Your Ultimate Guide to Sourcing Nema Connector

Introduction: Navigating the Global Market for nema connector

Navigating the complexities of the global market for NEMA connectors is vital for international B2B buyers looking to enhance their operational efficiencies. These connectors, which comply with the National Electrical Manufacturers Association standards, play a critical role in ensuring safe and reliable electrical connections in a variety of applications, from industrial machinery to commercial equipment. As businesses expand across borders, understanding the nuances of NEMA connectors becomes essential for mitigating risks and ensuring compliance with local regulations.

This guide offers a comprehensive exploration of NEMA connectors, covering various types, materials, manufacturing processes, and quality control standards. We delve into supplier options across different regions, providing insights into pricing structures and market dynamics that affect procurement decisions. By addressing frequently asked questions, we aim to demystify the complexities of sourcing NEMA connectors, empowering buyers with the knowledge needed to make informed decisions.

For buyers in Africa, South America, the Middle East, and Europe—including key markets like Mexico and Egypt—this guide serves as an invaluable resource. It not only highlights critical factors to consider when selecting NEMA connectors but also facilitates strategic sourcing that aligns with regional market trends and operational needs. Armed with this knowledge, businesses can confidently navigate the global landscape, ensuring they choose the right solutions that drive efficiency and reliability in their operations.

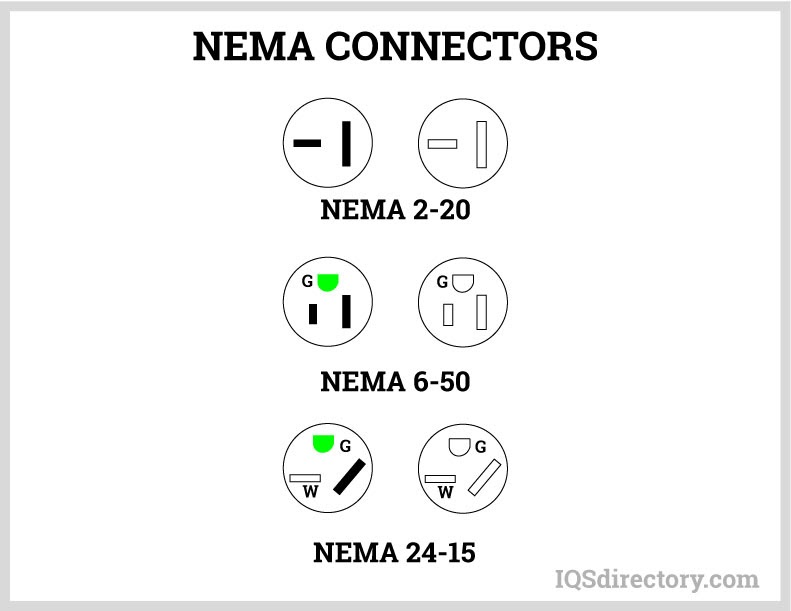

Understanding nema connector Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 5-15P | Standard 3-prong, 15A, 125V design | General-purpose electrical devices | Pros: Widely available, cost-effective. Cons: Limited to lower voltage applications. |

| NEMA 6-15P | 3-prong, 15A, 250V, designed for higher loads | Industrial equipment, machinery | Pros: Suitable for higher voltage. Cons: Not compatible with 120V devices. |

| NEMA 4-15P | Weatherproof and dust-tight design | Outdoor and harsh environment applications | Pros: Durable, weather-resistant. Cons: Higher cost due to robust design. |

| NEMA L5-30P | Locking design, 30A, 125V | Heavy machinery, commercial equipment | Pros: Secure connection, prevents accidental disconnection. Cons: Bulkier and more expensive. |

| NEMA 14-50P | 4-prong, 50A, 250V, used for electric vehicles | EV charging stations, high-power devices | Pros: High capacity, versatile. Cons: Requires specific installation, higher initial investment. |

NEMA 5-15P

The NEMA 5-15P connector is one of the most common types used in North America. It features a standard three-prong design, suitable for devices requiring up to 15A at 125V. This connector is ideal for general-purpose electrical devices, such as computers and home appliances. Buyers should consider its widespread availability and affordability, but note that it is limited to lower voltage applications, which may not suit industrial needs.

