Your Ultimate Guide to Sourcing Machine Vision Companies

Introduction: Navigating the Global Market for machine vision companies

Navigating the landscape of machine vision companies is essential for B2B buyers aiming to enhance operational efficiency and quality across various sectors. Machine vision technology has become a cornerstone of modern manufacturing and logistics, driving automation, accuracy, and cost reduction. With applications spanning automotive, pharmaceuticals, food and beverage, and beyond, the relevance of machine vision in the Fourth Industrial Revolution cannot be overstated.

This guide serves as a comprehensive resource, equipping international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—with actionable insights to make informed sourcing decisions. We delve into the diverse types of machine vision solutions, materials utilized, and manufacturing processes, along with critical aspects of quality control. Additionally, we explore supplier dynamics and cost considerations, providing a holistic view of the market landscape.

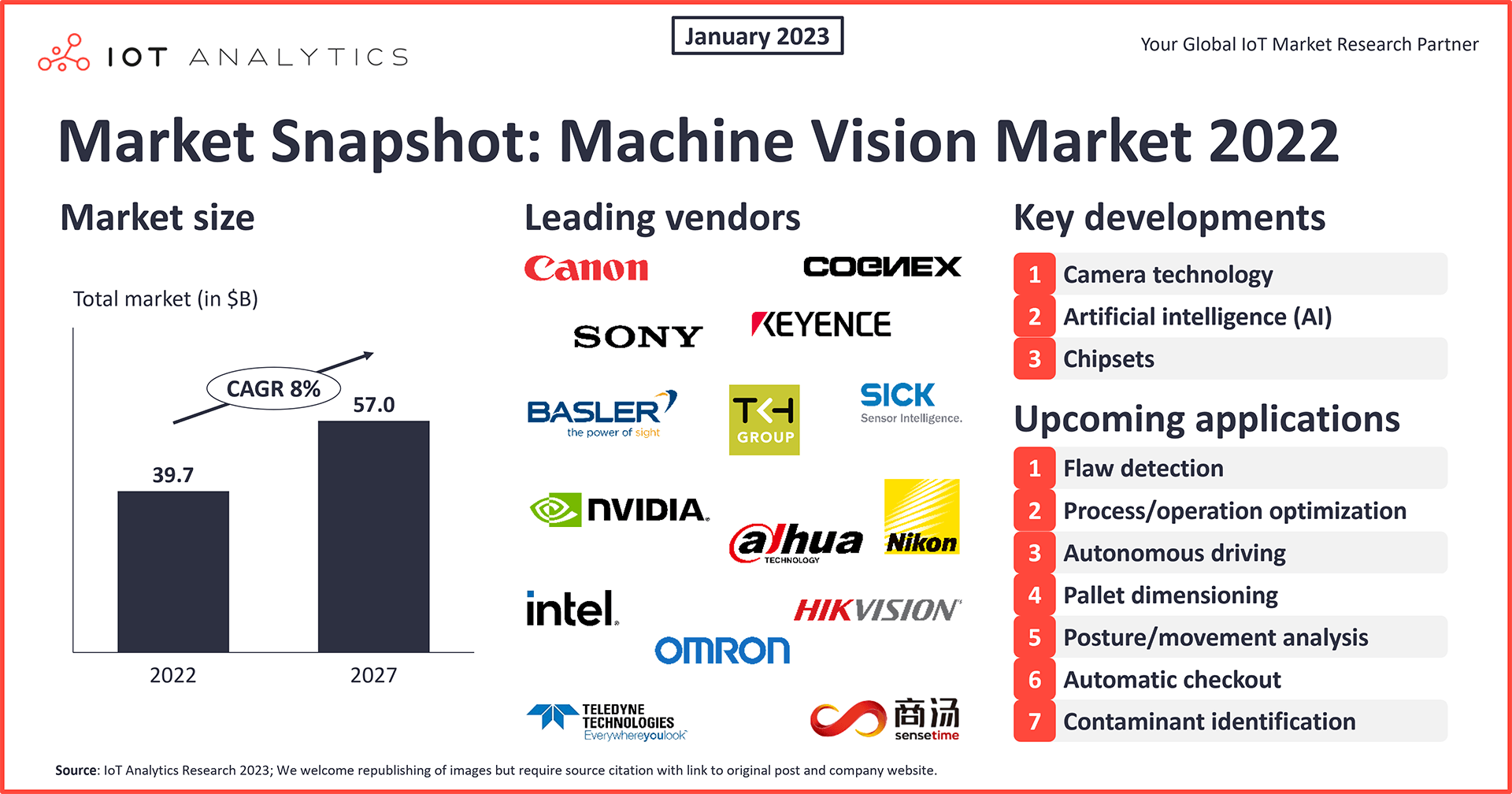

As the machine vision market continues to expand, projected to grow from USD 12 billion in 2023 to over USD 25 billion by 2030, understanding this sector’s intricacies is more vital than ever. The guide also addresses frequently asked questions to clarify common concerns and facilitate smoother procurement processes. By leveraging the insights within this guide, buyers can strategically navigate their sourcing journeys, ensuring they partner with the right machine vision companies to drive their businesses forward.

Understanding machine vision companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Automation Vision | Focus on high-speed image processing and real-time analysis. | Manufacturing, automotive assembly, quality control. | Pros: Increases efficiency; Cons: High initial investment. |

| Robotics Vision Systems | Integration with robotic systems for tasks like picking and placing. | Logistics, warehousing, assembly lines. | Pros: Enhances precision; Cons: Complex integration required. |

| Smart Cameras | Standalone cameras with built-in processing capabilities. | Retail analytics, security, traffic monitoring. | Pros: Easy to deploy; Cons: Limited processing power compared to integrated systems. |

| 3D Machine Vision | Utilizes depth perception for complex measurements and inspections. | Aerospace, medical devices, advanced manufacturing. | Pros: Accurate 3D modeling; Cons: Typically more expensive. |

