Your Ultimate Guide to Sourcing Infrared Oven

Introduction: Navigating the Global Market for infrared oven

Navigating the global market for infrared ovens presents a unique opportunity for international B2B buyers seeking efficient thermal processing solutions. As industries across Africa, South America, the Middle East, and Europe increasingly adopt advanced technologies, infrared ovens have emerged as a critical tool for enhancing production efficiency, reducing energy consumption, and improving product quality. These innovative ovens utilize infrared radiation to deliver rapid and targeted heating, making them ideal for diverse applications ranging from food processing to industrial manufacturing.

This comprehensive guide aims to empower B2B buyers with the knowledge necessary to make informed sourcing decisions. It will explore various types of infrared ovens, including electric, gas catalytic, and hybrid models, alongside their respective applications and benefits. Additionally, the guide will cover essential aspects such as manufacturing quality control, supplier selection, and cost considerations, ensuring that buyers understand the market landscape thoroughly.

By providing insights into the latest trends, technological advancements, and best practices in sourcing infrared ovens, this guide equips businesses with the tools to enhance their operational capabilities. Whether you are in South Africa, the UAE, or any other region, understanding the nuances of infrared oven technology will enable you to make strategic investments that drive growth and efficiency in your operations.

Understanding infrared oven Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Infrared Ovens | Rapid heat-up, precise temperature control, energy-efficient | Laminating, adhesive curing, food processing, metal heating | Pros: Fast ramp-up, uniform heating. Cons: Higher initial costs. |

| Gas Catalytic Infrared Ovens | Utilizes catalytic reaction for heating, low energy consumption | Powder coating pre-gelling, paint drying | Pros: Energy-efficient, quick processing. Cons: Limited to specific applications. |

| Infrared Convection Combination Ovens | Combines infrared and convection heating for uniformity | Curing coatings, industrial drying, composite fabrication | Pros: Versatile, improved heating consistency. Cons: More complex systems may require higher maintenance. |

| Infrared Curing Ovens | Designed for specialized coating processes | Automotive, aerospace, and electronics industries | Pros: Effective for specific coatings. Cons: May require specific setup and training. |

| Industrial Conveyor Ovens | Continuous operation with conveyor systems | High-volume production lines, food processing | Pros: Efficient for mass production. Cons: Requires space and setup for conveyor systems. |

Electric Infrared Ovens

Electric infrared ovens are characterized by their rapid heat-up times and precise temperature control, which make them ideal for processes requiring energy efficiency and uniform heating. They are widely used in applications such as laminating, adhesive curing, and food processing. When considering an electric infrared oven, buyers should evaluate the initial investment against long-term energy savings and operational efficiency, as these ovens often come with higher upfront costs but can lead to significant productivity gains.

Gas Catalytic Infrared Ovens

Gas catalytic infrared ovens generate heat through a catalytic reaction using natural gas or propane. This type of oven is particularly suited for powder coating processes where pre-gelling is necessary before the main curing stage. The key benefits include reduced energy consumption and quicker line speeds, making them attractive for manufacturers focused on efficiency. Buyers should consider the specific requirements of their coating processes and the compatibility of gas sources when opting for this type of oven.

Infrared Convection Combination Ovens

These ovens integrate both infrared and convection heating technologies, delivering rapid heat-up while ensuring uniform temperature distribution. This combination is especially beneficial for applications that require both surface and bulk heating, such as curing coatings and industrial drying. Buyers should assess their production needs to determine if the enhanced versatility and efficiency of these hybrid ovens justify the potentially higher complexity and maintenance requirements.

Infrared Curing Ovens

Infrared curing ovens are engineered specifically for coating processes, making them essential in industries such as automotive, aerospace, and electronics. Their design focuses on optimizing the curing of specific materials, ensuring high-quality finishes. When purchasing, buyers should consider the specific coatings and materials they intend to use, as well as the need for specialized training to operate these ovens effectively.

Industrial Conveyor Ovens

Industrial conveyor ovens are designed for continuous operation, making them ideal for high-volume production lines. They are commonly employed in food processing and other industries where consistent heating is crucial. Buyers must evaluate the space requirements and integration with existing production systems, as these ovens typically require a significant footprint and setup for conveyor mechanisms, but they offer substantial efficiency gains for mass production processes.

Related Video: Induction vs Infrared cooker | Difference between Infrared and Induction cooker in detail.

