Your Ultimate Guide to Sourcing Lost Wax Casting Suppliers

Introduction: Navigating the Global Market for lost wax casting suppliers

In today’s dynamic global marketplace, lost wax casting suppliers play a pivotal role in delivering high-precision metal components essential for various industries, including aerospace, medical technology, and automotive manufacturing. This ancient technique, known for its ability to produce intricate designs with exceptional surface finishes, has evolved significantly, harnessing modern technologies to meet the increasing demands of quality and efficiency. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including key markets like Colombia and Germany) seek reliable partners, understanding the landscape of lost wax casting suppliers becomes imperative.

This comprehensive guide is designed to empower you with critical insights into the lost wax casting industry. It covers a wide range of topics, including the types of casting processes available, the materials used, and manufacturing and quality control standards. Furthermore, it provides a curated list of top suppliers, an analysis of cost factors, and an overview of market trends that will inform your sourcing decisions.

By navigating through this guide, you will gain the knowledge needed to identify the right lost wax casting supplier that aligns with your project requirements, ensuring that you make informed and strategic procurement choices that drive value for your business. Whether you are looking for precision prototypes or high-volume production, this guide equips you with the tools to enhance your sourcing strategy effectively.

Understanding lost wax casting suppliers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| General Lost Wax Casting | Focuses on standard investment casting processes. | Aerospace, automotive, general manufacturing | Pros: Versatile, suitable for various metals. Cons: Longer lead times. |

| Specialty Lost Wax Casting | Tailored for niche applications, often using advanced techniques. | Jewelry, art, medical devices | Pros: High precision, unique designs. Cons: Higher costs due to complexity. |

| High-Volume Production | Optimized for mass production with streamlined processes. | Industrial components, machinery parts | Pros: Cost-effective for large runs. Cons: Less flexibility for custom designs. |

| Prototype Casting | Designed for creating prototypes and low-volume runs. | Product development, testing | Pros: Quick turnaround, material efficiency. Cons: May require more finishing work. |

| Hybrid Casting | Combines lost wax with other manufacturing processes. | Aerospace, automotive, complex assemblies | Pros: Enhanced material properties, design flexibility. Cons: Complexity in sourcing. |

General Lost Wax Casting

General lost wax casting suppliers focus on traditional investment casting techniques, suitable for producing a wide range of components. They typically serve industries such as aerospace and automotive, where precise and intricate designs are critical. Buyers should consider lead times, as these suppliers may require more time to fulfill orders due to the detailed nature of the process. This type of supplier is ideal for businesses needing reliable, versatile casting solutions across various metal types.

Specialty Lost Wax Casting

Specialty lost wax casting suppliers cater to niche markets, often employing advanced techniques to create unique and high-precision products. Common applications include jewelry, art, and medical devices, where intricate designs and high-quality finishes are paramount. Buyers should weigh the benefits of exceptional craftsmanship against potentially higher costs. These suppliers are well-suited for companies seeking bespoke solutions that stand out in the market.

High-Volume Production

Suppliers specializing in high-volume production of lost wax castings focus on efficiency and cost-effectiveness, catering to industries that require large quantities of components. They employ streamlined processes to reduce costs and lead times, making them ideal for industrial components and machinery parts. While these suppliers offer significant savings for large orders, buyers may find less flexibility in customizing designs. This option is best for companies with established product lines needing consistent quality.

Prototype Casting

Prototype casting suppliers excel in creating low-volume runs and prototypes, supporting product development and testing phases. Their processes allow for quick turnaround times and material efficiency, making them suitable for businesses looking to refine designs before mass production. However, buyers should be prepared for potential additional finishing work on prototypes. This type of supplier is essential for companies that prioritize rapid innovation and require functional testing of their designs.

Hybrid Casting

Hybrid casting suppliers combine lost wax casting with other manufacturing techniques, offering enhanced material properties and design flexibility. This approach is particularly beneficial for complex assemblies in industries like aerospace and automotive. Buyers should consider the complexity of sourcing and integrating different processes, which may affect overall project timelines. Hybrid casting is ideal for companies seeking innovative solutions that leverage the strengths of multiple manufacturing methods.

