Your Ultimate Guide to Sourcing Metal Conveyor Belts

Introduction: Navigating the Global Market for metal conveyor belts

Navigating the complexities of the global market for metal conveyor belts is essential for businesses aiming to enhance operational efficiency and reduce costs. As a critical component in various industries—including food processing, mining, and manufacturing—metal conveyor belts facilitate the smooth transport of materials, ensuring productivity and safety in high-demand environments. Their robust design, combined with advanced manufacturing techniques, offers unparalleled durability and reliability, making them an invaluable asset for companies worldwide.

This guide serves as a comprehensive resource for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, including key markets like Spain and Turkey. It delves into essential topics such as the different types of metal conveyor belts, the materials used in their construction, manufacturing and quality control processes, and supplier selection criteria. Additionally, it provides insights into cost considerations and market trends, equipping buyers with the knowledge they need to make informed sourcing decisions.

By understanding the intricacies of metal conveyor belts, buyers can identify the best solutions tailored to their operational needs, ensuring optimal performance and longevity. This guide empowers businesses to navigate the global landscape confidently, ensuring they choose reliable suppliers and high-quality products that will drive their success in an increasingly competitive market.

Understanding metal conveyor belts Types and Variations

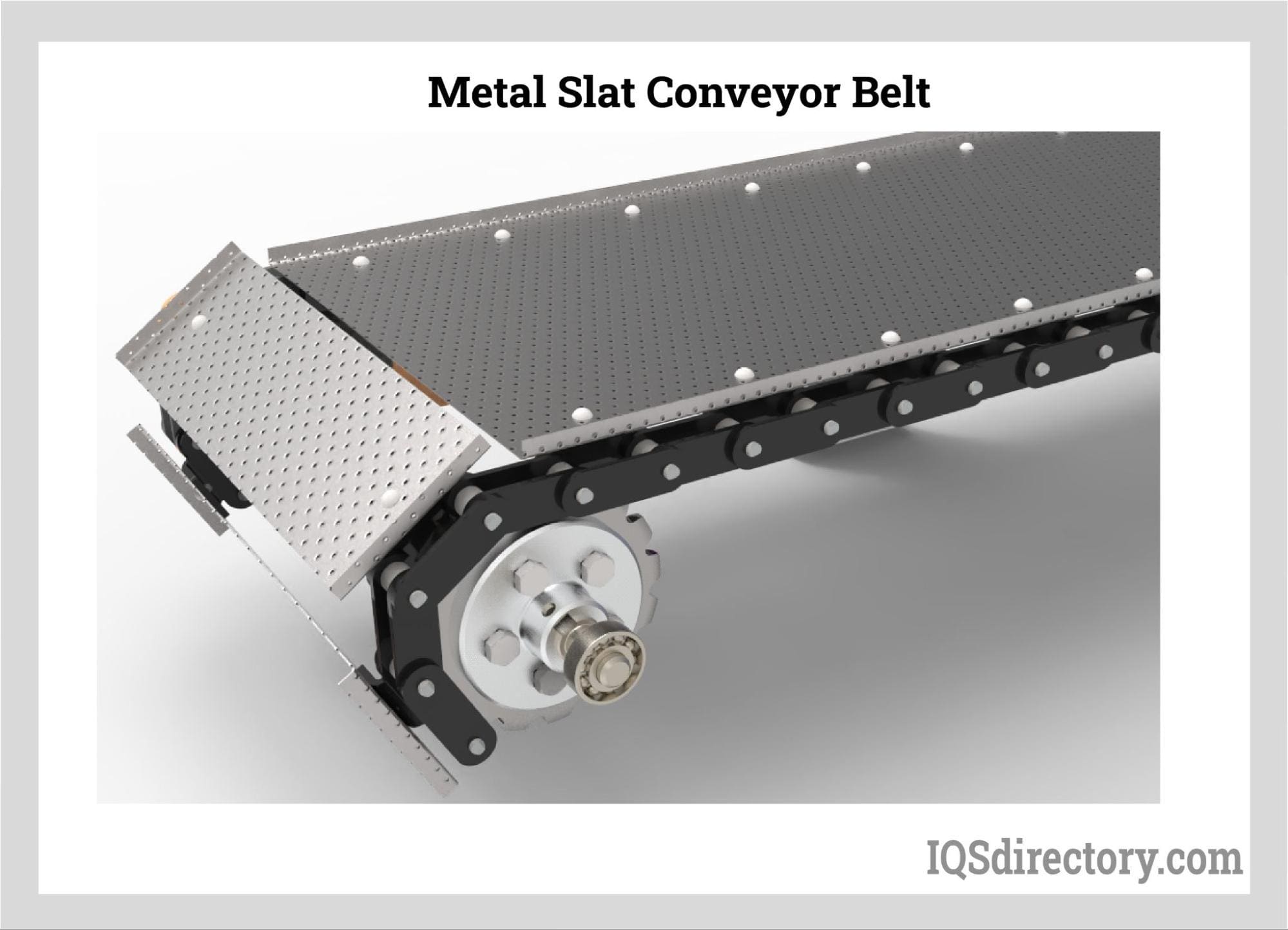

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Wire Belt | Strong, durable, and easy to clean; excellent tracking | Food processing, packaging | Pros: Long lifespan, easy maintenance. Cons: Limited load capacity compared to other types. |

| Spiral Belt | Continuous, flexible design; ideal for cooling and freezing | Food production, cooling systems | Pros: Efficient space utilization, smooth product flow. Cons: More complex installation and maintenance. |

| Modular Belt | Composed of interlocking plastic or metal modules; customizable | Automated manufacturing, logistics | Pros: Versatile, easy to replace sections. Cons: Higher initial costs and potential for wear over time. |

| Cam-Grid Belt | Superior strength with a fully collapsible design | Heavy-duty applications, industrial | Pros: High load capacity, easy cleaning. Cons: Heavier, may require stronger support structures. |

