Your Ultimate Guide to Sourcing Oem Near Me

Introduction: Navigating the Global Market for oem near me

In an increasingly interconnected world, sourcing Original Equipment Manufacturer (OEM) components locally has become essential for businesses striving to enhance their operational efficiency and reduce supply chain risks. The phrase “OEM near me” resonates particularly well with international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, as it signifies a search for reliable, accessible manufacturing solutions that can streamline production and ensure quality.

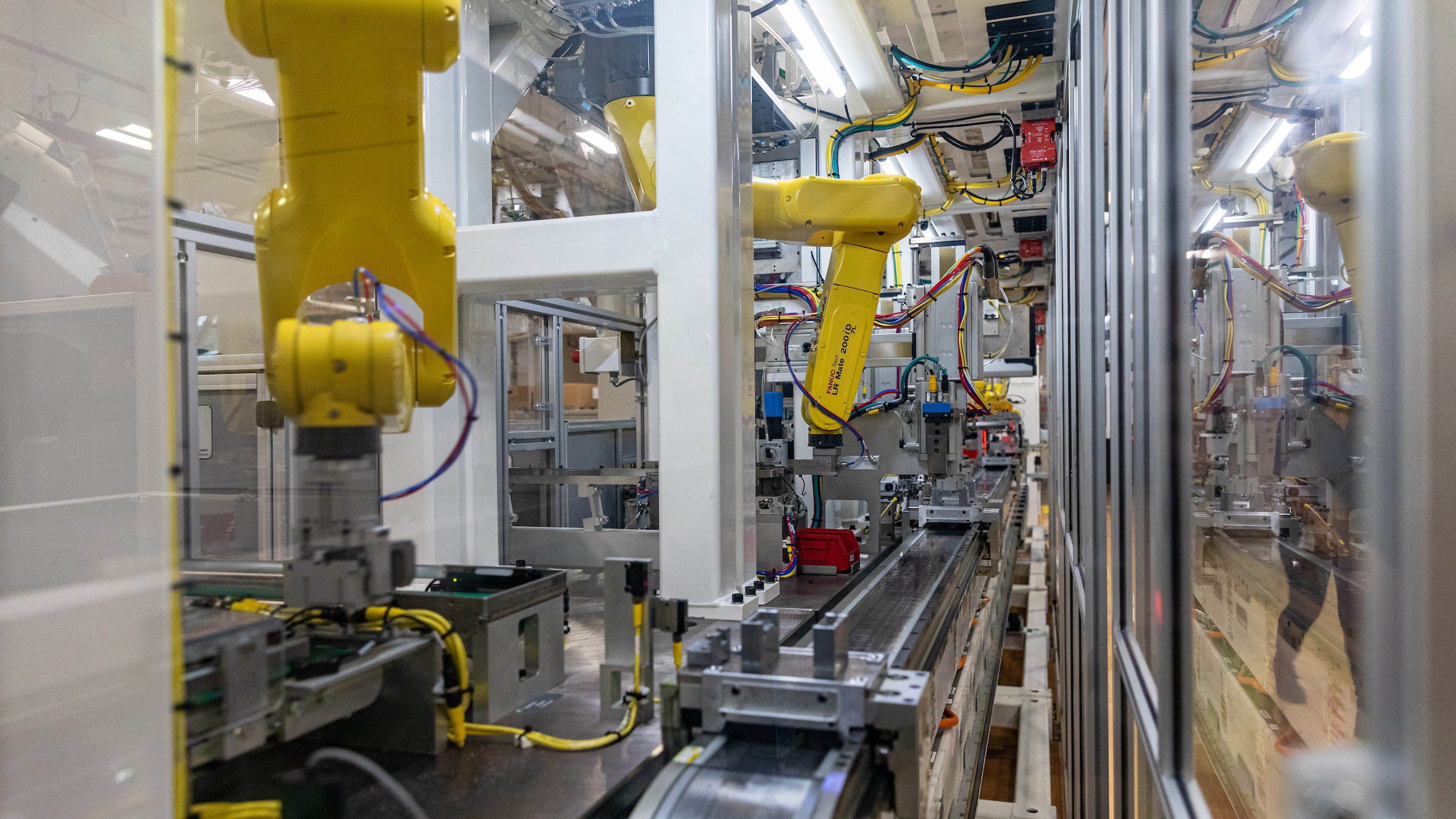

Illustrative Image (Source: Google Search)

This comprehensive guide aims to empower B2B buyers by providing in-depth insights into the OEM landscape. Readers will explore various types of OEM products, the materials used, and the manufacturing and quality control processes involved. Furthermore, the guide will illuminate how to identify reputable suppliers, assess cost factors, and navigate market dynamics effectively.

