Your Ultimate Guide to Sourcing Optical Comparitor

Introduction: Navigating the Global Market for optical comparitor

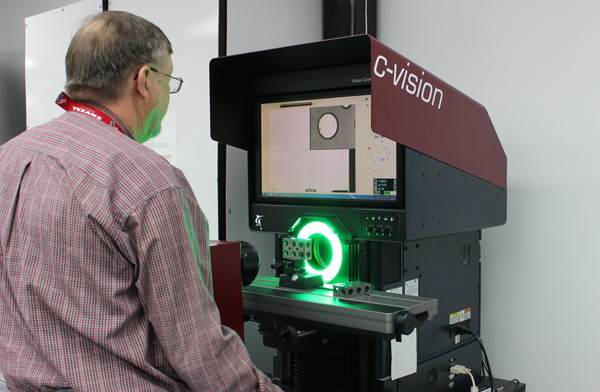

Navigating the intricate landscape of the global market for optical comparators requires a keen understanding of this indispensable measurement tool. Optical comparators, or profile projectors, are vital in ensuring quality control across various manufacturing sectors. Their ability to deliver precise measurements and detect surface imperfections positions them as essential assets in industries such as automotive, aerospace, and electronics. As international B2B buyers from Africa, South America, the Middle East, and Europe seek to enhance their production capabilities, understanding the nuances of optical comparators becomes critical.

This guide provides a comprehensive overview of optical comparators, covering essential topics such as types, materials, manufacturing and quality control processes, supplier landscapes, and cost factors. Additionally, it addresses common FAQs that buyers may encounter, empowering them to make informed sourcing decisions.

By exploring the different configurations—horizontal and vertical—as well as traditional and digital models, buyers can identify the most suitable solutions for their specific applications. Furthermore, insights into market trends and supplier evaluations will aid in navigating procurement challenges and optimizing operational efficiency. This resource not only simplifies the decision-making process but also equips B2B buyers with the knowledge to leverage optical comparators effectively, ensuring they remain competitive in an ever-evolving global market.

Understanding optical comparitor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Horizontal Optical Comparator | Projects side view silhouettes; ideal for fixed components | Aerospace, automotive, general manufacturing | Pros: Good for large parts; easy setup. Cons: Limited to side view, may miss complex features. |

| Vertical Optical Comparator | Projects top-down images; suitable for flat or flexible parts | Electronics, medical devices, precision machining | Pros: Effective for thin parts; better detail. Cons: Requires flat surfaces for accurate measurements. |

| Digital Optical Comparator | Integrates digital imaging; offers advanced measurement tools | High-tech industries, quality assurance labs | Pros: Enhanced accuracy; data storage capabilities. Cons: Higher initial investment; requires training. |

| Telecentric Optical Comparator | Maintains consistent magnification; ideal for variable distances | R&D, high-precision manufacturing | Pros: Accurate dimensional analysis; reduces errors. Cons: More complex and costly than standard models. |

| Fully Corrected Optical Comparator | Provides right-side-up images; minimizes distortion | Aerospace, automotive, tooling | Pros: High precision; versatile for various parts. Cons: Higher maintenance due to complexity. |

Horizontal Optical Comparator

Horizontal optical comparators utilize a side view projection method, making them well-suited for inspecting larger, fixed parts such as castings and screws. B2B buyers in sectors like aerospace and automotive appreciate the straightforward setup and ability to measure significant components efficiently. However, their design may limit the inspection of more intricate features that require a different viewing angle, potentially necessitating additional equipment for comprehensive quality control.

Vertical Optical Comparator

Vertical optical comparators project images from above, making them ideal for flat or flexible components such as gaskets and printed circuit boards. These comparators excel in applications within electronics and medical device manufacturing, where detailed surface inspection is crucial. Buyers should consider the requirement for parts to lie flat for accurate measurements, as any deviation can lead to significant errors in inspection results.

Digital Optical Comparator

Digital optical comparators represent a significant advancement in measurement technology, integrating digital imaging and advanced measurement tools. These devices are particularly beneficial in high-tech industries where precision is paramount, such as quality assurance labs. While they offer enhanced accuracy and data management capabilities, buyers must weigh the higher initial investment and the potential need for operator training against the long-term benefits of improved quality control.