| Precision Belt | Engineered for variable temperature environments | Bakery and confectionery industries | Pros: Excellent thermal management, precise tracking. Cons: More expensive due to specialized design. |

Flat Wire Belt

Flat wire belts are characterized by their robust construction and ease of cleaning, making them ideal for environments where hygiene is paramount, such as food processing and packaging. These belts provide excellent tracking and can handle moderate loads, but they may not be suitable for extremely heavy materials. When considering a flat wire belt, buyers should evaluate their specific load requirements and maintenance capabilities, as these belts require periodic cleaning to ensure optimal performance.

Spiral Belt

Spiral belts are designed with a continuous, flexible structure, allowing for efficient cooling and freezing processes in food production. Their design promotes smooth product flow and maximizes space in production lines. However, the installation and maintenance of spiral belts can be more complex compared to other types. B2B buyers should assess the operational environment and determine if the benefits of space-saving and product handling outweigh the potential challenges in maintenance and setup.

Modular Belt

Modular belts consist of interlocking plastic or metal modules, providing a highly customizable solution for various applications, especially in automated manufacturing and logistics. The modular design allows for easy replacement of individual sections, reducing downtime during maintenance. However, the initial investment may be higher compared to traditional belts, and buyers should consider the long-term cost savings associated with reduced maintenance and increased operational efficiency.

Cam-Grid Belt

The Cam-Grid belt features a robust construction designed to handle heavy-duty applications. Its fully collapsible design facilitates easy cleaning, making it suitable for industries with stringent hygiene standards. While it offers a high load capacity, the increased weight may necessitate stronger support structures in the conveyor system. Buyers should weigh the benefits of durability and ease of cleaning against the potential need for reinforced infrastructure.

Precision Belt

Precision belts are specifically engineered for environments with fluctuating temperatures, making them ideal for the bakery and confectionery industries. These belts provide excellent thermal management and precise tracking, ensuring product integrity during processing. However, their specialized design comes at a higher cost. B2B buyers should evaluate their temperature control needs and the potential return on investment from improved product quality and operational efficiency when considering precision belts.

