary for optimal machine performance and output.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, but this adds to the overall cost. Certifications (like ISO) can also increase expenses but provide assurance of quality.

-

Logistics: Shipping costs can be substantial, particularly for bulky machinery. Factors include the distance from the supplier, mode of transportation, and any tariffs or duties that may apply.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market average can help buyers negotiate better terms.

Price Influencers

Several factors can influence the pricing of hydraulic press machines:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Establishing long-term contracts may also yield favorable pricing.

-

Specifications/Customization: Custom-built machines tailored to specific operational needs may incur additional costs. Standard models are usually more cost-effective.

-

Materials: The choice of materials can vary significantly in cost. Buyers should assess whether premium materials are necessary for their applications.

-

Quality and Certifications: Machines with higher quality standards or specific certifications may command higher prices but can lead to lower maintenance costs and improved longevity.

-

Supplier Factors: Reputation, reliability, and customer service of the supplier play a significant role. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is essential as they can impact the total landed cost of the machinery.

Buyer Tips for Cost Efficiency

When sourcing hydraulic press machines, consider the following strategies to enhance cost efficiency:

-

Negotiate Pricing: Leverage your purchasing power by negotiating with suppliers. Discuss volume discounts and long-term contracts to secure better rates.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, operational costs, and potential downtime. A cheaper machine may result in higher TCO.

-

Understand Pricing Nuances: Be aware that prices may fluctuate based on market demand, geopolitical factors, and currency exchange rates. Keep abreast of industry trends to make informed decisions.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce logistics costs and lead times. Additionally, it may provide easier access to support and maintenance services.

-

Conduct Market Research: Comparing prices and specifications across different suppliers is crucial. Utilize platforms that aggregate supplier information to find competitive options.

Disclaimer

Prices for hydraulic press machines can vary widely based on the factors mentioned above and should be considered indicative. Always request detailed quotes from multiple suppliers to ensure an accurate understanding of the market landscape.

Spotlight on Potential hydrolic press machine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘hydrolic press machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for hydrolic press machine

Key Technical Properties of Hydraulic Press Machines

Understanding the technical specifications of hydraulic press machines is crucial for B2B buyers looking to make informed purchasing decisions. Below are several critical properties that should be considered:

-

Force Capacity: This specification indicates the maximum force the hydraulic press can exert, typically measured in tons. It is essential for determining whether the machine can handle the specific materials and processes required in your operations. For instance, a higher force capacity is necessary for heavy-duty applications in metal forming.

-

Stroke Length: The stroke length refers to the maximum distance the ram can travel. This property affects the size of the workpieces that can be processed and the types of operations that can be performed. A longer stroke length may be necessary for applications like deep drawing or forming large components.

-

Material Grade: The material used in the construction of the hydraulic press frame and components significantly influences its durability and performance. Common materials include high-grade steel or alloy materials, which provide the necessary strength and resistance to deformation under high pressure.

-

Precision and Tolerance: Precision refers to the machine’s ability to apply force consistently and accurately, while tolerance indicates the allowable deviation from specified dimensions in the manufactured parts. High precision and tight tolerances are critical for industries such as automotive and aerospace, where component quality is paramount.

-

Control Systems: Advanced hydraulic presses may include digital control systems that allow for precise adjustments in pressure and speed. These systems enhance operational efficiency and ensure consistent output quality, making them vital for high-volume manufacturing environments.

-

Safety Features: Essential for compliance with industry standards, safety features may include emergency stop buttons, safety guards, and overload protection. These features not only protect operators but also help to minimize downtime due to accidents.

Common Trade Terminology

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B landscape. Here are some key terms related to hydraulic press machines:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce equipment or components that are sold under another company’s brand name. Understanding OEM relationships can help buyers ensure they are purchasing genuine parts or machines that meet specific quality standards.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to know, as it can impact purchasing decisions, especially for companies looking to minimize inventory costs or trying out new products.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers requesting a detailed quote for specific products or services. It is a critical step in the procurement process, allowing buyers to compare pricing, specifications, and delivery terms.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for avoiding misunderstandings and ensuring smooth cross-border transactions.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time is crucial for planning production schedules and ensuring timely delivery of materials or equipment.

-

Service Level Agreement (SLA): An SLA is a contract that outlines the expected level of service between a supplier and a buyer. It typically includes performance metrics, responsibilities, and penalties for not meeting agreed-upon standards, ensuring accountability in supplier relationships.

By understanding these essential properties and terms, international B2B buyers can navigate the complexities of purchasing hydraulic press machines more effectively, ensuring they meet their operational needs while maximizing value.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hydrolic press machine Sector

Market Overview & Key Trends

The hydraulic press machine market is witnessing significant growth driven by several global factors, including industrialization, automation, and advancements in technology. As manufacturers in Africa, South America, the Middle East, and Europe seek to enhance productivity and efficiency, they increasingly turn to hydraulic presses for their versatility and precision. Key trends shaping this market include the rise of Industry 4.0 technologies, which integrate IoT and AI, allowing for real-time monitoring and data analytics. This shift not only optimizes operational efficiency but also facilitates predictive maintenance, reducing downtime.

Moreover, customization is becoming a prevalent trend, as businesses look for tailored solutions that fit their specific production needs. Suppliers are responding by offering more flexible and adaptable machines, which can be equipped with specialized tooling and control systems. Additionally, there is a growing demand for eco-friendly hydraulic press machines that utilize sustainable practices and materials, aligning with global sustainability goals.