Related Video: Lost Wax Casting Process from START to FINISH! EVERYTHING You Need to Know to Cast Jewelry At Home

Key Industrial Applications of lost wax casting suppliers

| Industry/Sector | Specific Application of lost wax casting suppliers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Production of turbine blades and complex engine components | High precision and strength for critical performance parts | Certification standards, material specifications |

| Medical Devices | Manufacturing of surgical instruments and implants | Customization and biocompatibility for patient-specific needs | Regulatory compliance, quality assurance processes |

| Automotive | Creation of precision components for engines and transmission systems | Enhanced performance and durability in high-stress environments | Supply chain reliability, turnaround times |

| Jewelry | Crafting intricate designs and bespoke pieces | Unique products that meet high aesthetic standards | Design collaboration, material selection |

| Oil and Gas | Production of valves and fittings for pipelines | High integrity and resistance to harsh conditions | Material certifications, lead times, and volume needs |

Aerospace

Lost wax casting suppliers play a crucial role in the aerospace industry by manufacturing turbine blades and complex engine components. These components require high precision and strength to withstand extreme operating conditions. International buyers, particularly from regions like Europe and the Middle East, must ensure that suppliers adhere to stringent certification standards and material specifications to meet safety regulations. This industry demands not only quality but also the ability to produce intricate designs that optimize performance.

Medical Devices

In the medical sector, lost wax casting is essential for creating surgical instruments and bespoke implants. The ability to customize components for specific patient needs is paramount, as is ensuring biocompatibility. B2B buyers from Africa and South America should prioritize suppliers that comply with strict regulatory standards and maintain rigorous quality assurance processes. This focus on quality is critical to ensuring the safety and efficacy of medical devices.

Automotive

The automotive industry utilizes lost wax casting for the production of precision components, particularly in engines and transmission systems. These components must exhibit enhanced performance and durability under high-stress conditions. Buyers should consider the reliability of the supply chain and the supplier’s ability to meet specific turnaround times, especially when sourcing parts from international suppliers in regions like Europe and South America, where automotive standards are stringent.

Jewelry

In the jewelry sector, lost wax casting enables the crafting of intricate designs and bespoke pieces that meet high aesthetic standards. This process allows jewelers to create unique products that stand out in a competitive market. For international buyers, engaging in design collaboration with suppliers is essential to achieve the desired outcome. Additionally, careful consideration of material selection can significantly impact the final product’s quality and appeal.

Oil and Gas

Lost wax casting is pivotal in the oil and gas industry for producing valves and fittings that must endure harsh conditions. The high integrity of these components is crucial for ensuring operational safety and efficiency. Buyers should focus on sourcing suppliers that provide material certifications, as well as those capable of meeting lead times and volume needs, particularly when operating in regions with demanding operational environments.

Related Video: Basics of Lost Wax Casting – Under 20 Minutes

Strategic Material Selection Guide for lost wax casting suppliers

When selecting materials for lost wax casting, international B2B buyers must consider several factors that directly impact product performance, manufacturing complexity, and cost. Here, we analyze four common materials used in lost wax casting, highlighting their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a melting point between 1400°C and 1450°C, making it suitable for various applications.

Pros & Cons:

The durability of stainless steel makes it ideal for components exposed to harsh environments. However, its higher cost compared to other metals can be a drawback for budget-conscious projects. Additionally, the complexity of machining stainless steel can lead to increased manufacturing times.

Impact on Application:

Stainless steel is compatible with a wide range of media, including water, oil, and chemicals, making it suitable for industries such as aerospace, automotive, and medical devices.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A276 for stainless steel specifications. Understanding local regulations regarding corrosion resistance and mechanical properties is essential, particularly in regions with specific environmental challenges.

2. Aluminum

Key Properties:

Aluminum is lightweight, has good corrosion resistance, and offers excellent thermal and electrical conductivity. It has a melting point of approximately 660°C, which allows for easier processing compared to heavier metals.

Pros & Cons:

The primary advantage of aluminum is its low weight, which is beneficial for applications where reducing mass is crucial. However, aluminum is less durable than steel and may not be suitable for high-stress applications. Additionally, it can be more expensive than other non-ferrous metals.