Key Industrial Applications of infrared oven

| Industry/Sector | Specific Application of Infrared Oven | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Curing paint and coatings | Enhanced finish quality and reduced drying time | Ensure compatibility with existing production lines and coatings used. |

| Food Processing | Cooking and drying food products | Improved efficiency and better product quality | Check for compliance with food safety standards and energy efficiency ratings. |

| Plastics and Composites | Laminating and thermoforming | Faster processing times and reduced energy consumption | Assess the oven’s temperature control and uniformity for specific materials. |

| Electronics | Soldering and curing electronic components | Increased production speed and reliability | Evaluate the oven’s precision and ability to handle varying component sizes. |

| Textile Industry | Drying and curing textile coatings | Higher throughput and improved color retention | Confirm the oven’s capacity and adaptability to different fabric types. |

Automotive Manufacturing

In the automotive sector, infrared ovens are primarily utilized for curing paint and coatings. This application significantly reduces drying times while enhancing the quality of the finish, leading to superior aesthetics and durability. For international buyers, particularly in regions like South Africa and the UAE, it’s essential to ensure that the infrared ovens are compatible with existing production lines and the specific coatings used. Additionally, understanding energy consumption and maintenance needs can impact overall operational costs.

Food Processing

Infrared ovens are increasingly adopted in food processing for cooking and drying food products. This technology provides rapid heating, leading to improved efficiency and better retention of taste and texture. B2B buyers from Africa and South America should prioritize ovens that comply with local food safety standards while also being energy-efficient. The ability to handle various food types and sizes is crucial for meeting diverse processing requirements.

Plastics and Composites

In the plastics and composites industry, infrared ovens are used for laminating and thermoforming processes. These ovens facilitate faster processing times, which can lead to higher productivity and reduced energy consumption. For buyers in Europe and the Middle East, assessing the oven’s temperature control and uniformity is vital to ensure optimal results for specific materials. Customization options to fit unique production needs can also be a key factor in the sourcing decision.

Electronics

Infrared ovens play a critical role in soldering and curing electronic components, enabling increased production speed and reliability. The precise heating capabilities of these ovens help prevent damage to sensitive components while ensuring effective soldering. International buyers should evaluate the oven’s precision and capability to accommodate varying component sizes and shapes. Understanding the specific heating requirements for different electronic applications will aid in selecting the right equipment.

Textile Industry

In the textile industry, infrared ovens are employed for drying and curing textile coatings, resulting in higher throughput and improved color retention. This technology ensures that textiles are treated uniformly, enhancing the overall quality of the finished product. Buyers from diverse regions should confirm the oven’s capacity to handle different fabric types and production volumes, as well as its adaptability to specific coating processes. Ensuring that the equipment meets local regulations and standards will also be crucial for successful implementation.

Related Video: Industrial Powder Coating Oven Technology. Introduction to Infrared Heating Technology

Strategic Material Selection Guide for infrared oven

When selecting materials for infrared ovens, it’s crucial to consider the specific performance characteristics required for optimal operation. Below are analyses of four common materials used in the construction of infrared ovens, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance and high-temperature tolerance, making it suitable for environments where moisture and heat are prevalent. It typically withstands temperatures up to 800°C (1472°F) without losing structural integrity.

Pros & Cons:

Stainless steel is durable and easy to clean, which is essential for maintaining hygiene in food processing applications. However, it can be more expensive than other materials, and its manufacturing complexity may increase production costs.

Impact on Application:

Stainless steel is compatible with various media, including food products and chemicals, making it ideal for diverse applications. Its resistance to corrosion ensures longevity, reducing maintenance costs.

Considerations for International Buyers:

Buyers should ensure compliance with local standards, such as ASTM A240 for stainless steel, and consider the availability of specific grades in their region. In markets like South Africa and the UAE, sourcing high-quality stainless steel may be critical due to varying local standards.

2. Aluminum

Key Properties:

Aluminum is lightweight and has excellent thermal conductivity, which allows for rapid heating and cooling. It can typically handle temperatures up to 400°C (752°F) effectively.

Pros & Cons:

Aluminum is generally less expensive than stainless steel, making it a cost-effective choice for many applications. However, it is less durable under high-temperature conditions and can be prone to warping or deformation.

Impact on Application:

Due to its thermal properties, aluminum is ideal for applications requiring quick heat transfer, such as in food processing and lightweight components. However, its lower temperature tolerance may limit its use in high-heat applications.