Related Video: Belt conveyor | Tutorial | Types | Applications | Grades | Splicing | Joining | Steel cord | Safety

Key Industrial Applications of metal conveyor belts

| Industry/Sector | Specific Application of metal conveyor belts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Transporting baked goods through ovens | Ensures uniform heating and efficient production flow | Compliance with food safety standards; heat resistance |

| Mining | Material handling in ore extraction | Enhances operational efficiency and reduces downtime | Durability in harsh environments; high load capacity |

| Manufacturing | Parts assembly in automotive production | Streamlines assembly lines and reduces labor costs | Customization options for specific production needs |

| Pharmaceuticals | Conveying products through sterilization processes | Maintains product integrity and compliance with regulations | Resistance to chemicals; easy cleaning capabilities |

| Recycling | Sorting and transporting recyclable materials | Improves sorting efficiency and reduces waste | Robust design for heavy loads; adaptability for different materials |

Food Processing

Metal conveyor belts are critical in food processing, particularly for transporting baked goods through ovens. Their design allows for optimal air circulation, ensuring even cooking and consistent product quality. Buyers in this sector must prioritize compliance with food safety standards and select belts that can withstand high temperatures. Additionally, the belts should be easy to clean to maintain hygiene and prevent contamination.

Mining

In the mining industry, metal conveyor belts are used extensively for handling materials such as ores and coal. Their durability and strength make them ideal for transporting heavy loads over long distances while minimizing downtime. International buyers should consider the belts’ resistance to wear and tear, as well as their capacity to operate in harsh environments. Custom solutions may be necessary to fit specific site conditions and requirements.

Manufacturing

Metal conveyor belts play a vital role in automotive manufacturing, where they facilitate the assembly of various vehicle components. By streamlining production lines, these belts help reduce labor costs and improve overall efficiency. Buyers should look for belts that can be customized to match specific production needs, including length, width, and load capacity. Additionally, the ability to integrate with existing systems is crucial for seamless operations.

Pharmaceuticals

In the pharmaceutical industry, metal conveyor belts are essential for transporting products through sterilization processes. Their design helps maintain product integrity while ensuring compliance with strict industry regulations. Buyers must focus on sourcing belts that are resistant to chemicals and can be easily cleaned to meet hygiene standards. The ability to withstand temperature variations during processing is also a key consideration for international buyers.

Recycling

Metal conveyor belts are widely used in recycling facilities to sort and transport recyclable materials. They enhance sorting efficiency by providing a robust and reliable means of moving various materials, thus reducing waste. Buyers in this sector should prioritize belts that can handle heavy loads and adapt to different types of materials. Additionally, sourcing durable belts that require minimal maintenance will contribute to long-term operational efficiency.

Strategic Material Selection Guide for metal conveyor belts

When selecting metal conveyor belts for various industrial applications, understanding the properties and suitability of different materials is crucial. Here, we analyze four common materials used in metal conveyor belts: stainless steel, carbon steel, aluminum, and specialty alloys. Each material has unique characteristics that can significantly impact performance, cost, and application compatibility.