NEMA 6-15P

Designed for applications requiring higher voltage, the NEMA 6-15P connector supports 15A at 250V. Its robust design makes it suitable for industrial equipment and machinery that operate at higher power levels. Buyers should appreciate its capability to handle more demanding environments; however, it is essential to ensure compatibility with 250V systems, as it cannot be used with standard 120V devices.

NEMA 4-15P

The NEMA 4-15P connector is engineered for outdoor and harsh environments. It features a weatherproof and dust-tight design, making it ideal for applications exposed to moisture and dirt, such as construction sites and agricultural machinery. While its durability is a significant advantage, buyers should be prepared for a higher cost due to its robust construction.

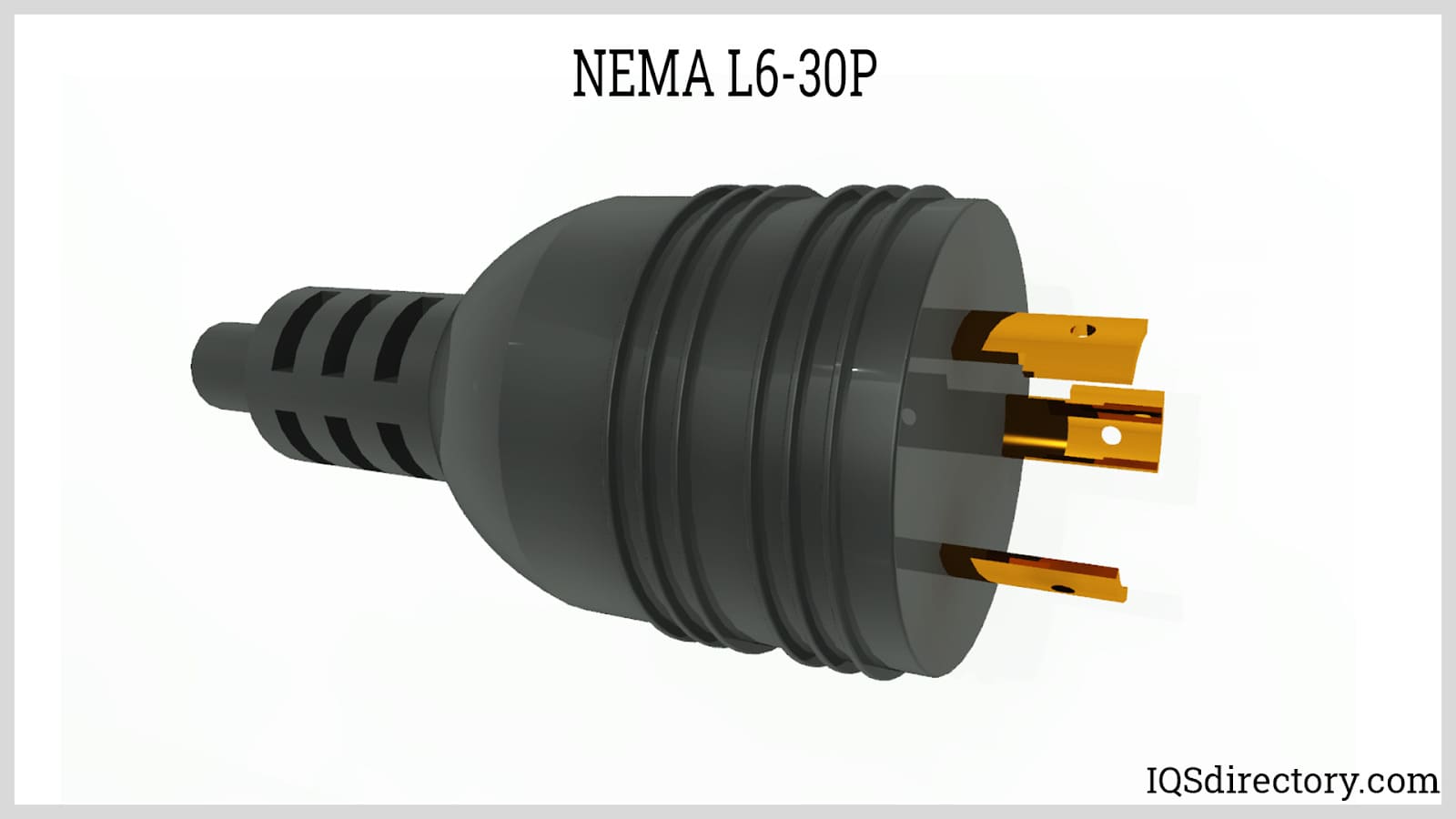

NEMA L5-30P

The NEMA L5-30P connector is a locking type, designed for secure connections in high-demand applications. It supports 30A at 125V, making it suitable for heavy machinery and commercial equipment. Its locking mechanism prevents accidental disconnection, which is crucial in industrial settings. However, buyers must consider its bulkier design and higher price point compared to standard connectors.

NEMA 14-50P

The NEMA 14-50P connector is a four-prong design that supports 50A at 250V, commonly used for electric vehicle charging stations and other high-power applications. Its versatility makes it a popular choice for both residential and commercial use. While it offers high capacity, buyers should be aware of the specific installation requirements and the higher initial investment associated with this connector type.

Related Video: NEMA Connectors: The Complete Guide + International Plugs

Key Industrial Applications of nema connector

| Industry/Sector | Specific Application of NEMA Connector | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power distribution in machinery | Ensures reliable power supply and safety | Compatibility with existing systems and standards |

| Renewable Energy | Solar panel connections | Facilitates efficient energy transfer | Environmental resistance and certification compliance |

| Transportation | Electric vehicle charging stations | Enhances infrastructure for electric mobility | Durability and weatherproofing features |

| Telecommunications | Data center equipment interconnections | Supports high-speed data transfer | Compliance with international safety standards |

| Food and Beverage | Equipment connections in processing plants | Maintains operational efficiency and safety | Hygiene standards and ease of cleaning |