| AI-Powered Vision Systems | Leverages artificial intelligence for enhanced image recognition. | Quality assurance, predictive maintenance, defect detection. | Pros: Adaptive learning; Cons: Requires robust data for training. |

Industrial Automation Vision

Industrial automation vision companies focus on high-speed image processing and real-time analysis, making them essential for sectors like manufacturing and automotive assembly. These systems are designed to monitor production lines and ensure quality control, allowing businesses to significantly enhance operational efficiency. When considering a purchase, B2B buyers should evaluate the system’s integration capabilities with existing machinery and the potential for ROI through productivity gains.

Robotics Vision Systems

Robotics vision systems are specifically designed to work in tandem with robotic platforms, enabling tasks such as picking, placing, and sorting. These systems are commonly used in logistics and warehousing environments where precision and speed are critical. Buyers should assess the compatibility of vision systems with their robotic applications and consider the complexity of integration, as this can impact overall efficiency and effectiveness.

Smart Cameras

Smart cameras are standalone devices equipped with built-in processing capabilities, making them versatile for various applications, including retail analytics and security. They can be easily deployed in multiple environments without needing extensive infrastructure. However, buyers should be mindful of their limited processing power compared to more complex integrated systems, which may affect performance in high-demand situations.

3D Machine Vision

3D machine vision companies utilize advanced technologies to provide depth perception, enabling accurate measurements and inspections. This type of vision is particularly valuable in specialized industries such as aerospace and medical devices, where precision is paramount. B2B buyers should consider the cost implications and the specific needs of their applications when investing in 3D vision technology, as it often requires a higher initial investment.

AI-Powered Vision Systems

AI-powered vision systems leverage artificial intelligence to enhance image recognition capabilities, making them suitable for applications like quality assurance and predictive maintenance. These systems can learn and adapt over time, improving their performance in defect detection and other critical tasks. Buyers should evaluate the amount of data available for training the AI models, as robust datasets are essential for maximizing the benefits of these advanced systems.