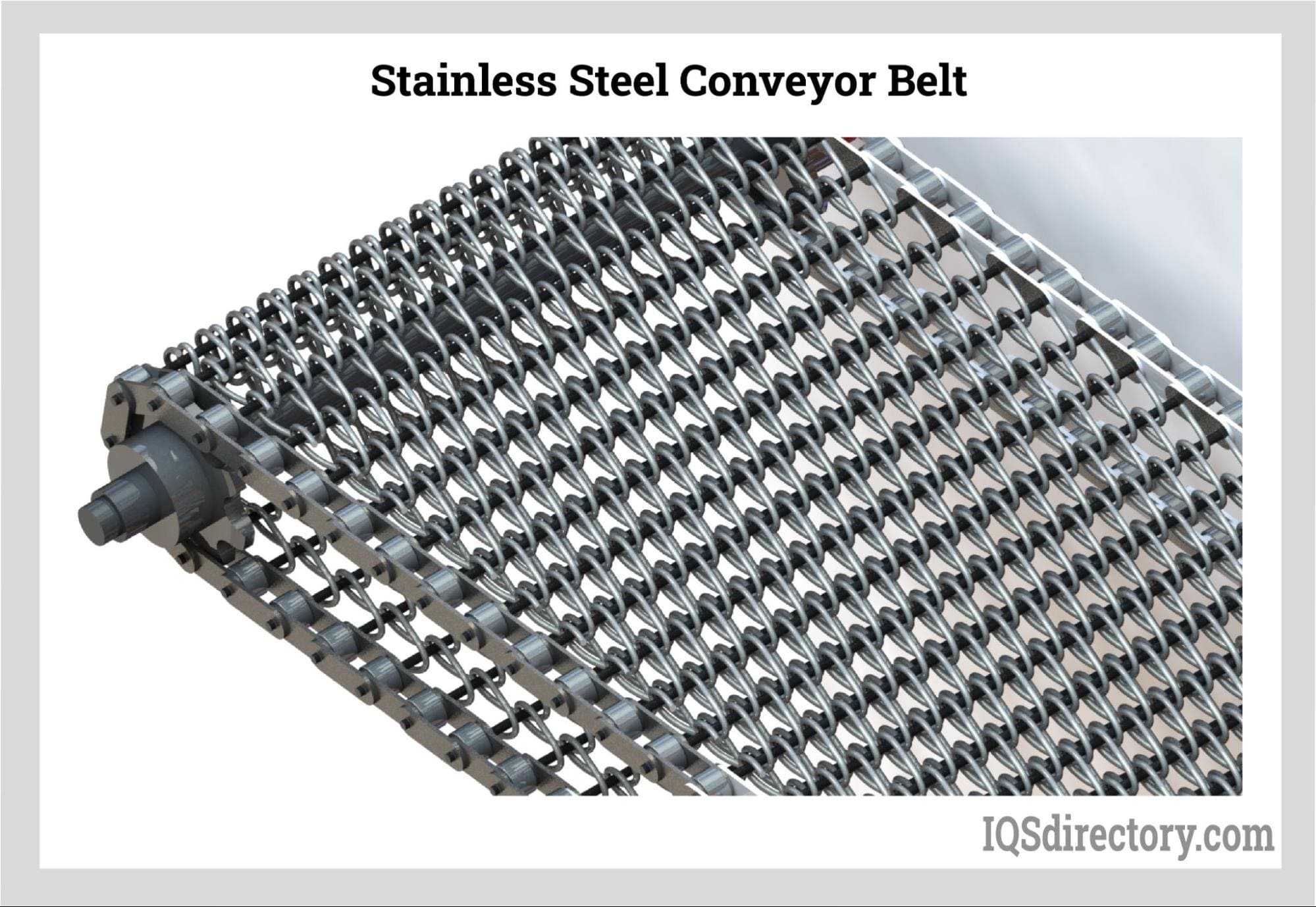

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating up to 1,200°F (650°C) and can endure high-pressure environments.

Pros & Cons: The durability of stainless steel makes it ideal for harsh environments, such as food processing and chemical handling. However, it tends to be more expensive than other materials, which can be a barrier for some buyers. The manufacturing process is complex, often requiring specialized equipment.

Impact on Application: Stainless steel belts are compatible with a wide range of media, including corrosive substances. They are particularly favored in industries that prioritize hygiene and cleanliness, such as food and pharmaceuticals.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is essential. Buyers from regions like Europe and the Middle East often prefer stainless steel for its reliability and performance in stringent regulatory environments.

Carbon Steel

Key Properties: Carbon steel is characterized by its high tensile strength and durability. It can withstand temperatures up to 800°F (427°C) and is generally resistant to wear.

Pros & Cons: This material is cost-effective, making it a popular choice for applications where budget constraints are significant. However, carbon steel is prone to rust and corrosion if not properly coated or maintained, which limits its use in wet or corrosive environments.

Impact on Application: Carbon steel belts are suitable for transporting heavy materials in industries such as mining and construction. Their strength makes them ideal for handling abrasive materials.

Considerations for International Buyers: Buyers should consider the need for protective coatings to enhance corrosion resistance. Compliance with local standards is also crucial, especially in regions like Africa and South America, where environmental conditions can vary widely.

Aluminum

Key Properties: Aluminum is lightweight and offers good corrosion resistance, with a temperature rating of around 500°F (260°C). It is also non-magnetic, which can be advantageous in certain applications.

Pros & Cons: The lightweight nature of aluminum allows for easier handling and installation, reducing labor costs. However, it is less durable compared to stainless and carbon steel, making it unsuitable for high-load applications.

Impact on Application: Aluminum belts are often used in light-duty applications, such as packaging and assembly lines, where weight and corrosion resistance are more critical than strength.

Considerations for International Buyers: Aluminum’s cost-effectiveness appeals to buyers in regions with budget constraints. However, understanding local recycling regulations and material sourcing is essential, particularly in Europe, where sustainability is a priority.

Specialty Alloys

Key Properties: Specialty alloys, such as Inconel or Monel, offer exceptional strength and corrosion resistance at high temperatures, often exceeding 1,500°F (815°C). These materials are engineered for specific applications.

