Your Ultimate Guide to Sourcing Linear Slide Rail System

Introduction: Navigating the Global Market for linear slide rail system

In today’s rapidly evolving industrial landscape, the linear slide rail system stands as a critical component in ensuring precision and efficiency across various applications. These systems serve as the backbone for machinery in sectors such as automation, robotics, and manufacturing. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance operational capabilities, understanding the intricacies of linear slide rail systems becomes paramount.

This comprehensive guide delves into the essential elements of linear slide rail systems, including the various types and materials available, manufacturing processes, and quality control measures. It highlights how different designs cater to specific industrial needs, ensuring optimal performance and durability. Moreover, we will explore reputable suppliers in the market, providing insights into pricing structures that align with budgetary constraints while maintaining quality standards.

By equipping buyers with actionable insights and data-driven analysis, this guide empowers informed sourcing decisions. Key FAQs will also be addressed, demystifying common concerns that can arise during the procurement process. Whether you are in Saudi Arabia looking for robust solutions or in Kenya seeking cost-effective options, this resource aims to bridge the gap between demand and supply, facilitating strategic partnerships and enhancing operational efficiencies.

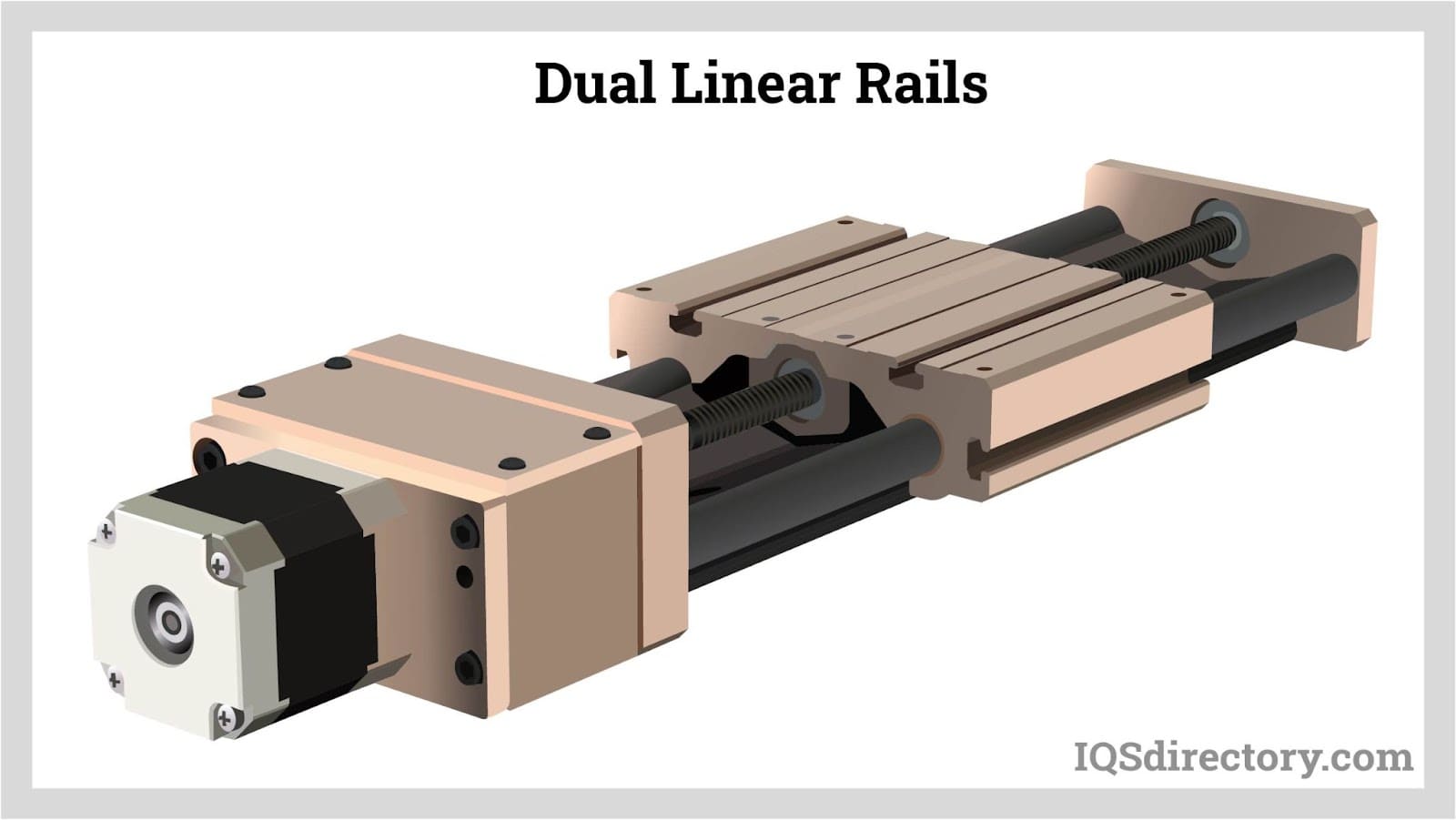

Understanding linear slide rail system Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Profile Rail System | Rigid structure, high load capacity, and low friction | CNC machines, automated assembly lines | Pros: High precision, excellent stability. Cons: Higher initial cost. |

| Round Rail System | Smooth cylindrical rails, good for low load applications | Packaging machines, light automation | Pros: Cost-effective, easy installation. Cons: Limited load capacity. |

| Ball Slide System | Incorporates ball bearings, high-speed operation | Robotics, conveyor systems | Pros: High speed, reduced wear. Cons: Requires regular maintenance. |

| Linear Shaft System | Uses shafts and bearings, simple design | 3D printers, medical devices | Pros: Compact design, versatile. Cons: Limited precision compared to others. |

| Magnetic Slide System | Utilizes magnetic forces for movement | Semiconductor manufacturing, cleanrooms | Pros: No contact wear, high speed. Cons: Sensitive to environmental factors. |

