Your Ultimate Guide to Sourcing Linear Bearing

Introduction: Navigating the Global Market for linear bearing

Navigating the global market for linear bearings is essential for B2B buyers seeking to enhance their operational efficiency and product reliability. Linear bearings play a critical role in diverse applications, from automation and robotics to manufacturing and material handling. Their ability to facilitate smooth, precise linear motion makes them indispensable in machinery and equipment across various industries.

This comprehensive guide aims to empower international buyers, particularly from Africa, South America, the Middle East, and Europe, by providing a wealth of information on linear bearings. Within these pages, you will find detailed insights into different types of linear bearings, including ball and roller configurations, and the materials used in their construction, which can significantly impact performance and longevity.

Additionally, we delve into manufacturing and quality control processes, ensuring that you understand the standards to look for when sourcing these critical components. A thorough analysis of market trends and pricing strategies will also be included, equipping you with the knowledge to make informed purchasing decisions.

Moreover, we address frequently asked questions, clarifying common misconceptions and providing actionable guidance to streamline your sourcing efforts. By leveraging this guide, buyers can navigate the complexities of the linear bearing market with confidence, ultimately enhancing their supply chain and operational success.

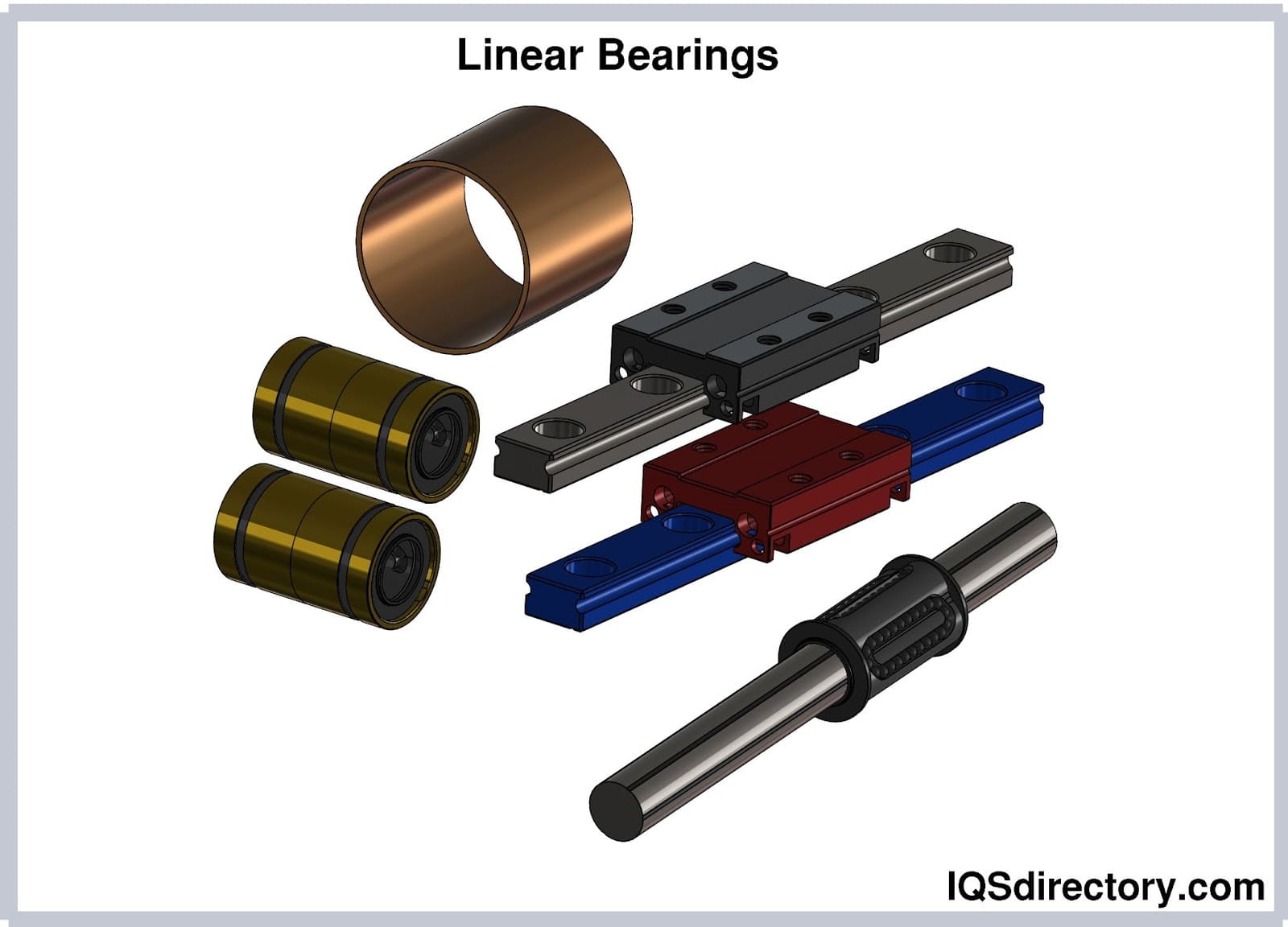

Understanding linear bearing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ball Linear Bearings | Utilize balls to reduce friction; high load capacity | Automation, CNC machines, robotics | Pros: Smooth operation, high precision. Cons: Sensitive to dirt and debris. |

| Roller Linear Bearings | Employ cylindrical rollers for load distribution; robust | Heavy machinery, material handling | Pros: Greater load capacity, durability. Cons: Higher friction than ball bearings. |

| Magnetic Linear Bearings | Use magnetic fields for contactless motion; low friction | Semiconductor manufacturing, cleanrooms | Pros: No wear, maintenance-free. Cons: Higher initial cost, complex setup. |