Pros & Cons: The primary advantage of specialty alloys is their performance in extreme conditions, making them ideal for aerospace and chemical processing. However, they are significantly more expensive and may require longer lead times for production.

Impact on Application: These alloys are suitable for applications involving harsh chemicals or extreme temperatures, ensuring longevity and reliability.

Considerations for International Buyers: Buyers must consider the availability and sourcing of specialty alloys, as they may not be readily available in all regions. Compliance with international standards is critical, especially in industries with stringent safety regulations.

Summary Table

| Material | Typical Use Case for metal conveyor belts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical handling | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Mining, construction | Cost-effective and high strength | Prone to rust without coatings | Medium |

| Aluminum | Packaging, assembly lines | Lightweight and easy to handle | Less durable for high-load applications | Medium |

| Specialty Alloys | Aerospace, chemical processing | Exceptional performance in extreme conditions | Very high cost and longer lead times | High |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions when sourcing metal conveyor belts, considering their specific industrial requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for metal conveyor belts

The manufacturing processes and quality assurance protocols for metal conveyor belts are critical for ensuring high performance and longevity in demanding industrial environments. Understanding these processes not only aids B2B buyers in making informed purchasing decisions but also empowers them to assess the capabilities of potential suppliers.

Manufacturing Processes

The production of metal conveyor belts typically involves several key stages, each with specific techniques and considerations:

1. Material Preparation

The first step in manufacturing metal conveyor belts is the selection and preparation of raw materials. Common materials used include stainless steel, carbon steel, and specialized alloys. The choice of material affects the belt’s strength, durability, and resistance to corrosion.

- Material Testing: Before use, materials undergo testing for tensile strength, elongation, and hardness to ensure they meet industry specifications.

- Cutting: Raw materials are cut to size using precision cutting tools. This step is crucial as it sets the foundation for the entire belt.

2. Forming

After preparation, the metal is formed into the desired shape. This process may involve various techniques:

- Welding: For many metal conveyor belts, sections are welded together using methods such as spot welding or TIG welding. This ensures strong joints that can withstand heavy loads.

- Bending and Shaping: Metal strips are bent and shaped into specific configurations, depending on the application. This may include flat wire, modular plastic links, or spiral designs.

3. Assembly

Once the components are formed, they are assembled into a complete conveyor belt:

- Link Assembly: Individual links or segments are connected, often using pins or rods, to create a flexible yet durable belt.

- Edge Finishing: The edges of the belt are often finished to prevent fraying and to ensure smooth operation along conveyor tracks.

4. Finishing

The final stage involves surface treatment and finishing processes to enhance the belt’s performance:

- Coating: Depending on the application, belts may receive protective coatings to enhance corrosion resistance or reduce friction.

- Quality Check: At this stage, the belt undergoes initial inspections to identify any defects or inconsistencies.

Quality Assurance

Quality assurance is integral to the manufacturing process, ensuring that metal conveyor belts meet international standards and specific industry requirements. Here are the key aspects of quality control:

International Standards

B2B buyers should be aware of relevant international standards that govern the quality of conveyor belts:

- ISO 9001: This standard outlines the criteria for a quality management system, emphasizing customer satisfaction and continual improvement.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

Industry-Specific Standards

Different industries may have additional requirements:

- API Standards: For industries like oil and gas, adherence to American Petroleum Institute (API) standards may be necessary.

- Food Safety Standards: In food processing applications, compliance with FDA or HACCP regulations is essential.

Quality Control Checkpoints

Quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor adherence to quality standards.

- Final Quality Control (FQC): Once the conveyor belt is fully assembled, a thorough inspection is carried out to ensure it meets all specifications before shipment.

Common Testing Methods

Several testing methods are employed to verify the integrity and performance of metal conveyor belts:

- Tensile Testing: Measures the strength of the material under tension.

- Fatigue Testing: Assesses how the belt performs under repeated stress conditions.

- Corrosion Resistance Testing: Evaluates the material’s ability to withstand corrosive environments, crucial for industries like food processing and mining.

Verification of Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are actionable insights:

- Supplier Audits: Conduct regular audits of potential suppliers to evaluate their manufacturing processes, quality assurance protocols, and compliance with international standards.

- Request Documentation: Ask for quality assurance documentation, including test reports, certifications, and compliance with relevant standards. This documentation provides insight into the supplier’s commitment to quality.