Impact on Application:

Aluminum is compatible with various environments but may not perform well in high-temperature applications. It is widely used in the automotive and aerospace industries, where weight reduction is critical.

Considerations for International Buyers:

Buyers should be aware of the differing standards for aluminum alloys across regions, such as DIN in Europe and JIS in Japan. Ensuring that the selected alloy meets the required specifications for strength and corrosion resistance is vital.

3. Bronze

Key Properties:

Bronze, an alloy primarily of copper and tin, offers excellent corrosion resistance and good machinability. It has a melting point around 950°C, making it suitable for casting intricate designs.

Pros & Cons:

Bronze is known for its durability and aesthetic appeal, making it a popular choice for decorative items and art. However, it can be more expensive than aluminum and may require additional finishing processes to achieve the desired surface quality.

Impact on Application:

Bronze is particularly well-suited for marine applications due to its resistance to seawater corrosion. It is also used in electrical applications due to its good conductivity.

Considerations for International Buyers:

Buyers should consider the specific bronze alloy used, as different compositions can significantly impact performance. Compliance with ASTM B505 for bronze specifications is crucial for ensuring quality and performance.

4. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and toughness, with a melting point of approximately 1425°C. It is less resistant to corrosion compared to stainless steel but can be treated for improved performance.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness and strength, making it suitable for a wide range of applications. However, its susceptibility to rust and corrosion can be a significant limitation, especially in humid or corrosive environments.

Impact on Application:

Carbon steel is commonly used in construction and heavy machinery due to its strength. However, it may not be suitable for applications requiring high corrosion resistance.

Considerations for International Buyers:

Buyers should ensure that carbon steel components meet relevant standards such as ASTM A36. Understanding local environmental conditions is essential for determining the need for protective coatings or treatments.

Summary Table

| Material | Typical Use Case for lost wax casting suppliers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Aerospace, automotive, medical devices | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Automotive, aerospace | Lightweight and good conductivity | Less durable than steel | Medium |

| Bronze | Marine applications, decorative items | Durability and aesthetic appeal | Higher cost and finishing required | Medium |

| Carbon Steel | Construction, heavy machinery | Cost-effective and strong | Susceptible to corrosion | Low |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions regarding lost wax casting materials, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for lost wax casting suppliers

The manufacturing process for lost wax casting is a meticulous series of stages that ensures high precision and quality in the final products. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes and the associated quality assurance measures is crucial for selecting reliable suppliers. Below is a detailed overview of the typical manufacturing processes, quality control standards, and how buyers can effectively evaluate suppliers.