Profile Rail System

Profile rail systems are characterized by their robust structure and high load capacity, making them ideal for demanding industrial applications such as CNC machines and automated assembly lines. These systems provide exceptional precision and stability, which are crucial for maintaining high-quality production standards. When considering a profile rail system, buyers should evaluate the initial investment against the long-term benefits of durability and performance.

Round Rail System

The round rail system features smooth cylindrical rails that facilitate movement, making them suitable for lighter load applications such as packaging machines and light automation setups. This type is often favored for its cost-effectiveness and ease of installation, appealing to businesses with budget constraints or those new to automation. However, potential buyers should consider the limitations in load capacity, especially if their applications require heavier loads.

Ball Slide System

Ball slide systems utilize ball bearings to reduce friction and enable high-speed operations, making them a popular choice in robotics and conveyor systems. These systems excel in environments where speed and efficiency are paramount. While they offer significant advantages in terms of speed and reduced wear, buyers must be prepared for the need for regular maintenance to ensure optimal performance over time.

Linear Shaft System

Linear shaft systems are known for their simple design, which incorporates shafts and bearings to facilitate movement. They are commonly used in applications such as 3D printers and medical devices, where space is often limited. The compact design and versatility of these systems make them attractive to manufacturers. However, buyers should be aware that they may not offer the same level of precision as other types, which could be a critical factor depending on the application.

Magnetic Slide System

Magnetic slide systems leverage magnetic forces to achieve movement without physical contact, making them ideal for sensitive environments like semiconductor manufacturing and cleanrooms. These systems offer the advantage of no contact wear, which prolongs their lifespan and enhances performance. However, potential buyers should consider that magnetic systems can be sensitive to environmental factors, which may impact their reliability in certain applications.

