Your Ultimate Guide to Sourcing Membraine Keyboard

Introduction: Navigating the Global Market for membraine keyboard

Navigating the global market for membrane keyboards presents a unique opportunity for international B2B buyers to enhance their product offerings with versatile and cost-effective solutions. Membrane keyboards, characterized by their thin, flexible design and durable construction, are utilized across various industries—from consumer electronics to industrial control panels, medical devices, and automotive interfaces. Their growing demand is driven by the need for reliable, low-maintenance input devices that can withstand harsh environments while offering a user-friendly experience.

This comprehensive guide serves as an essential resource for B2B buyers, particularly those based in Africa, South America, the Middle East, and Europe, including regions like Italy and Colombia. It delves into the critical aspects of membrane keyboards, covering key topics such as types, materials, manufacturing processes, quality control standards, and supplier selection. Moreover, it provides insights into cost considerations and market trends that influence purchasing decisions.

By empowering buyers with actionable insights and detailed information, this guide aims to facilitate informed sourcing decisions that align with business objectives. Whether you are looking to enhance your existing product line or explore new applications for membrane keyboards, understanding the nuances of this market will enable you to partner effectively with suppliers and optimize your procurement strategies.

Understanding membraine keyboard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Membrane Keyboard | Thin, flexible design; low-profile; no tactile feedback | Consumer electronics, office equipment | Pros: Cost-effective, easy to clean. Cons: Less responsive typing experience. |

| Custom Membrane Keyboard | Tailored designs; various materials; specific application needs | Industrial control panels, medical devices | Pros: High durability, customizable features. Cons: Higher initial cost, longer lead times. |

| Backlit Membrane Keyboard | Integrated LED backlighting; enhanced visibility | Automotive interfaces, gaming devices | Pros: Improved usability in low-light conditions. Cons: Increased complexity and cost. |

| Sealed Membrane Keyboard | Waterproof and dustproof; robust construction | Military applications, outdoor equipment | Pros: Excellent durability, easy maintenance. Cons: Heavier and bulkier than standard options. |

| Touch-sensitive Membrane Keyboard | No physical keys; capacitive touch technology | Smart appliances, kiosks | Pros: Sleek design, easy to clean. Cons: May have accidental activation issues. |

Standard Membrane Keyboard

Standard membrane keyboards are characterized by their thin and flexible design, typically lacking tactile feedback. This type is widely used in consumer electronics and office equipment due to its cost-effectiveness and low-profile design. For B2B buyers, the major consideration is the balance between affordability and performance; while they are easy to clean and maintain, the less responsive typing experience can be a drawback in high-volume typing environments.

Custom Membrane Keyboard

Custom membrane keyboards are designed to meet specific application requirements, utilizing various materials and configurations. They are commonly employed in industrial control panels and medical devices where durability and tailored features are essential. Buyers should consider the initial investment and lead times, as customization can lead to higher costs and longer manufacturing periods. However, the resulting robustness and suitability for demanding environments often justify the expense.

Backlit Membrane Keyboard

Backlit membrane keyboards incorporate integrated LED lighting, making them ideal for automotive interfaces and gaming devices where visibility is critical. This feature enhances usability in low-light environments, providing a significant advantage for end-users. B2B buyers should weigh the benefits of improved user experience against the potential increase in complexity and cost associated with backlighting technologies.

Sealed Membrane Keyboard

Sealed membrane keyboards are designed to be waterproof and dustproof, making them suitable for military applications and outdoor equipment. Their robust construction offers excellent durability and ease of maintenance, which is crucial in harsh environments. Buyers need to consider the trade-off between the added weight and bulkiness compared to standard options, as these features may impact integration into existing systems.

Touch-sensitive Membrane Keyboard

Touch-sensitive membrane keyboards utilize capacitive touch technology, eliminating physical keys for a sleek design. They are commonly found in smart appliances and kiosks, offering a modern aesthetic and easy cleaning. However, B2B buyers should be cautious of potential accidental activations, especially in high-traffic areas. The innovative design can enhance user interaction, but it may also require a shift in user behavior and training.