Manufacturing Process

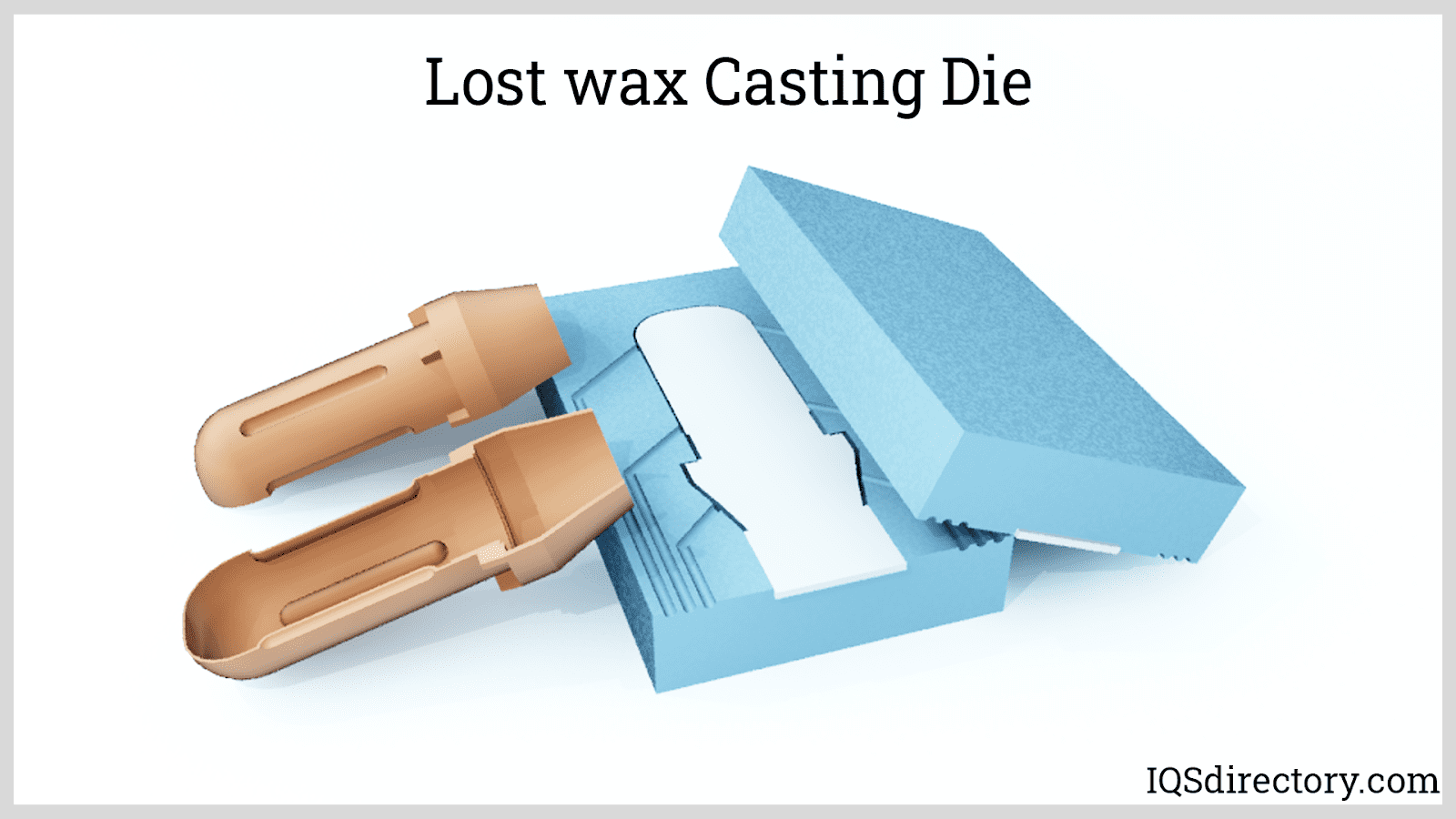

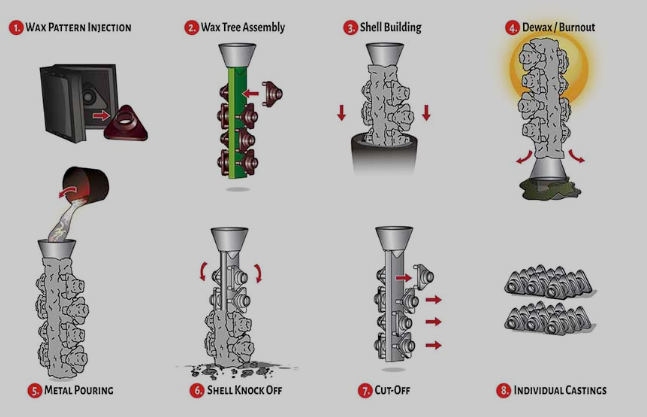

1. Material Preparation

The first step in the lost wax casting process involves selecting the appropriate materials. Wax is primarily used to create the initial model, which can be made from various wax types depending on the desired characteristics. This wax model is typically produced using methods such as injection molding or 3D printing, allowing for intricate designs.

Key Techniques:

– Wax Pattern Creation: High-precision wax patterns are crafted to represent the final product accurately.

– Material Selection: Various metals can be used, including stainless steel, aluminum, and bronze, depending on the product requirements.

2. Forming

Once the wax patterns are ready, they are assembled onto a central sprue to form a tree-like structure. This assembly is then coated with a ceramic shell to create a mold.

Key Techniques:

– Shell Building: The wax assembly is dipped in a ceramic slurry and coated with fine sand, which hardens into a robust shell.

– Dewaxing: The ceramic shell is heated to melt away the wax, leaving a cavity that matches the shape of the original wax model.

3. Assembly

After dewaxing, the mold is preheated to ensure optimal metal flow during casting. The molten metal is poured into the cavity, filling it completely.

