Your Ultimate Guide to Sourcing North America Electrical

Introduction: Navigating the Global Market for north america electrical plug

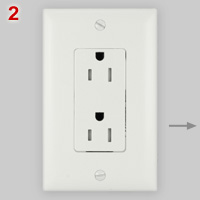

Navigating the global market for electrical plugs, particularly those standardized for North America, is critical for international B2B buyers seeking reliable and compliant solutions. The North American electrical plug, characterized by its unique design and specifications, serves as a vital component in powering various devices, from consumer electronics to industrial machinery. Understanding its significance goes beyond mere compliance; it ensures safety, efficiency, and interoperability in diverse applications.

This comprehensive guide delves into the essential aspects of North American electrical plugs, offering insights into various types, materials, manufacturing standards, quality control measures, and leading suppliers. Buyers will find detailed analyses of cost factors and market trends, enabling them to make informed sourcing decisions. Whether you are based in Africa, South America, the Middle East, or Europe, this guide aims to equip you with the knowledge necessary to navigate the complexities of sourcing electrical plugs that meet both regional requirements and global standards.

Key features of this guide include:

- Types of Plugs: An overview of standard plug types used across North America.

- Materials and Manufacturing: Insights into materials used and manufacturing processes to ensure durability and safety.

- Quality Control: An exploration of the quality standards and certifications relevant to electrical plugs.

- Supplier Directory: A curated list of reliable manufacturers and distributors.

- Cost Analysis: Factors influencing pricing and cost-saving strategies.

- Market Overview: Current trends and forecasts in the electrical plug market.

- FAQs: Answers to common questions that international buyers may have.

By leveraging the information presented in this guide, B2B buyers can confidently approach the sourcing process, ensuring they procure high-quality electrical plugs tailored to their specific needs.

Understanding north america electrical plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 1-15 | Two flat parallel blades, no ground pin | General appliances, lighting | Pros: Widely used; Cons: No ground protection. |

| NEMA 5-15 | Two flat blades and a round ground pin | Consumer electronics, office equipment | Pros: Grounded for safety; Cons: Limited to 15A. |

| NEMA 6-15 | Two flat blades, a round ground pin, rated for higher voltage | Heavy-duty tools, industrial equipment | Pros: Higher voltage capacity; Cons: Not as common. |

| NEMA L5-30 | Twist-lock design, three pins (two flat, one ground) | Industrial applications, generators | Pros: Secure connection; Cons: More expensive. |

| NEMA 14-30 | Four pins (two hot, one neutral, one ground) | Electric dryers, commercial appliances | Pros: High capacity; Cons: Requires specific receptacle. |

NEMA 1-15

The NEMA 1-15 plug features two flat parallel blades and is typically ungrounded. It is commonly found in light fixtures and small appliances. While its widespread use makes it easy to source, the absence of grounding can pose safety risks, particularly in environments where electrical faults could occur. Buyers should consider their specific application needs and whether the lack of grounding is acceptable.

NEMA 5-15

The NEMA 5-15 is a grounded version of the NEMA 1-15, featuring two flat blades and a round ground pin. This plug is the standard for most household and office electronics, providing an essential safety feature. Its grounding capability makes it suitable for a wide range of applications, from computers to kitchen appliances. Buyers should prioritize this type for environments where safety is a concern, especially in high-use areas.

NEMA 6-15

Designed for higher voltage applications, the NEMA 6-15 plug includes two flat blades and a round ground pin. It is ideal for heavy-duty tools and industrial equipment. While it offers enhanced performance and safety for higher voltage needs, it is less common than the NEMA 5-15, which may limit availability. Buyers in industrial sectors should assess their power requirements and the compatibility of their existing infrastructure before purchasing.

NEMA L5-30

The NEMA L5-30 is a twist-lock plug that features a secure connection with three pins. It is commonly used in industrial settings for heavy machinery and generators. Its design prevents accidental disconnection, making it a reliable choice for demanding applications. However, the cost is generally higher than standard plugs, and compatibility with existing systems should be verified before buying.