| Plastic Linear Bearings | Made from polymer materials; lightweight and corrosion-resistant | Food processing, medical devices | Pros: Cost-effective, resistant to chemicals. Cons: Lower load capacity than metal bearings. |

| Linear Guide Rails | Integrated rail system providing stability and guidance | Assembly lines, packaging machines | Pros: High rigidity, easy installation. Cons: Requires precise alignment. |

Ball Linear Bearings

Ball linear bearings consist of balls that roll between the bearing surfaces, providing low friction and high precision. They are ideal for applications requiring smooth motion and accuracy, such as automation and CNC machines. When purchasing, buyers should consider the operating environment, as these bearings can be sensitive to contaminants like dust and dirt, which can impact performance and lifespan.

Roller Linear Bearings

Roller linear bearings utilize cylindrical rollers to distribute loads evenly, making them suitable for heavy-duty applications such as material handling and industrial machinery. They offer higher load capacities compared to ball bearings, but buyers should be mindful that they may generate more friction, which can affect speed and efficiency. Additionally, ensuring proper lubrication and maintenance is crucial for optimal performance.

Magnetic Linear Bearings

Magnetic linear bearings operate without physical contact, utilizing magnetic fields to achieve motion. This feature makes them particularly valuable in cleanroom environments and semiconductor manufacturing, where contamination is a concern. While they eliminate wear and maintenance needs, the initial investment can be higher, and the setup may require specialized knowledge, which buyers must consider.

Plastic Linear Bearings

Constructed from advanced polymer materials, plastic linear bearings are lightweight and resistant to corrosion, making them an excellent choice for industries like food processing and medical applications. They are generally more cost-effective than metal alternatives, but buyers should assess their load capacity, as they may not be suitable for high-load applications. Understanding the specific chemical and environmental conditions is essential for ensuring longevity.