Considerations for International Buyers:

Buyers should be aware of the specific alloy used, as different alloys offer varying degrees of strength and corrosion resistance. Compliance with standards such as ASTM B221 is essential for ensuring quality in regions like Europe and South America.

3. Ceramic

Key Properties:

Ceramic materials are highly resistant to heat and can withstand temperatures exceeding 1200°C (2192°F). They also exhibit excellent thermal insulation properties.

Pros & Cons:

Ceramics are durable and resistant to thermal shock, making them suitable for high-temperature applications. However, they can be brittle, leading to potential breakage during handling or installation.

Impact on Application:

Ceramics are often used in infrared emitters due to their ability to efficiently convert electrical energy into infrared radiation. Their compatibility with high temperatures makes them ideal for industrial applications.

Considerations for International Buyers:

Buyers should consider the specific type of ceramic, as some may require specialized handling or installation techniques. Compliance with international standards like ISO 13006 is important for ensuring product quality.

4. Quartz

Key Properties:

Quartz is a type of glass that can withstand high temperatures (up to 1000°C or 1832°F) and is known for its excellent transparency to infrared radiation.

Pros & Cons:

Quartz is effective in transmitting infrared energy, making it ideal for heating applications. However, it can be more expensive than other materials and is susceptible to thermal shock.

Impact on Application:

Due to its ability to emit infrared radiation efficiently, quartz is commonly used in infrared heating elements. Its transparency ensures minimal energy loss during heating processes.

Considerations for International Buyers:

Buyers should ensure that quartz components meet relevant safety standards, particularly in regions with stringent regulations, such as Europe. Understanding local sourcing options for high-quality quartz can also impact overall project costs.

Summary Table

| Material | Typical Use Case for infrared oven | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, industrial applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight components, food processing | Cost-effective and lightweight | Lower temperature tolerance | Medium |

| Ceramic | Infrared emitters, high-temperature applications | High temperature resistance | Brittle and prone to breakage | Medium |

| Quartz | Heating elements in infrared ovens | Efficient infrared transmission | Susceptible to thermal shock | High |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when sourcing infrared ovens, ensuring compatibility with their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for infrared oven

The manufacturing processes and quality assurance for infrared ovens are critical for ensuring high performance, safety, and longevity. Understanding these processes can empower international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Manufacturing Process

The production of infrared ovens typically involves several key stages, each crucial for achieving the desired quality and performance. Here’s a breakdown of these stages:

1. Material Preparation

The manufacturing process begins with the careful selection and preparation of raw materials. Common materials used in infrared ovens include high-quality metals for the frame, heat-resistant ceramics for the emitters, and insulation materials to minimize heat loss.

- Material Sourcing: Ensure that materials meet international quality standards (e.g., ASTM, ISO).

- Pre-Treatment: Metals may undergo processes such as cleaning, de-greasing, and surface treatment to enhance durability.

2. Forming

Once the materials are prepared, they are shaped and formed into the components of the infrared oven. This stage includes:

- Metal Fabrication: Utilizing techniques such as laser cutting, bending, and welding to create the oven body and structural components.

- Emitter Production: Infrared emitters are produced from specialized materials like quartz or ceramic, designed for optimal radiant heat output.

3. Assembly

The assembly stage involves the integration of all components into a cohesive unit. This includes:

- Component Integration: Careful assembly of the oven body, heating elements, insulation, and control systems.

- Electrical Wiring: Skilled technicians connect the electrical components, ensuring compliance with safety standards.

4. Finishing

The finishing stage enhances both the aesthetic and functional aspects of the oven.

- Surface Treatment: Coatings or paints may be applied to prevent corrosion and enhance appearance.

- Quality Checks: Initial quality checks occur to ensure all components function as intended before final testing.

Quality Assurance

Quality assurance is vital in the manufacturing of infrared ovens to maintain safety and performance standards. Here are the key aspects of quality assurance relevant to B2B buyers:

International Standards

Compliance with international quality standards is essential. Key standards include:

- ISO 9001: A framework for quality management systems that helps manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Important for manufacturers dealing with oil and gas applications, ensuring equipment meets stringent safety and performance criteria.

Quality Control Checkpoints

Quality control (QC) is typically implemented at several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials and components before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product before it is shipped.