Telecentric Optical Comparator

Telecentric optical comparators are designed to maintain a constant magnification across varying distances, allowing for accurate measurements regardless of the part’s position on the stage. This feature is particularly advantageous in research and development settings and high-precision manufacturing. B2B buyers should be aware of the increased complexity and cost associated with these systems, which may require more technical expertise to operate effectively.

Fully Corrected Optical Comparator

Fully corrected optical comparators provide right-side-up images and minimize distortion, making them versatile tools for measuring a wide range of components. Industries such as aerospace and automotive rely on these comparators for their precision and capability to handle various part shapes and sizes. Buyers should consider the higher maintenance needs associated with these systems, as their complexity can lead to increased operational costs over time.

Related Video: Denoising Diffusion Probabilistic Models | DDPM Explained

Key Industrial Applications of optical comparitor

| Industry/Sector | Specific Application of Optical Comparator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Quality control of engine components | Ensures precision in critical parts, reducing failures and recalls | Calibration standards, compatibility with existing systems, service support |

| Aerospace | Inspection of intricate parts like gears and brackets | Enhances safety and compliance with stringent regulations | Certification of equipment, precision requirements, supplier reliability |

| Medical Devices | Measurement of surgical instruments and implants | Guarantees compliance with health regulations, ensuring patient safety | Regulatory compliance, material compatibility, accuracy in measurement |

| Electronics | Quality assurance for circuit boards and components | Minimizes defects, improving product reliability and customer satisfaction | Speed of measurement, adaptability to various component sizes, digital integration |

| Manufacturing | Inspection of machined parts and assemblies | Increases production efficiency by reducing scrap and rework | Versatility in measurements, ease of use, training and support for operators |

Automotive Industry

In the automotive sector, optical comparators are utilized for the quality control of engine components. They provide a non-contact method to inspect critical parts, such as valves and pistons, ensuring they meet precise specifications. This application helps in minimizing failures and recalls, which can be costly and damage brand reputation. International buyers should consider calibration standards and the compatibility of the optical comparator with existing quality control systems to ensure seamless integration.

Aerospace Industry

The aerospace industry demands the utmost precision in the inspection of intricate parts like gears and brackets. Optical comparators facilitate this by projecting magnified images of components, allowing for detailed measurements against stringent regulatory standards. This application not only enhances safety but also ensures compliance with aviation regulations. Buyers should prioritize suppliers who can provide certified equipment that meets industry-specific precision requirements.

Medical Devices Sector

In the medical devices sector, optical comparators are crucial for measuring surgical instruments and implants. The accuracy of these measurements is vital for ensuring compliance with health regulations, directly impacting patient safety. Optical comparators help detect flaws and dimensional errors that could compromise device functionality. When sourcing, buyers should focus on regulatory compliance, material compatibility, and the accuracy of measurements to meet the high standards of the healthcare industry.

Electronics Sector

Quality assurance in the electronics sector often involves the use of optical comparators for inspecting circuit boards and components. This application minimizes defects, ensuring product reliability and enhancing customer satisfaction. Optical comparators allow for quick measurements of various component sizes, which is essential in fast-paced production environments. Buyers in this sector should consider the speed of measurement and the adaptability of the comparator to different component types, alongside potential for digital integration.

General Manufacturing

Within general manufacturing, optical comparators are employed to inspect machined parts and assemblies. Their ability to provide accurate measurements helps increase production efficiency by reducing scrap and rework costs. This is particularly beneficial in environments where precision is critical. International buyers should look for comparators that offer versatility in measurements, ease of use, and adequate training and support for operators to maximize their investment.

Related Video: Uses of Mirrors and Lenses in Optical Devices | Grade 10 Science DepEd MELC Quarter 2 Module 5

Strategic Material Selection Guide for optical comparitor

When selecting materials for optical comparators, it is crucial to consider the properties, advantages, disadvantages, and specific applications of each material. Below is an analysis of four common materials used in the construction of optical comparators, tailored for international B2B buyers.

1. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can withstand moderate temperatures and pressures, making it suitable for various manufacturing environments.

Pros & Cons:

Aluminum’s lightweight nature makes it easy to handle and install, reducing shipping costs. It is also relatively inexpensive compared to other metals. However, it may not be as durable as heavier metals like steel and can deform under high stress.