Key Techniques:

– Metal Pouring: The choice of pouring technique (gravity, pressure, or vacuum) can affect the quality and integrity of the final product.

– Cooling: The mold is allowed to cool, solidifying the metal into the desired shape.

4. Finishing

After the metal has cooled, the ceramic shell is removed, and the cast part is cleaned and finished.

Key Techniques:

– Shell Removal: The ceramic shell is broken away, revealing the cast component.

– Post-Casting Treatment: This may include machining, polishing, and other surface treatments to achieve the desired finish and tolerances.

Quality Assurance

Quality control in lost wax casting is paramount to ensure that the final products meet international standards and client specifications. B2B buyers should familiarize themselves with key quality assurance processes and standards.

Relevant International Standards

Several international standards are critical for lost wax casting suppliers:

– ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

– CE Marking: Relevant for suppliers targeting the European market, this indicates compliance with EU safety, health, and environmental protection standards.

– API Standards: Particularly important for suppliers in the oil and gas industry, ensuring that products meet specific operational and safety requirements.

Quality Control Checkpoints

Quality assurance should be integrated throughout the manufacturing process, with specific checkpoints to monitor quality:

– Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages to identify and address any issues in real-time.

– Final Quality Control (FQC): Thorough inspection of finished products to verify they meet all specifications and standards before shipment.

Common Testing Methods

Several testing methods are commonly employed to assess the quality of lost wax castings:

– Visual Inspection: For surface defects and overall appearance.

– Dimensional Inspection: Using tools like calipers and micrometers to ensure precise measurements.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection to detect internal flaws without damaging the product.

Illustrative Image (Source: Google Search)

Verifying Supplier Quality Control

For B2B buyers, especially those from diverse regions, verifying a supplier’s quality control processes is crucial. Here are actionable steps:

-

Audits: Conduct regular supplier audits to evaluate their manufacturing processes, quality control systems, and compliance with international standards. This could include on-site visits or remote audits using digital tools.

-

Request Reports: Ask suppliers for quality control reports and certifications that demonstrate compliance with relevant standards. These documents should detail their quality management practices and any certifications achieved.

-

Third-Party Inspections: Engage third-party inspection agencies to conduct independent evaluations of the supplier’s processes and products. This adds an extra layer of assurance regarding quality.

-

Performance Metrics: Assess suppliers based on key performance indicators (KPIs) such as defect rates, delivery times, and customer feedback. This data can provide insights into their reliability and quality.

Conclusion

Understanding the manufacturing processes and quality assurance measures involved in lost wax casting is essential for international B2B buyers. By familiarizing themselves with the stages of production, relevant quality standards, and effective verification techniques, buyers can make informed decisions and choose suppliers that consistently deliver high-quality products. This knowledge is particularly valuable for buyers in Africa, South America, the Middle East, and Europe, enabling them to navigate the complexities of international sourcing effectively.

Comprehensive Cost and Pricing Analysis for lost wax casting suppliers Sourcing

In the realm of lost wax casting, understanding the cost structure and pricing dynamics is essential for international B2B buyers. This process involves various cost components that contribute to the final pricing of cast products. Below is a comprehensive analysis tailored to assist buyers from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver in lost wax casting is the raw materials. This includes the wax for pattern making, refractory materials for molds, and the metal alloys used for casting. The choice of metal significantly influences cost; for example, precious metals like gold or platinum will be substantially more expensive than aluminum or stainless steel.

-

Labor: Skilled labor is required for various stages of the casting process, including pattern creation, mold making, and finishing. Labor costs can vary significantly based on the region and the expertise of the workforce. Countries with higher labor costs may reflect this in their pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility costs. Overhead can vary widely depending on the supplier’s location and operational efficiency.

-

Tooling: Although lost wax casting is less tooling-intensive than other methods, there are still costs associated with creating molds and patterns. Custom tooling for unique designs can add to the initial costs.

-

Quality Control (QC): Ensuring that products meet the required specifications involves rigorous quality control measures. This includes inspection processes, testing, and certifications, which can add to the overall cost.