Key Industrial Applications of membraine keyboard

| Industry/Sector | Specific Application of Membrane Keyboard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Patient monitoring systems | Ensures reliability and easy cleaning, crucial for hygiene standards | Suppliers must understand medical regulations and provide durable materials. |

| Industrial Control Panels | Machinery control interfaces | Offers robustness in harsh environments, reducing downtime | Manufacturers should focus on adhesive quality and environmental resistance. |

| Automotive | Climate control and navigation systems | Enhances user experience with intuitive interfaces | Look for vendors with experience in automotive standards and certifications. |

| POS Terminals | Retail checkout systems | Provides a sleek, easy-to-clean interface, boosting efficiency | Consider suppliers that offer customization options for branding and functionality. |

| Military and Aerospace | Control panels for aircraft and naval vessels | Ensures functionality in extreme conditions | ISO certification and responsive support are essential for compliance and reliability. |

Medical Devices

In the medical sector, membrane keyboards are widely utilized in patient monitoring systems, diagnostic machines, and other healthcare devices. Their sealed construction makes them easy to clean and sterilize, which is critical in preventing cross-contamination. Buyers should prioritize suppliers who understand medical regulations and offer materials that withstand frequent cleaning without degrading. Additionally, the ability to customize layouts and functionalities can enhance user experience, making it essential to communicate specific requirements clearly.

Industrial Control Panels

Membrane keyboards are integral to industrial control panels, where they function as interfaces for machinery and equipment. Their durability and resistance to harsh conditions such as moisture, dust, and chemicals make them ideal for factory settings. Buyers should consider the adhesive quality used for installation, as this can significantly impact the longevity of the keyboard. Vendors must also demonstrate expertise in materials that can withstand extreme temperatures or corrosive environments, ensuring minimal downtime for operations.

Automotive

In the automotive industry, membrane keyboards are commonly found in climate control systems and navigation interfaces. They provide a sleek and modern look while ensuring ease of use for drivers and passengers. B2B buyers should seek manufacturers who have experience with automotive standards and can produce keyboards that meet specific ergonomic and aesthetic requirements. Customization options, such as backlighting and multimedia keys, can enhance functionality, making it crucial to engage with suppliers who can accommodate these needs.

POS Terminals

Membrane keyboards are essential in point-of-sale (POS) terminals, where they facilitate quick and efficient transactions. Their low-profile design and ease of cleaning are significant advantages in high-traffic retail environments. When sourcing, businesses should look for suppliers that offer customization options to align with branding and user interface needs. Additionally, the ability to withstand heavy usage without compromising performance is vital, so buyers should confirm the durability standards of the keyboards.

Military and Aerospace

In military and aerospace applications, membrane keyboards are used in control panels for aircraft and naval vessels. Their ability to function reliably in extreme conditions, including temperature fluctuations and exposure to various elements, is critical. Buyers should prioritize suppliers who are ISO certified and can provide responsive customer support, ensuring compliance with stringent industry standards. Understanding the specific operational environment will help in selecting the right materials and design features for optimal performance.

Related Video: Advantages and Uses of ICT devices || Applications of ICT devices || Computer Basics

Strategic Material Selection Guide for membraine keyboard

When selecting materials for membrane keyboards, international B2B buyers must consider various factors that influence product performance, cost, and application suitability. Below, we analyze four common materials used in membrane keyboards, highlighting their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

1. Silicone Rubber

Key Properties:

Silicone rubber is known for its excellent flexibility, temperature resistance (up to 200°C), and durability. It is also resistant to UV light, ozone, and various chemicals, making it suitable for harsh environments.

Pros & Cons:

Silicone rubber offers high durability and a good tactile feel, enhancing user experience. However, it can be more expensive than other materials and may require specialized manufacturing techniques, which can increase lead times.

Impact on Application:

Silicone rubber is compatible with various media, including cleaning agents and oils, making it ideal for applications in medical devices and industrial control panels.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM D2000 for rubber materials. In regions like Europe, adherence to REACH regulations is essential for chemical safety.