Common Testing Methods

Several testing methods are employed to ensure infrared ovens meet quality standards:

- Thermal Efficiency Testing: Measures how effectively the oven converts energy into heat.

- Safety Testing: Includes checks for electrical safety and heat resistance.

- Functional Testing: Ensures that all operational features work correctly and meet specified performance criteria.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are strategies for ensuring supplier reliability:

- Supplier Audits: Conduct on-site audits to assess the manufacturing processes, quality control measures, and compliance with international standards.

- Request Quality Reports: Ask suppliers for documentation related to their quality management systems, including certifications and test results.

- Third-Party Inspections: Consider hiring independent inspectors to evaluate the manufacturing facility and processes, ensuring unbiased assessments.

QC/Certifications Nuances for International Buyers

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of certifications and quality control is vital.

- Regional Compliance: Be aware of specific regulations that may vary by country or region, such as environmental standards or safety protocols.

- Local Partnerships: Collaborating with local partners can provide insights into the supplier’s reputation and adherence to quality standards within the region.

- Documentation: Ensure that all necessary documentation, including compliance certificates and testing reports, are available in a language and format that is easily understandable.

Conclusion

By comprehensively understanding the manufacturing processes and quality assurance measures for infrared ovens, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. Engaging with suppliers who prioritize quality and adhere to international standards will not only safeguard investments but also enhance operational efficiency in the long run.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for infrared oven Sourcing

When sourcing infrared ovens, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis breaks down the primary cost components, price influencers, and provides actionable tips for negotiations and cost management, particularly for buyers in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The raw materials used in infrared ovens, such as specialized metals, ceramics, and heating elements, significantly impact costs. The quality of these materials dictates durability and performance, influencing the overall pricing.

-

Labor: Labor costs encompass the workforce involved in manufacturing, engineering, and quality control. Skilled labor is essential, particularly for custom designs, which can elevate costs due to the need for specialized expertise.

-

Manufacturing Overhead: This includes costs related to the operational facilities, utilities, and administrative expenses. A manufacturer with a streamlined operation may offer more competitive pricing compared to those with higher overhead costs.

-

Tooling: For custom infrared ovens, tooling costs can be substantial. This includes the design and creation of molds and fixtures necessary for production. Buyers should consider how tooling expenses can be amortized over larger production runs.

-

Quality Control (QC): Rigorous QC processes ensure the reliability and safety of infrared ovens. The costs associated with testing and certification can vary widely based on the complexity of the product and the certifications required for different markets.

-

Logistics: Transporting ovens from manufacturers to buyers involves shipping, handling, and customs clearance costs. These can be significant, especially for international shipments where tariffs and duties may apply.

-

Margin: Manufacturers typically mark up prices to ensure profitability. Understanding the margin expectations of suppliers can help buyers gauge the fairness of quotes received.

Price Influencers

-

Volume/MOQ: Pricing is often tiered based on the minimum order quantity (MOQ). Larger orders can lead to bulk discounts, so negotiating for higher volumes can yield better pricing.

-

Specifications/Customization: Custom features or specifications can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Materials and Quality/Certifications: Higher quality materials and additional certifications (like ISO or CE) can drive up costs. Buyers should balance the need for certifications with the associated costs.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers with a track record of reliability may charge more but offer better support and quality assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) will affect the total landed cost. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears various costs and risks during transportation.

Buyer Tips

-

Negotiation: Leverage your position as a buyer by negotiating terms and pricing. Consider discussing payment terms, volume discounts, and delivery timelines to optimize costs.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes initial purchase price, operational costs (like energy consumption), maintenance, and potential downtime. A higher upfront cost may lead to lower long-term operational expenses.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa or South America should be aware of fluctuating currency rates and import duties that can affect pricing. It’s advisable to factor these into overall budget planning.

-

Disclaimer for Indicative Prices: It’s important to note that pricing for infrared ovens can vary widely based on the factors discussed above. Buyers should obtain multiple quotes and conduct thorough due diligence before making purchasing decisions.

By understanding these components and influences, B2B buyers can make informed decisions when sourcing infrared ovens, ensuring they achieve the best value for their investments.

Spotlight on Potential infrared oven Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘infrared oven’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for infrared oven

Infrared ovens are sophisticated tools essential for a wide range of industrial applications, characterized by specific technical properties and industry terminology that are crucial for B2B buyers. Understanding these aspects can greatly influence purchasing decisions and operational efficiency.