-

Logistics: Shipping and handling costs, especially for international orders, can significantly impact pricing. Factors such as distance, shipping method, and Incoterms (International Commercial Terms) play a crucial role in determining these costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on their positioning in the market and the competitive landscape.

Price Influencers

Several factors influence the pricing of lost wax casting services:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Suppliers are usually more flexible with pricing for bulk orders.

-

Specifications/Customization: Custom designs and specifications can lead to increased costs. Detailed and complex designs may require more time and resources, which will be reflected in the pricing.

-

Materials: As mentioned, the choice of material can substantially influence cost. High-performance alloys or specialized materials will increase the price.

-

Quality and Certifications: Suppliers that provide certifications for quality, such as ISO, often charge a premium. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The supplier’s reputation, experience, and geographical location can affect pricing. Established suppliers with a track record of quality may command higher prices.

-

Incoterms: Understanding the agreed-upon Incoterms is crucial for buyers to calculate the total cost of ownership. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will affect how costs are allocated.

Buyer Tips

-

Negotiation: Engage in discussions with suppliers to negotiate pricing based on volume and long-term relationships. Suppliers may offer discounts for repeat business.

-

Cost-Efficiency: Evaluate the total cost of ownership rather than just the unit price. Consider logistics, duty fees, and potential wastage in the overall assessment.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and how they can impact pricing. Additionally, understanding local market conditions can help in negotiating better terms.

-

Research and Benchmarking: Conduct thorough research on multiple suppliers and compare their offerings. Benchmarking against industry standards can provide leverage in negotiations.

-

Plan for Contingencies: Always have a buffer in your budget for unexpected costs, such as increased shipping fees or changes in material prices.

Disclaimer

Prices and cost structures can vary significantly based on numerous factors, including market conditions, supplier capabilities, and geographical location. Buyers are encouraged to obtain detailed quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Spotlight on Potential lost wax casting suppliers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘lost wax casting suppliers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for lost wax casting suppliers

Key Technical Properties of Lost Wax Casting

Understanding the essential technical properties of lost wax casting is crucial for B2B buyers to ensure they select the right suppliers and materials for their projects. Here are some critical specifications to consider:

-

Material Grade

– Definition: Refers to the specific classification of the metal being used in the casting process, such as stainless steel, aluminum, or bronze.

– Importance: Different material grades have varying mechanical properties, corrosion resistance, and thermal characteristics. Selecting the appropriate material grade is vital for the application and longevity of the final product. -

Tolerance

– Definition: The permissible limit of variation in a physical dimension or measured value. For instance, a tolerance of ±0.01 mm indicates that the actual dimension may vary by that amount from the specified value.

– Importance: High tolerance levels are essential in industries like aerospace and medical technology, where precision is critical. Ensuring that the supplier can meet the required tolerances can prevent costly rework or product failures. -

Surface Finish

– Definition: The texture and smoothness of the final cast product, which can be affected by the mold material and casting process.

– Importance: A superior surface finish enhances both aesthetic appeal and functional performance. In applications such as jewelry or medical devices, the surface quality can be a determining factor in customer satisfaction and regulatory compliance. -

Casting Weight

– Definition: The total weight of the cast component, which can impact shipping costs and handling.

– Importance: Understanding the casting weight helps in logistics planning and cost estimation. It also affects the selection of materials and the design of the component, particularly in weight-sensitive applications like automotive and aerospace.

- Dimensional Accuracy

– Definition: The degree to which the dimensions of the finished casting conform to the specifications.

– Importance: High dimensional accuracy is essential for components that must fit together with other parts in an assembly. This property ensures that the final product functions as intended without additional machining.

Common Trade Terminology

Familiarity with industry-specific jargon can facilitate smoother communication and negotiations with suppliers. Here are some common terms used in the lost wax casting industry:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding if a supplier operates as an OEM can clarify their role in the supply chain, particularly in terms of quality assurance and intellectual property. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ helps buyers determine whether a supplier can meet their needs, especially for small-scale projects. It also influences cost efficiency and inventory management. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to solicit price proposals for specific products or services.

– Significance: An RFQ is a critical tool for buyers to compare costs and capabilities among different suppliers. It allows for informed decision-making based on detailed quotations. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions.