NEMA 14-30

The NEMA 14-30 plug is characterized by its four-pin configuration, designed to handle higher power demands, making it suitable for electric dryers and other large appliances. Its design includes two hot wires, a neutral, and a ground, ensuring a safe and effective connection. Buyers should ensure they have the appropriate receptacle and wiring in place to accommodate this plug, as it requires a specific installation setup.

Related Video: What Are The Different Atomic Models? Dalton, Rutherford, Bohr and Heisenberg Models Explained

Key Industrial Applications of north america electrical plug

| Industry/Sector | Specific Application of North America Electrical Plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering industrial machinery | Ensures reliable operation of equipment, reducing downtime and maintenance costs | Compliance with safety standards, durability for heavy use, and compatibility with existing systems |

| Construction | Use in power tools and temporary power setups | Enhances efficiency on job sites by providing consistent power to tools | Weather resistance, portability, and ease of connection for temporary setups |

| Consumer Electronics | Charging and powering devices like laptops and appliances | Facilitates user convenience and product compatibility in various markets | Compliance with international standards, voltage ratings, and adaptability to different plug types |

| Hospitality | Power supply for appliances in hotels and restaurants | Improves guest experience through reliable power access for devices and appliances | Safety certifications, energy efficiency, and compatibility with local electrical systems |

| Telecommunications | Equipment powering for communication devices | Ensures continuous operation of critical communication infrastructure | Reliability under varying load conditions, safety standards, and compatibility with global standards |

Manufacturing

In the manufacturing sector, North America electrical plugs are essential for powering industrial machinery. These plugs ensure reliable operation, which is crucial for minimizing downtime and reducing maintenance costs. B2B buyers should focus on sourcing plugs that comply with safety standards and are durable enough to withstand heavy use. Additionally, compatibility with existing electrical systems is vital to ensure seamless integration into the manufacturing environment.

Construction

In the construction industry, North America electrical plugs are widely used in power tools and for temporary power setups. These plugs enhance efficiency on job sites by providing a consistent power source, allowing workers to operate tools without interruption. Buyers in this sector should consider sourcing plugs that are weather-resistant and portable, as they often need to be moved around job sites. Easy connection features are also important for quick setup and breakdown.

Consumer Electronics

For the consumer electronics sector, North America electrical plugs are crucial for charging and powering devices such as laptops, hairdryers, and other appliances. They facilitate user convenience and ensure product compatibility across various markets. International B2B buyers must prioritize plugs that comply with international safety standards and voltage ratings, as well as those that can adapt to different plug types to meet diverse consumer needs.

Hospitality

In the hospitality sector, electrical plugs are vital for powering appliances in hotels and restaurants, significantly improving the guest experience. Reliable power access is essential for devices such as coffee makers, hairdryers, and entertainment systems. Buyers should look for plugs that have safety certifications and energy efficiency ratings, as well as compatibility with local electrical systems to avoid any operational issues.

Telecommunications

In telecommunications, North America electrical plugs are used to power critical communication devices and infrastructure. Ensuring continuous operation is paramount, as any downtime can lead to significant losses. B2B buyers should focus on sourcing plugs that are reliable under varying load conditions and adhere to safety standards. Compatibility with global standards is also essential to facilitate international operations and equipment integration.

Related Video: Brady 3-In-1 Electrical Plug Lockout | How to install

Strategic Material Selection Guide for north america electrical plug

When selecting materials for North American electrical plugs, several factors come into play, including performance characteristics, manufacturing processes, and compliance with international standards. Below is an analysis of four common materials used in electrical plug manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a widely used thermoplastic known for its excellent insulation properties and resistance to moisture and chemicals. It can withstand temperatures up to 105°C and has good mechanical strength.

Pros & Cons:

PVC is relatively inexpensive and easy to mold, making it a cost-effective choice for mass production. However, it can become brittle over time, especially when exposed to UV light, which may limit its durability in outdoor applications.