Key Technical Properties of Infrared Ovens

-

Heating Element Material

Infrared ovens typically utilize heating elements made from materials like ceramic, quartz, or metal. The choice of material affects the oven’s thermal efficiency and durability. High-quality materials can withstand extreme temperatures and provide consistent heating, making them essential for processes such as curing and drying. -

Temperature Range

The temperature range of an infrared oven indicates its capability to perform various heating tasks. Most industrial infrared ovens can reach temperatures between 100°C to 600°C. Understanding the required temperature range for specific applications is vital to ensure that the oven can meet operational demands without compromising product quality. -

Watt Density

Watt density refers to the amount of power (in watts) applied per unit area of the heating element. Higher watt densities can lead to faster heating times and improved processing efficiency. Buyers should assess the watt density based on the speed and efficiency required for their specific applications, particularly in high-volume production settings. -

Oven Size and Configuration

The size and configuration of an infrared oven are critical for fitting into existing production lines and accommodating the dimensions of the materials being processed. Options range from compact batch ovens to large conveyor systems. Buyers must consider their production capacity and space constraints when selecting the appropriate oven configuration. -

Control Systems

Advanced control systems enhance precision in temperature regulation and process monitoring. Look for ovens equipped with digital interfaces and programmable settings, which allow for automation and improved consistency in manufacturing processes. This feature is especially important for industries requiring strict compliance with quality standards. -

Energy Efficiency

The energy efficiency of an infrared oven can significantly impact operational costs. Ovens designed to minimize heat loss and optimize energy consumption help reduce utility expenses and environmental impact. Buyers should evaluate energy ratings and operational costs when selecting ovens for long-term investments.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing high-quality components and ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand their purchasing thresholds and negotiate better terms, especially when dealing with custom or specialized infrared ovens. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products. This process is essential for comparing different suppliers and ensuring that the best price and terms are secured for infrared ovens. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery obligations, which are critical for international procurement. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. It is a vital consideration for planning production schedules and inventory management. Buyers should inquire about lead times to avoid disruptions in their operations. -

Certification Standards

Certification standards indicate compliance with industry regulations and safety standards. Understanding these certifications is crucial for ensuring that the infrared ovens meet local and international quality requirements, safeguarding both the buyer’s investment and operational integrity.