By addressing frequently asked questions and offering actionable strategies, this guide equips international buyers with the knowledge to make informed sourcing decisions. It emphasizes the importance of local partnerships that not only foster economic growth but also enhance supply chain resilience. Whether you’re based in Nigeria, Italy, or elsewhere, understanding how to leverage the “OEM near me” approach can significantly impact your procurement strategy and overall business success.

Understanding oem near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Local OEMs | Proximity to buyer; shorter lead times; easier communication. | Manufacturing components for local industries. | Pros: Faster delivery; easier logistics. Cons: Limited scalability. |

| Global OEMs | Access to a wider range of products and technologies; often lower costs. | Electronics, automotive parts, consumer goods. | Pros: Cost-effective; diverse offerings. Cons: Longer lead times; potential language barriers. |

| Specialized OEMs | Focus on niche markets or products; often provide customized solutions. | Aerospace, medical devices, specialized machinery. | Pros: Tailored solutions; high-quality standards. Cons: Higher costs; limited production capacity. |

| Contract Manufacturers | Offer production services under a brand’s name; often handle logistics. | Electronics, apparel, automotive components. | Pros: Flexibility; allows brands to scale without heavy investment. Cons: Less control over production quality. |

| Hybrid OEMs | Combine features of local and global OEMs; adaptable to various markets. | Diverse sectors including consumer electronics and automotive. | Pros: Versatile; can cater to different market needs. Cons: Complexity in managing relationships. |

Local OEMs

Local OEMs are manufacturers located close to the buyer, which enables shorter lead times and more effective communication. They are particularly suitable for businesses that require quick turnaround times and want to minimize shipping costs. When purchasing from local OEMs, buyers should consider the balance between cost and the speed of delivery, as well as the potential for building strong, long-term partnerships that can adapt to changing needs.

Global OEMs

Global OEMs provide access to a wide variety of products and technologies, often at lower costs due to economies of scale. They are ideal for businesses looking to source components for electronics or automotive parts. However, buyers should be aware of longer lead times and potential challenges such as language barriers and cultural differences. Conducting thorough due diligence on the supplier’s reliability and quality standards is critical in this context.

Specialized OEMs

Specialized OEMs focus on niche markets, offering products that often require specific expertise or technology. They are well-suited for industries like aerospace or medical devices, where customization and high-quality standards are paramount. Buyers should evaluate these suppliers based on their ability to meet specific quality certifications and their experience in the relevant industry, even if it means higher costs.

Contract Manufacturers

Contract manufacturers provide production services under a brand’s name, allowing businesses to outsource manufacturing while maintaining brand integrity. This model is prevalent in sectors like electronics and apparel. Buyers should consider the flexibility and scalability that contract manufacturers offer, but also be mindful of the potential trade-offs in quality control and oversight.

Hybrid OEMs

Hybrid OEMs merge the advantages of local and global sourcing, offering adaptability across various markets. They can cater to diverse sectors, including consumer electronics and automotive. Buyers should weigh the benefits of versatility against the complexities of managing multiple supplier relationships, ensuring that they have clear communication and quality assurance processes in place to mitigate risks.

Related Video: Mercedes Models Explained (2020 model range) | Let Me Explain

Key Industrial Applications of oem near me

| Industry/Sector | Specific Application of oem near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom parts manufacturing | Enhanced vehicle performance and safety | Supplier certifications, quality control processes |

| Aerospace | Precision components for aircraft | Improved reliability and compliance | Regulatory compliance, material specifications |

| Medical Devices | Production of specialized medical equipment | Higher patient safety and treatment efficacy | Quality assurance certifications, delivery timelines |

| Construction | Manufacturing of building materials | Cost efficiency and project timelines | Local sourcing for faster delivery, material standards |

| Textiles | Custom fabric production | Unique product offerings and market differentiation | Supplier reliability, ethical sourcing practices |

Automotive Industry

In the automotive sector, oem near me is essential for sourcing custom parts manufacturing. Local suppliers can produce components tailored to specific vehicle models, enhancing performance and safety. International buyers, particularly from Africa and Europe, should consider suppliers’ certifications and their quality control processes to mitigate risks of defects and ensure compliance with safety standards.