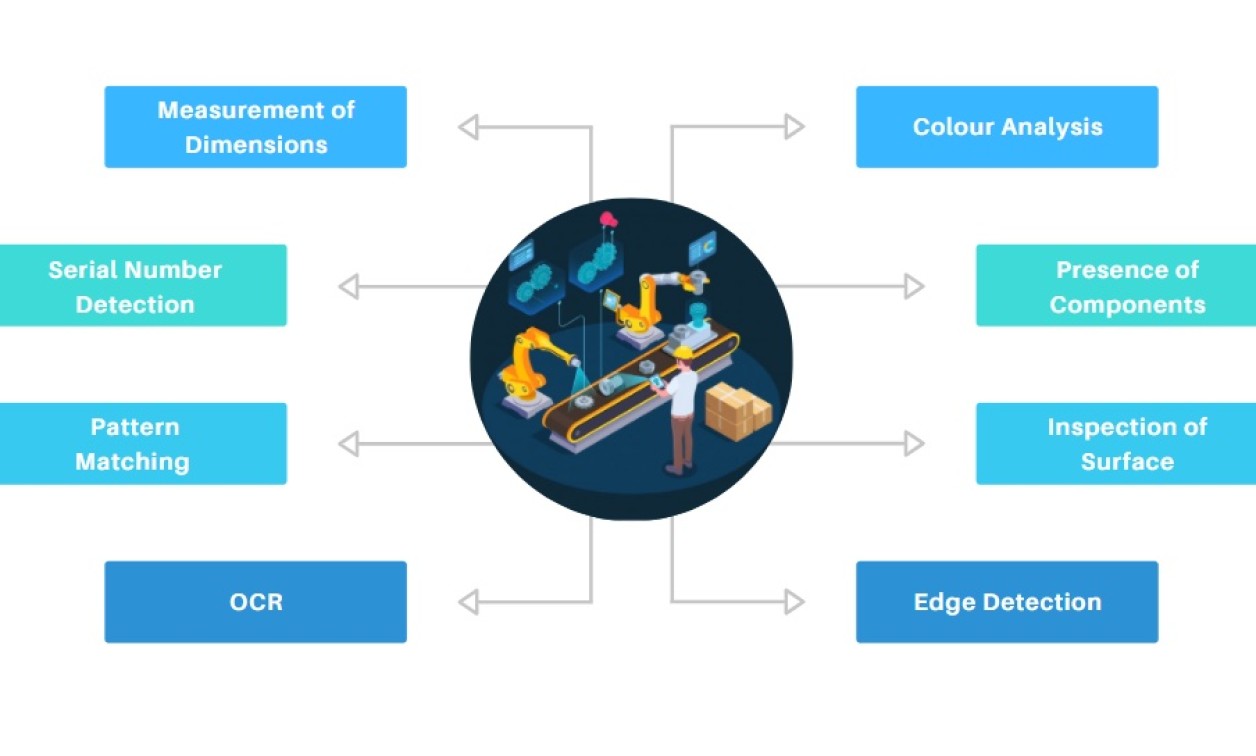

Key Industrial Applications of machine vision companies

| Industry/Sector | Specific Application of machine vision companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Automated quality inspection of parts and assemblies | Reduces defects, enhances safety, and increases throughput | Compatibility with existing assembly lines and software systems |

| Food & Beverage | Quality control for packaging and labeling | Ensures compliance with regulations and enhances consumer trust | Regulatory compliance, speed of inspection, and reliability |

| Pharmaceuticals | Inspection of vials and packaging for defects | Guarantees product integrity and reduces recalls | Precision requirements, integration with production systems |

| Electronics Manufacturing | Component placement verification in PCB assembly | Increases accuracy and efficiency, reducing rework costs | System adaptability to various component types and sizes |

| Logistics & Warehousing | Automated sorting and tracking of packages | Optimizes operations and reduces labor costs | Scalability, integration with existing warehouse management systems |

Automotive Industry

In the automotive sector, machine vision companies provide automated quality inspection systems that assess parts and assemblies during production. These systems utilize high-resolution cameras and AI algorithms to detect defects, ensuring that only high-quality components proceed to assembly. For international buyers, particularly in regions like Europe and the Middle East, sourcing systems that are compatible with existing assembly lines and software infrastructure is crucial to minimize downtime and integration challenges.

Food & Beverage Industry

Machine vision technology plays a critical role in the food and beverage industry by ensuring quality control for packaging and labeling. Automated inspection systems can identify mislabeling, damaged packaging, or contamination, helping companies maintain compliance with stringent health regulations. Buyers from Africa and South America should prioritize systems that offer high-speed inspection capabilities and are reliable under varying environmental conditions to ensure consistent product quality.

Pharmaceuticals Industry

In pharmaceuticals, machine vision systems are essential for inspecting vials and packaging for defects. These systems help maintain product integrity, significantly reducing the risk of recalls and ensuring that products meet regulatory standards. B2B buyers in this sector should focus on sourcing solutions that offer high precision and can be easily integrated into existing production lines, particularly in regions with strict regulatory environments like Europe.