Manufacturing

In the manufacturing sector, NEMA connectors are crucial for power distribution in various machinery. They provide a safe and reliable method for connecting power sources to equipment, which is vital for uninterrupted operations. For international buyers, especially in regions like Africa and South America, sourcing connectors that comply with local electrical standards and are capable of withstanding environmental conditions is essential. This ensures that machinery operates efficiently and reduces the risk of downtime due to electrical failures.

Renewable Energy

The renewable energy sector, particularly in solar energy applications, utilizes NEMA connectors for interconnecting solar panels and inverters. These connectors facilitate efficient energy transfer and play a significant role in enhancing the overall performance of solar installations. For B2B buyers in Europe and the Middle East, it is important to consider connectors that offer environmental resistance, such as UV protection and moisture sealing, to ensure longevity and reliability in diverse climates.

Transportation

In the transportation industry, especially with the rise of electric vehicles (EVs), NEMA connectors are integral to charging stations. They provide a standardized connection for charging EVs, ensuring compatibility and safety during the charging process. International buyers must focus on sourcing durable connectors that can withstand outdoor conditions and have weatherproofing features to ensure they remain operational in various environments, particularly in regions with extreme weather conditions.

Telecommunications

NEMA connectors are also used in telecommunications, particularly for interconnecting equipment in data centers. These connectors support high-speed data transfer and are essential for maintaining the integrity of communication networks. Buyers from South America and Europe should prioritize sourcing connectors that comply with international safety standards, as this ensures reliability and reduces the risk of data loss or equipment failure in high-demand environments.

Illustrative Image (Source: Google Search)

Food and Beverage

In the food and beverage industry, NEMA connectors are employed in equipment connections within processing plants. They help maintain operational efficiency and ensure safety standards are met, which is critical in environments where hygiene is paramount. For international buyers, sourcing connectors that meet hygiene standards and are easy to clean is vital to comply with regulatory requirements and ensure safe food processing operations.