Aerospace Industry

The aerospace industry relies heavily on precision components for aircraft. Utilizing oem near me allows manufacturers to source locally, ensuring that parts meet stringent regulatory compliance and quality standards. Buyers from regions like the Middle East and South America must prioritize suppliers with proven track records in aerospace manufacturing, focusing on their ability to meet material specifications and delivery schedules.

Medical Devices Sector

In the medical devices sector, oem near me facilitates the production of specialized medical equipment, crucial for enhancing patient safety and treatment efficacy. Buyers should seek suppliers that hold quality assurance certifications, such as ISO 13485, and can meet specific delivery timelines. This is particularly vital for international buyers who need to comply with various regulatory frameworks across different markets.

Construction Industry

Construction companies benefit from oem near me by sourcing building materials directly from local manufacturers, which can lead to cost efficiencies and improved project timelines. For international buyers, especially in regions like South America and Africa, it’s critical to evaluate suppliers based on their ability to meet local material standards and delivery capabilities to avoid project delays.

Textiles Industry

In the textiles industry, oem near me enables manufacturers to produce custom fabric that meets specific design requirements, offering unique product offerings that differentiate them in the market. Buyers must ensure that their suppliers are reliable and adhere to ethical sourcing practices, particularly when dealing with international suppliers, to maintain brand integrity and consumer trust.

Related Video: What is Industrial Automation?

Strategic Material Selection Guide for oem near me

Material Analysis for OEM Applications

When selecting materials for OEM applications, it’s crucial to understand the specific properties, advantages, and limitations of commonly used materials. This analysis focuses on four materials frequently utilized in various industries, providing actionable insights for international B2B buyers.

1. Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it suitable for applications requiring significant load-bearing capabilities. It typically features excellent temperature and pressure ratings, with corrosion resistance varying based on the alloy and treatment.

Pros & Cons:

Steel’s primary advantage is its strength and versatility, allowing it to be used in a wide range of applications from automotive to construction. However, it can be prone to rust if not properly treated, which may increase maintenance costs. Manufacturing complexity can also be higher due to the need for precise machining and welding.

Impact on Application:

Steel’s compatibility with various media, including oils and chemicals, makes it a preferred choice in industrial applications. However, its susceptibility to corrosion can limit its use in harsher environments without protective coatings.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or ISO certifications. In Europe, adherence to DIN standards is essential. Understanding the availability of specific steel grades locally can also impact cost and lead times.

2. Aluminum

Key Properties:

Aluminum is lightweight, has excellent corrosion resistance, and good thermal and electrical conductivity. Its low density makes it ideal for applications where weight reduction is critical.

Pros & Cons:

The key advantage of aluminum is its lightweight nature, which can lead to improved fuel efficiency in transportation applications. However, it is generally less durable than steel, making it unsuitable for high-stress applications. The manufacturing process can be complex, especially for intricate designs.

Impact on Application:

Aluminum’s corrosion resistance allows it to be used in outdoor applications or environments with moisture. Its compatibility with various coatings can enhance its performance in specific media applications.

Considerations for International Buyers:

For buyers in the Middle East, where high temperatures can affect material performance, selecting the right aluminum alloy is crucial. Compliance with international standards like JIS for aluminum products is also important for ensuring quality and performance.

3. Plastic (Polymer)

Key Properties:

Plastics are versatile materials known for their lightweight, corrosion resistance, and flexibility. They can be engineered to withstand varying temperatures and pressures, depending on the type.

Pros & Cons:

The primary advantage of plastics is their adaptability and lower cost compared to metals. However, they may not be suitable for high-stress applications and can degrade under UV exposure unless treated. Manufacturing processes for plastics can be simpler, allowing for faster production rates.

Impact on Application:

Plastics are often used in applications involving chemicals or moisture, where corrosion resistance is vital. However, their compatibility with certain media must be assessed to avoid chemical reactions that could compromise performance.

Considerations for International Buyers:

Buyers should be aware of the specific grades of plastic that meet local compliance standards. In Europe, for instance, REACH regulations may impact the selection of certain plastic materials due to environmental concerns.

4. Composite Materials

Key Properties:

Composite materials combine two or more materials to achieve superior properties, including high strength-to-weight ratios and enhanced durability. They can be engineered for specific applications, offering tailored performance characteristics.