Impact on Application:

PVC is suitable for general-purpose electrical plugs, especially in indoor environments. Its chemical resistance makes it compatible with various media, but it may not perform well in extreme temperatures.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure that PVC products comply with local environmental regulations regarding the use of phthalates and other additives, as some countries have stringent restrictions.

2. Thermoplastic Elastomer (TPE)

Key Properties:

TPE combines the properties of rubber and plastic, offering flexibility, durability, and excellent insulation. It can operate effectively within a temperature range of -40°C to 120°C.

Pros & Cons:

TPE provides superior durability and flexibility compared to PVC, making it suitable for applications requiring frequent handling. However, it is generally more expensive than PVC, which could impact the overall cost of the product.

Impact on Application:

TPE is ideal for electrical plugs used in portable applications, such as power tools and consumer electronics, where flexibility and durability are critical.

Considerations for International Buyers:

Buyers should verify that TPE materials meet ASTM standards and consider the cost implications, especially when sourcing from regions with limited manufacturing capabilities.

3. Nylon

Key Properties:

Nylon is a robust synthetic polymer known for its high tensile strength and resistance to abrasion and chemicals. It can withstand temperatures up to 120°C and has excellent electrical insulating properties.

Pros & Cons:

Nylon is highly durable and resistant to wear, making it suitable for heavy-duty applications. However, it is more expensive than PVC and TPE, which may deter cost-sensitive buyers.

Impact on Application:

Nylon is commonly used in industrial plugs and connectors where high mechanical strength and resistance to harsh environments are required.

Considerations for International Buyers:

Nylon products should comply with relevant international standards, such as UL and IEC, to ensure safety and reliability. Buyers from the Middle East and Europe may favor nylon for its performance in high-temperature environments.

4. Metal (Copper/Aluminum)

Key Properties:

Copper and aluminum are metals known for their excellent electrical conductivity. They can operate effectively at high temperatures but may require additional coatings for corrosion resistance.

Pros & Cons:

Metal connectors provide superior conductivity and are essential in high-power applications. However, they are more susceptible to corrosion unless treated, and their cost can be significantly higher than plastic alternatives.

Impact on Application:

Metal components are crucial in high-performance plugs, such as those used in industrial machinery and high-load electrical systems.

Considerations for International Buyers:

International buyers must consider the compliance of metal components with standards such as RoHS and REACH, especially in Europe, where regulations on hazardous substances are strict.

Summary Table

| Material | Typical Use Case for North America Electrical Plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General-purpose indoor plugs | Cost-effective and easy to mold | Becomes brittle with UV exposure | Low |

| TPE | Portable applications (power tools, electronics) | Superior flexibility and durability | Higher cost compared to PVC | Medium |

| Nylon | Heavy-duty industrial plugs | High tensile strength and abrasion resistance | More expensive than PVC and TPE | High |

| Metal (Copper/Aluminum) | High-performance industrial plugs | Excellent electrical conductivity | Susceptible to corrosion without treatment | Medium to High |

This strategic material selection guide should aid international B2B buyers in making informed decisions regarding the procurement of electrical plugs, considering both performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for north america electrical plug

When considering the procurement of North American electrical plugs, international B2B buyers must understand the intricacies of the manufacturing processes and quality assurance measures that underpin these products. This section delves into the typical stages of manufacturing and the quality control protocols that ensure the safety and reliability of electrical plugs.

Manufacturing Processes

The manufacturing of North American electrical plugs involves several critical stages, each of which contributes to the overall quality of the final product.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials include:

- Thermoplastics: Used for the outer casing due to their durability and electrical insulation properties.

- Copper: Often used for the conductors, copper offers excellent conductivity.

- Nickel or Tin Plating: Applied to the contacts to prevent corrosion and enhance conductivity.

Materials undergo rigorous inspection to ensure they meet industry standards before proceeding to the next stage.

2. Forming

In the forming stage, raw materials are shaped into the required components. Key techniques include:

- Injection Molding: This method is commonly used for creating the plastic housings of plugs. It ensures uniformity and precision in dimensions.