Electronics Manufacturing

Machine vision is pivotal in electronics manufacturing, especially for verifying the placement of components on printed circuit boards (PCBs). By utilizing advanced imaging systems, companies can ensure that components are correctly placed, reducing rework costs and increasing production efficiency. International buyers, particularly from regions like Europe and the Middle East, need to consider the adaptability of these systems to various component types and sizes to maximize their return on investment.

Logistics & Warehousing

In logistics and warehousing, machine vision systems are deployed for automated sorting and tracking of packages. These systems streamline operations by accurately identifying and sorting items, significantly reducing labor costs and increasing efficiency. For buyers in Africa and South America, sourcing scalable solutions that integrate seamlessly with existing warehouse management systems is essential for optimizing logistics operations and enhancing overall productivity.

Related Video: Introduction to Machine Vision Part 1, Definition & Applications

Strategic Material Selection Guide for machine vision companies

When selecting materials for machine vision systems, it is essential to consider the specific properties and performance requirements that will impact the end product’s effectiveness. Below, we analyze four common materials used in machine vision applications, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Aluminum

Key Properties:

Aluminum is lightweight, with excellent thermal conductivity and corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for various environments.

Pros & Cons:

Aluminum is durable and easy to manufacture, which allows for complex designs. However, it can be more expensive than some alternatives and may not be suitable for high-stress applications.

Impact on Application:

Aluminum is often used in camera housings and frames due to its lightweight nature and ability to dissipate heat effectively. It is compatible with various media, including oils and solvents.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN for quality assurance. In regions like Europe, the preference for lightweight materials may drive demand for aluminum components.

2. Stainless Steel

Key Properties:

Stainless steel offers high strength, excellent corrosion resistance, and the ability to withstand high temperatures and pressures.

Pros & Cons:

While stainless steel is incredibly durable and suitable for harsh environments, it is heavier and more expensive than aluminum. Its manufacturing process can also be complex, which may lead to longer lead times.

Impact on Application:

This material is ideal for applications requiring robust protection against environmental factors, such as in food and beverage industries. It is compatible with a wide range of chemicals, making it versatile.

Considerations for International Buyers:

Buyers in regions like the Middle East and Africa should be aware of local corrosion risks and choose stainless steel grades that meet specific environmental conditions. Compliance with ASTM standards is crucial for ensuring product reliability.

3. Polycarbonate

Key Properties:

Polycarbonate is a high-impact resistant plastic that provides excellent optical clarity and UV resistance. It can operate effectively in a wide temperature range.

Pros & Cons:

This material is lightweight and cost-effective, making it suitable for various applications. However, it can be less durable than metals and may scratch easily, which could affect optical performance over time.

Impact on Application:

Polycarbonate is commonly used in protective covers for cameras and sensors, where transparency and impact resistance are critical. It is also compatible with various cleaning agents.

Considerations for International Buyers:

Buyers should verify that polycarbonate components meet local safety standards and regulations, especially in Europe, where compliance with REACH regulations is essential. Understanding the local market’s preferences for lightweight materials can also guide selection.

4. Glass

Key Properties:

Glass is known for its excellent optical properties, high chemical resistance, and ability to withstand high temperatures.

Pros & Cons:

While glass provides superior clarity and durability, it is heavy and can be fragile, making it less suitable for high-impact environments. The manufacturing process can also be expensive.

Impact on Application:

Glass is often used in lenses and protective windows for cameras due to its optical clarity. It is resistant to many chemicals, enhancing its suitability for various industrial applications.

Considerations for International Buyers:

In regions like South America and Europe, buyers should consider the implications of shipping and handling glass components due to their fragility. Compliance with international safety standards is also essential to avoid liability issues.

Summary Table

| Material | Typical Use Case for machine vision companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Camera housings and frames | Lightweight and thermal conductivity | Higher cost than some alternatives | Medium |

| Stainless Steel | Robust protective enclosures | High strength and corrosion resistance | Heavy and complex manufacturing | High |

| Polycarbonate | Protective covers for cameras | Lightweight and cost-effective | Less durable and prone to scratching | Low |

| Glass | Lenses and protective windows | Superior optical clarity | Heavy and fragile | Medium |

This guide serves as a strategic resource for international B2B buyers to make informed decisions regarding material selection in machine vision applications, ensuring compatibility with local standards and operational requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for machine vision companies

Understanding Manufacturing Processes for Machine Vision Companies

The manufacturing processes for machine vision systems are intricate and require precision at each stage. For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can help in evaluating suppliers and ensuring product quality. The primary stages of manufacturing machine vision systems include material preparation, forming, assembly, and finishing.