Strategic Material Selection Guide for nema connector

When selecting materials for NEMA connectors, international B2B buyers must consider several factors that impact performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in NEMA connectors, highlighting their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Thermoplastic

Key Properties:

Thermoplastics are known for their excellent electrical insulation properties and resistance to chemicals. They can withstand a wide range of temperatures, typically from -40°C to 105°C, depending on the specific type.

Pros & Cons:

Thermoplastics are lightweight and cost-effective, making them a popular choice for many applications. However, they may not offer the same level of mechanical strength as metals, which can be a drawback in high-stress environments.

Impact on Application:

These materials are suitable for applications where electrical insulation is critical, such as in industrial automation and control systems. However, they may not be ideal for environments with extreme mechanical stress.

Considerations for International Buyers:

Buyers should ensure that the thermoplastic materials comply with relevant standards such as ASTM or IEC. In regions like Africa and South America, where environmental conditions can vary significantly, selecting thermoplastics with enhanced UV resistance may be beneficial.

2. Aluminum

Key Properties:

Aluminum connectors are lightweight, with good corrosion resistance and thermal conductivity. They can typically handle temperatures up to 150°C.

Pros & Cons:

Aluminum is durable and relatively inexpensive, making it a common choice for outdoor applications. However, it can be prone to galvanic corrosion when in contact with other metals, necessitating careful selection of mating materials.

Impact on Application:

Aluminum is well-suited for applications in harsh environments, such as marine or industrial settings. Its lightweight nature also makes it advantageous for portable equipment.

Considerations for International Buyers:

Buyers in regions like the Middle East, where humidity and saline conditions are prevalent, should prioritize aluminum connectors with protective coatings to enhance corrosion resistance. Compliance with local standards such as JIS or DIN is also essential.

3. Stainless Steel

Key Properties:

Stainless steel offers excellent mechanical strength and corrosion resistance, particularly in harsh environments. It can withstand high temperatures, often exceeding 200°C.

Pros & Cons:

While stainless steel connectors are highly durable and suitable for demanding applications, they are more expensive than other materials. Additionally, they can be heavier, which may be a consideration for certain applications.

Impact on Application:

These connectors are ideal for environments exposed to chemicals, moisture, or extreme temperatures, such as food processing or oil and gas industries.

Considerations for International Buyers:

Buyers should verify that the stainless steel used meets international standards for corrosion resistance, such as ASTM A276. In Europe, compliance with EN standards is also critical.

4. Brass

Key Properties:

Brass connectors provide good electrical conductivity and resistance to corrosion, particularly in humid environments. They typically operate effectively at temperatures up to 120°C.

Pros & Cons:

Brass is relatively inexpensive and easy to machine, making it a popular choice for many applications. However, it can be susceptible to dezincification in certain environments, which can compromise its integrity.

Impact on Application:

Brass is commonly used in applications requiring good conductivity, such as electrical connections in automotive or industrial machinery.

Considerations for International Buyers:

Buyers should be aware of the potential for dezincification and ensure that the brass used complies with relevant standards. In regions like South America, where environmental conditions can vary, selecting brass with appropriate coatings may be necessary.

Summary Table

| Material | Typical Use Case for NEMA Connector | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic | Electrical insulation in control systems | Lightweight and cost-effective | Lower mechanical strength | Low |

| Aluminum | Outdoor applications in harsh environments | Good corrosion resistance | Prone to galvanic corrosion | Medium |

| Stainless Steel | Chemical and moisture-exposed environments | High durability and strength | Higher cost and weight | High |

| Brass | Electrical connections in machinery | Good conductivity | Susceptible to dezincification | Medium |

This guide provides a comprehensive overview of material selection for NEMA connectors, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for nema connector

Manufacturing Processes for NEMA Connectors

The manufacturing of NEMA connectors involves several crucial stages, ensuring that these components meet the rigorous demands of industrial applications. Understanding these processes can help international B2B buyers make informed decisions when sourcing NEMA connectors.

Illustrative Image (Source: Google Search)

Material Preparation

The initial stage of manufacturing involves the selection and preparation of raw materials, typically high-grade metals such as copper and aluminum, along with insulating materials like thermoplastics. The quality of these materials is critical as they directly influence the performance and durability of the connectors.