Pros & Cons:

Composites provide significant advantages in terms of weight reduction and corrosion resistance. However, they can be more expensive and complex to manufacture, requiring specialized processes and equipment.

Impact on Application:

Composites are ideal for applications in aerospace and automotive industries, where weight and performance are critical. Their compatibility with various media can vary widely based on the constituent materials.

Considerations for International Buyers:

International buyers should consider the availability of composite materials in their regions and ensure that suppliers comply with relevant industry standards. In regions like Africa, where infrastructure may vary, understanding local manufacturing capabilities is essential.

Summary Table

| Material | Typical Use Case for OEM Near Me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, Automotive | High strength and durability | Prone to rust without treatment | Medium |

| Aluminum | Aerospace, Transportation | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Plastic (Polymer) | Consumer Goods, Packaging | Cost-effective and versatile | Not suitable for high-stress use | Low |

| Composite Materials | Aerospace, Sports Equipment | High strength-to-weight ratio | Expensive and complex to manufacture | High |

This guide provides a comprehensive overview of material selection considerations for OEM applications, enabling international B2B buyers to make informed decisions based on their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for oem near me

When evaluating OEM (Original Equipment Manufacturer) suppliers, understanding their manufacturing processes and quality assurance practices is critical for international B2B buyers. This knowledge ensures that products meet required specifications and standards while minimizing risks associated with sourcing.

Manufacturing Processes for OEM

The manufacturing process for OEM products typically consists of four main stages:

1. Material Preparation

The first stage involves sourcing and preparing raw materials. This step includes:

- Material Selection: Choosing the right materials based on product specifications. For example, metals for automotive parts or plastics for consumer electronics.

- Processing: Raw materials may undergo processes such as cutting, machining, or chemical treatment to meet specific requirements.

2. Forming

Forming is the process where raw materials are shaped into components. Key techniques include:

- Casting: Pouring molten material into a mold to create complex shapes.

- Forging: Using compressive forces to shape materials, which enhances their strength.

- Molding: Common in plastics manufacturing, where heated material is formed into a desired shape.

3. Assembly

Once components are formed, they are assembled into final products. This stage can involve:

- Manual Assembly: Skilled workers assemble products, often used for intricate or sensitive items.

- Automated Assembly: Machines and robotics handle assembly, increasing efficiency and consistency.

4. Finishing

The finishing stage enhances the product’s appearance and performance. Techniques may include:

- Painting and Coating: Protects the product and improves aesthetic appeal.

- Heat Treatment: Alters the physical properties of materials, enhancing durability.

- Polishing: Improves surface finish, particularly important for consumer-facing products.

Quality Assurance Standards

Quality assurance (QA) is vital for maintaining product integrity throughout the manufacturing process. International standards play a significant role in ensuring that OEM suppliers meet quality benchmarks.

Relevant International Standards

- ISO 9001: This standard outlines criteria for a quality management system (QMS) and is applicable to any organization, regardless of size. Certification indicates a commitment to quality processes.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards within the European Economic Area. Essential for products sold in Europe.

- API Standards: Relevant for suppliers in the oil and gas industry, ensuring quality and safety in manufacturing equipment.

Quality Control Checkpoints

Quality control (QC) involves systematic processes to ensure products meet specified requirements. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspects materials upon arrival to ensure they meet specified standards before production.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to identify and rectify issues early.

- Final Quality Control (FQC): Comprehensive testing of finished products to confirm they meet quality and safety standards before shipment.

Common Testing Methods

To ensure quality, various testing methods are employed, such as:

- Destructive Testing: Involves testing samples to failure to determine their performance limits.

- Non-Destructive Testing (NDT): Techniques like ultrasonic, magnetic particle, or radiographic testing assess the integrity of materials without causing damage.

- Functional Testing: Ensures that the product operates as intended under specified conditions.

Verifying Supplier Quality Control

B2B buyers can implement several strategies to verify the quality control practices of OEM suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s processes, equipment, and quality management systems directly.

- Quality Reports: Requesting detailed quality reports and documentation from suppliers helps assess their compliance with standards.

- Third-Party Inspections: Engaging independent inspection agencies provides unbiased evaluations of product quality and supplier practices.

Navigating Quality Control Nuances for International Buyers

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of QC is essential:

- Cultural Differences: Be aware of varying approaches to quality standards and practices across regions. For instance, European suppliers might have stricter adherence to regulatory standards compared to some suppliers in emerging markets.