Main Stages of Manufacturing

-

Material Preparation

– Component Selection: High-quality materials such as silicon for sensors, specialized optics, and durable housing materials are chosen based on performance requirements.

– Pre-processing: Components may undergo treatments such as cleaning, cutting, or coating to ensure optimal performance and compatibility with other parts. -

Forming

– Fabrication Techniques: Advanced techniques like CNC machining, injection molding, and 3D printing are commonly employed to create precise components.

– Quality Control: During this stage, initial inspections are conducted to ensure that the dimensions and specifications of the components meet industry standards. -

Assembly

– Integration of Components: Skilled technicians or automated systems assemble the various parts, including cameras, sensors, and processing units, ensuring that each component fits perfectly.

– Testing During Assembly: Inline quality checks (IPQC) are performed to detect any issues early in the assembly process, reducing waste and rework. -

Finishing

– Final Assembly and Calibration: After the main assembly, systems undergo calibration to ensure that they meet required performance metrics. This includes adjusting focus, alignment, and software configurations.

– Packaging: The final product is carefully packaged to protect it during shipping and to ensure that it reaches the customer in perfect condition.

Quality Assurance in Machine Vision Manufacturing

Quality assurance (QA) is critical in the manufacturing of machine vision systems, especially given the complex technology involved. B2B buyers should be aware of the international standards and practices that ensure product quality and reliability.

Relevant International Standards

- ISO 9001: This standard outlines requirements for a quality management system (QMS) and is crucial for ensuring consistent quality in manufacturing processes. Companies adhering to ISO 9001 demonstrate a commitment to quality and customer satisfaction.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. This is particularly important for machine vision systems used in critical applications.

- API Standards: For industries like oil and gas, compliance with API (American Petroleum Institute) standards ensures that products meet specific safety and performance criteria.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This phase involves inspecting raw materials and components before they enter the production process. Suppliers should provide certificates of compliance, and inspections should be thorough to identify defects early. -

In-Process Quality Control (IPQC)

– Continuous monitoring during manufacturing helps catch defects as they occur. Techniques such as statistical process control (SPC) can be employed to analyze data and maintain quality throughout the process. -

Final Quality Control (FQC)

– Before products are shipped, they undergo rigorous testing to ensure they meet all specifications and performance standards. This might include functional testing, environmental testing, and compliance checks.

Common Testing Methods

- Visual Inspections: Technicians check for physical defects, misalignments, or surface imperfections.

- Functional Testing: Ensures that the machine vision systems operate correctly under various conditions.

- Performance Testing: Evaluates the system’s ability to handle tasks such as image processing speed and accuracy.

How B2B Buyers Can Verify Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

- Conduct Audits: Regular audits of suppliers can provide insights into their quality management systems and manufacturing processes. Buyers should request audit reports and certifications.

- Request Documentation: Suppliers should provide comprehensive documentation regarding their quality assurance processes, including test reports and compliance certificates.

- Engage Third-party Inspectors: Hiring third-party inspection services can add an extra layer of assurance. These inspectors can conduct unbiased evaluations of the manufacturing process and product quality.

Quality Control and Certification Nuances for International Buyers

Understanding the nuances of quality control and certifications is particularly important for international buyers. Here are key considerations:

- Cultural Differences: Different regions may have varying standards for quality and reliability. Buyers should familiarize themselves with the specific expectations and norms of the regions they are dealing with.

- Regulatory Compliance: Buyers must ensure that the products comply with local regulations in their countries. This includes understanding import regulations, safety standards, and any specific industry requirements.

- Language Barriers: Effective communication is crucial. Buyers should ensure that all documentation, including quality reports and certification documents, are available in a language they understand.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols in the machine vision industry empowers B2B buyers to make informed decisions. By focusing on these critical aspects, buyers can ensure that they partner with suppliers who prioritize quality, reliability, and compliance, ultimately leading to successful business outcomes.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for machine vision companies Sourcing

In the machine vision industry, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will provide insights into the various cost components involved, the factors that influence pricing, and actionable tips for buyers, particularly from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary costs in machine vision systems come from high-quality materials, including sensors, cameras, lenses, and specialized software. The choice of materials significantly impacts the performance and durability of the systems.