- Key Techniques:

- Material Testing: Before use, materials undergo testing for conductivity, tensile strength, and thermal resistance.

- Surface Treatment: Processes such as plating (e.g., nickel plating) are often applied to enhance corrosion resistance and conductivity.

Forming

Once materials are prepared, they undergo various forming processes to achieve the desired shapes and sizes.

- Key Techniques:

- Stamping and Die-Cutting: Metal sheets are stamped into precise shapes using dies, which ensures uniformity across all connectors.

- Injection Molding: For thermoplastic components, injection molding is employed to create complex shapes with high precision. This process allows for efficient mass production while maintaining quality.

Assembly

The assembly stage is where the individual parts come together to form a complete NEMA connector. This step is critical as it influences the overall functionality and safety of the product.

- Key Techniques:

- Automated Assembly: Many manufacturers use automated systems to ensure consistent assembly quality, which reduces the risk of human error.

- Soldering and Welding: Connections between metal parts are typically secured through soldering or welding, ensuring a robust electrical connection.

Finishing

After assembly, the connectors undergo finishing processes to enhance their performance and aesthetic appeal.

- Key Techniques:

- Coating: Protective coatings may be applied to prevent oxidation and wear.

- Testing: Final products are subjected to rigorous testing to ensure they meet operational standards and specifications.

Quality Assurance for NEMA Connectors

Quality assurance is paramount in the manufacturing of NEMA connectors, as these components often operate in critical environments. Implementing robust quality control (QC) measures ensures reliability and safety.

International Standards

Manufacturers of NEMA connectors typically adhere to several international standards to maintain quality. Notable among these are:

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries. Certification indicates that the manufacturer maintains consistent quality in their processes.

- CE Marking: In Europe, CE marking demonstrates compliance with EU safety and environmental requirements.

- API Standards: For connectors used in oil and gas applications, adherence to API standards is essential.

QC Checkpoints

Quality control processes are implemented at various stages of manufacturing to ensure that each connector meets the required specifications.

- Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, random samples are tested at various stages to ensure that production processes are within quality parameters.

- Final Quality Control (FQC): Finished products undergo comprehensive testing, including electrical performance tests and visual inspections, before they are packaged for shipment.

Common Testing Methods

Several testing methods are employed to ensure the quality and reliability of NEMA connectors:

- Electrical Testing: This includes tests for insulation resistance, dielectric strength, and continuity to ensure that the connectors perform safely under operational conditions.

- Environmental Testing: Connectors may be subjected to temperature cycling, humidity, and salt spray tests to evaluate their performance in adverse conditions.

- Mechanical Testing: Testing for mechanical strength and durability, including vibration and impact tests, helps confirm that connectors can withstand physical stresses.

Verifying Supplier QC

For B2B buyers, particularly those sourcing from international markets, ensuring that suppliers adhere to stringent quality control measures is crucial.

- Supplier Audits: Conducting audits of suppliers can provide insight into their manufacturing processes and quality control practices. Audits should assess compliance with international standards and the effectiveness of their QC systems.

- Quality Reports: Requesting detailed quality reports, including testing results and compliance certifications, can help buyers evaluate a supplier’s capabilities.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes and product quality.

QC and Certification Nuances for International Buyers

International buyers must be aware of specific nuances related to quality control and certification when sourcing NEMA connectors from different regions:

- Regional Compliance: Understand the local regulations and standards that may differ from international norms. For example, in Africa and the Middle East, compliance with local standards may be mandatory.

- Documentation: Ensure that suppliers provide all necessary documentation, including certificates of compliance, test reports, and warranty information.

- Cultural Considerations: Cultural differences can impact communication and business practices. Establish clear communication channels and expectations regarding quality standards and delivery timelines.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can confidently source NEMA connectors that meet their operational needs while ensuring compliance with international standards.

Related Video: Factory IO – Students Project – Production line

Comprehensive Cost and Pricing Analysis for nema connector Sourcing

When sourcing NEMA connectors, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. Here, we break down the cost components, price influencers, and provide actionable tips for negotiation and cost efficiency.