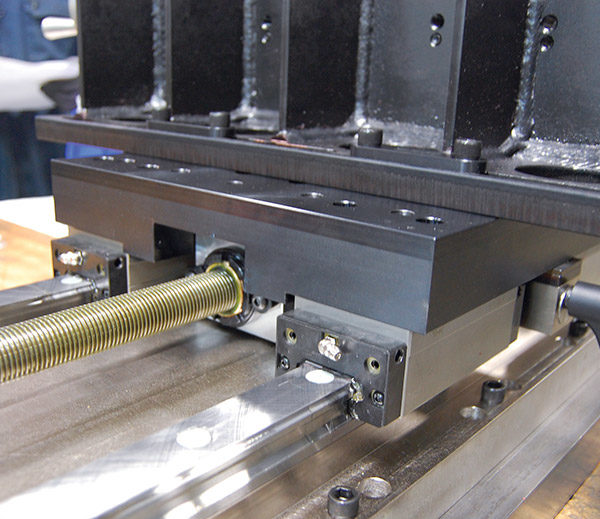

Linear Guide Rails

Linear guide rails provide a robust framework for motion systems, offering stability and guidance for moving components. They are commonly used in assembly lines and packaging machines. While they are relatively easy to install, buyers must ensure precise alignment during installation to prevent performance issues. The rigidity and reliability of guide rails can significantly enhance operational efficiency, making them a valuable investment for businesses focused on automation.

Related Video: Linear Bearings 101 – What is a Linear Slide Bearing and how do they work.

Key Industrial Applications of linear bearing

| Industry/Sector | Specific Application of Linear Bearing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machinery | Enhanced precision and reduced maintenance costs. | Ensure compatibility with existing machinery and specifications for load capacity. |

| Automation & Robotics | Robotic Arms | Improved speed and accuracy in automated processes. | Look for lightweight materials and high durability ratings to withstand repeated use. |

| Medical Equipment | Surgical Instruments | Increased reliability and precision in critical applications. | Compliance with medical standards and certifications is essential for sourcing. |

| Transportation | Rail Systems | Greater stability and reduced friction for safety. | Consider environmental factors like humidity and temperature for material selection. |

| Packaging | Automated Packaging Lines | Faster production rates and reduced downtime. | Evaluate the bearing’s load rating and lubrication requirements for optimal performance. |

Detailed Applications

Manufacturing: CNC Machinery

In the manufacturing sector, linear bearings are integral to CNC (Computer Numerical Control) machines, which require high precision for cutting and shaping materials. These bearings allow for smooth linear motion, reducing friction and wear on machine components. For international buyers, particularly in regions like Africa and South America, sourcing high-quality linear bearings that meet stringent specifications can lead to significant reductions in maintenance costs and improved operational efficiency.

Automation & Robotics: Robotic Arms

Linear bearings play a crucial role in the operation of robotic arms used in automation. They facilitate smooth and precise movements, which are essential for tasks such as assembly, welding, and material handling. For buyers in the Middle East and Europe, the focus should be on sourcing lightweight bearings that can handle high speeds and cycles, thereby enhancing productivity and reducing energy consumption in automated processes.

Medical Equipment: Surgical Instruments

In the medical field, linear bearings are used in surgical instruments and robotic surgical systems to ensure precision and reliability during operations. The performance of these bearings directly impacts patient safety and outcomes. Buyers must prioritize sourcing from manufacturers that comply with medical device regulations and standards, ensuring that the bearings can withstand sterilization processes without compromising quality.

Transportation: Rail Systems

Linear bearings are essential in rail systems, providing stability and reducing friction in train movements. This application is critical for maintaining safety and efficiency in transportation networks. International buyers should consider the environmental conditions in which these bearings will operate, such as humidity and temperature extremes, to select materials that will endure without degradation.

Packaging: Automated Packaging Lines

In the packaging industry, linear bearings enhance the performance of automated packaging lines by allowing for faster and more efficient movement of products. This results in higher production rates and lower downtime. Buyers should evaluate the load ratings and lubrication needs of the bearings to ensure they can withstand the demands of high-speed operations, particularly in regions with varying operational conditions.

Strategic Material Selection Guide for linear bearing

When selecting materials for linear bearings, international B2B buyers must consider various factors that impact performance, cost, and suitability for specific applications. Here, we analyze four common materials used in linear bearings: steel, aluminum, plastic, and ceramic. Each material possesses unique properties that can significantly influence the operational efficiency and longevity of linear bearing systems.