Related Video: Efficiency Production Slide Rail System – 4-Sided System INSTALLED

Key Industrial Applications of linear slide rail system

| Industry/Sector | Specific Application of linear slide rail system | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated assembly lines | Increases efficiency and reduces labor costs | Ensure compatibility with existing machinery and high load capacity. |

| Robotics | Robotic arms and manipulation systems | Enhances precision in tasks and operations | Look for high-precision slides and ease of integration into robotic systems. |

| Medical Equipment | Patient positioning systems | Improves patient safety and comfort | Sourcing should focus on durability and wear resistance to ensure longevity. |

| Logistics | Automated storage and retrieval systems | Optimizes space and speeds up operations | Consider load capacity and ease of maintenance for continuous operation. |

| Textile Industry | Fabric cutting and handling equipment | Increases accuracy and reduces material waste | Ensure compatibility with various textile materials and ease of cleaning. |

Detailed Applications

Manufacturing

In manufacturing, linear slide rail systems are integral to automated assembly lines. They facilitate the smooth and precise movement of components, significantly enhancing operational efficiency. By minimizing errors and downtime, businesses can reduce labor costs and increase throughput. Buyers should prioritize sourcing slides that can handle heavy loads and are compatible with existing machinery, especially in regions like South America and Africa where industrial setups may vary.

Robotics

Linear slide rail systems play a crucial role in robotics, particularly in robotic arms and manipulation systems. These systems require high precision to perform tasks such as assembly, welding, or painting. The use of linear slides ensures that movements are accurate and repeatable, which is vital for quality control. Buyers should seek high-precision slides that integrate seamlessly with robotic systems, considering local availability of parts and support services in markets like the Middle East and Europe.

Medical Equipment

In the medical sector, linear slide rail systems are employed in patient positioning systems, such as those found in MRI machines or surgical tables. These systems must provide smooth and reliable motion to ensure patient safety and comfort. Durability and wear resistance are key considerations, as medical equipment is often in continuous use. Buyers from Africa and the Middle East should focus on suppliers that offer robust solutions with a proven track record in healthcare applications.

Logistics

Automated storage and retrieval systems in logistics utilize linear slide rail systems to optimize space and enhance operational speed. These systems improve inventory management by allowing for quick access to stored items, thus increasing efficiency. When sourcing, businesses should consider the load capacity of the slides and their ease of maintenance to ensure uninterrupted operations. This is especially critical for logistics firms in Europe, where efficiency is paramount.

Textile Industry

In the textile industry, linear slide rail systems are used in fabric cutting and handling equipment. They provide the necessary precision to minimize material waste and enhance productivity. Buyers should ensure that the slides are compatible with various textile materials and easy to clean, as this can affect the quality of the final product. Sourcing from reliable manufacturers is essential to maintain operational efficiency, particularly in regions like South America where textile production is significant.

Related Video: Linear Bearings 101 – What is a Linear Slide Bearing and how do they work.

Strategic Material Selection Guide for linear slide rail system

When selecting materials for linear slide rail systems, international B2B buyers must consider various factors that affect performance, cost, and suitability for specific applications. Below is an analysis of four common materials used in linear slide rail systems, focusing on their properties, advantages, disadvantages, and implications for buyers in Africa, South America, the Middle East, and Europe.

Aluminum

Key Properties: Aluminum is lightweight and exhibits excellent corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for a variety of environments.

Pros & Cons:

– Pros: Aluminum is easy to machine and fabricate, which reduces manufacturing complexity. Its lightweight nature makes it ideal for applications where weight is a concern.

– Cons: While it is durable, aluminum may not withstand high loads compared to other metals. Its cost can be moderate, depending on the alloy used.

Impact on Application: Aluminum is compatible with many media and is often used in environments where corrosion is a concern, such as in food processing or marine applications.

Considerations for Buyers: Buyers should ensure that the aluminum used meets local standards (e.g., ASTM or DIN) and consider the environmental conditions in their region, such as humidity and temperature fluctuations, which can affect performance.

Steel

Key Properties: Steel is known for its high strength and load-bearing capacity. It can be treated for enhanced corrosion resistance and can handle high temperatures and pressures.