Cost Components

-

Materials: The primary cost driver for NEMA connectors is the raw materials used in their production. Common materials include copper, aluminum, and various plastics. Prices can fluctuate based on global market trends, so it’s essential to stay informed about material costs.

-

Labor: Labor costs vary significantly by region. Countries with higher wage standards, such as those in Europe, may see increased production costs compared to regions like South America or Africa, where labor can be more affordable.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can help reduce overhead and should be a consideration when evaluating suppliers.

-

Tooling: Initial tooling costs can be substantial, particularly for custom or specialized connectors. These costs are often amortized over large production runs, making it beneficial to discuss volume commitments with suppliers.

-

Quality Control (QC): Ensuring product quality is paramount, especially for connectors used in critical applications. QC processes and certifications (such as ISO standards) can add to the cost but are necessary for maintaining reliability and safety.

-

Logistics: Shipping costs can vary widely based on the origin of the connectors, distance to the buyer, and chosen Incoterms. International buyers should consider these logistics costs as part of the overall pricing.

-

Margin: Supplier profit margins can differ based on their market position and the competitive landscape. It’s essential to understand the margin structure of potential suppliers to gauge the fairness of their pricing.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit prices. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications/Customization: Customized connectors or those with specific features will typically incur higher costs. Clearly defining requirements upfront can help manage expectations and avoid unexpected charges.

-

Materials and Quality Certifications: Higher quality materials and specific certifications can lead to increased costs. Buyers should weigh the benefits of these factors against their application needs.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Evaluating multiple suppliers can provide leverage in negotiations.

-

Incoterms: Understanding the terms of shipping and delivery can affect overall costs. Terms like CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can shift financial responsibilities and risks.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, focusing on volume discounts and long-term partnerships. Be prepared to share your purchasing forecasts to strengthen your negotiating position.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors like durability, maintenance, and warranty when evaluating potential suppliers.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and tariffs that may impact pricing. Establishing contracts in stable currencies can mitigate some risks.

-

Research and Benchmarking: Conduct thorough research on prevailing market prices and compare quotes from multiple suppliers. This benchmarking can reveal competitive pricing and help identify outliers.

Disclaimer

Prices for NEMA connectors can vary significantly based on the factors outlined above. The information provided here is indicative and should be supplemented with direct quotes from suppliers to ensure accuracy. Always conduct due diligence when evaluating cost structures and pricing.

Spotlight on Potential nema connector Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘nema connector’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for nema connector

Key Technical Properties of NEMA Connectors

Understanding the essential technical properties of NEMA connectors is crucial for B2B buyers seeking reliability and compatibility in their electrical systems. Below are some critical specifications that should be considered:

-

Material Grade: NEMA connectors are typically made from materials like thermoplastic or thermoset plastics, with metal components often made from aluminum or brass. The material choice affects durability and resistance to environmental conditions. For buyers in harsh climates (e.g., parts of Africa and South America), selecting connectors with higher-grade materials can prevent failures and reduce long-term costs.

-

Current Rating: This specification indicates the maximum amount of current the connector can safely handle, usually expressed in amperes (A). Understanding current ratings is essential for ensuring that the connector can support the electrical load of the application, preventing overheating and potential hazards.

-

Voltage Rating: Similar to current ratings, voltage ratings specify the maximum voltage that a connector can withstand without breaking down. This is particularly important for international buyers who may deal with varying electrical standards across regions, ensuring compliance and safety.

-

Environmental Ratings: Many NEMA connectors come with environmental protection ratings, such as NEMA 4, 6, or 12, which define their resistance to moisture, dust, and other environmental factors. Buyers should assess the operating environment to select the appropriate rating, which is vital for maintaining equipment integrity in diverse settings.

-

Tolerance and Fit: This specification refers to the allowable deviation in dimensions, ensuring that connectors fit securely within their intended applications. Proper tolerance helps prevent issues such as loose connections, which can lead to equipment failure.

-

Mounting Style: NEMA connectors may come in various mounting styles, including panel-mounted or inline. Understanding the mounting requirements of your equipment is essential for ensuring proper installation and functionality.