Illustrative Image (Source: Google Search)

Steel

Key Properties:

Steel is known for its high strength and durability, making it suitable for high-load applications. It typically offers good wear resistance and can withstand elevated temperatures, making it ideal for industrial environments.

Pros & Cons:

The primary advantage of steel is its robustness, which translates to longer service life under heavy loads. However, steel bearings can be prone to corrosion if not properly treated, which may necessitate additional coatings or treatments, increasing manufacturing complexity and cost.

Impact on Application:

Steel linear bearings are compatible with a wide range of media, including oils and greases. However, they may not perform well in highly corrosive environments, such as those found in chemical processing.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM or DIN for material specifications. In regions like Africa and South America, where environmental conditions can vary significantly, selecting the right corrosion-resistant treatment is crucial.

Aluminum

Key Properties:

Aluminum is lightweight and offers good corrosion resistance, making it suitable for applications where weight savings are critical. It also has decent thermal conductivity, which can be beneficial in heat dissipation.

Pros & Cons:

While aluminum bearings are easier to manufacture and install due to their lightweight nature, they typically have lower load-bearing capacity compared to steel. This can limit their use in heavy-duty applications.

Impact on Application:

Aluminum is compatible with various lubricants and operates well in environments where weight is a concern, such as in aerospace and automotive applications. However, it may not be suitable for high-temperature applications.

Considerations for International Buyers:

Buyers in Europe and the Middle East should be aware of specific regulations regarding aluminum use in certain industries, such as aerospace. Compliance with standards like EN or JIS may also be necessary.

Plastic

Key Properties:

Plastic bearings are known for their low friction and self-lubricating properties, which can lead to reduced maintenance costs. They are also resistant to many chemicals and moisture, making them ideal for specific environments.

Pros & Cons:

The key advantage of plastic bearings is their lightweight and corrosion-resistant nature. However, they generally have lower load capacities and can wear out faster under heavy loads compared to metal bearings.

Impact on Application:

Plastic linear bearings are often used in food processing and medical applications due to their resistance to corrosion and ease of cleaning. However, they may not be suitable for high-temperature applications.

Considerations for International Buyers:

Buyers should consider the specific chemical compatibility of plastic materials with the media they will encounter in their applications. Additionally, compliance with food safety standards (e.g., FDA regulations) is critical for buyers in the food processing sector.

Ceramic

Key Properties:

Ceramic materials provide excellent wear resistance and can operate at high temperatures. They are also non-magnetic and chemically inert, making them suitable for specialized applications.

Pros & Cons:

The primary advantage of ceramic bearings is their durability and ability to withstand extreme conditions. However, they tend to be more expensive and can be brittle, making them less suitable for applications subject to shock or impact.

Impact on Application:

Ceramic bearings are ideal for high-precision applications, such as in aerospace or semiconductor manufacturing. They are also suitable for environments where magnetic interference is a concern.

Considerations for International Buyers:

Buyers should evaluate the cost-benefit ratio of ceramic bearings, especially in regions where budget constraints are significant. Compliance with industry-specific standards is also crucial for ensuring performance reliability.

Summary Table

| Material | Typical Use Case for Linear Bearing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy industrial applications | High strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | Aerospace and automotive | Lightweight and corrosion-resistant | Lower load capacity | Medium |

| Plastic | Food processing and medical | Low friction and self-lubricating | Lower load capacity and durability | Low |

| Ceramic | High-precision applications | Excellent wear resistance | Higher cost and brittleness | High |

This material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions tailored to their specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for linear bearing

Manufacturing linear bearings involves several critical stages and techniques designed to ensure that the final product meets stringent performance and quality standards. This section provides a detailed overview of the manufacturing processes and quality assurance measures relevant to international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

1. Material Preparation

The manufacturing of linear bearings begins with the careful selection and preparation of raw materials. Common materials include high-carbon steel, stainless steel, and specialized alloys. These materials are chosen for their strength, durability, and resistance to wear.

- Material Inspection: Before processing, materials undergo inspections to confirm compliance with specifications. This includes checking for material integrity, hardness, and surface quality.