- Stamping and Machining: Used for creating metal contacts and other components, ensuring tight tolerances and proper fit.

Advanced machinery and robotics are often employed to enhance efficiency and reduce human error during this phase.

3. Assembly

Once individual components are produced, they are assembled into the final product. This involves:

- Component Integration: Metal contacts are inserted into the molded plastic housing.

- Screw Fastening: Ensures that all parts are securely attached.

- Soldering: Electrical connections may be soldered to ensure a strong electrical bond.

Automation plays a significant role in this stage, with assembly lines designed to maximize speed while maintaining quality.

4. Finishing

The final stage involves finishing processes that enhance the product’s performance and aesthetics. This includes:

- Surface Treatment: Processes like polishing and coating may be applied to improve appearance and resistance to wear.

- Quality Inspection: Each plug undergoes a thorough inspection to ensure it meets design specifications before packaging.

Quality Assurance

Quality assurance is paramount in the manufacturing of electrical plugs, especially given their role in safety and compliance with international standards.

Relevant International Standards

B2B buyers should be aware of the following standards that govern electrical plugs:

- ISO 9001: This standard outlines requirements for a quality management system (QMS) that ensures consistent product quality.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- UL Certification: Underwriters Laboratories (UL) certification is critical for electrical safety in the United States and Canada.

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to detect defects early. This includes dimensional checks and functionality tests.

- Final Quality Control (FQC): A comprehensive inspection of the finished products, often including electrical safety tests and visual inspections.

Common Testing Methods

B2B buyers should be familiar with various testing methods employed to ensure product reliability:

- Electrical Testing: Verifying insulation resistance, dielectric strength, and continuity.

- Mechanical Testing: Assessing the durability of the plug under stress conditions, including pull tests and impact resistance.

- Environmental Testing: Subjecting plugs to temperature, humidity, and corrosion tests to ensure long-term performance.

Verifying Supplier Quality Control

To ensure that suppliers adhere to the highest quality standards, B2B buyers should consider the following strategies:

- Supplier Audits: Conduct on-site audits to assess manufacturing processes, QC protocols, and compliance with international standards.

- Quality Reports: Request detailed reports on quality inspections and testing results. Reliable suppliers should provide documentation that outlines their QC procedures.

- Third-Party Inspections: Engage independent third-party inspection agencies to conduct random checks on product quality before shipment.

Quality Control Nuances for International Buyers

International buyers from regions such as Africa, South America, the Middle East, and Europe should pay particular attention to:

- Regulatory Compliance: Ensure that the products meet the specific regulatory requirements of the destination country. This may include additional certifications not required in North America.

- Logistical Considerations: Understand the implications of shipping and handling, as improper handling can lead to damage and compromise product integrity.

- Cultural Differences: Be aware of cultural differences in business practices and communication styles that may affect negotiations and quality expectations.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance measures for North American electrical plugs is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control protocols, buyers can ensure they source high-quality products that meet their needs and regulatory requirements. Engaging with suppliers who prioritize quality and compliance will ultimately lead to better business outcomes and customer satisfaction.

Related Video: How to Amazing Electrical Wire Manufacturing in Factory Process

Comprehensive Cost and Pricing Analysis for north america electrical plug Sourcing

When sourcing electrical plugs from North America, understanding the comprehensive cost structure is essential for international B2B buyers. This analysis will cover the primary cost components, factors influencing pricing, and practical tips for negotiating favorable terms, particularly for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The cost of raw materials significantly impacts the final price of electrical plugs. Common materials include plastics, metals (like copper and aluminum), and insulation materials. Prices can fluctuate based on market conditions, making it vital for buyers to stay informed about commodity trends.

-

Labor: Labor costs in North America are generally higher than in many developing regions. Skilled labor is essential for manufacturing high-quality electrical plugs, which can add to production costs. Buyers should consider labor costs when evaluating suppliers.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and administrative expenses. Overhead costs can vary significantly depending on the supplier’s operational efficiency and geographic location.