2. Polyurethane

Key Properties:

Polyurethane is a versatile material known for its excellent abrasion resistance, flexibility, and ability to withstand a wide range of temperatures (-40°C to 90°C). It also offers good chemical resistance.

Pros & Cons:

The key advantage of polyurethane is its durability and resistance to wear, which prolongs the lifespan of the keyboard. However, it can be prone to yellowing when exposed to UV light over time, which may affect aesthetics.

Impact on Application:

Polyurethane is suitable for environments where exposure to oils and solvents is common, making it a good choice for automotive and industrial applications.

Considerations for International Buyers:

Buyers should verify that the polyurethane used meets relevant standards, such as ISO 9001 for quality management systems. Additionally, understanding local preferences for material properties can enhance product acceptance.

3. Polyester

Key Properties:

Polyester films are known for their high tensile strength, dimensional stability, and resistance to moisture and chemicals. They can operate effectively in a temperature range of -40°C to 120°C.

Pros & Cons:

Polyester is cost-effective and offers good clarity for printed graphics. However, it may not provide the same tactile feedback as silicone or polyurethane, which could impact user satisfaction.

Impact on Application:

Polyester is commonly used in consumer electronics and POS terminals, where visual clarity and durability are crucial.

Considerations for International Buyers:

Buyers should consider compliance with standards such as DIN 53370 for testing the properties of plastic films. In regions with stringent environmental regulations, ensuring that polyester is sourced sustainably can be a selling point.

4. PVC (Polyvinyl Chloride)

Key Properties:

PVC is a widely used thermoplastic that offers good chemical resistance, durability, and ease of processing. It can withstand temperatures up to 60°C.

Pros & Cons:

PVC is relatively inexpensive and easy to manufacture, making it a popular choice for budget-conscious projects. However, it is less flexible than silicone or polyurethane and may not perform well in extreme temperatures.

Impact on Application:

PVC is suitable for applications where cost is a primary concern, such as basic consumer electronics. However, its limited temperature range may restrict its use in more demanding environments.

Considerations for International Buyers:

Buyers should ensure that PVC complies with local regulations regarding phthalates and other harmful substances, particularly in Europe where regulations are stringent.

Summary Table

| Material | Typical Use Case for membrane keyboard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Rubber | Medical devices, industrial controls | Excellent durability and flexibility | Higher cost, complex manufacturing | High |

| Polyurethane | Automotive, industrial applications | Good abrasion resistance | Prone to UV yellowing | Medium |

| Polyester | Consumer electronics, POS terminals | Cost-effective and clear graphics | Less tactile feedback | Low |

| PVC | Basic consumer electronics | Inexpensive and easy to process | Limited flexibility and temperature range | Low |

This strategic material selection guide provides critical insights for international B2B buyers, enabling them to make informed decisions based on performance requirements, cost considerations, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for membraine keyboard

When sourcing custom membrane keyboards, understanding the manufacturing processes and quality assurance protocols is critical for international B2B buyers. This knowledge not only ensures that the products meet specific requirements but also mitigates risks associated with poor quality and material inconsistencies. Below is an in-depth examination of the typical manufacturing processes, quality control measures, and actionable insights for buyers particularly from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

The production of membrane keyboards involves several key stages, each critical to ensuring the final product meets quality and performance standards.

1. Material Preparation

The first step in manufacturing membrane keyboards is the selection and preparation of materials. Common materials include:

- Top Layer: Typically made of polyester or polycarbonate, this layer is printed with key symbols and graphics.

- Conductive Layer: This middle layer consists of conductive traces made from materials like copper or silver.

- Back Layer: Usually constructed from a durable plastic, this layer provides structural support.

Actionable Insight: Buyers should inquire about the types of materials used and their sourcing practices. High-quality materials will enhance durability and performance, especially in harsh environments.

2. Forming

In this stage, the prepared materials are formed into the desired shape. Techniques include:

- Printing: The top layer is printed using techniques like screen printing or digital printing to create the necessary graphics.