Pros & Cons:

– Pros: Steel’s durability and strength make it suitable for heavy-duty applications. It is often more cost-effective than aluminum for high-load applications.

– Cons: Steel is heavier than aluminum, which may not be suitable for all applications. It also requires protective coatings to prevent corrosion, adding to maintenance costs.

Impact on Application: Steel is ideal for industrial applications where high load capacity and durability are essential, such as in manufacturing and automation systems.

Considerations for Buyers: Buyers should verify that the steel meets relevant international standards and consider the long-term maintenance implications of corrosion protection, especially in humid or corrosive environments.

Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance and is suitable for high-temperature applications. It maintains strength under various environmental conditions.

Pros & Cons:

– Pros: Its corrosion resistance makes stainless steel ideal for harsh environments, including chemical processing and food industries. It also has a long lifespan.

– Cons: Stainless steel is typically more expensive than both aluminum and carbon steel. Its manufacturing process can be complex, leading to higher costs.

Impact on Application: Stainless steel is particularly effective in applications involving exposure to corrosive substances, making it a preferred choice in the pharmaceutical and food industries.

Considerations for Buyers: Buyers should look for compliance with international standards (e.g., JIS, ASTM) and consider the specific grades of stainless steel that best suit their application, as different grades offer varying levels of corrosion resistance.

Plastic Composites

Key Properties: Plastic composites are lightweight and resistant to corrosion and chemical exposure. They can operate effectively in a wide range of temperatures.

Pros & Cons:

– Pros: These materials are often less expensive than metals and can be molded into complex shapes, offering design flexibility.

– Cons: Plastic composites may not have the same load-bearing capacity as metals and can be less durable under extreme conditions.

Impact on Application: Plastic composites are suitable for applications where weight reduction is critical, such as in robotics and lightweight machinery.

Considerations for Buyers: Buyers should ensure that the plastic composites meet relevant safety and performance standards and consider the environmental impact of using plastics in their applications.

Summary Table

| Material | Typical Use Case for linear slide rail system | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight machinery, food processing | Excellent corrosion resistance | Lower load capacity compared to steel | Medium |

| Steel | Heavy-duty industrial applications | High strength and load-bearing capacity | Requires corrosion protection | Low |

| Stainless Steel | Chemical processing, food industry | Superior corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic Composites | Robotics, lightweight machinery | Lightweight and design flexibility | Lower load capacity than metals | Low |

This guide serves as a foundational tool for international B2B buyers to make informed decisions regarding material selection for linear slide rail systems, ensuring performance, compliance, and cost-effectiveness in their applications.

In-depth Look: Manufacturing Processes and Quality Assurance for linear slide rail system

Manufacturing Processes for Linear Slide Rail Systems

The manufacturing of linear slide rail systems involves several key stages that ensure the production of high-quality, precise, and durable components. Understanding these processes is crucial for international B2B buyers looking to source reliable products.

Material Preparation

The first step in the manufacturing process is material preparation. High-quality materials, typically steel or aluminum, are selected based on the required performance characteristics, such as load capacity and wear resistance. The materials undergo rigorous testing to verify their mechanical properties, ensuring they meet industry standards.

- Material Selection: Choose materials that offer optimal balance between strength, weight, and cost-effectiveness. For instance, aluminum is lightweight, while steel provides superior strength.

- Surface Treatment: Apply treatments like anodizing or hardening to enhance wear resistance and corrosion protection. This step is crucial for extending the lifespan of the linear slide rail systems.

Forming

Once the materials are prepared, they move into the forming stage. This involves shaping the raw materials into the desired configurations through techniques such as machining, extrusion, or forging.

- Machining: Precision machining processes are used to create accurate dimensions and tolerances. CNC (Computer Numerical Control) machines are commonly employed to achieve high precision.

- Extrusion: For aluminum components, extrusion allows for the creation of complex shapes while maintaining material integrity.