– Significance: Understanding Incoterms is essential for navigating shipping and logistics, especially in cross-border transactions. They clarify who is responsible for shipping costs, insurance, and risk during transport. -

Lead Time

– Definition: The amount of time that passes from the initiation of a process until its completion, particularly in manufacturing.

– Significance: Knowing the lead time helps buyers plan their production schedules and manage inventory effectively. It is crucial for timely project execution and meeting customer demands.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when selecting lost wax casting suppliers, ultimately enhancing their project outcomes and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the lost wax casting suppliers Sector

Market Overview & Key Trends

The global lost wax casting market is experiencing significant growth, driven by the increasing demand for precision-engineered components across various industries, including aerospace, automotive, medical, and jewelry. As of 2021, the market was valued at approximately $20.5 billion, with projections estimating it to reach $31.4 billion by 2030, reflecting a robust CAGR of 6.5%. International B2B buyers should note that the resurgence of manufacturing in regions like Africa and South America is creating new sourcing opportunities. Companies are leveraging technological advancements, such as 3D printing and computer-aided design (CAD), to enhance the efficiency and accuracy of the lost wax casting process. This trend is particularly relevant for buyers seeking suppliers that can provide quick turnaround times for prototypes and small production runs.

Moreover, there is a noticeable shift towards local sourcing as companies aim to mitigate risks associated with global supply chains. For buyers in Europe, the Middle East, and Latin America, establishing partnerships with local suppliers not only reduces lead times but also aligns with regional economic development initiatives. The demand for customization and complex designs is also on the rise, encouraging suppliers to invest in advanced manufacturing technologies. International buyers should focus on suppliers that demonstrate flexibility and innovation in their casting capabilities, as this will be critical in meeting the evolving market demands.

Sustainability & Ethical Sourcing in B2B

In the context of lost wax casting, sustainability is becoming an essential consideration for B2B buyers. The environmental impact of metal casting processes can be significant, particularly concerning energy consumption and waste generation. Consequently, many suppliers are adopting green practices, such as utilizing recycled materials and energy-efficient technologies, to reduce their carbon footprint. Buyers should prioritize suppliers that are committed to sustainability, as this not only contributes to environmental stewardship but also enhances brand reputation.

Additionally, the importance of ethical sourcing is gaining traction. Buyers are increasingly scrutinizing supply chains to ensure that their suppliers adhere to ethical labor practices and contribute positively to local communities. Certifications such as ISO 14001 for environmental management and SA8000 for social accountability can serve as indicators of a supplier’s commitment to sustainable and ethical practices. By selecting suppliers with these certifications, B2B buyers can ensure that their sourcing decisions align with their corporate social responsibility (CSR) goals while also meeting regulatory requirements.

Brief Evolution/History

The lost wax casting technique, also known as investment casting, has a rich history that dates back thousands of years. Originating in ancient civilizations, this method was initially used to create intricate jewelry and ceremonial objects. Over time, advancements in materials and techniques have transformed lost wax casting into a sophisticated manufacturing process essential for producing high-precision metal components.

In the modern era, the integration of technologies such as computer-aided design (CAD) and 3D printing has revolutionized the industry, allowing for rapid prototyping and complex designs. This evolution has made lost wax casting a preferred choice for industries requiring high-quality, intricate components, highlighting its enduring relevance in today’s manufacturing landscape. As international B2B buyers navigate this sector, understanding its historical context can provide valuable insights into the capabilities and future potential of lost wax casting suppliers.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of lost wax casting suppliers

-

What key factors should I consider when vetting lost wax casting suppliers?

When vetting lost wax casting suppliers, prioritize their experience, reputation, and capabilities. Look for suppliers with a proven track record in your specific industry, as they will better understand your needs. Request references and case studies to assess their work quality. Additionally, evaluate their certifications (such as ISO 9001) to ensure adherence to quality standards. Assess their technology and equipment to confirm they can handle the complexities of your designs. Finally, consider their communication responsiveness and willingness to collaborate on custom solutions. -

Can lost wax casting suppliers customize products to meet my specifications?