- Language Barriers: Ensure clear communication regarding quality expectations and standards. This may require multilingual documentation or translators during audits.

- Regulatory Compliance: Familiarize yourself with local regulations and standards that may affect product quality, such as import regulations in your region.

Conclusion

Understanding the manufacturing processes and quality assurance practices of OEM suppliers is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, and by adhering to established quality standards, buyers can mitigate risks and enhance their supply chain resilience. Engaging in thorough QC practices, including audits and third-party inspections, ensures that suppliers deliver high-quality products that meet international standards, ultimately supporting business growth and sustainability.

Related Video: BMW 5 Series (2024) PRODUCTION 🇩🇪 Car Manufacturing Process

Comprehensive Cost and Pricing Analysis for oem near me Sourcing

To effectively navigate the complexities of sourcing OEM products locally, international buyers must understand the fundamental components of cost structures and pricing strategies. This insight is crucial for making informed purchasing decisions and optimizing supply chain efficiency.

Cost Components

-

Materials: The choice of materials directly impacts costs. Premium materials typically lead to higher prices, while bulk purchasing can reduce costs significantly. Buyers should assess the trade-offs between cost and quality to ensure they meet their specifications without overspending.

-

Labor: Labor costs vary by region and can significantly influence overall pricing. For instance, sourcing from regions with lower labor costs can reduce expenses, but it’s essential to evaluate the trade-off with potential quality and efficiency.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Understanding a supplier’s overhead costs can provide insights into their pricing structure and help buyers identify more cost-effective options.

-

Tooling: If custom tooling is required, this can add to initial costs. Buyers should inquire about tooling costs upfront, particularly if they anticipate high volumes, as these costs can be amortized over larger production runs.

-

Quality Control (QC): Investing in quality control processes is vital for ensuring product standards. However, rigorous QC measures can also increase costs. Buyers should weigh the importance of quality against their budget constraints.

-

Logistics: Transportation and handling costs must be factored into the total cost of ownership. For international buyers, understanding Incoterms is crucial as they define responsibility for shipping costs and risks.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market conditions and competition. Understanding these margins can help buyers negotiate better terms.

Price Influencers

Several factors can influence the pricing of OEM products:

-

Volume/MOQ: Larger orders usually come with discounts due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize their purchasing power.

-

Specifications/Customization: Custom products often incur additional costs. Clearly defining specifications can help suppliers provide accurate quotes and avoid unexpected price increases.

-

Materials: The choice of materials affects both cost and lead time. Buyers should consider alternative materials that may reduce costs without compromising quality.

-

Quality/Certifications: Higher quality and specific certifications (e.g., ISO, CE) can increase costs. Buyers should assess the necessity of certifications based on their market requirements.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can influence pricing. Established suppliers may charge a premium but often provide better quality and service.

-

Incoterms: Understanding Incoterms can help buyers manage logistics costs effectively. For example, opting for DDP (Delivered Duty Paid) can simplify the shipping process but may be more expensive.

Buyer Tips

To maximize value and ensure cost-efficiency, consider the following strategies:

-

Negotiate: Always negotiate pricing and terms. Suppliers expect negotiation, and there’s often flexibility in pricing.

-

Total Cost of Ownership (TCO): Evaluate the total cost over the product’s lifecycle, not just the initial purchase price. This includes maintenance, shipping, and disposal costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import duties that can affect overall pricing. Establishing relationships with local suppliers can mitigate some of these costs.

-

Research and Benchmark: Conduct market research to compare prices and services from multiple suppliers. Benchmarking against competitors can provide leverage in negotiations.

By understanding these elements, international B2B buyers can make more informed decisions, ultimately leading to better sourcing outcomes and enhanced competitive advantage. Always keep in mind that indicative prices may vary based on market conditions and specific supplier capabilities.

Spotlight on Potential oem near me Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘oem near me’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for oem near me

When sourcing components or products from OEMs (Original Equipment Manufacturers), understanding the technical properties and trade terminology is crucial for making informed purchasing decisions. This knowledge enables B2B buyers to communicate effectively with suppliers, ensuring they receive products that meet their specific needs.

Essential Technical Properties

-

Material Grade

– Definition: This refers to the classification of materials based on their mechanical and chemical properties. Common grades include stainless steel, aluminum alloys, and plastics.