- Forging: This technique is often used for steel components to enhance strength through grain structure alignment.

Assembly

After forming, the components are assembled. This stage is critical as it ensures that the various parts fit together correctly and operate smoothly.

- Component Integration: The assembly process involves combining the slide rail with the slider and any additional components such as bearings or seals.

- Alignment and Calibration: Proper alignment is essential for ensuring precision in movement. Automated systems may be used to calibrate components to tight tolerances.

Finishing

The final stage is finishing, which enhances the appearance and functionality of the linear slide rail systems.

- Surface Finishing: Techniques such as grinding, polishing, and coating are used to achieve a smooth surface finish. This not only improves aesthetics but also reduces friction during operation.

- Quality Inspections: Before shipping, the finished products undergo thorough inspections to ensure they meet specifications.

Quality Assurance in Manufacturing

Quality assurance (QA) is a critical aspect of the manufacturing process for linear slide rail systems. It ensures that products meet both international standards and specific customer requirements.

International Standards

Buyers should be familiar with relevant international standards that govern manufacturing quality. Key standards include:

- ISO 9001: This standard outlines requirements for a quality management system (QMS) and is applicable to organizations in any industry.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, adherence to American Petroleum Institute (API) standards is crucial.

Quality Control Checkpoints

Quality control involves several checkpoints throughout the manufacturing process to ensure consistency and reliability. These include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival at the facility to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing monitoring during the manufacturing process to detect issues early and prevent defects.

- Final Quality Control (FQC): Comprehensive testing of finished products before they are shipped. This includes dimensional checks and functional testing.

Common Testing Methods

Various testing methods are employed to verify the quality and performance of linear slide rail systems:

- Dimensional Inspection: Utilizing tools like calipers and micrometers to ensure components meet exact specifications.

- Load Testing: Assessing the load capacity and stability of the slide rail systems under operational conditions.

- Wear Testing: Simulating operational environments to evaluate the wear resistance and longevity of the components.

Verifying Supplier Quality Control

For international buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps:

- Supplier Audits: Conduct on-site audits to evaluate the manufacturing process, quality control measures, and overall operational efficiency.

- Request Quality Reports: Ask suppliers for documentation detailing their quality control processes and results of recent inspections or tests.

- Third-Party Inspections: Engage independent inspection agencies to verify the quality of products before shipment. This can provide an unbiased assessment of the product’s compliance with standards.

Quality Control Nuances for International Buyers

When sourcing linear slide rail systems from international suppliers, it is important to be aware of regional nuances in quality assurance:

- Cultural Differences: Understand that manufacturing standards and practices may vary significantly between regions. Buyers should be prepared to adapt their expectations based on the local context.

- Regulatory Compliance: Ensure that suppliers are familiar with and comply with local regulations regarding product safety and environmental impact.

- Communication: Establish clear communication channels with suppliers to address any quality concerns promptly and effectively. Language barriers can pose challenges, so consider using translation services if necessary.

By focusing on these critical aspects of manufacturing processes and quality assurance, international B2B buyers can make informed decisions when sourcing linear slide rail systems, ultimately leading to improved operational efficiency and product reliability.

Related Video: Control Linear Slide Rail Guid with Arduino – Banggood

Comprehensive Cost and Pricing Analysis for linear slide rail system Sourcing

When sourcing linear slide rail systems, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. The costs can vary significantly based on several components, and recognizing these can lead to more effective negotiation and procurement strategies.

Cost Components

-

Materials: The primary materials used in linear slide rail systems typically include high-grade steel, aluminum, and specialized polymers. The choice of materials significantly affects both performance and cost. For instance, using lightweight aluminum can reduce overall system weight but may come at a higher material cost compared to standard steel.

-

Labor: Labor costs depend on the manufacturing location and complexity of the slide rail system. Regions with higher labor rates, such as parts of Europe, may see increased costs, while countries in Africa or South America might offer competitive labor pricing. However, this can be offset by differences in skill levels and productivity.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can minimize overhead costs, which is especially important for high-volume orders.