- Third-Party Inspections: Consider engaging third-party inspection services to assess the quality of products before shipment. This can mitigate risks associated with poor-quality materials and manufacturing defects.

Quality Control Nuances for International Buyers

When sourcing metal conveyor belts globally, buyers should be aware of specific nuances:

- Cultural and Regulatory Differences: Different regions may have varying regulations and quality expectations. Understanding local market conditions can help in negotiating terms and ensuring compliance.

- Logistical Considerations: Lead times and shipping conditions can impact the quality of metal conveyor belts. Buyers should factor in these elements when setting timelines and expectations for delivery.

By understanding these manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions when selecting suppliers for metal conveyor belts, ensuring they receive high-quality products that meet their operational needs.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for metal conveyor belts Sourcing

Understanding the cost structure and pricing dynamics of metal conveyor belts is essential for international B2B buyers, especially those from diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will break down the various cost components, price influencers, and provide actionable tips for effective sourcing.

Cost Components

-

Materials: The primary cost driver in metal conveyor belts is the raw materials used, typically including stainless steel, carbon steel, or specialized alloys. The choice of material directly influences durability, corrosion resistance, and overall performance.

-

Labor: Labor costs encompass both the manufacturing workforce and skilled technicians required for assembly and quality assurance. In regions with higher labor costs, such as Western Europe, this can significantly affect the final price.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, impacting pricing positively.

-

Tooling: Investment in specialized machinery and tools necessary for producing customized belts can add to the initial costs. Buyers should consider suppliers who can balance tooling costs with production quality.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. Enhanced QC measures may increase upfront costs but can lead to lower failure rates and maintenance expenses in the long run.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping and handling costs can vary significantly based on the supplier’s location, the destination market, and the chosen shipping method. International buyers should factor in customs duties and potential delays that could impact delivery timelines.

-

Margin: Supplier margins vary based on competition, market demand, and the perceived value of their products. Understanding the margin can provide insight into pricing flexibility during negotiations.

Price Influencers

-

Volume/MOQ: Bulk purchases often result in lower unit prices. Establishing long-term contracts with minimum order quantities (MOQ) can also secure better pricing terms.

-

Specifications/Customization: Customized solutions may attract higher costs due to unique manufacturing processes and materials. Buyers should weigh the benefits of customization against standard options.

-

Materials: The choice of materials not only affects performance but also the cost. High-performance materials may come with a premium price but can reduce overall operational costs due to longevity.

-

Quality/Certifications: Products with recognized certifications (e.g., ISO, ASTM) may command higher prices. However, they often ensure higher quality and compliance, reducing risks and potential costs associated with non-compliance.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: The terms of trade defined by Incoterms can influence total costs significantly. Buyers should understand who bears the shipping costs, insurance, and risk during transit to accurately calculate the total landed cost.

Buyer Tips

-

Negotiation: Leverage multiple quotes from different suppliers to negotiate better terms. Establishing a relationship can also yield discounts and more favorable payment terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as maintenance, downtime, and energy efficiency, which can significantly impact overall costs.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, local taxes, and import duties that may affect pricing. Engaging in forward contracts for currency exchange can mitigate these risks.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and access to new product innovations.

-

Market Research: Regularly assess the market for price changes and new entrants. This knowledge can empower buyers to make informed decisions and avoid overpaying.

Disclaimer

Prices for metal conveyor belts can vary widely based on the aforementioned factors. It’s advisable to obtain updated quotes and conduct thorough market research before making purchasing decisions.

Spotlight on Potential metal conveyor belts Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘metal conveyor belts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for metal conveyor belts

Metal conveyor belts are vital components in various industrial processes, and understanding their essential technical properties and associated trade terminology is crucial for international B2B buyers. Below is an overview of critical specifications and industry terms that can aid in making informed purchasing decisions.