Impact on Application:

Aluminum is compatible with most optical systems, providing a good balance between performance and weight. However, it may not be suitable for environments with extreme temperatures or corrosive substances.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and ISO for aluminum alloys. In regions like Africa and South America, the availability of specific aluminum grades may vary, affecting sourcing decisions.

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high strength, and durability. It can withstand high temperatures and pressures, making it ideal for demanding environments.

Pros & Cons:

The primary advantage of stainless steel is its longevity and resistance to rust and corrosion, which is crucial for optical comparators used in harsh conditions. However, it is heavier and more expensive than aluminum, which can increase shipping and handling costs.

Impact on Application:

Stainless steel is suitable for optical comparators that require high precision and durability, particularly in industries like aerospace and medical manufacturing. Its robust nature allows it to perform well in various media, including oils and chemicals.

Considerations for International Buyers:

International buyers should look for compliance with standards such as ASTM A240 or DIN 1.4301. In regions like the Middle East, where humidity can be high, stainless steel is often preferred for its resistance to corrosion.

3. Glass

Key Properties:

Optical glass is designed for high clarity and low distortion, essential for accurate measurements in optical comparators. It can handle moderate temperatures but is sensitive to impacts.

Pros & Cons:

The key advantage of optical glass is its ability to provide clear images without distortion, enhancing measurement accuracy. However, it is fragile and can break easily, which may lead to higher replacement costs.

Impact on Application:

Glass is critical in the optical components of comparators, such as lenses and screens. Its clarity is essential for applications requiring precise measurements, but its fragility limits its use in high-impact environments.

Considerations for International Buyers:

Buyers should ensure that the glass meets international optical standards, such as JIS or DIN. In regions with high shipping costs, the weight and fragility of glass components may influence purchasing decisions.

4. Composite Materials

Key Properties:

Composite materials, often made from a combination of polymers and fibers, offer lightweight, high strength, and resistance to corrosion. They can be engineered to withstand specific environmental conditions.

Pros & Cons:

The main advantage of composites is their versatility and ability to be tailored for specific applications, providing excellent performance while being lightweight. However, they can be more expensive to manufacture and may not have the same durability as metals.

Impact on Application:

Composites are suitable for optical comparators used in environments where weight reduction is essential, such as portable models. They can also resist chemical exposure, making them ideal for various applications.

Considerations for International Buyers:

Buyers should verify the compliance of composite materials with relevant international standards. In regions like Europe, where sustainability is a priority, composites may be favored for their lower environmental impact.

Summary Table

| Material | Typical Use Case for optical comparitor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight frames and structures | Cost-effective and easy to handle | Less durable under stress | Low |

| Stainless Steel | High-precision components in harsh environments | Excellent corrosion resistance | Heavier and more expensive | High |

| Glass | Lenses and screens for optical clarity | High clarity and low distortion | Fragile and sensitive to impacts | Medium |

| Composite | Portable optical comparators | Lightweight and customizable | Higher manufacturing costs | Medium to High |

This material selection guide provides valuable insights for B2B buyers in various regions, helping them make informed decisions tailored to their specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for optical comparitor

The manufacturing of optical comparators involves several meticulous stages, each essential for ensuring precision and quality. Understanding these processes can help international B2B buyers make informed decisions when sourcing these critical measurement tools.

Manufacturing Processes

1. Material Preparation

The manufacturing process begins with the selection of high-quality materials. Common materials include aluminum, steel, and specialized optical glass. These materials are chosen for their durability and optical clarity, which are vital for the functioning of optical comparators. Suppliers typically conduct material inspections to ensure compliance with specifications, which is crucial for maintaining consistency in production.

2. Forming

Once the materials are prepared, they undergo forming processes. This may involve machining, such as milling and turning, to create the necessary shapes for components like the base, stage, and optical assemblies. Precision in this stage is critical, as any deviation can impact the accuracy of measurements. Computer Numerical Control (CNC) machines are commonly used for their ability to produce complex shapes with high precision.