- Die-Cutting: This method is used to cut the layers into precise shapes that fit the design specifications.

Actionable Insight: Ensure the manufacturer uses advanced printing technology to avoid issues like fading or smudging, which can affect the usability and aesthetics of the keyboard.

3. Assembly

The assembly process involves layering the components and affixing them together. Key steps include:

- Layer Alignment: Each layer must be aligned accurately to ensure proper functionality.

- Adhesive Application: High-quality adhesives are applied to secure the layers. The choice between Low-Surface Energy and High-Surface Energy adhesives depends on the application surface.

Actionable Insight: Confirm that the supplier has the capability for in-house assembly to reduce delays and ensure better quality control.

4. Finishing

This final stage includes quality checks and additional features:

- Coating: A protective coating may be applied to enhance durability and resistance to environmental factors.

- Testing: Initial testing for functionality and durability occurs before packaging.

Actionable Insight: Buyers should request information about the finishing techniques used and whether they include protective coatings that suit the intended application.

Quality Assurance

Quality control is essential in the manufacturing of membrane keyboards. Adhering to international standards and implementing rigorous testing protocols can help ensure product reliability.

International Standards

Buyers should look for suppliers that comply with recognized quality standards such as:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: This indicates compliance with European safety, health, and environmental protection standards.

Actionable Insight: Request documentation proving compliance with these standards. This not only demonstrates a commitment to quality but also eases market entry in regions with strict regulatory environments.

Quality Control Checkpoints

Quality control is typically segmented into several checkpoints:

- Incoming Quality Control (IQC): Inspect raw materials upon receipt to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): Conduct checks during the manufacturing process to identify defects early.

- Final Quality Control (FQC): Perform comprehensive testing on the finished product to confirm it meets all specifications.

Actionable Insight: Engage with suppliers to understand their QC processes and ensure they have robust mechanisms for identifying and addressing defects.

Common Testing Methods

Testing methods used in quality assurance include:

- Functional Testing: Verifying that all keys register properly when pressed.

- Environmental Testing: Assessing the keyboard’s performance under various environmental conditions (temperature, humidity, etc.).

- Durability Testing: Simulating wear and tear to determine the keyboard’s lifespan.

Actionable Insight: Buyers should request test reports and certifications that demonstrate compliance with these testing methods. This can help ensure that the keyboards will perform reliably in their intended applications.

Verification of Supplier QC

B2B buyers can take several steps to verify the quality control practices of their suppliers:

- Audits: Conduct regular audits of the manufacturing facility to assess compliance with quality standards and practices.

- Reports: Request regular QC reports that outline testing results and any issues encountered during production.

- Third-Party Inspections: Engage independent inspection agencies to verify the quality of the products before shipment.

Actionable Insight: Establish a clear communication channel with suppliers regarding quality assurance practices and ensure that you receive timely updates throughout the manufacturing process.

Conclusion

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures for membrane keyboards is crucial. By focusing on material selection, assembly techniques, and rigorous quality control practices, buyers can mitigate risks and ensure that they receive high-quality products that meet their specific needs. Always prioritize working with experienced manufacturers who demonstrate a commitment to quality and compliance with international standards.

Related Video: Mechanical Keyboard Factory Production Process【2022】

Comprehensive Cost and Pricing Analysis for membraine keyboard Sourcing

Understanding the cost structure and pricing dynamics of membrane keyboards is essential for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, price influencers, and practical tips for negotiating favorable terms.

Cost Components

-

Materials: The primary materials used in membrane keyboards include silicone, polyester, and various adhesives. The choice of materials significantly influences the overall cost. For example, high-quality silicone may incur higher costs but offers better durability and resistance to harsh environments.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Countries with lower labor costs may provide cheaper options, but this can sometimes compromise quality. It’s crucial to balance labor costs with the expertise required for producing high-quality membrane keyboards.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Manufacturers with advanced technology and efficient processes can reduce overhead costs, impacting the final price positively.