-

Tooling: Initial tooling costs can be substantial, especially for custom or specialized electrical plugs. These costs are often amortized over larger production runs, making higher volume orders more cost-effective.

-

Quality Control (QC): Ensuring compliance with safety standards and certifications can add to costs. Rigorous QC processes are crucial in preventing defects and ensuring product reliability, which is particularly important for international buyers.

-

Logistics: Transportation costs can vary based on the shipping method, distance, and weight of the products. International shipping often involves additional fees, customs duties, and taxes that should be factored into the total cost.

-

Margin: Suppliers typically include a profit margin that can vary based on their business model, market demand, and competition. Understanding the expected margin can help buyers gauge the fairness of pricing.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly influence pricing. Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their demand forecasts.

-

Specifications/Customization: Custom designs or specific certifications can increase costs. Buyers need to clearly communicate their requirements to avoid unexpected price increases.

-

Materials and Quality Certifications: Higher quality materials and compliance with international standards (like UL, CE, or ISO certifications) can lead to higher prices. However, investing in quality can reduce long-term costs related to failures or recalls.

-

Supplier Factors: The reputation, reliability, and track record of suppliers can influence pricing. Established suppliers may charge more but offer better service and quality assurance.

- Incoterms: The terms of trade (Incoterms) will affect the overall cost. Buyers should understand the implications of different terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), as they dictate who bears shipping costs and risks.

Buyer Tips

-

Negotiation: Leverage competitive quotes from multiple suppliers to negotiate better pricing. Building a long-term relationship with suppliers can also provide opportunities for discounts on future orders.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, handling, and potential maintenance costs. Choosing high-quality plugs may incur a higher initial cost but can lead to savings over time.

-

Pricing Nuances: Be aware of fluctuations in the North American market that can affect pricing, such as changes in tariffs, trade policies, or raw material availability.

-

Regional Considerations: Buyers from Africa, South America, the Middle East, and Europe should factor in currency exchange rates and international shipping times, which can impact the total cost and delivery schedules.

Disclaimer: Prices for electrical plugs can vary widely based on the factors discussed above and should be treated as indicative. Buyers are encouraged to conduct thorough market research and supplier evaluation to obtain accurate and current pricing.

Spotlight on Potential north america electrical plug Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘north america electrical plug’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for north america electrical plug

Key Technical Properties of North American Electrical Plugs

When sourcing electrical plugs for North American markets, understanding specific technical properties is crucial for ensuring compatibility, safety, and performance. Here are some essential specifications:

-

Material Grade: The materials used in electrical plugs must meet specific standards for durability and electrical conductivity. Common materials include thermoplastic for housings and copper for conductors. High-grade materials reduce the risk of overheating and ensure longevity, which is vital for B2B buyers who prioritize reliability.

-

Voltage and Current Ratings: North American plugs typically operate at 120 volts and have current ratings of 15 or 20 amps. Selecting plugs with appropriate voltage and current ratings is critical for ensuring they can handle the power requirements of connected devices without risk of failure or fire.

-

Tolerance: This refers to the permissible limits of variation in dimensions of the plug components. Tighter tolerances ensure better fit and compatibility with sockets, reducing the chances of electrical arcing or connection issues. For buyers, this means fewer maintenance costs and improved safety.

-

Environmental Ratings: Many plugs are rated for environmental factors such as moisture, dust, and temperature. For instance, plugs with an IP (Ingress Protection) rating can indicate suitability for outdoor or industrial environments. Understanding these ratings helps buyers select products that will perform in their specific operating conditions.

-

Safety Certifications: Look for plugs that have been certified by recognized standards organizations such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association). These certifications indicate that the plugs meet rigorous safety standards, which is particularly important for B2B buyers concerned about compliance and liability.