-

Tooling: Custom tooling may be required for specific designs, which adds to upfront costs. This is particularly relevant for buyers seeking tailored solutions that meet unique specifications.

-

Quality Control (QC): Ensuring high standards through rigorous QC can add to costs but is essential for maintaining product reliability and performance. Certifications such as ISO or industry-specific standards can also influence pricing.

-

Logistics: Transportation costs can vary widely depending on the supplier’s location and the buyer’s destination. Import duties, taxes, and shipping methods (air freight vs. sea freight) further complicate logistics costs.

-

Margin: Supplier profit margins typically range from 10% to 30%, depending on market conditions, competition, and the uniqueness of the product. High-demand items may command higher margins.

Price Influencers

-

Volume/MOQ: Purchasing in larger quantities often leads to significant discounts. Understanding the Minimum Order Quantity (MOQ) is crucial for negotiating better prices.

-

Specifications/Customization: Customized products may incur additional costs due to the need for specialized tooling and materials. Clearly defining specifications upfront can help manage costs.

-

Quality/Certifications: Higher quality and certified products usually come at a premium. Buyers should assess the balance between cost and quality to ensure long-term reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is essential for determining who bears the cost at different stages of shipping and delivery. This can impact overall pricing and should be factored into cost calculations.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing and be prepared to leverage competing quotes. Building relationships can also lead to more favorable terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just initial purchase prices. Consider factors such as maintenance, lifespan, and potential downtime.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, it’s important to be aware of currency fluctuations, import tariffs, and regional market conditions that may affect pricing.

-

Disclaimer: Prices can vary based on market conditions, supplier capabilities, and specific order requirements. Always seek multiple quotes and conduct due diligence to ensure competitive pricing.

By taking these factors into account, international B2B buyers can navigate the complexities of sourcing linear slide rail systems effectively, ensuring they receive quality products at competitive prices.

Spotlight on Potential linear slide rail system Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘linear slide rail system’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for linear slide rail system

Key Technical Properties of Linear Slide Rail Systems

When sourcing linear slide rail systems, understanding the technical specifications is crucial for ensuring optimal performance and compatibility with your equipment. Here are several key properties to consider:

-

Material Grade

The material used in linear slide rails significantly impacts their durability and performance. Common materials include carbon steel, stainless steel, and aluminum. Stainless steel, for instance, offers excellent corrosion resistance, making it suitable for humid environments often found in the Middle East and coastal areas of South America. Selecting the right material helps ensure longevity and reduces maintenance costs. -

Load Capacity

Load capacity refers to the maximum weight that the linear slide can support without failure. It’s essential to match the load capacity with your application requirements to avoid equipment failure. For heavy-duty applications, such as in manufacturing or automotive assembly, a higher load capacity is critical. This specification directly affects the design and efficiency of your machinery. -

Precision and Tolerance

Precision indicates how accurately the linear slide can guide movement, while tolerance measures the allowable deviation from specified dimensions. High precision and tight tolerances are essential for applications requiring exact positioning, such as robotics and CNC machinery. Investing in high-precision components can lead to improved product quality and reduced operational costs. -

Wear Resistance

Wear resistance is the ability of the slide rail system to withstand friction and abrasion over time. Enhanced wear resistance can be achieved through surface treatments, such as hardening or coating. This property is particularly important in industries where the equipment is subject to continuous use, as it prolongs the lifespan of the components and minimizes downtime for replacements.

Illustrative Image (Source: Google Search)

- Ease of Installation

A linear slide system designed for easy installation can significantly reduce setup time and labor costs. Features such as pre-drilled holes and clear installation guides facilitate quicker assembly. For international buyers, particularly in regions like Africa and South America, where skilled labor may be scarce, this property can be a decisive factor in the purchasing decision.