-

Tooling: Custom tooling for unique designs or features can add significant upfront costs. While this is a one-time expense, it’s essential to factor it into the pricing model, especially for smaller orders.

-

Quality Control (QC): Investing in robust QC processes ensures that the keyboards meet required specifications and certifications, which can add to costs but ultimately reduce the risk of defects and returns.

-

Logistics: Shipping costs can vary greatly based on distance, shipping method, and Incoterms. Understanding the logistics involved can help buyers anticipate costs related to freight and customs duties.

-

Margin: Manufacturers typically apply a markup based on production costs, market conditions, and competitive pricing. Margins can vary by region and manufacturer, affecting the final purchase price.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly influence pricing. Larger orders often lead to lower unit prices due to economies of scale, while smaller orders may incur higher per-unit costs.

-

Specifications/Customization: Customized features, such as backlighting or specific key layouts, can increase costs. Buyers should clearly outline their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: The use of premium materials and adherence to international quality standards (e.g., ISO certifications) can elevate costs but are often justified by better performance and durability.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers may charge more due to their experience and proven track record.

-

Incoterms: The choice of Incoterms affects who bears the shipping costs and risks, which can influence the total cost of ownership. Buyers should negotiate terms that minimize their risk and control costs effectively.

Buyer Tips

-

Negotiation: Leverage volume purchasing to negotiate better pricing. Establish long-term partnerships with suppliers to enhance bargaining power.

-

Cost Efficiency: Assess the total cost of ownership, which includes not just the purchase price but also long-term maintenance and replacement costs. Opt for suppliers who offer warranties and reliable customer support.

-

Pricing Nuances: Be aware that pricing can vary by region. For instance, suppliers in Europe may have different pricing structures compared to those in Africa or South America due to local market conditions and cost structures.

-

Local Regulations: Familiarize yourself with import duties and local regulations that may affect pricing. This knowledge can help in negotiating better terms and understanding the total landed cost.

-

Supplier Communication: Maintain open lines of communication with suppliers to clarify specifications and requirements upfront. This proactive approach can prevent costly misunderstandings later in the process.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, specific supplier agreements, and customization requirements. Always conduct thorough research and engage in direct negotiations to obtain the most accurate pricing.