-

Labor: Skilled labor is essential for the development, assembly, and maintenance of machine vision systems. Labor costs can vary widely based on geographic location, with higher costs typically in developed regions such as Europe and North America.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Companies that operate in regions with higher operational costs may have increased overhead, which can reflect in the final pricing.

-

Tooling: Investment in specialized tooling for production can be substantial. Custom tooling is often required for unique specifications, which can elevate initial costs but may lead to efficiencies in mass production.

-

Quality Control (QC): Rigorous QC processes are vital to ensure reliability and performance. The costs associated with testing and certification can be significant, particularly for systems that must comply with international standards.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping and handling costs vary based on distance, shipping method, and the volume of goods. International shipping can introduce additional complexities, including customs duties and tariffs, which buyers need to account for.

-

Margin: The profit margin for machine vision companies typically ranges from 15% to 30%, influenced by market demand, competition, and value-added services.

Price Influencers

-

Volume/MOQ: Larger order volumes often lead to reduced per-unit costs. Buyers should consider negotiating minimum order quantities (MOQs) to achieve better pricing.

-

Specifications/Customization: Custom solutions may involve higher costs due to the unique requirements and additional engineering time. Buyers should clearly define their specifications to avoid unexpected costs.

-

Materials: The choice of materials can greatly affect the price. Opting for lower-cost materials may reduce upfront costs but could compromise quality and longevity.

-

Quality/Certifications: Systems that meet international quality standards or have specific certifications often come at a premium. Buyers should assess whether these certifications align with their operational needs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established companies may charge more for their products but can offer better support and warranty options.

-

Incoterms: Understanding international trade terms is vital. Incoterms determine who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost.

Buyer Tips

-

Negotiation: Effective negotiation can lead to significant savings. Buyers should be prepared to discuss volume discounts, payment terms, and long-term partnerships to improve pricing.

-

Cost Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and operational costs over the system’s lifespan. This approach often reveals that higher-quality systems may be more cost-effective in the long run.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, local taxes, and import duties that can affect pricing. Engaging with local agents or distributors can provide insights into market-specific pricing strategies.

-

Research and Benchmarking: Conduct thorough market research and compare prices from multiple suppliers. This practice helps in identifying competitive pricing and understanding market standards.

-

Leverage Technology: Utilize online platforms and marketplaces that specialize in machine vision products to access a broader range of options and competitive pricing.

Disclaimer

The prices and cost estimates discussed in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Buyers should conduct detailed due diligence before making purchasing decisions.

Spotlight on Potential machine vision companies Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘machine vision companies’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for machine vision companies

Key Technical Properties in Machine Vision

Understanding the technical specifications of machine vision systems is essential for making informed purchasing decisions. Here are several critical properties to consider:

-

Resolution

– Definition: Refers to the amount of detail an image holds, typically measured in pixels. Higher resolution indicates more detail.

– B2B Importance: In applications like quality control, high-resolution images are crucial for detecting minute defects. Buyers must assess resolution to ensure that the system meets their specific inspection needs. -

Frame Rate

– Definition: The number of images captured per second, usually expressed in frames per second (FPS).

– B2B Importance: A higher frame rate is beneficial in dynamic environments, such as assembly lines, where speed is essential for capturing accurate data without motion blur. This is vital for maintaining production efficiency.

Illustrative Image (Source: Google Search)

-

Field of View (FOV)

– Definition: The observable area that a camera can capture, typically measured in degrees or millimeters.

– B2B Importance: The FOV should align with the application’s requirements. A wider FOV is suitable for larger objects or areas, while a narrower FOV may be necessary for detailed inspections of smaller components. -

Lighting Conditions

– Definition: Refers to the types of lighting used in machine vision applications, which can include ambient light, LED lighting, or backlighting.

– B2B Importance: Proper lighting is critical for image clarity and contrast. Buyers should consider how lighting impacts the machine vision system’s performance under varying conditions. -

Connectivity and Compatibility

– Definition: The ability of the machine vision system to connect with other devices and software, including protocols like GigE, USB3, and Ethernet.