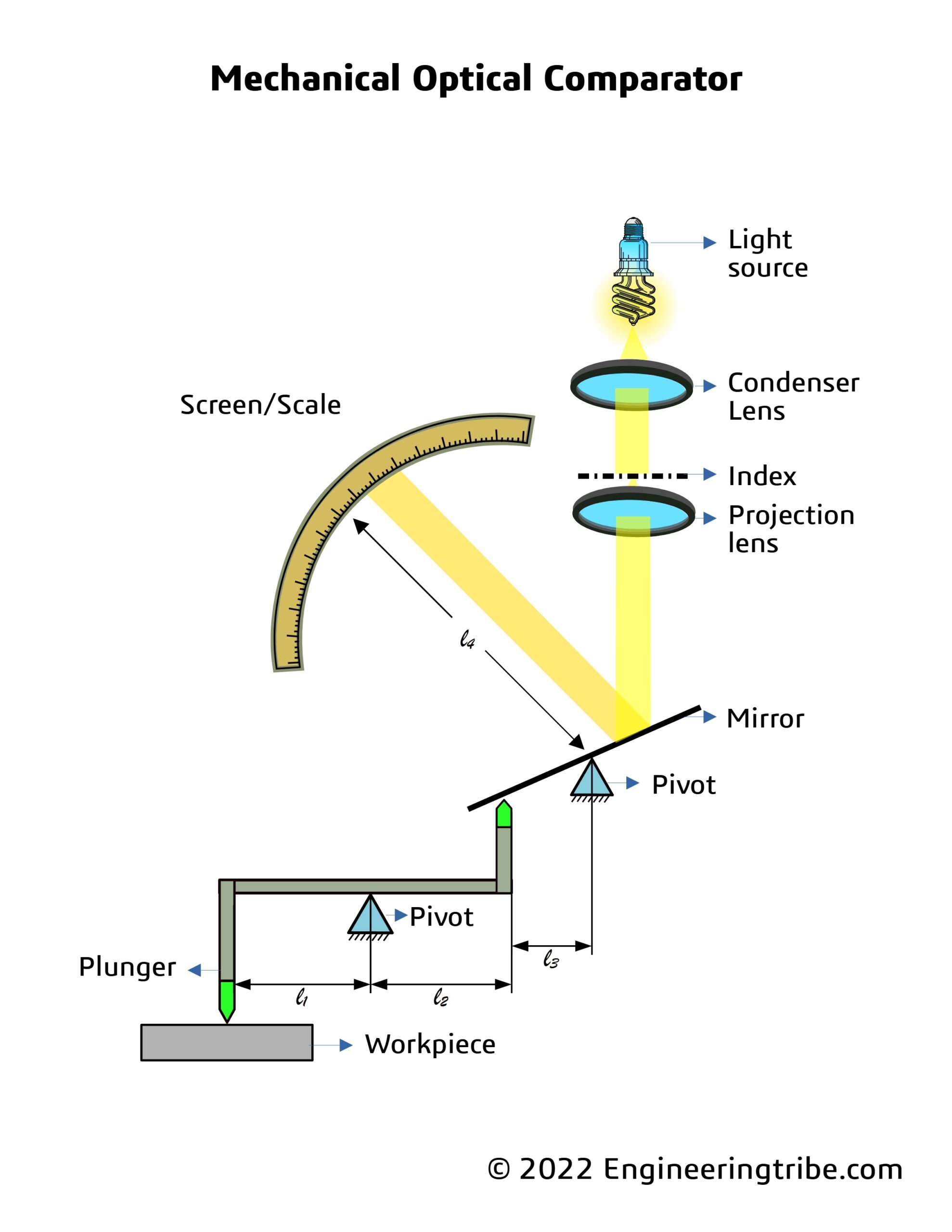

3. Assembly

Following forming, components are meticulously assembled. This stage often includes the installation of optical systems, including lenses and mirrors, which must be aligned with extreme precision. Assembly is typically performed in a controlled environment to avoid contamination that could affect optical performance. During this phase, manufacturers may employ automated systems for repetitive tasks, ensuring consistency and reducing human error.

4. Finishing

The finishing stage involves several processes, including surface treatment and coating. Optical surfaces may receive anti-reflective coatings to enhance clarity and reduce glare. Additionally, all components are cleaned thoroughly to eliminate dust and residues, which could interfere with optical measurements. Aesthetic considerations, such as anodizing or painting, may also be applied to enhance the product’s appearance and corrosion resistance.