Common Trade Terminology

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions involving NEMA connectors. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs can help buyers identify reliable suppliers and assess the quality of components.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their purchasing strategies and inventory management, especially when dealing with international suppliers who may have different MOQs.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This term is critical for buyers looking to compare prices and negotiate better terms.

-

Incoterms (International Commercial Terms): These are a set of rules that define the responsibilities of buyers and sellers in international transactions, including shipping costs, insurance, and risk transfer. Understanding Incoterms is vital for buyers to manage logistics and ensure compliance with international trade regulations.

-

Lead Time: This refers to the amount of time between placing an order and receiving the product. For B2B buyers, especially in regions with longer supply chains, understanding lead times can help in planning production schedules and managing customer expectations.

-

Certification Standards: These are benchmarks that products must meet to ensure safety and reliability. For NEMA connectors, certifications like UL (Underwriters Laboratories) or CE (Conformité Européenne) can indicate compliance with safety regulations, which is particularly important in international markets.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring that they procure the right NEMA connectors for their applications while navigating the complexities of international trade.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the nema connector Sector

Market Overview & Key Trends

The global NEMA connector market is witnessing significant growth driven by the increasing demand for efficient and reliable electrical connections in various industrial applications. Key factors propelling this growth include the rise of automation in manufacturing, the expansion of renewable energy sources, and the proliferation of smart technologies. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must stay attuned to the following trends:

-

Technological Advancements: The integration of IoT and Industry 4.0 technologies is reshaping the landscape of electrical connectors, including NEMA connectors. Buyers should consider suppliers who are at the forefront of these innovations to ensure compatibility with modern systems.

-

Customization and Flexibility: There is an increasing demand for customized solutions that cater to specific industrial needs. Buyers should engage with manufacturers offering flexible design options to meet unique requirements, particularly in niche markets.

-

Regional Variability: Understanding local market dynamics is crucial. For instance, buyers in Africa may prioritize ruggedness and durability due to harsher environmental conditions, while those in Europe may focus on compliance with stringent safety and efficiency standards.

-

Supply Chain Resilience: Recent global disruptions have highlighted the importance of resilient supply chains. International buyers should evaluate suppliers’ logistics capabilities and their ability to adapt to changing market conditions.

By aligning sourcing strategies with these trends, international B2B buyers can enhance their procurement processes and ensure the longevity of their electrical systems.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a crucial consideration in the procurement of NEMA connectors. The environmental impact of manufacturing processes and the materials used in production are under scrutiny. As international B2B buyers, particularly from emerging markets, navigate these concerns, it is essential to prioritize ethical sourcing practices:

-

Environmental Impact: Buyers should assess the lifecycle of NEMA connectors, from raw material extraction to end-of-life disposal. Opting for suppliers that utilize sustainable materials and practices can significantly reduce ecological footprints.

-

Ethical Supply Chains: Engaging with manufacturers who adhere to ethical labor practices and transparent sourcing can enhance brand reputation and compliance with international regulations. Buyers should request certifications that demonstrate a commitment to ethical practices.

-

‘Green’ Certifications and Materials: Look for products that are certified by recognized standards, such as RoHS (Restriction of Hazardous Substances) or WEEE (Waste Electrical and Electronic Equipment Directive). These certifications indicate a product’s compliance with environmental regulations and its suitability for sustainable applications.

By adopting sustainable sourcing strategies, international B2B buyers can contribute to a more environmentally friendly industry while also addressing the growing demand for ethical business practices.

Brief Evolution/History

The NEMA connector, designed to meet the standards set by the National Electrical Manufacturers Association, has evolved significantly since its inception in the mid-20th century. Initially created for the North American market, these connectors have gained global traction, particularly as industrial automation and electrical safety standards have become paramount. Over the years, advancements in materials and manufacturing techniques have enhanced the durability and efficiency of NEMA connectors, making them suitable for a wider range of applications across various sectors, including renewable energy and industrial machinery. As the market continues to evolve, the focus on innovation and sustainability remains crucial for suppliers and buyers alike.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of nema connector

-

What should I consider when vetting suppliers for NEMA connectors?