– Importance: The material grade affects durability, weight, corrosion resistance, and overall performance. Selecting the right grade is critical to ensuring the longevity and reliability of the final product. -

Tolerance

– Definition: Tolerance indicates the allowable deviation from a specified dimension in manufacturing. It is typically expressed as a range (e.g., ±0.01 mm).

– Importance: Precise tolerances are vital for parts that must fit together accurately, especially in assemblies. Poor tolerance can lead to malfunction or increased wear, impacting product quality and operational efficiency. -

Surface Finish

– Definition: This term describes the texture and smoothness of a material’s surface. Common finishes include rough, polished, anodized, or coated.

– Importance: The surface finish can affect aesthetic appeal, corrosion resistance, and friction. A proper finish can enhance the product’s functionality and lifespan. -

Load Capacity

– Definition: Load capacity refers to the maximum weight or force a component can support without failure.

– Importance: Knowing the load capacity is essential for components used in structural applications. Underestimating this can lead to catastrophic failures and safety issues. -

Lifecycle and Warranty

– Definition: This encompasses the expected operational lifespan of a product and any warranties provided by the manufacturer.

– Importance: Understanding lifecycle and warranty terms helps businesses assess long-term costs and risks associated with product failure or replacement.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding the role of OEMs is crucial for buyers looking for high-quality components that meet specific industry standards. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ helps buyers gauge their purchasing power and manage inventory effectively. It can also influence the decision to switch suppliers based on order flexibility. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting a quote for specific products or services.

– Significance: RFQs are vital for comparing pricing and terms across different suppliers, enabling buyers to make cost-effective decisions. -

Incoterms (International Commercial Terms)

– Definition: These are standardized trade terms used in international sales contracts that define the responsibilities of buyers and sellers.

– Significance: Understanding Incoterms is essential for B2B transactions to clarify shipping costs, insurance, and risks involved in the transportation of goods. -

Lead Time

– Definition: Lead time is the period between placing an order and receiving the product.

– Significance: Knowing the lead time is critical for inventory management and planning production schedules, especially in industries where timing is crucial.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can enhance their sourcing strategies, minimize risks, and ensure they procure the right products to meet their business needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the oem near me Sector

Market Overview & Key Trends

The OEM (Original Equipment Manufacturer) sector is experiencing significant shifts driven by globalization, technological advancements, and changing consumer demands. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Global Drivers: Economic growth in emerging markets is creating a demand for localized production, prompting OEMs to establish partnerships closer to their target markets. This shift not only reduces logistics costs but also shortens lead times, enhancing competitiveness. Furthermore, the rise of e-commerce and digital platforms is making it easier for businesses to connect with suppliers globally, fostering a more interconnected market.

Current and Emerging Trends: One notable trend is the increasing adoption of Industry 4.0 technologies, such as IoT (Internet of Things) and AI (Artificial Intelligence), which are enhancing operational efficiency and supply chain transparency. Buyers should look for OEM partners who leverage these technologies to optimize production processes and reduce waste. Additionally, supply chain resilience is becoming a priority. With recent disruptions due to global events, companies are diversifying their supplier base to mitigate risks associated with single-source dependencies.

Market Dynamics: For B2B buyers, the emphasis on strategic sourcing is essential. This involves not just finding the lowest cost supplier but evaluating the entire supply chain for reliability, quality, and ethical practices. Buyers from diverse regions must also consider local regulations and standards, which can vary significantly, affecting procurement strategies and compliance requirements.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a peripheral concern; it has become a fundamental pillar of business strategy in the OEM sector. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to prioritize suppliers who demonstrate commitment to sustainable practices. This includes reducing carbon footprints, minimizing waste, and using renewable energy sources.

Importance of Ethical Supply Chains: Ethical sourcing plays a vital role in building brand reputation and customer loyalty. B2B buyers should seek OEM partners who adhere to strict ethical standards, ensuring fair labor practices and responsible sourcing of materials. This not only aligns with global sustainability goals but also enhances the buyer’s own market position.

Green Certifications and Materials: Buyers should actively look for OEMs that possess recognized green certifications, such as ISO 14001 or LEED, which indicate adherence to environmental management standards. Moreover, sourcing materials that are recycled or sustainably sourced can significantly reduce environmental impact. Incorporating these practices not only contributes to a healthier planet but also can lead to cost savings in the long run, as energy-efficient processes often translate to lower operational costs.