Quality Assurance

Quality assurance (QA) is a critical aspect of optical comparator manufacturing, ensuring that each unit meets strict industry standards. Here are some key elements of the QA process:

International Standards

Optical comparators must comply with various international quality standards. ISO 9001 is a widely recognized standard that outlines requirements for a quality management system (QMS). Adhering to ISO 9001 demonstrates a manufacturer’s commitment to quality and continuous improvement. Additionally, industry-specific standards such as CE marking for products sold in Europe and API standards for those used in the petroleum industry may apply.

Quality Control Checkpoints

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial step involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, various inspections are performed to monitor the quality of components being produced. This can include dimensional checks and performance tests.

- Final Quality Control (FQC): Once the optical comparator is fully assembled, a thorough final inspection is conducted. This may involve functional testing to ensure that all optical and mechanical aspects operate correctly.

Common Testing Methods

Manufacturers employ various testing methods to verify the performance and accuracy of optical comparators, including:

- Dimensional Inspection: Using calibrated tools to measure dimensions against specifications.

- Optical Testing: Assessing the clarity and distortion of optical components under controlled conditions.

- Functional Testing: Ensuring that the comparator operates correctly, projecting clear and accurate images.

Verifying Supplier Quality Control

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe (including Turkey and Mexico), it is essential to verify the quality control practices of potential suppliers. Here are actionable steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess a manufacturer’s QMS and production practices firsthand. This includes reviewing documentation, processes, and compliance with relevant standards.

-

Quality Reports: Requesting quality assurance reports can provide insights into a supplier’s performance history. These reports should detail compliance with international standards and highlight any non-conformance issues.

-

Third-Party Inspections: Engaging independent inspection agencies to evaluate products before shipment can serve as an additional layer of assurance. These agencies can perform comprehensive testing and provide certification that the products meet specified standards.

Quality Control and Certification Nuances

International B2B buyers must be aware of specific nuances related to QC and certification:

- Cultural Considerations: Different regions may have varying expectations regarding quality and compliance. Buyers should familiarize themselves with local standards and practices.

- Documentation Requirements: Ensure that all quality certifications and reports are available in a language and format that is understandable. This is particularly important when navigating international transactions.

- Regulatory Compliance: Buyers should verify that suppliers are compliant with both local regulations and international standards, as this can impact the usability and acceptance of products in different markets.

By understanding the manufacturing processes and quality assurance measures involved in the production of optical comparators, B2B buyers can make informed decisions that align with their quality expectations and operational needs. This comprehensive approach to sourcing not only enhances product reliability but also builds lasting partnerships with suppliers committed to excellence.

Related Video: BMW Car Factory – ROBOTS Fast PRODUCTION Manufacturing

Comprehensive Cost and Pricing Analysis for optical comparitor Sourcing

When sourcing optical comparators, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This section delves into the key cost components, price influencers, and practical tips for effective negotiation and procurement.

Cost Components

- Materials: The core components of optical comparators include high-quality optics, precision lenses, mirrors, and robust casings. The choice of materials significantly affects the cost, as superior materials enhance durability and performance. For example, telecentric lenses can be more expensive but offer better accuracy.

Illustrative Image (Source: Google Search)

-

Labor: Skilled labor is essential for the assembly and calibration of optical comparators. The labor cost varies significantly across regions. Countries with lower wage structures may provide more cost-effective options, but this could affect quality and service levels.

-

Manufacturing Overhead: This includes costs related to the facilities, utilities, and administrative expenses involved in the production process. Manufacturers in regions with high operational costs may reflect these expenses in their pricing.

-

Tooling: Specialized tools and equipment are necessary for producing optical comparators. The initial investment in tooling can be substantial, influencing the final price of the product.

-

Quality Control (QC): Rigorous quality assurance processes are integral to manufacturing optical comparators. The costs associated with testing and certification can vary widely, impacting the overall price.

-

Logistics: Shipping costs, including freight and insurance, are significant, especially for international buyers. The choice of shipping method (air vs. sea) and distance to the destination can greatly affect logistics costs.

-

Margin: Supplier profit margins will vary based on the competitive landscape, brand reputation, and perceived value of the product. Established brands may command higher prices due to their reputation for reliability and quality.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can influence pricing. Higher volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize their purchasing strategy.