– B2B Importance: Compatibility with existing systems is essential for seamless integration. This affects the scalability of operations and ensures that investment in new technology enhances productivity without extensive reconfiguration. -

Software Capabilities

– Definition: The range of features provided by the machine vision software, including image processing, analysis, and machine learning functionalities.

– B2B Importance: Advanced software capabilities allow for customized solutions and flexibility in adapting to specific business needs. Buyers should evaluate software features to ensure they can leverage data effectively.

Common Trade Terminology in Machine Vision

Familiarity with industry jargon is crucial for effective communication and negotiation. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility of components in machine vision systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their purchasing strategies and manage inventory costs effectively. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to request pricing and terms from suppliers for specific products or services.

– Importance: Submitting an RFQ allows buyers to gather competitive pricing and evaluate different suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A series of international sales terms that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks associated with international purchases, which is particularly relevant for buyers from diverse regions. -

Calibration

– Definition: The process of adjusting the precision of a machine vision system to ensure accuracy in measurements and inspections.

– Importance: Regular calibration is essential for maintaining the integrity of machine vision systems, making it a key consideration for B2B buyers looking to invest in reliable technology. -

Throughput

– Definition: The amount of material or items processed within a given timeframe.

– Importance: High throughput rates are essential for maximizing efficiency in production lines. Buyers should assess throughput capabilities to ensure alignment with operational goals.

By understanding these technical properties and trade terms, international B2B buyers can navigate the machine vision market more effectively, ensuring they select systems that meet their operational needs and contribute to their competitive advantage.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the machine vision companies Sector

Market Overview & Key Trends

The machine vision market is experiencing robust growth, projected to expand from USD 12 billion in 2023 to over USD 23 billion by 2032, with a compound annual growth rate (CAGR) of 7.69%. This surge is largely driven by the increasing demand for automation across various sectors, particularly in manufacturing, automotive, and pharmaceuticals. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Key trends shaping the market include the integration of AI and deep learning technologies into machine vision systems, which enhances their capabilities in real-time image processing and decision-making. Additionally, the rise of smart cameras and edge computing is enabling faster processing at the source, reducing latency and increasing efficiency. Buyers should also be aware of the shift towards customized solutions, as companies increasingly seek systems tailored to their specific operational needs.

Furthermore, with the Fourth Industrial Revolution underway, machine vision is becoming integral to Industry 4.0 initiatives, promoting interconnectedness and data-driven decision-making. For instance, logistics and supply chain management are seeing transformative changes through advanced image recognition systems that optimize tracking and quality control. Buyers from diverse regions should prioritize partnerships with companies that not only provide innovative technologies but also demonstrate adaptability to local market conditions and regulatory requirements.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central concern for machine vision companies, driven by both regulatory pressures and consumer expectations. The environmental impact of manufacturing processes, including energy consumption and waste generation, necessitates a shift towards sustainable practices. For B2B buyers, it is essential to prioritize suppliers that implement eco-friendly operations, such as energy-efficient manufacturing techniques and responsible waste management.

Ethical sourcing is equally important in the machine vision sector. Buyers should seek companies that demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and do not contribute to environmental degradation. Look for green certifications such as ISO 14001 or the Energy Star label, which indicate a commitment to sustainable practices. Additionally, the use of recyclable materials in product packaging and manufacturing processes can significantly enhance a company’s sustainability profile.

By aligning with suppliers that prioritize sustainability and ethical sourcing, B2B buyers not only contribute to environmental preservation but also enhance their brand reputation and meet the growing demand for responsible business practices.

Brief Evolution/History

Machine vision technology has evolved significantly since its inception in the late 20th century. Initially focused on simple inspection tasks, advancements in computing power and image processing algorithms have transformed machine vision into a sophisticated tool capable of handling complex applications across various industries. The integration of AI and machine learning has further propelled its capabilities, enabling real-time analysis and decision-making.

As industries continue to embrace automation and seek efficiency gains, the role of machine vision is expected to expand, paving the way for innovations that will shape the future of manufacturing and quality control. Understanding this evolution helps B2B buyers appreciate the technological advancements and the potential for future applications in their operations.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of machine vision companies

-

What criteria should I use to vet machine vision suppliers?