Common Trade Terminology

Navigating the landscape of electrical components also requires familiarity with industry-specific terminology. Here are some key terms relevant to B2B transactions:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of electrical plugs, knowing the OEM can help buyers understand product reliability and compatibility with existing systems.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. For international buyers, understanding MOQs is essential for budgeting and inventory management, as purchasing below this threshold may not be feasible.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process is critical for buyers to compare prices, terms, and conditions across multiple vendors, ensuring they secure the best deal.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help B2B buyers understand shipping costs, risk management, and delivery timelines.

-

Lead Time: This refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory planning and ensuring that projects remain on schedule, especially in industries with tight deadlines.

-

Compliance: This term refers to the adherence to regulations and standards set by governing bodies. For electrical plugs, compliance with local and international safety standards is not only a legal requirement but also a critical factor in maintaining customer trust and brand reputation.

By comprehending these technical properties and trade terms, international B2B buyers can make informed purchasing decisions, ensuring that they select the right electrical plugs that meet their operational needs while adhering to safety and quality standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the north america electrical plug Sector

Market Overview & Key Trends

The North American electrical plug sector is experiencing significant transformations driven by various global factors. One of the primary drivers is the increasing demand for energy-efficient and smart technologies. As businesses across Africa, South America, the Middle East, and Europe seek to modernize their operations, the need for compatible electrical solutions has risen, particularly with the proliferation of electric vehicles and renewable energy systems. International B2B buyers are now looking for suppliers that can provide innovative products that adhere to these new standards.

Emerging sourcing trends in this sector include a shift towards digital platforms for supplier discovery and procurement. Platforms like Thomasnet offer extensive databases of manufacturers, enabling buyers to quickly identify potential partners and request quotes. Additionally, the rise of automation and the Internet of Things (IoT) is influencing product designs, with smart plugs and integrated technologies gaining traction. These advancements not only enhance functionality but also improve safety and energy management, making them appealing to international buyers looking to stay competitive.

Furthermore, as the market evolves, there is a noticeable emphasis on compliance with international standards. Buyers are increasingly prioritizing suppliers who can demonstrate adherence to certifications such as ISO, UL, and CSA, which assure product quality and safety. This trend is particularly relevant for companies sourcing from regions with varying regulatory frameworks, as it mitigates risks associated with non-compliance.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration in the electrical plug sector, reflecting a broader global movement towards environmental responsibility. The production and disposal of electrical plugs can have significant environmental impacts, including the depletion of natural resources and electronic waste accumulation. B2B buyers are increasingly aware of these issues and are seeking suppliers who prioritize eco-friendly practices.

Illustrative Image (Source: Google Search)

Ethical sourcing is another critical aspect that international buyers should consider. This involves ensuring that suppliers maintain responsible supply chains, which are free from labor exploitation and environmental degradation. Many manufacturers in North America are now pursuing ‘green’ certifications, such as Energy Star and RoHS compliance, which signify adherence to environmental standards. Utilizing materials that are recyclable or sourced from sustainable practices is also becoming common.

Moreover, buyers can leverage sustainability as a competitive advantage. Companies that can demonstrate their commitment to green practices often appeal to a broader customer base and enhance their brand reputation. This is particularly true in regions like Europe, where consumers increasingly favor products that contribute to sustainability goals.

Brief Evolution/History

The electrical plug has evolved significantly since its inception in the late 19th century, transitioning from simple designs to complex, safety-oriented products. Initially developed for basic electrical connections, the design has undergone numerous iterations to accommodate increasing power demands and safety regulations.

In the mid-20th century, standardized plug types emerged, such as the NEMA configurations in North America, which facilitated easier trade and compatibility across devices. Today, the focus has shifted towards integrating technology with traditional plug designs, leading to innovations like smart plugs that provide enhanced functionality. This evolution reflects the ongoing demand for efficiency and safety in electrical systems, aligning with the broader technological advancements in the B2B landscape.

In summary, international B2B buyers in the electrical plug sector must navigate a landscape marked by rapid technological advancements, heightened sustainability concerns, and evolving market dynamics. Emphasizing partnerships with suppliers who align with these trends will be crucial in maintaining competitiveness and meeting consumer expectations.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of north america electrical plug

-

What should I consider when vetting suppliers for North American electrical plugs?