-

Specifications/Customization: Custom features or specific technical requirements may increase costs. Buyers should weigh the need for customization against standard models to ensure they receive the best value.

-

Quality/Certifications: Optical comparators that comply with international standards and possess necessary certifications (ISO, CE) often come at a premium. However, these certifications can ensure reliability and performance, justifying the higher cost.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Buyers should consider suppliers with a proven track record in quality and service to mitigate risks.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the overall cost structure.

Buyer Tips

-

Negotiation: Engage in discussions with multiple suppliers to leverage competitive pricing. Highlight your potential for repeat business to negotiate better terms.

-

Cost-Efficiency: Consider total cost of ownership rather than just the upfront price. This includes maintenance, operational efficiency, and longevity of the equipment.

-

Pricing Nuances: Be aware of regional pricing strategies. For instance, buyers from Africa and South America may face different pricing structures compared to European buyers due to local market dynamics.

-

Research and Compare: Conduct thorough research on various suppliers and their offerings. Utilize online platforms and trade shows to gather insights and make informed decisions.

-

Local Partnerships: Establishing relationships with local distributors can help mitigate logistics costs and provide better support post-purchase.

Disclaimer

The pricing information discussed here is indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always seek detailed quotes and conduct due diligence before making procurement decisions.

Spotlight on Potential optical comparitor Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘optical comparitor’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for optical comparitor

Optical comparators are vital tools in quality control, providing precise measurements and inspections of manufactured parts. Understanding their technical properties and industry terminology is crucial for international B2B buyers aiming to make informed purchasing decisions.

Key Technical Properties of Optical Comparators

-

Magnification Range

The magnification range of an optical comparator determines the level of detail that can be observed and measured. Typically, magnification can vary from 10x to 100x. A higher magnification allows for more detailed inspections, which is critical in industries like aerospace or medical manufacturing where precision is paramount. -

Screen Size

The screen size of an optical comparator impacts the size of the parts that can be inspected. Common sizes range from 12 to 36 inches. Larger screens allow for the inspection of bigger components without the need for repositioning, enhancing efficiency in high-volume production environments. -

Measurement Accuracy

Measurement accuracy, often expressed as tolerance levels (e.g., ±0.001 mm), is crucial for ensuring that parts meet specified standards. High accuracy levels reduce the risk of defects, which can lead to costly rework or production delays. B2B buyers must prioritize comparators with tight tolerance specifications to maintain quality control. -

Optical System Type

Optical comparators utilize various optical systems, including simple optics, corrected optics, and telecentric optics. Telecentric systems, for example, provide a consistent magnification regardless of the object’s position, which is vital for accurate measurements of complex geometries. Understanding these systems helps buyers select the right tool for their specific applications. -

Lighting Configuration

The type of lighting used in an optical comparator (e.g., transmitted vs. reflected) can influence visibility and measurement quality. Different lighting configurations are better suited for different materials and surface finishes. Buyers should consider their specific inspection needs when evaluating lighting options. -

Material Grade

The material grade of the comparator’s components (e.g., aluminum, steel) affects durability and precision. Higher-grade materials often provide better stability and longevity, making them a sound investment for industries that require frequent usage.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers looking for reliable suppliers of optical comparators and related components. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity a supplier is willing to sell. B2B buyers must be aware of MOQ requirements to optimize inventory management and avoid excess stock, especially in regions like Africa and South America, where supply chain logistics can be challenging. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. Buyers should prepare comprehensive RFQs that detail their specifications to receive accurate and competitive quotes. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms helps buyers from different regions navigate shipping, insurance, and risk transfer effectively. -

Calibration

Calibration refers to the process of adjusting the optical comparator to ensure accurate measurements. Regular calibration is essential for maintaining the integrity of quality control processes, and buyers should inquire about calibration services when selecting equipment. -

GD&T (Geometric Dimensioning and Tolerancing)

GD&T is a system for defining and communicating engineering tolerances. It is crucial for ensuring that manufactured parts meet design specifications, making it an important consideration for buyers involved in precision engineering.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their quality control processes and ultimately lead to better product outcomes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the optical comparitor Sector

Market Overview & Key Trends

The optical comparator market is experiencing significant growth driven by the increasing demand for precision measurement tools across various industries, such as aerospace, automotive, and medical manufacturing. The global push for quality assurance in manufacturing processes is propelling the adoption of optical comparators, which are essential for evaluating component tolerances and ensuring product compliance with stringent standards.