2. Forming

The next stage is the forming process, where raw materials are shaped into the components of the linear bearings.

- Machining: This is typically done using CNC (Computer Numerical Control) machines that provide high precision. Key operations include turning, milling, and grinding.

- Heat Treatment: Components may undergo heat treatment to enhance hardness and strength. This process can include quenching and tempering, which alter the material’s microstructure.

3. Assembly

After forming, the various components of the linear bearings are assembled.

- Component Assembly: This includes the insertion of balls or rollers into the raceways. Proper alignment is crucial to ensure smooth operation.

- Lubrication: Appropriate lubrication is applied during assembly to reduce friction and wear during operation.

4. Finishing

The final stage of manufacturing involves finishing processes that enhance the performance and aesthetics of the linear bearings.

- Surface Treatment: Techniques such as coating, plating, or anodizing are often applied to improve corrosion resistance and reduce friction.

- Final Inspection: A thorough inspection is conducted to ensure that all components meet design specifications and quality standards.

Quality Assurance

Quality assurance in the manufacturing of linear bearings is essential to ensure reliability and performance. B2B buyers must be aware of international standards and industry-specific regulations that govern quality control.

Relevant International Standards

- ISO 9001: This is a globally recognized standard for quality management systems. Compliance indicates that a manufacturer has established processes to ensure consistent quality.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Specifications: For applications in the oil and gas industry, manufacturers may need to comply with API standards to ensure reliability under extreme conditions.

Quality Control Checkpoints

Quality control is an ongoing process that occurs at various stages of manufacturing:

- Incoming Quality Control (IQC): This involves the inspection of raw materials and components upon arrival at the manufacturing facility.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to ensure that processes are operating within specified parameters.

- Final Quality Control (FQC): Before shipment, finished products undergo comprehensive testing to verify they meet design and performance specifications.

Common Testing Methods

To ensure the quality and functionality of linear bearings, several testing methods are employed:

- Dimensional Inspection: Verifying that the components meet the specified dimensions.

- Load Testing: Assessing the bearing’s ability to withstand operational loads without failure.

- Life Testing: Simulating long-term operational conditions to evaluate wear and performance over time.

Verifying Supplier Quality Control

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, it is crucial to verify the quality control measures of potential suppliers. Here are some strategies:

- Supplier Audits: Conducting on-site audits of manufacturing facilities can provide insight into the processes and quality management systems in place.

- Quality Reports: Requesting documentation of quality control processes, including inspection reports and compliance certifications, can help assess supplier reliability.

- Third-party Inspections: Engaging independent third-party inspection services can provide an objective evaluation of the supplier’s quality management practices.

Quality Control and Certification Nuances

Understanding the nuances of quality control and certification is vital for international B2B transactions. Buyers should consider the following:

- Cultural and Regional Differences: Quality standards may vary significantly across regions. It is essential to understand local regulations and standards applicable in the buyer’s market.

- Language Barriers: Documentation and communication may pose challenges. Ensuring that quality reports and certifications are available in a language understood by the buyer can facilitate better understanding.

- Risk Management: Buyers should be aware of the risks associated with international sourcing, including the potential for supply chain disruptions. Establishing clear quality expectations and maintaining open communication with suppliers can mitigate these risks.

By understanding the manufacturing processes and quality assurance measures for linear bearings, B2B buyers can make informed decisions, ensuring they select suppliers that meet their quality standards and operational needs.

Related Video: how ball bearings are made | bearing manufacturing process | bearing assembly

Comprehensive Cost and Pricing Analysis for linear bearing Sourcing

When sourcing linear bearings, understanding the comprehensive cost structure is essential for international B2B buyers. The total cost comprises several components, including materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins. Each of these elements contributes to the final pricing and can vary significantly based on multiple factors.

Cost Components

-

Materials: Linear bearings are typically made from steel, aluminum, or specialized polymers. The choice of material impacts the cost directly. For instance, high-grade steel or corrosion-resistant materials increase the price due to their enhanced performance and durability.