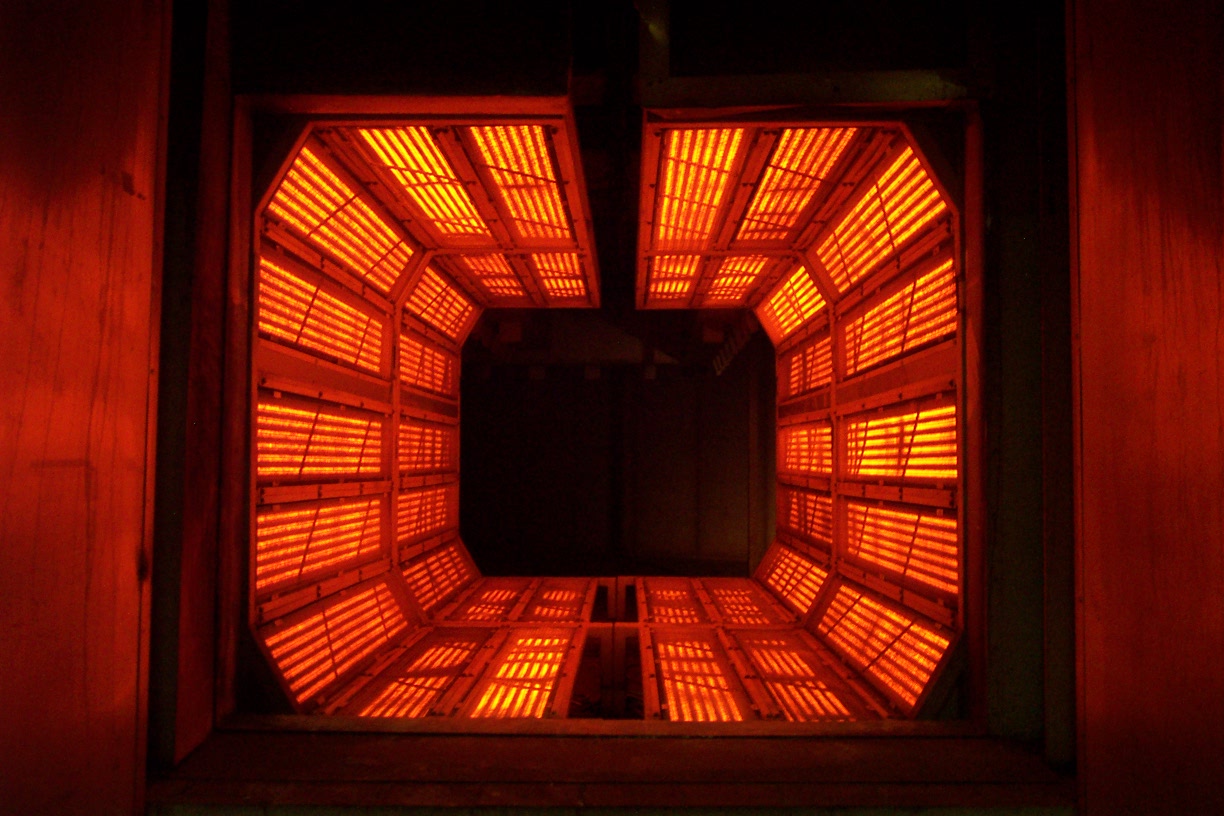

Illustrative Image (Source: Google Search)

Incorporating this knowledge into purchasing strategies can enhance decision-making and ensure the selection of infrared ovens that align with operational needs and industry standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the infrared oven Sector

Global drivers are shaping the infrared oven market, as businesses seek enhanced efficiency and rapid processing capabilities. The rise of automation and Industry 4.0 technologies is pushing manufacturers to adopt advanced thermal solutions that integrate seamlessly with smart factory systems. Additionally, the growing demand for energy-efficient equipment is compelling organizations across Africa, South America, the Middle East, and Europe to invest in infrared ovens, which are known for their rapid heating and lower operational costs compared to traditional ovens.

Illustrative Image (Source: Google Search)

Emerging B2B trends highlight the increasing preference for customized solutions tailored to specific industry needs, such as food processing, automotive, and aerospace. Buyers are looking for suppliers that can provide turn-key solutions that include installation, training, and ongoing support. Moreover, the trend toward hybrid systems, such as infrared convection combination ovens, is gaining traction due to their ability to optimize heating efficiency and product quality.

Market dynamics are also influenced by geopolitical factors and trade agreements. In regions like the Middle East and Africa, local suppliers are becoming more competitive, providing buyers with diverse sourcing options. This regional shift necessitates a careful evaluation of supply chain resilience, as buyers should consider suppliers’ geographic proximity, logistical capabilities, and compliance with international standards.

Sustainability & Ethical Sourcing in B2B

The environmental impact of industrial operations is a pressing concern for B2B buyers in the infrared oven sector. Infrared ovens, particularly electric models, offer significant advantages in reducing energy consumption, which can lead to lower greenhouse gas emissions. As sustainability becomes a core business strategy, buyers should prioritize suppliers who demonstrate a commitment to eco-friendly practices.

Ethical sourcing is equally important. Buyers should assess suppliers based on their adherence to environmental regulations and their use of sustainable materials in manufacturing. Certifications such as ISO 14001 (Environmental Management) and Energy Star can serve as indicators of a supplier’s dedication to sustainability. Moreover, the demand for green materials and recyclable components is on the rise, as companies seek to minimize their carbon footprint throughout the product lifecycle.

Investing in suppliers who prioritize sustainability not only enhances brand reputation but can also lead to cost savings through energy efficiency and waste reduction. As global regulations tighten, aligning with ethical suppliers is critical for long-term operational viability and compliance.

Brief Evolution/History

The infrared oven has evolved significantly since its inception in the mid-20th century. Initially used primarily in the food industry for cooking and heating, advancements in materials science and heating technologies have expanded their application across various industrial sectors.

In the late 20th century, the introduction of electric infrared ovens revolutionized manufacturing processes, allowing for more precise temperature control and faster processing times. Today, infrared ovens are integral in diverse applications, from curing paints and coatings to drying textiles and food products. This evolution reflects a broader shift toward efficiency and sustainability in industrial practices, catering to the growing demands of global markets.