When vetting suppliers, prioritize their industry experience, reputation, and certifications. Look for suppliers that have a proven track record in producing NEMA connectors, as well as certifications such as ISO 9001, which indicates quality management. Additionally, check for customer reviews and testimonials, and ask for references. It’s also beneficial to understand their manufacturing capabilities and whether they can meet your specific requirements in terms of quality and delivery timelines. -

Can I customize NEMA connectors to suit my specific needs?

Yes, many manufacturers offer customization options for NEMA connectors. You can request changes in design, materials, or specifications to fit your application. It’s essential to communicate your requirements clearly and verify if the supplier has the capability to deliver customized solutions. Inquire about the design process, prototyping, and any additional costs associated with customization to avoid surprises later on. -

What are the minimum order quantities (MOQ) and lead times for NEMA connectors?

MOQs and lead times can vary significantly between suppliers. Generally, larger orders might allow for lower per-unit costs, while smaller orders could have higher costs. Lead times also depend on the complexity of the order and the supplier’s production capacity. Always confirm these details upfront and consider discussing flexible options, especially if you are testing a new product line or entering a new market. -

What payment terms should I expect when sourcing NEMA connectors internationally?

Payment terms vary by supplier and region, but common options include advance payments, letter of credit, or payment upon delivery. Ensure you understand the terms and negotiate favorable conditions that protect your interests. It’s also advisable to use secure payment methods and consider the implications of currency exchange rates when dealing with international suppliers, as this can affect your overall costs. -

How can I ensure quality assurance and certification of NEMA connectors?

To ensure quality, request documentation for certifications and compliance with international standards, such as UL or CE marking, which indicate safety and reliability. Ask suppliers about their quality control processes, including testing methods and inspection protocols. If possible, arrange for third-party inspections or audits to validate the supplier’s claims and maintain quality standards in your supply chain. -

What logistics considerations should I keep in mind when importing NEMA connectors?

Logistics are crucial when importing NEMA connectors. Consider shipping options, customs clearance, and potential tariffs or taxes that may apply. Work with a reliable freight forwarder who understands international trade regulations and can assist with documentation. Also, plan for lead times that include both production and shipping, and ensure your supply chain is resilient to avoid delays. -

How should I handle disputes with suppliers of NEMA connectors?

Disputes can arise from delivery issues, quality concerns, or contractual disagreements. To mitigate risks, establish clear terms in your contract, including dispute resolution mechanisms such as mediation or arbitration. Maintain open communication with your supplier to address issues promptly. If disputes escalate, consult legal advice familiar with international trade laws relevant to your contract and jurisdiction. -

What factors influence the pricing of NEMA connectors?

Pricing for NEMA connectors is influenced by several factors, including material costs, manufacturing processes, customization, and order volume. Market demand and regional economic conditions can also affect pricing. When negotiating, consider the total cost of ownership, including shipping and handling, to make informed decisions. Building long-term relationships with suppliers may lead to better pricing and terms over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for nema connector

In the ever-evolving landscape of electrical connectivity, the strategic sourcing of NEMA connectors emerges as a pivotal component for international B2B buyers. Understanding the technical specifications, compatibility, and quality standards of NEMA connectors is essential for ensuring efficient and reliable operations across various industries. Buyers from Africa, South America, the Middle East, and Europe should prioritize sourcing from reputable manufacturers that offer comprehensive product support, including compatibility checks and lifecycle management.

Key takeaways for buyers include the importance of evaluating suppliers based on their ability to provide robust customer service, technical expertise, and tailored solutions that meet specific project needs. Leveraging partnerships with reliable manufacturers can significantly reduce downtime and enhance productivity, ultimately leading to better project outcomes.

As we look towards the future, the demand for advanced connectivity solutions will only increase, fueled by trends such as automation and smart manufacturing. International buyers are encouraged to stay informed about emerging technologies and seek out innovative products that can provide a competitive edge. By investing in strategic sourcing practices today, businesses can position themselves for success in tomorrow’s dynamic market.