-

Labor: Labor costs can differ based on the geographical location of the manufacturer. Regions with lower labor costs may offer competitive pricing, but this can sometimes compromise quality. Understanding the labor market in the supplier’s region is crucial for assessing potential risks and benefits.

-

Manufacturing Overhead: This includes utilities, rent, and administrative costs associated with production. Efficient manufacturers often optimize these costs, which can lead to more competitive pricing.

-

Tooling: Tooling costs are particularly relevant for custom or specialized bearings. Initial investments in tooling can be substantial, which may be reflected in the pricing of low-volume orders.

-

Quality Control (QC): Ensuring quality through rigorous testing and certification processes adds to the cost. Buyers should consider whether certifications, such as ISO or specific industry standards, are necessary for their applications, as these can significantly influence the price.

-

Logistics: Shipping costs can vary widely based on the origin, destination, and chosen Incoterms. International buyers should account for duties, tariffs, and insurance, which can add to the total cost.

-

Margin: Supplier margins can vary significantly based on market dynamics, competition, and the supplier’s positioning. Understanding how much markup a supplier applies can help buyers negotiate better prices.

Price Influencers

Several factors influence the pricing of linear bearings:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Understanding the minimum order quantity (MOQ) is crucial for buyers looking to optimize their budgets.

-

Specifications/Customization: Custom specifications can increase costs due to the need for specialized materials or unique manufacturing processes. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality/Certifications: Higher quality bearings with industry certifications may command a premium. Buyers should weigh the benefits of enhanced quality against the additional costs.

-

Supplier Factors: Supplier reliability, reputation, and financial stability play a role in pricing. Engaging with reputable suppliers may yield more favorable terms and assurances regarding product quality.

-

Incoterms: The choice of Incoterms affects the distribution of costs and responsibilities in shipping. Understanding these terms helps buyers evaluate total costs more accurately.

Buyer Tips

-

Negotiation: Leverage volume purchasing and long-term relationships to negotiate better terms and pricing. Suppliers are often willing to offer discounts for repeat business.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs over the product’s life cycle. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and economic conditions in the supplier’s country, as these can impact pricing. Building relationships with local suppliers can also provide insights into market trends and pricing strategies.

-

Research and Compare: Engage in thorough market research and compare multiple suppliers to understand competitive pricing structures. This diligence can help identify the best value propositions.

In summary, a thorough understanding of the cost components and price influencers, along with strategic negotiation and evaluation of total costs, will empower international buyers to make informed sourcing decisions in the linear bearing market. Keep in mind that indicative prices should be verified directly with suppliers to ensure accuracy.

Illustrative Image (Source: Google Search)

Spotlight on Potential linear bearing Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘linear bearing’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for linear bearing

Key Technical Properties of Linear Bearings

Understanding the technical specifications of linear bearings is crucial for B2B buyers, particularly when selecting components that will meet the demands of diverse applications. Here are several essential properties to consider:

-

Material Grade

Linear bearings are typically made from materials like stainless steel, aluminum, or polymers. Material grade affects durability, corrosion resistance, and weight. For instance, stainless steel offers high strength and resistance to rust, making it suitable for harsh environments, while aluminum is lighter and can be ideal for applications where weight is a concern. -

Load Rating

This specification refers to the maximum load a bearing can support without failure. It is essential for ensuring that the bearing can handle the expected operational loads in your application. Buyers must consider both dynamic (moving) and static (stationary) load ratings to ensure optimal performance and longevity. -

Tolerance

Tolerance is the allowable deviation from a specified dimension. It plays a critical role in the precision of linear motion systems. A tighter tolerance typically results in improved performance and reduced wear, but can also increase cost. Understanding tolerance levels is important for applications requiring high precision, such as in robotics or CNC machinery. -

Speed Rating

This specification indicates the maximum speed at which the bearing can operate efficiently. It is crucial for applications involving rapid motion. Buyers should ensure that the speed rating aligns with their operational requirements to avoid premature wear or failure. -

Lubrication Type

Linear bearings may be designed for various lubrication methods, including grease, oil, or self-lubricating materials. The choice of lubrication affects the bearing’s performance, operating temperature, and maintenance needs. Selecting the right lubrication type is vital for minimizing friction and prolonging service life. -

Size and Configuration

The dimensions and design (such as profile or mounting options) of linear bearings must be compatible with the application’s requirements. Buyers should consider both the physical space and the intended motion path when selecting a linear bearing to ensure fit and functionality.