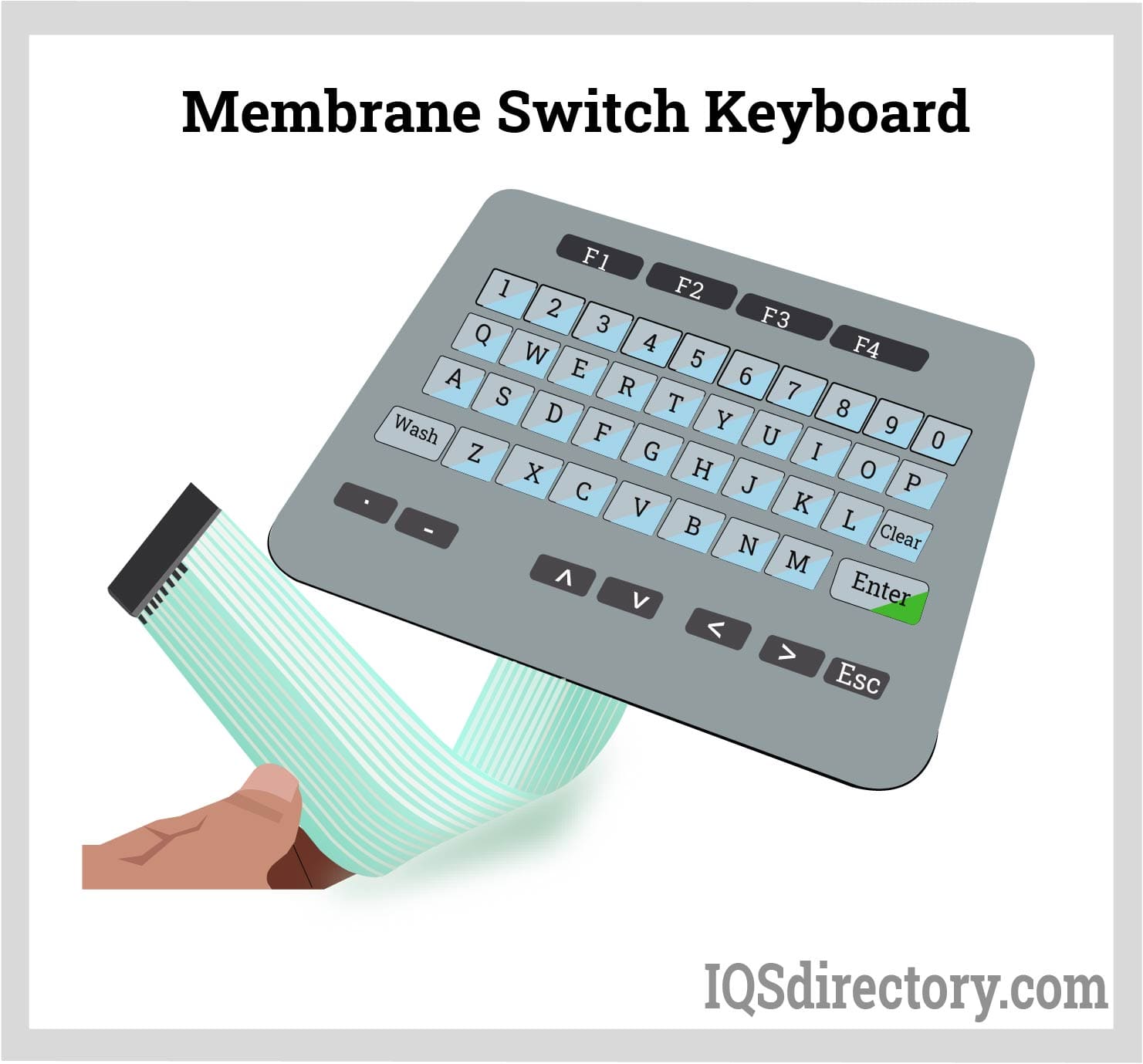

Illustrative Image (Source: Google Search)

Spotlight on Potential membraine keyboard Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘membraine keyboard’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for membraine keyboard

Critical Technical Properties of Membrane Keyboards

Understanding the essential technical properties of membrane keyboards is crucial for B2B buyers, as these specifications directly impact product performance, durability, and compatibility with various applications. Here are some key properties to consider:

-

Material Grade

Membrane keyboards typically utilize materials such as silicone rubber or polyurethane for their membrane layers. The choice of material affects flexibility, durability, and resistance to chemicals or moisture. For industries operating in harsh environments, selecting high-grade materials ensures longevity and reliability. -

Layer Configuration

A standard membrane keyboard consists of three primary layers: the top membrane layer (with printed symbols), a middle layer containing conductive traces, and a bottom layer with conductive pads. Understanding this configuration helps buyers assess how well the keyboard will perform in their specific applications, such as medical devices or industrial control panels. -

Operating Temperature Range

Each membrane keyboard is rated for specific temperature ranges. This specification is vital for applications in extreme environments, such as automotive or aerospace, where keyboards may be exposed to high or low temperatures. Ensuring compatibility with these conditions helps avoid failures and costly replacements. -

IP Rating (Ingress Protection)

The IP rating indicates the level of protection against dust and moisture. For instance, an IP65 rating means the keyboard is dust-tight and can withstand low-pressure water jets. This property is particularly important for applications in kitchens, laboratories, or outdoor settings where exposure to spills or contaminants is likely. -

Tactile Feedback

The tactile feedback provided by the membrane switch is essential for user experience. While membrane keyboards generally offer less feedback than mechanical keyboards, the presence of dome switches can enhance the typing experience. Buyers should evaluate whether this meets the operational needs of their end-users. -

Lifecycle and Durability

Membrane keyboards are often rated for a specific number of key presses (e.g., up to one million presses). Understanding this durability metric is essential for industries requiring high-frequency usage, such as medical or industrial applications, ensuring that the investment will last over time.