Brief Evolution/History

The OEM sector has evolved significantly over the decades, transitioning from a focus primarily on manufacturing to a broader emphasis on value-added services. Initially, OEMs were seen mainly as suppliers of parts; however, the rise of globalization and technological advancements has transformed them into integral partners in product development and innovation. This evolution has empowered buyers to leverage OEM capabilities not just for cost savings, but for enhancing product quality and driving innovation. As markets continue to evolve, OEMs that adapt to these changes will be best positioned to meet the demands of international B2B buyers.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of oem near me

-

What should I consider when vetting OEM suppliers near me?

When vetting OEM suppliers, prioritize their industry experience, certifications, and customer references. Check for compliance with international quality standards such as ISO 9001. Evaluate their production capabilities, capacity, and technology. It’s also crucial to assess their financial stability to ensure they can fulfill long-term contracts. Conduct site visits if possible, and consider using platforms like Thomasnet to verify supplier legitimacy and gather insights from other buyers. -

Can I customize products when sourcing from OEMs?

Yes, many OEMs offer customization options tailored to your specifications. Discuss your requirements upfront, including design, materials, and production processes. Ensure that the OEM has the capability to accommodate these changes without significantly impacting lead times or costs. Request prototypes to assess quality before committing to larger orders. Clear communication is essential throughout the customization process to avoid misunderstandings. -

What are typical minimum order quantities (MOQ) and lead times with OEMs?

MOQs can vary significantly among OEMs based on the product type and manufacturing processes. Generally, higher volumes lead to lower per-unit costs. Lead times typically range from a few weeks to several months, depending on the complexity of the product and the OEM’s production schedule. Always inquire about lead times before placing an order, and factor in potential delays due to logistics or sourcing materials. -

What payment terms are commonly used in international OEM transactions?

Payment terms can vary widely, but common practices include advance payment, letters of credit, or net payment terms after delivery. For international transactions, consider using secure payment methods that provide buyer protection. Negotiate terms that align with your cash flow and risk tolerance. Establishing a clear payment schedule in the contract can help mitigate disputes and ensure timely deliveries. -

How can I ensure quality assurance and certifications from my OEM supplier?

To ensure quality assurance, request documentation of the supplier’s quality management systems, including relevant certifications like ISO 9001 or industry-specific standards. Schedule regular quality audits or inspections during production, and consider third-party quality assurance services if necessary. Establish clear quality control criteria in your contract, and communicate your expectations regarding product quality and compliance with regulations. -

What logistics considerations should I keep in mind when sourcing from OEMs?

Logistics is critical in international sourcing. Assess the OEM’s shipping capabilities, including their experience with customs regulations and international shipping methods. Understand the costs associated with transportation, duties, and taxes, and consider using freight forwarders to streamline the shipping process. Ensure that the OEM can provide tracking information and updates throughout the shipping process to maintain visibility. -

What should I do if a dispute arises with my OEM supplier?

If a dispute arises, start by reviewing your contract to understand the terms and conditions. Communicate directly with the OEM to discuss the issue and seek a resolution. If necessary, involve a mediator or legal counsel specializing in international trade. Maintaining a professional relationship is vital, so approach disputes with a focus on finding a mutually agreeable solution. Document all communications for reference.

Illustrative Image (Source: Google Search)

- How can I build long-term relationships with OEM suppliers?

Building long-term relationships with OEM suppliers involves clear communication, trust, and mutual benefit. Regularly share feedback and discuss performance metrics to foster transparency. Consider long-term contracts that provide stability for both parties. Engage in collaborative product development initiatives to align goals and innovation. Attend industry events and maintain open lines of communication to strengthen the partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for oem near me

In conclusion, strategic sourcing is a pivotal element for international B2B buyers seeking to optimize their operations and enhance competitiveness. By leveraging local and global suppliers, businesses can achieve significant cost savings, improve product quality, and mitigate risks associated with supply chain disruptions. The process of identifying, evaluating, and engaging with suppliers is not just about procurement; it’s about building lasting partnerships that drive innovation and sustainability.

Key takeaways include the importance of thorough market research, the value of diverse sourcing strategies, and the necessity of ongoing supplier evaluation. For businesses in Africa, South America, the Middle East, and Europe, embracing these strategies can lead to a more resilient and efficient supply chain.

As you move forward, consider the potential of local OEMs to streamline your sourcing efforts. Engage with suppliers that align with your business goals, and foster relationships that can adapt to market changes. Take action now to explore the wealth of opportunities that effective sourcing can bring to your organization, positioning yourself for success in the global marketplace.