Common Trade Terminology in Linear Bearing Procurement

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement process. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs can help buyers ensure compatibility and quality in their supply chain. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is particularly important for international buyers, as it can affect inventory costs and shipping logistics. Buyers should negotiate MOQs that align with their demand and storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price bids for specified products or services. It is an essential step in the procurement process that allows buyers to compare offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing shipping costs and risks effectively. -

Lead Time

This term refers to the amount of time it takes from placing an order until it is delivered. For B2B buyers, knowing the lead time helps in planning production schedules and managing supply chain logistics. -

Certification Standards

Certifications, such as ISO or CE, indicate that a product meets specific safety and quality standards. Buyers should look for these certifications to ensure compliance with industry regulations and to reduce liability risks.

By grasping these essential properties and trade terms, international B2B buyers can make more informed decisions when sourcing linear bearings, ultimately leading to improved operational efficiency and product reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the linear bearing Sector

Market Overview & Key Trends

The linear bearing market is currently experiencing significant growth, driven by several global factors. Key among these are the increasing demand for automation in manufacturing, advancements in technology, and a push for higher precision in engineering applications. As industries across Africa, South America, the Middle East, and Europe evolve, the need for reliable, efficient linear motion solutions becomes paramount.

Emerging technologies such as the Internet of Things (IoT) and Industry 4.0 are reshaping sourcing trends. B2B buyers are increasingly looking for suppliers who can provide smart bearings equipped with sensors for real-time monitoring and predictive maintenance. This trend not only enhances operational efficiency but also reduces downtime, which is critical for businesses in competitive markets. Moreover, as supply chains become more globalized, international buyers must navigate complexities including logistics, tariffs, and regulatory compliance, particularly when sourcing from diverse regions such as Mexico and Nigeria.

Sourcing practices are also shifting towards more localized suppliers to mitigate risks associated with geopolitical instability and trade barriers. Buyers are advised to prioritize partnerships with manufacturers that have a strong reputation for quality and reliability, ensuring that their linear bearing solutions meet international standards.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial factor in the linear bearing sector, with an increasing emphasis on minimizing environmental impact. The production of linear bearings often involves materials that can be harmful to the environment if not sourced responsibly. Therefore, B2B buyers must consider suppliers that adhere to sustainable practices, such as using recycled materials and reducing waste in the manufacturing process.

Ethical sourcing is equally important, as businesses are held accountable for their supply chains. Buyers should seek suppliers that are transparent about their sourcing practices and have certifications indicating adherence to environmental and social governance (ESG) standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainable practices.

Furthermore, the adoption of “green” materials, such as biodegradable lubricants and coatings, is gaining traction. By choosing suppliers who prioritize sustainability, B2B buyers can not only contribute to environmental preservation but also enhance their brand reputation in an increasingly eco-conscious market.

Brief Evolution/History

The evolution of linear bearings has been closely tied to advancements in engineering and manufacturing technologies. Initially, linear bearings were simple mechanical devices, but they have transformed into highly sophisticated components that incorporate advanced materials and smart technologies. The introduction of materials such as polymers and ceramics has allowed for improved performance and reduced weight, making them suitable for a wider range of applications.

In recent years, the focus has shifted towards integrating linear bearings into automated systems, driven by the rise of robotics and smart manufacturing. This evolution underscores the importance of continuous innovation in the sector, as companies strive to meet the growing demands for efficiency, precision, and sustainability in their operations.

As the linear bearing market continues to evolve, B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their operational goals and sustainability commitments.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of linear bearing

-

What criteria should I use to vet suppliers of linear bearings?