When vetting machine vision suppliers, prioritize their industry experience, technological capabilities, and customer reviews. Evaluate their product portfolio to ensure it aligns with your specific needs, such as resolution, speed, and compatibility with existing systems. Additionally, check for certifications such as ISO or industry-specific standards, which indicate adherence to quality management practices. Engaging in discussions with existing clients can provide insights into the supplier’s reliability and service quality. -

Can machine vision solutions be customized for specific applications?

Yes, many machine vision companies offer customization options to tailor solutions for specific applications. This can include adjustments in software algorithms, camera specifications, and integration with existing machinery. When considering customization, communicate your requirements clearly and ask potential suppliers about their past experiences with similar projects. Understanding their development timeline and flexibility in accommodating changes is crucial to ensure that the final product meets your operational needs. -

What are typical minimum order quantities (MOQs) and lead times for machine vision products?

Minimum order quantities (MOQs) can vary widely among machine vision suppliers, depending on the product and complexity. Standard components may have lower MOQs, while specialized systems could require larger orders. Lead times also depend on customization levels and supplier capabilities, generally ranging from a few weeks to several months. It’s advisable to discuss your specific needs early in the negotiation process to establish clear timelines and avoid potential disruptions in your supply chain. -

What payment options are commonly offered by machine vision companies?

Payment options for machine vision products typically include upfront payments, partial payments during production, and payment upon delivery. International buyers should also consider payment methods such as letters of credit or escrow services, which can provide added security. Discussing payment terms during initial negotiations can help establish a mutual understanding, ensuring a smoother transaction process and minimizing the risk of disputes later on. -

How do machine vision companies ensure quality assurance and certification?

Machine vision companies usually implement rigorous quality assurance (QA) processes, which may include testing equipment at various production stages and adhering to international standards. Certifications such as ISO 9001 reflect a commitment to quality management systems. Request documentation of QA processes and relevant certifications when evaluating suppliers to ensure that their products meet your quality expectations and regulatory requirements. -

What logistics considerations should I keep in mind when sourcing machine vision systems?

Logistics play a crucial role in the procurement of machine vision systems. Consider factors such as shipping methods, customs regulations, and potential tariffs that may impact delivery times and costs. Suppliers with experience in international shipping can provide valuable insights and assistance in navigating these challenges. Additionally, ensure that the supplier has a reliable tracking system in place to keep you informed about the status of your order. -

How can I resolve disputes with machine vision suppliers?

To effectively resolve disputes with machine vision suppliers, maintain clear communication and documentation throughout the procurement process. Establish a formal dispute resolution mechanism in your contract, such as mediation or arbitration, to address potential issues amicably. If disputes arise, refer to the terms of your agreement, including delivery schedules, payment terms, and product specifications, to guide negotiations. Building a collaborative relationship with your supplier can also facilitate smoother resolutions. -

What are the key trends impacting the machine vision industry today?

The machine vision industry is currently being shaped by advancements in artificial intelligence (AI), deep learning, and edge computing. These technologies enhance image processing capabilities and increase automation across various sectors. International buyers should keep an eye on these trends as they can significantly influence product development and pricing strategies. Additionally, the growing emphasis on sustainability may drive machine vision companies to innovate greener solutions, which can be advantageous for businesses aiming to enhance their environmental responsibility.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for machine vision companies

The machine vision sector is rapidly evolving, driven by advancements in artificial intelligence and automation technologies. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, strategic sourcing in this space offers significant advantages, including enhanced operational efficiency, cost reduction, and improved product quality.

Investing in machine vision solutions can transform your manufacturing and logistics processes, enabling smarter decision-making and increased competitiveness. As the market is projected to grow substantially in the coming years, aligning with reputable machine vision companies will be critical. Key players such as Cognex, Omron, and Vitronic are setting benchmarks with innovative products that cater to diverse industry needs.

Actionable Insights:

– Evaluate Providers: Assess potential suppliers based on their technology offerings, market presence, and customer support.

– Leverage Local Expertise: Engage with local distributors or partners who understand regional market dynamics and can provide tailored solutions.

– Stay Informed: Keep abreast of industry trends and technological advancements to make informed purchasing decisions.

As we move towards an increasingly automated future, now is the time to explore strategic partnerships in the machine vision domain. By doing so, you can position your business at the forefront of Industry 4.0 and unlock new growth opportunities.