When vetting suppliers, prioritize their industry reputation, certifications, and compliance with North American standards (such as UL and CSA). Check for reviews and testimonials from previous clients, especially those in your region. It’s also beneficial to assess their production capacity, lead times, and ability to handle customization requests. Establish communication to understand their responsiveness and willingness to address your specific needs, which can be a good indicator of their reliability. -

Can I customize North American electrical plugs for my specific needs?

Yes, many manufacturers offer customization options for electrical plugs to meet specific requirements. This can include variations in plug types, colors, lengths, and material specifications. Be sure to communicate your needs clearly during the initial discussions with suppliers. Request samples to evaluate the quality and ensure that the customization meets your standards before placing larger orders. -

What are the typical minimum order quantities (MOQs) and lead times for electrical plugs?

Minimum order quantities can vary significantly between suppliers, typically ranging from 100 to 1,000 units depending on the type and customization of the plugs. Lead times can also differ, usually spanning from 2 to 12 weeks based on the complexity of the order and current demand. It is advisable to confirm these details upfront to avoid unexpected delays in your supply chain. -

What payment terms are commonly offered by suppliers?

Payment terms can vary widely, but most suppliers require a deposit (often 30% to 50%) before production, with the balance due upon completion or shipment. Some suppliers may offer credit terms for established businesses, while others may require full payment in advance, especially for first-time orders. Always negotiate payment terms that align with your cash flow and financial management strategies. -

What quality assurance measures should I look for in suppliers?

Verify that suppliers adhere to recognized quality management systems such as ISO 9001 or similar certifications. Request details on their quality control processes, including testing protocols for electrical safety and performance. Ask for documentation of past quality audits and compliance with North American safety standards. This will help ensure that the plugs meet your quality expectations and regulatory requirements. -

How can I ensure efficient logistics for importing electrical plugs?

To streamline logistics, establish a clear understanding of shipping options, including air and sea freight. Work with suppliers who have experience in international shipping and can assist with customs documentation. Consider using freight forwarders who specialize in your region to navigate logistics challenges. Additionally, clarify delivery timelines and costs upfront to avoid surprises and ensure timely delivery to your facilities. -

What should I do if I encounter a dispute with a supplier?

Begin by addressing the issue directly with the supplier through clear and constructive communication. Document all interactions and agreements to provide a record of your discussions. If the dispute cannot be resolved amicably, refer to the terms of your contract regarding dispute resolution, which may include mediation or arbitration. Engaging legal counsel familiar with international trade can also help navigate complex issues. -

Are there specific certifications I should look for when sourcing electrical plugs?

Yes, ensure that the electrical plugs comply with North American safety standards such as UL (Underwriters Laboratories) and CSA (Canadian Standards Association). These certifications indicate that the products have been tested for safety and performance. Additionally, look for RoHS (Restriction of Hazardous Substances) compliance if you aim to meet environmental standards. Request copies of certifications from your suppliers to verify compliance before finalizing orders.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for north america electrical plug

In conclusion, the strategic sourcing of electrical plugs in North America offers significant opportunities for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. Understanding the diverse range of suppliers and manufacturers available, along with their certifications and compliance standards, is crucial for making informed purchasing decisions.

Key takeaways include:

- Diverse Supplier Base: Engage with a wide array of manufacturers, ensuring to evaluate their quality certifications such as ISO and ANSI to guarantee product reliability.

- Customization and Innovation: Many suppliers offer customized solutions that can cater to specific regional requirements, enhancing the adaptability of products in various markets.

- Sustainability Trends: Look for suppliers who prioritize sustainable practices, as this is increasingly becoming a key consideration for businesses worldwide.

As the global market continues to evolve, staying ahead of trends and leveraging strategic sourcing will be pivotal for success. We encourage international buyers to actively seek partnerships with North American manufacturers to capitalize on quality, innovation, and reliability. By doing so, you can ensure your business remains competitive in an increasingly interconnected world.