Key Technical Properties

-

Material Grade

– Metal conveyor belts are typically constructed from stainless steel, carbon steel, or specialty alloys. The choice of material affects durability, corrosion resistance, and suitability for specific applications. For instance, stainless steel is preferred in food processing due to its hygienic properties. -

Tensile Strength

– This measures the belt’s ability to withstand pulling forces without breaking. Higher tensile strength indicates a greater capacity to carry heavy loads, making it essential for industries like mining and manufacturing. Buyers should match the tensile strength of the belt to the operational demands of their processes. -

Belt Thickness

– The thickness of the belt influences its strength, flexibility, and weight. Thicker belts are generally more robust and can handle heavier loads, but they may also be less flexible. Understanding the required thickness helps in selecting a belt that balances durability and operational efficiency. -

Open Area Percentage

– This refers to the proportion of the belt’s surface that is open space versus solid material. A higher open area percentage allows for better airflow, drainage, and cooling, which is critical in applications like baking or metal processing. Buyers should assess the open area based on the specific needs of their processes. -

Temperature Tolerance

– Different metal conveyor belts can operate at varying temperature ranges. For example, some belts are designed to withstand extreme heat, while others perform better in cooler conditions. Knowing the temperature tolerance is essential for applications involving high-temperature materials or environments. -

Surface Finish

– The surface finish of the belt can impact its friction properties, cleanliness, and wear resistance. Smooth finishes are often used in food processing to facilitate cleaning, while textured surfaces may provide better grip for specific applications.

Common Trade Terminology

- OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital when sourcing conveyor belts, as it can influence quality and compatibility with existing systems.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers assess whether a supplier fits their purchasing needs, especially for smaller operations or projects. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Utilizing RFQs can help buyers compare offers and negotiate better terms, ensuring they receive competitive pricing. -

Incoterms (International Commercial Terms)

– These are a set of predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities. -

Lead Time

– This term refers to the time taken from placing an order to the delivery of the product. Understanding lead times is essential for planning production schedules and minimizing downtime in operations. -

Certification Standards

– Certifications such as ISO or FDA can indicate compliance with specific quality and safety standards. Knowing the relevant certifications for metal conveyor belts can aid buyers in selecting products that meet regulatory requirements and industry best practices.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that they select the right metal conveyor belts for their specific applications and operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the metal conveyor belts Sector

Market Overview & Key Trends

The metal conveyor belts sector is experiencing significant growth driven by the increasing demand for automation and efficiency across various industries, including food processing, pharmaceuticals, and mining. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly adopting advanced conveyor systems to enhance operational productivity. Key trends include the integration of Industry 4.0 technologies, such as IoT and AI, which facilitate real-time monitoring and predictive maintenance, reducing downtime and operational costs.

Sourcing trends are also evolving, with buyers prioritizing suppliers that offer customizable solutions tailored to specific industry needs. As competition intensifies, the importance of supplier reliability and product quality cannot be overstated. B2B buyers should focus on establishing long-term partnerships with manufacturers that demonstrate a commitment to innovation and consistent quality control. Additionally, a shift towards localized sourcing is emerging as companies seek to mitigate risks associated with global supply chain disruptions.

Emerging materials and designs, such as modular metal belts and hybrid systems, are gaining traction. These innovations not only enhance flexibility in production lines but also improve maintenance efficiencies. Buyers should keep an eye on these developments, as they can significantly impact overall operational effectiveness and cost savings.

Sustainability & Ethical Sourcing in B2B

The environmental impact of manufacturing processes in the metal conveyor belts sector has become a focal point for many businesses. B2B buyers are increasingly aware of the need for sustainable practices, not only to comply with regulations but also to meet consumer expectations for environmentally responsible products. Metal conveyor belts, when sourced from manufacturers that prioritize recycling and energy-efficient processes, can significantly reduce the carbon footprint of production lines.

Ethical sourcing is critical in today’s market landscape. Buyers should seek suppliers who are transparent about their supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability. Additionally, the use of ‘green’ materials, such as recycled metals or sustainably sourced alloys, can further enhance a company’s reputation and appeal in the marketplace.

Sustainability also extends to the end-of-life management of conveyor belts. Buyers should consider suppliers who offer take-back programs or recycling options, ensuring that materials are repurposed rather than ending up in landfills. By prioritizing sustainability and ethical sourcing, B2B buyers can align their procurement strategies with global sustainability goals, ultimately benefiting both their brand image and the environment.

Brief Evolution/History

The evolution of metal conveyor belts has been marked by technological advancements and increasing industrial demands. Originally designed for simple material handling, these belts have evolved into sophisticated systems capable of operating in extreme conditions and specialized applications. Over the decades, the introduction of new materials and manufacturing techniques has led to enhanced durability and efficiency.