Common Trade Terminology in Membrane Keyboard Procurement

Familiarity with industry terminology streamlines communication and decision-making during the procurement process. Here are some essential terms for B2B buyers:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are sold under another company’s brand. For buyers, partnering with an OEM can facilitate customized solutions tailored to specific needs, ensuring quality and consistency. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of product that a supplier is willing to sell. Understanding MOQ helps buyers manage inventory and budget effectively, as it can impact overall purchasing costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. By issuing an RFQ, buyers can compare offers from multiple vendors, ensuring they secure the best possible deal. -

Incoterms (International Commercial Terms)

These are a set of standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and manage risks associated with international trade. -

Lead Time

This term refers to the time between placing an order and receiving the product. Understanding lead times is crucial for planning and inventory management, especially when working with suppliers from different regions. -

Customization Options

This refers to the ability to modify features of the membrane keyboard, such as layout, key functions, and backlighting. Knowing the customization capabilities of suppliers allows buyers to choose products that meet their specific application requirements.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the membraine keyboard Sector

Market Overview & Key Trends

The membrane keyboard market is experiencing significant growth, driven by increasing demand for versatile, cost-effective, and durable input devices across various industries. As of 2024, the market was valued at approximately USD 3.41 billion and is projected to reach USD 5.19 billion by 2032, with a CAGR of 5.40%. International B2B buyers from Africa, South America, the Middle East, and Europe should note the rising adoption of membrane keyboards in sectors such as consumer electronics, industrial applications, and healthcare.

Emerging trends include customization capabilities, where manufacturers are increasingly offering tailored solutions to meet specific application needs, such as moisture resistance for medical devices or backlit keys for low-light environments. Moreover, the integration of smart technologies in membrane keyboards is gaining traction, enabling enhanced user interfaces in automotive and industrial control systems. This shift towards digitalization and automation is particularly pertinent for buyers in rapidly developing markets, where demand for innovative, user-friendly interfaces is on the rise.

Additionally, the market is witnessing a movement towards lightweight and compact designs, making membrane keyboards suitable for portable devices. As competition intensifies, buyers should focus on sourcing from manufacturers with a proven track record in quality control and customer service, ensuring that their specifications are met without unexpected costs or delays.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central concern in the membrane keyboard sector, prompting buyers to prioritize suppliers that adhere to ethical sourcing practices. The environmental impact of production processes, particularly concerning material selection and waste management, is under scrutiny. Suppliers utilizing green materials, such as recyclable plastics and non-toxic inks, are increasingly preferred.

B2B buyers should look for manufacturers that possess ISO certifications or other recognized green certifications, indicating compliance with international environmental standards. These certifications not only demonstrate a commitment to reducing ecological footprints but also enhance the credibility of the supplier in the global market.

Illustrative Image (Source: Google Search)

Moreover, ethical supply chains are essential for ensuring fair labor practices and minimizing the carbon footprint associated with transportation. By choosing suppliers committed to sustainable practices, businesses can enhance their brand image and appeal to environmentally conscious consumers, particularly in Europe and North America, where sustainability is often a key purchasing criterion.

Brief Evolution/History

The membrane keyboard has evolved significantly since its inception in the 1980s. Initially used in simple electronic devices due to their low cost and durability, advancements in materials and manufacturing processes have transformed them into sophisticated input devices suitable for various applications. Over the years, the introduction of touch-sensitive technologies and customization options has broadened their usability, making them a preferred choice in both consumer and industrial markets.

Today, the membrane keyboard stands at the intersection of functionality and design, reflecting the needs of modern users while maintaining the benefits of traditional keyboards. As the market continues to expand, understanding the historical context can provide B2B buyers with insights into potential future developments and innovations.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of membraine keyboard

-

What should I look for when vetting a supplier for membrane keyboards?