Common Trade Terminology in Linear Slide Rail Systems

Familiarity with industry jargon can enhance communication with suppliers and ensure smoother transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another manufacturer. Understanding the distinction between OEM and aftermarket parts is crucial for ensuring compatibility and quality in your machinery. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ helps you plan your inventory and budget accordingly. Suppliers in Europe may have different MOQs compared to those in Africa or South America, influencing your purchasing strategy. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For international buyers, preparing a comprehensive RFQ can lead to better pricing and terms, as it allows suppliers to understand your needs more clearly. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including who pays for shipping, insurance, and tariffs. Familiarity with these terms is essential for avoiding unexpected costs and ensuring smooth logistics, particularly in trade between Europe and Africa or South America. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is vital for inventory management and production scheduling. Different regions may experience varying lead times due to factors such as shipping routes and customs processes.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing linear slide rail systems, ensuring they choose products that meet their operational needs efficiently.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the linear slide rail system Sector

Market Overview & Key Trends

The linear slide rail system market is currently experiencing significant growth driven by advancements in automation, robotics, and manufacturing efficiency. Emerging economies in Africa and South America are increasingly adopting these technologies to enhance production capabilities. In the Middle East, particularly in Saudi Arabia, investments in industrial diversification and smart manufacturing are propelling demand for linear motion systems. In Europe, a push for high-precision manufacturing continues to drive innovations in linear slide rail technology.

Key trends influencing the market include the adoption of Industry 4.0 practices, which emphasize smart factories and interconnected devices. International B2B buyers are increasingly sourcing linear slide rails that incorporate IoT capabilities for real-time monitoring and predictive maintenance. Additionally, lightweight materials and compact designs are becoming crucial as industries seek to optimize space and energy efficiency. The rise of 3D modeling and simulation tools is allowing manufacturers to customize solutions more rapidly, aligning with the unique needs of diverse industries.

Moreover, sustainability is becoming a pivotal factor in sourcing decisions. Buyers are prioritizing suppliers who demonstrate eco-friendly practices, such as using recyclable materials and minimizing waste in production processes. As global supply chains become more interconnected, international buyers must stay attuned to these dynamics to make informed purchasing decisions that align with both operational needs and sustainability goals.

Sustainability & Ethical Sourcing in B2B

Sustainability in the linear slide rail system sector is no longer optional; it has become a core requirement for B2B buyers. The environmental impact of production processes, including energy consumption and waste generation, necessitates a focus on sustainable sourcing. Buyers should seek suppliers who employ eco-friendly manufacturing techniques, such as using low-energy machinery and recyclable materials, to minimize their carbon footprint.

The importance of ethical supply chains cannot be overstated. Companies must ensure that their sourcing practices do not contribute to labor exploitation or environmental degradation. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are essential indicators of a supplier’s commitment to sustainable practices. Furthermore, the integration of “green” materials in the manufacturing of linear slide rails—such as bio-based polymers and recycled metals—can significantly enhance a product’s sustainability profile.

To align with global sustainability goals, international B2B buyers are encouraged to engage with suppliers who transparently report their environmental and social impacts. This not only fosters trust but also enhances brand reputation in increasingly eco-conscious markets.

Brief Evolution/History

The evolution of linear slide rail systems can be traced back to the early 20th century, when mechanical engineering first began to incorporate precision motion control. Initially, these systems were rudimentary, primarily serving basic industrial applications. However, as manufacturing technology advanced, so did the complexity and functionality of linear slide rails.

The introduction of advanced materials and manufacturing techniques in the late 20th century allowed for the creation of more durable and precise systems. With the advent of automation and robotics in the 21st century, linear slide rails have become integral to high-speed production lines and automated machinery. Today, they are essential components in industries ranging from automotive to electronics, reflecting a significant shift towards precision engineering and efficiency in global manufacturing practices.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of linear slide rail system

-

What criteria should I use to vet suppliers of linear slide rail systems?