When vetting suppliers, prioritize their experience in the industry, customer reviews, and certifications such as ISO 9001. Request references from previous clients, especially those in similar markets. Ensure that the supplier has a robust quality assurance process and is compliant with international standards. Additionally, consider their capacity to handle your volume needs and their ability to provide technical support. This due diligence can mitigate risks associated with product quality and reliability. -

Can I customize linear bearings to meet specific requirements?

Yes, many suppliers offer customization options for linear bearings. You can specify dimensions, materials, and load capacities based on your application needs. When discussing customization, provide detailed specifications and the intended application context. Be aware that custom orders may have longer lead times and higher costs, so clarify these aspects upfront to align with your project timelines and budgets. -

What are the typical minimum order quantities (MOQ) and lead times for linear bearings?

MOQs for linear bearings can vary widely by supplier and product type, often ranging from 50 to 500 units. Lead times typically range from 2 to 8 weeks, depending on whether the bearings are standard or customized. When planning your purchase, confirm these details with your supplier to ensure they align with your production schedule. It’s advisable to place orders in advance, especially if you anticipate fluctuating demand. -

What payment terms should I expect when sourcing linear bearings internationally?

Payment terms can vary significantly among suppliers. Common practices include wire transfers, letters of credit, and PayPal for smaller transactions. Negotiate payment terms that are favorable for both parties, ensuring they align with your cash flow needs. Some suppliers may require a deposit upfront, particularly for custom orders. Always verify the total cost, including shipping and customs duties, to avoid unexpected expenses.

-

How can I ensure quality assurance and certification for linear bearings?

Request copies of quality certifications from your supplier, such as ISO 9001 or industry-specific certifications. Many suppliers provide detailed quality control reports and testing results for their products. Establish clear quality expectations in your purchase agreement, including acceptable tolerances and testing methods. Consider conducting an on-site audit or requesting third-party inspections to further ensure product quality before shipment. -

What logistics considerations should I keep in mind when importing linear bearings?

Logistics is critical when importing linear bearings. Assess the supplier’s ability to handle shipping and customs documentation. Choose a reliable freight forwarder familiar with international shipping regulations to minimize delays. Ensure that you understand the incoterms (e.g., FOB, CIF) agreed upon in your contract, as they dictate responsibilities for shipping costs and risks. Proper planning can prevent disruptions in your supply chain. -

What should I do if I encounter a dispute with a supplier?

In the event of a dispute, first attempt to resolve the issue amicably through direct communication with the supplier. Document all communications and agreements. If resolution fails, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Engaging a legal professional familiar with international trade can provide guidance on your options and help protect your interests. -

How can I stay updated on industry trends and innovations in linear bearings?

To stay informed, subscribe to industry publications and attend trade shows or webinars focused on linear motion technologies. Joining professional associations or forums can provide networking opportunities with peers and experts. Additionally, consider following leading manufacturers and suppliers on social media platforms for real-time updates on new products and innovations. Keeping abreast of trends can enhance your competitive edge and inform future sourcing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for linear bearing

The strategic sourcing of linear bearings is essential for optimizing supply chain efficiency and enhancing product quality across various industries. By leveraging global suppliers, businesses in Africa, South America, the Middle East, and Europe can ensure access to high-performance components that meet their specific operational demands. Key takeaways include the importance of evaluating supplier capabilities, understanding local market conditions, and fostering long-term partnerships to mitigate risks associated with supply chain disruptions.

Value of Strategic Sourcing:

– Cost Efficiency: Engaging multiple suppliers can lead to competitive pricing and reduced procurement costs.

– Quality Assurance: Partnering with reputable manufacturers ensures consistent product quality and reliability.

– Innovation Access: Collaborating with suppliers can drive innovation, enabling businesses to adopt the latest technologies in linear bearing applications.

As the global market evolves, international buyers should remain proactive in their sourcing strategies. By staying informed about industry trends and technological advancements, businesses can better position themselves to capitalize on emerging opportunities.

Call to Action: Take the next step in enhancing your procurement strategy by evaluating your current suppliers and exploring new partnerships. The future of your business depends on the quality and reliability of the components you choose today.