When vetting suppliers, consider their industry experience, reputation, and manufacturing capabilities. Request samples to evaluate quality and ensure they can meet your specific application requirements. Additionally, check for certifications such as ISO to guarantee adherence to quality standards. A responsive supplier who understands your market and can communicate effectively in your preferred language is essential for smooth operations, especially for international transactions. -

Can membrane keyboards be customized to meet my specific needs?

Yes, most manufacturers offer customization options for membrane keyboards, including size, layout, and additional features like backlighting or tactile feedback. It’s crucial to clearly outline your requirements before engaging with a supplier. Discuss materials, colors, and functionalities that align with your application to ensure the final product meets your expectations. This approach minimizes the risk of miscommunication and ensures that the end product is tailored to your needs. -

What are the typical minimum order quantities (MOQs) and lead times for membrane keyboards?

MOQs vary by supplier and can range from a few hundred to several thousand units, depending on customization and production capabilities. Lead times typically range from 4 to 12 weeks, influenced by the complexity of the design and the supplier’s current workload. For international buyers, it’s advisable to discuss these parameters upfront and consider placing larger orders to benefit from better pricing and shorter lead times, especially in regions with longer shipping durations. -

What payment terms should I expect when sourcing membrane keyboards internationally?

Payment terms can vary significantly among suppliers. Common practices include upfront deposits (20-50%) with the balance due before shipping. Some suppliers may offer letters of credit or payment through escrow services for added security. It’s essential to negotiate terms that protect both parties and provide flexibility. Be aware of any additional costs related to international transactions, such as currency conversion fees and transaction charges. -

How can I ensure quality assurance (QA) and certifications for membrane keyboards?

To ensure quality, request documentation of the supplier’s QA processes and certifications. Look for ISO certifications that indicate a commitment to quality management. Ask about their testing procedures for durability, functionality, and compliance with international standards. Consider conducting on-site visits or third-party inspections, especially for large orders, to verify that the manufacturing processes align with your quality expectations. -

What logistics considerations should I keep in mind when sourcing membrane keyboards?

Logistics can be complex, especially for international shipping. Discuss shipping methods, costs, and estimated delivery times with your supplier. Consider potential customs duties and import regulations in your country, as these can impact total costs. Working with a logistics partner familiar with international trade can streamline the process and help mitigate risks related to delays or lost shipments. -

How should I handle disputes with a supplier?

Establish clear communication channels and document all agreements in writing to minimize misunderstandings. In the event of a dispute, try to resolve it amicably through direct communication first. If necessary, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Having a legal framework in place prior to any issues arising can facilitate smoother resolutions and protect your interests. -

What are the common challenges when sourcing membrane keyboards internationally?

Common challenges include language barriers, cultural differences, and varying quality standards. Ensure that you and your supplier are aligned on specifications and expectations to avoid miscommunication. Additionally, be mindful of fluctuating shipping costs and potential delays due to customs procedures. Establishing a strong relationship with your supplier and maintaining open lines of communication can help mitigate these challenges and lead to successful long-term partnerships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for membraine keyboard

Strategic sourcing of custom membrane keyboards is vital for international B2B buyers aiming to optimize performance and cost efficiency in their operations. Understanding the specific application needs, such as environmental conditions and required durability, allows buyers to select the right materials and features. Partnering with experienced and ISO-certified manufacturers ensures that quality standards are met, reducing the risk of costly errors and delays.

Key considerations include:

– Vendor experience: Choose suppliers familiar with your industry to avoid compatibility issues.

– Adhesive quality: Ensure the right adhesive is used for your application surfaces to guarantee longevity.

– Responsive communication: Opt for suppliers that prioritize clear communication and quick responses to inquiries.

As the membrane keyboard market continues to grow, with an expected CAGR of 5.40% through 2032, now is the time for buyers from Africa, South America, the Middle East, and Europe to leverage strategic sourcing to enhance their competitive edge. By making informed choices and fostering strong supplier relationships, businesses can significantly improve their product offerings and operational efficiency. Embrace the opportunity to innovate and enhance your product lines with high-quality membrane keyboards today.