International B2B buyers must navigate a complex landscape of sourcing dynamics. Factors such as geopolitical stability, trade agreements, and currency fluctuations can significantly impact procurement strategies. Engaging with reliable suppliers who demonstrate compliance with international quality standards and ethical practices is essential for mitigating risks and ensuring long-term success in this sector.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the hydraulic press machine sector, driven by increasing environmental regulations and consumer demand for responsible manufacturing. The production and operation of hydraulic machines can have notable environmental impacts, particularly concerning energy consumption and the use of hydraulic fluids. Thus, it is imperative for buyers to prioritize suppliers who adopt sustainable practices.

Ethical sourcing extends beyond environmental considerations. It encompasses the entire supply chain, emphasizing transparency and fairness. Buyers should seek partnerships with manufacturers that prioritize ethical labor practices, ensuring that their sourcing aligns with social responsibility standards.

Moreover, green certifications and the use of eco-friendly materials are gaining traction. Buyers can look for suppliers that offer hydraulic press machines designed with recyclable components or those that utilize biodegradable hydraulic fluids. Implementing these practices not only enhances a company’s brand reputation but also contributes to a more sustainable industrial ecosystem.

Brief Evolution/History

The hydraulic press machine has evolved significantly since its inception in the 17th century, when Blaise Pascal introduced the principles of hydraulic power. Initially, these machines were used in simple applications like metal shaping and forming. However, as industrial needs grew, the technology advanced, leading to the development of more complex and powerful hydraulic systems. By the 19th century, hydraulic presses became integral to manufacturing processes across various industries, including automotive and aerospace. Today, the integration of digital technologies and a focus on sustainability mark the latest phase in the evolution of hydraulic presses, ensuring their relevance in a rapidly changing industrial landscape.

This historical context provides valuable insights for B2B buyers, highlighting the importance of choosing suppliers who not only understand the technology but also embrace the innovations and ethical considerations that shape the future of manufacturing.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of hydrolic press machine

-

What factors should I consider when vetting suppliers of hydraulic press machines?

When vetting suppliers, focus on their industry experience, reputation, and financial stability. Check for certifications such as ISO 9001, which indicates quality management systems. Request references from previous clients and evaluate their responsiveness during initial communications. Additionally, consider their after-sales support and maintenance services, as this can significantly impact your operations in the long run. -

Can I customize hydraulic press machines to suit specific applications?

Yes, many manufacturers offer customization options for hydraulic press machines. You can request modifications such as specialized tooling, enhanced safety features, or specific operational capacities. It’s important to clearly communicate your requirements during the initial discussions and ensure that the supplier has a robust process for implementing custom solutions. -

What are the typical minimum order quantities (MOQ) and lead times for hydraulic press machines?

MOQs can vary significantly depending on the manufacturer and the complexity of the machine. Standard hydraulic presses might have an MOQ of one unit, while custom machines could require larger orders. Lead times typically range from 4 to 12 weeks, depending on the customization level and the supplier’s production capacity. Always confirm these details during negotiations to avoid unexpected delays. -

What payment options are available when purchasing hydraulic press machines internationally?

Payment options can include bank transfers, letters of credit, or payment through escrow services. For large purchases, letters of credit are often preferred as they provide security for both parties. Ensure you have a clear agreement on payment terms before finalizing the order, and consider negotiating partial payments, with a deposit upfront and the balance upon delivery. -

What quality assurance practices should I look for in suppliers?

Suppliers should have comprehensive quality assurance processes, including regular testing and inspection of their products. Look for certifications such as CE marking or compliance with relevant international standards. Request documentation of quality control measures, including test reports, and inquire about their process for handling defective units or warranty claims. -

How can I ensure smooth logistics when importing hydraulic press machines?

Collaborate with your supplier to understand the logistics process, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling machinery imports, and confirm that the supplier provides all necessary shipping documents. Additionally, consider the impact of tariffs and duties in your total cost analysis to avoid unexpected expenses. -

What should I do if there is a dispute with a supplier?

In the event of a dispute, first try to resolve the issue amicably through direct communication with the supplier. Document all communications and agreements. If the situation escalates, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Engaging legal counsel familiar with international trade can also provide guidance on your rights and options. -

Are there specific certifications I should look for when sourcing hydraulic press machines?

Yes, look for certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and CE marking for compliance with European safety standards. If you are sourcing from specific regions, ensure that the supplier meets local regulations and standards. This not only guarantees quality but also ensures that the machinery is safe and compliant for use in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hydrolic press machine

In conclusion, the strategic sourcing of hydraulic press machines is pivotal for international B2B buyers looking to optimize their manufacturing processes. Key takeaways include the importance of understanding various types of hydraulic presses—such as C-frame and H-frame models—and their specific applications. Buyers should prioritize precision, control, and customization options to meet their unique operational needs.

Value of Strategic Sourcing:

By leveraging strategic sourcing, companies can enhance operational efficiency, reduce costs, and improve product quality. This approach allows businesses to identify reliable suppliers, negotiate favorable terms, and ensure timely delivery of high-quality machinery, which is crucial in competitive markets across Africa, South America, the Middle East, and Europe.

Looking Ahead:

As industries evolve and demand for advanced manufacturing solutions increases, the role of hydraulic press machines will only grow. International buyers are encouraged to stay informed about technological advancements and emerging trends in hydraulic systems. Now is the time to invest in innovative machinery that can elevate your production capabilities. Engage with reputable manufacturers and suppliers today to secure a competitive edge in your market.