When vetting suppliers, prioritize their manufacturing capabilities, industry experience, and reputation. Request references from previous clients and assess their compliance with international standards such as ISO certifications. Additionally, evaluate their production capacity to meet your demand and ensure they have a robust quality assurance process in place. For international buyers, consider suppliers who have experience exporting to your region and can navigate local regulations and customs efficiently. -

Can I customize linear slide rail systems to meet specific requirements?

Yes, many suppliers offer customization options for linear slide rail systems. Be clear about your specifications, such as load capacity, length, and material requirements. Discuss your needs with potential suppliers early in the negotiation process to understand their capabilities and limitations. Customization may involve additional costs and lead times, so factor these into your project timeline and budget. -

What are typical minimum order quantities (MOQs) and lead times for linear slide rail systems?

Minimum order quantities can vary significantly among suppliers, often ranging from a few units to several hundred. Lead times typically depend on the complexity of the order and the supplier’s production schedule, averaging anywhere from 4 to 12 weeks. It’s advisable to confirm these details upfront to avoid unexpected delays. For urgent needs, inquire about expedited options and their associated costs. -

What payment terms should I expect when sourcing linear slide rail systems internationally?

Payment terms can vary widely, but common options include advance payment, letters of credit, or payment upon delivery. For larger orders, suppliers may offer flexible terms, such as partial payments at different stages of production. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and ensure they are secure. Additionally, consider negotiating terms that protect your investment, such as escrow services for large transactions. -

What quality assurance measures should I look for in suppliers?

Ensure that your suppliers have established quality assurance protocols, including regular inspections and testing of their products. Request documentation of compliance with international standards, such as ISO 9001, and inquire about their testing methodologies for durability, precision, and load capacity. A reputable supplier should be transparent about their quality assurance practices and willing to provide certifications or test reports. -

How can I manage logistics and shipping for international orders of linear slide rail systems?

Effective logistics management involves understanding the shipping options available, including air and sea freight. Discuss shipping costs and timelines with your supplier, and ensure they are familiar with customs regulations in your country. Consider using a freight forwarder to streamline the process, especially for large or complex shipments. Additionally, ensure that your supplier provides proper documentation to avoid delays at customs. -

What steps should I take if I encounter disputes with a supplier?

In the event of a dispute, first attempt to resolve the issue through direct communication with the supplier. Document all correspondence and agreements for reference. If resolution fails, consider mediation or arbitration as outlined in your contract. Familiarize yourself with international trade laws relevant to your transaction, as they may provide avenues for dispute resolution. Having a clear contract with defined terms can significantly aid in resolving conflicts. -

What are the common certifications I should verify before purchasing linear slide rail systems?

Look for certifications that indicate compliance with international safety and quality standards, such as ISO 9001 (quality management) and ISO 14001 (environmental management). Additionally, check for CE marking (for products sold in Europe) and RoHS compliance (restricting hazardous substances). These certifications not only ensure product quality but also demonstrate the supplier’s commitment to regulatory compliance, which can be crucial for your business operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for linear slide rail system

In conclusion, the strategic sourcing of linear slide rail systems is pivotal for international B2B buyers seeking to enhance operational efficiency and reliability. Key takeaways from this guide highlight the importance of selecting high-precision, durable, and easy-to-maintain systems that can adapt to diverse industrial applications. By prioritizing suppliers with advanced manufacturing capabilities, such as those offering Guangdong linear slides, businesses can significantly reduce downtime and maintenance costs while improving overall productivity.

Furthermore, as global industries increasingly embrace automation and robotics, the demand for innovative linear motion solutions will continue to rise. Buyers from regions like Africa, South America, the Middle East, and Europe should leverage strategic sourcing as a means to not only secure superior products but also foster long-term partnerships with manufacturers who understand the unique challenges of their markets.

Looking ahead, international B2B buyers are encouraged to stay informed about emerging technologies and trends in linear slide systems. This proactive approach will ensure that they remain competitive and can meet the evolving demands of their industries. Engage with suppliers, explore new solutions, and invest in quality—your operations will thank you.

Illustrative Image (Source: Google Search)