As international B2B buyers navigate this dynamic landscape, understanding the evolution of infrared oven technology can provide valuable insights into supplier capabilities and market opportunities.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of infrared oven

-

What should I consider when vetting suppliers for infrared ovens?

When vetting suppliers, focus on their industry experience, reputation, and customer reviews. Check for certifications like ISO 9001 or industry-specific standards that ensure quality and compliance. Inquire about their manufacturing capabilities, including technology used and customization options. It’s also beneficial to ask for case studies or references from similar industries to gauge their expertise in your specific application. Additionally, assess their responsiveness and communication skills, as these are critical for long-term partnerships. -

Can infrared ovens be customized to meet specific application needs?

Yes, many manufacturers offer customization options to tailor infrared ovens to specific applications. You can request modifications in size, heating elements (electric or gas), and control systems. Discuss your process requirements, such as temperature ranges and throughput, with the supplier’s engineering team to ensure the design meets your operational needs. Be prepared to provide detailed specifications and examples of your products to facilitate a more accurate customization process. -

What are the typical minimum order quantities (MOQ) and lead times for infrared ovens?

Minimum order quantities can vary significantly based on the supplier and the complexity of the oven. Custom infrared ovens often have higher MOQs due to the bespoke nature of manufacturing. Lead times typically range from 6 to 12 weeks, depending on the customization level and supplier workload. It’s essential to discuss these aspects upfront to align your project timelines with the supplier’s production capabilities, especially when planning for peak operational periods. -

What payment terms should I expect when purchasing an infrared oven?

Payment terms can differ by supplier but generally include options such as a deposit upfront (commonly 30-50%) with the balance due upon delivery or installation. Some suppliers may offer financing or leasing options, which can ease budget constraints. Always clarify payment methods accepted (bank transfers, letters of credit, etc.) and any implications for international transactions, such as currency exchange rates and transaction fees. -

What quality assurance processes should be in place for infrared ovens?

Reputable manufacturers should have a comprehensive quality assurance (QA) program that includes in-process inspections, final testing, and certifications. Request documentation on the QA processes and any relevant certifications that guarantee product reliability and safety. Inquire about the testing methods used, such as performance under extreme conditions, and whether they offer trial runs before shipment to ensure the oven meets your specifications. -

How do logistics and shipping work for international purchases of infrared ovens?

Logistics for international shipments of infrared ovens typically involve collaboration between the buyer and supplier to manage transportation, customs clearance, and delivery. Discuss the shipping methods available (e.g., sea freight, air freight) and the associated costs. Make sure to clarify who bears responsibility for customs duties and taxes in your country. It’s also advisable to have a logistics plan in place for installation and setup upon arrival, including any necessary local regulations or certifications. -

What steps can I take to resolve disputes with suppliers?

To mitigate disputes, establish clear contracts detailing terms of service, delivery timelines, and payment conditions. Maintain open communication throughout the transaction process to address issues promptly. If a dispute arises, attempt to resolve it amicably through direct negotiation. If necessary, refer to the contract for dispute resolution clauses, which may include mediation or arbitration. Document all communications and agreements to support your position if the issue escalates. -

What certifications should I look for in infrared ovens to ensure safety and compliance?

Look for internationally recognized certifications such as CE marking for compliance with European safety standards, UL certification for North American markets, and ISO certifications that reflect quality management practices. Inquire whether the ovens comply with local regulations in your market, such as those pertaining to environmental impact and energy efficiency. Ensuring that your supplier provides these certifications helps mitigate risks associated with safety and regulatory compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for infrared oven

In conclusion, strategic sourcing of infrared ovens presents a unique opportunity for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. By understanding the diverse applications and benefits of infrared technology, organizations can significantly enhance their production efficiency, reduce energy consumption, and improve product quality. Key considerations include evaluating the specific heating needs, energy sources, and integration capabilities of infrared ovens to ensure alignment with operational goals.

The value of strategic sourcing cannot be overstated; it enables businesses to identify reliable suppliers, negotiate favorable terms, and ensure that the selected oven systems meet stringent performance and safety standards. With the right partnerships, buyers can tap into cutting-edge technology that not only meets their immediate needs but also positions them for future growth.

As the demand for efficient thermal processing solutions continues to rise, now is the time to engage with reputable manufacturers and explore customized options that cater to your unique application requirements. Take the next step in your sourcing journey—evaluate your current processes, reach out to suppliers, and discover how infrared ovens can transform your operations into a competitive advantage.