Yes, most lost wax casting suppliers offer customization options to meet specific client needs. This includes tailoring the design, material selection, and finishing processes. When discussing your project, provide detailed specifications and any necessary drawings or CAD files. It’s beneficial to engage in early discussions about your requirements, as this allows suppliers to offer insights on feasibility and potential improvements. Be sure to confirm their experience with similar custom projects to gauge their capability in delivering your unique requirements. -

What are the typical minimum order quantities (MOQ) and lead times for lost wax casting?

Minimum order quantities (MOQ) for lost wax casting can vary significantly among suppliers, often ranging from 50 to several hundred units, depending on the complexity of the parts and the production capabilities. Lead times also fluctuate based on order size, complexity, and supplier capacity, typically ranging from 4 to 12 weeks. To streamline your supply chain, it’s advisable to discuss your production schedule and potential bulk discounts early in negotiations. Establishing a long-term relationship with a supplier may also lead to more favorable terms regarding MOQs and lead times. -

What payment terms are commonly offered by lost wax casting suppliers?

Payment terms can vary widely depending on the supplier and the specifics of your order. Common practices include a deposit (often 30-50%) upfront, with the balance due upon completion or prior to shipment. Some suppliers may offer net payment terms (e.g., 30 days) for established clients. It’s essential to discuss and agree upon payment terms upfront to avoid misunderstandings. Additionally, consider using letters of credit or escrow services for larger orders to mitigate financial risks associated with international transactions. -

How do lost wax casting suppliers ensure quality assurance and certification?

Quality assurance in lost wax casting involves rigorous inspection and testing processes at various stages of production. Suppliers typically implement quality control measures such as dimensional inspections, material testing, and surface finish evaluations. Look for suppliers with relevant certifications (ISO 9001, AS9100 for aerospace, etc.) that demonstrate their commitment to quality standards. Request documentation of their quality assurance processes and any third-party audits to ensure compliance. A reliable supplier will be transparent about their QA practices and willing to provide test reports for your review. -

What logistics considerations should I keep in mind when sourcing from lost wax casting suppliers?

Logistics are crucial when sourcing from international lost wax casting suppliers. Consider shipping options, costs, and potential customs duties that may affect your total landed cost. Discuss with suppliers about their shipping capabilities and whether they handle logistics or if you’ll need to arrange them independently. Be aware of lead times for shipping and factor this into your overall project timeline. Additionally, establish clear communication regarding tracking shipments and managing any potential delays to ensure timely delivery. -

How can I resolve disputes with lost wax casting suppliers?

To effectively resolve disputes with suppliers, establish clear communication channels from the outset. Document all agreements, specifications, and expectations in writing to minimize misunderstandings. In the event of a dispute, attempt to resolve issues directly through open dialogue. If necessary, refer to your contractual terms regarding dispute resolution, which may include mediation or arbitration. Building a strong relationship with your supplier can also facilitate better communication and resolution processes, making it easier to address concerns collaboratively. -

What role does technology play in the lost wax casting process?

Technology significantly enhances the lost wax casting process, improving precision and efficiency. Many suppliers now utilize advanced CAD software for design and 3D printing for pattern creation, allowing for complex geometries that were previously challenging to achieve. Automation in molding and casting processes helps reduce human error and speed up production. When selecting a supplier, inquire about their technological capabilities and how they integrate modern techniques into their operations, as this can impact the quality and consistency of the final products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lost wax casting suppliers

In conclusion, strategic sourcing of lost wax casting suppliers is essential for international B2B buyers seeking precision and quality in their manufacturing processes. The lost wax casting method stands out due to its ability to produce intricate designs and superior surface finishes, making it a preferred choice across diverse industries such as aerospace, medical technology, and jewelry. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers with proven track records, robust quality control measures, and material versatility to ensure they meet their unique project requirements.

As the global lost wax casting market continues to expand, with projected growth reaching over $31 billion by 2030, now is the time to leverage this opportunity. Engaging with reliable suppliers not only enhances product quality but also fosters long-term partnerships that can drive innovation and efficiency in your production lines.

Take action today by evaluating potential suppliers based on their capabilities, customer feedback, and industry reputation. Establishing strong relationships with top-tier lost wax casting companies will position your business for success in a competitive marketplace.

Illustrative Image (Source: Google Search)