In the late 20th century, the integration of automation technologies transformed conveyor systems, making them integral to modern production lines. Today, metal conveyor belts are pivotal in sectors ranging from food processing to heavy manufacturing, showcasing their versatility and adaptability. As the industry continues to innovate, buyers can expect even more advanced solutions that meet the challenges of a rapidly changing global market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of metal conveyor belts

-

What should I consider when vetting suppliers for metal conveyor belts?

When vetting suppliers, prioritize their industry experience, reputation, and product quality. Check for certifications relevant to your industry, such as ISO 9001 for quality management systems. Request references from previous clients and assess their customer service responsiveness. Additionally, evaluate their ability to provide custom solutions tailored to your specific needs, as well as their track record in international trade, especially in your region. -

Can I customize metal conveyor belts to meet my specific requirements?

Yes, many manufacturers offer customization options for metal conveyor belts. This can include variations in material, size, mesh type, and design features tailored to your operational needs. When discussing customization, provide detailed specifications and expected performance metrics to ensure the manufacturer understands your requirements. It’s also beneficial to request prototypes or samples before placing a large order. -

What are typical minimum order quantities (MOQs) and lead times for metal conveyor belts?

MOQs can vary significantly by supplier and the complexity of the order. Generally, MOQs range from a few hundred to several thousand meters of belt. Lead times are influenced by the supplier’s production capacity and your order’s specifications, typically ranging from 2 to 8 weeks. When negotiating, clarify these terms upfront to avoid unexpected delays in your supply chain. -

What payment terms are common in international transactions for conveyor belts?

Payment terms can differ based on the supplier’s policies and your negotiation outcomes. Common options include letters of credit, advance payments, or payment upon delivery. It’s advisable to discuss terms that minimize risk while ensuring timely delivery. Additionally, consider using escrow services for larger transactions to protect both parties until the goods are received and verified. -

How can I ensure quality assurance and certifications from my supplier?

Request a copy of the supplier’s quality assurance certifications and ask for detailed documentation on their manufacturing processes. Many reputable suppliers will provide test reports and compliance certifications, such as CE marking or specific industry standards. Engaging third-party inspection services before shipment can also help validate the quality of the conveyor belts you are purchasing. -

What logistics considerations should I keep in mind when importing metal conveyor belts?

Logistics play a crucial role in international trade. Assess the supplier’s ability to handle shipping logistics, including customs clearance and freight forwarding. Understand the incoterms (International Commercial Terms) that apply to your agreement, as they define responsibilities for shipping costs and risks. Additionally, plan for potential delays due to customs or logistical issues and factor these into your supply chain management. -

How should I handle disputes with suppliers during the purchasing process?

Clear communication is key to preventing disputes. Establish a written contract outlining all terms, including delivery schedules, payment terms, and quality expectations. In the event of a dispute, attempt to resolve it amicably through direct dialogue. If issues persist, consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming. Always document all communications related to the dispute for reference. -

What are the best practices for maintaining metal conveyor belts post-purchase?

Regular maintenance is crucial for prolonging the life of metal conveyor belts. Implement a routine inspection schedule to identify wear and tear early. Clean belts to prevent build-up of materials that could affect performance, and lubricate moving parts according to the manufacturer’s guidelines. Training your staff on proper usage and maintenance procedures can also reduce the risk of damage and enhance operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for metal conveyor belts

In the evolving landscape of industrial operations, strategic sourcing of metal conveyor belts plays a pivotal role in enhancing efficiency and reducing operational costs. Key takeaways for international B2B buyers include the importance of selecting reliable suppliers who not only provide high-quality products but also offer tailored solutions and responsive support. This is particularly crucial in regions like Africa, South America, the Middle East, and Europe, where varying market dynamics and operational challenges demand agility and adaptability.

Investing in the right metal conveyor belt can significantly minimize downtime, improve productivity, and extend the lifespan of your equipment. As industries continue to innovate, the demand for specialized conveyor solutions will only grow, making it essential for buyers to stay informed about the latest technologies and materials.

Looking ahead, international buyers should prioritize partnerships with manufacturers that demonstrate a commitment to sustainability and technological advancement. By taking proactive steps in sourcing, businesses can not only meet current operational needs but also position themselves for future growth. Now is the time to evaluate your sourcing strategy and explore new opportunities in the metal conveyor belt market to ensure your business remains competitive and resilient.