In recent years, the emergence of digital optical comparators has transformed the landscape, offering enhanced capabilities such as automated measurements, data analytics integration, and improved user interfaces. These advancements facilitate real-time monitoring of production quality, which is particularly appealing to B2B buyers from regions like Africa, South America, the Middle East, and Europe, where manufacturing sectors are rapidly evolving.

Moreover, the trend towards Industry 4.0 is influencing the sourcing of optical comparators, with an increasing emphasis on smart manufacturing technologies. Buyers are now looking for solutions that not only meet measurement needs but also integrate seamlessly with existing digital systems, allowing for better data management and process optimization. As markets in Turkey and Mexico expand, international B2B buyers must be aware of local suppliers that can provide these advanced optical systems, ensuring both compatibility and support.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor in the optical comparator sector, as manufacturers face growing scrutiny regarding their environmental impact. The production of optical comparators involves various materials and processes that can be harmful to the environment if not managed responsibly. Therefore, B2B buyers should prioritize suppliers who demonstrate a commitment to reducing their ecological footprint through sustainable practices.

Ethical sourcing is equally important, as it ensures that materials used in the production of optical comparators are obtained responsibly, without contributing to social or environmental injustices. Buyers should look for certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) that indicate compliance with sustainable practices. Additionally, suppliers that utilize recycled materials or implement energy-efficient manufacturing processes can enhance their appeal to environmentally conscious buyers.

By focusing on sustainability and ethical sourcing, B2B buyers can not only meet regulatory requirements but also align their procurement strategies with the growing consumer demand for responsible manufacturing, ultimately fostering a positive corporate image.

Brief Evolution/History

The optical comparator, first patented in 1925, has seen minimal changes in its fundamental design, primarily evolving through advancements in digital technology and calibration methods. Initially utilized for basic measurement tasks, optical comparators have adapted to meet the increasing complexity of modern manufacturing. The integration of digital functionalities has revolutionized these tools, enabling them to provide enhanced accuracy and efficiency that align with contemporary quality control standards. As industries continue to demand higher precision, the evolution of optical comparators remains vital, positioning them as indispensable instruments in the manufacturing process.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of optical comparitor

-

How can I effectively vet suppliers of optical comparators?

When vetting suppliers, consider their reputation, experience, and certifications. Look for manufacturers with a track record in your industry, as well as ISO or other relevant certifications that assure quality standards. Request references from previous clients and conduct background checks. Additionally, evaluate their production capabilities and technology used in manufacturing optical comparators. Engaging in direct communication can also provide insights into their customer service and responsiveness. -

Can I customize the optical comparator to fit specific requirements?

Yes, many suppliers offer customization options for optical comparators. You can specify features such as screen size, magnification levels, and additional measurement capabilities tailored to your industry needs. Ensure to discuss your requirements in detail with the supplier, including any specific applications or components you intend to inspect. This dialogue will help confirm that the final product meets your operational standards. -

What are the typical minimum order quantities (MOQs) and lead times for optical comparators?

MOQs for optical comparators can vary significantly based on the supplier and the complexity of the equipment. Generally, manufacturers may set MOQs between 1-5 units for standard models, while custom orders may require larger quantities. Lead times can range from a few weeks to several months, depending on production schedules and customization requirements. Always confirm these details during your negotiations to align expectations with your project timelines.

Illustrative Image (Source: Google Search)

-

What payment options are commonly accepted by optical comparator suppliers?

Suppliers often accept various payment methods, including bank transfers, letters of credit, and sometimes credit cards. For large transactions, letters of credit are preferred as they provide security to both parties. Always clarify payment terms, including deposits and final payments, before finalizing the purchase. Additionally, inquire about any potential discounts for upfront payments or bulk orders. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers will adhere to strict quality assurance protocols, including in-process inspections and final testing of optical comparators before shipment. They should provide certifications that validate their compliance with industry standards. Request documentation on their quality management system and any test reports for the specific models you are purchasing. This information ensures the equipment meets your specifications and operational standards. -

How are logistics and shipping handled for international orders?

Logistics for international orders typically involve a combination of freight forwarders and customs brokers. Suppliers can often assist with arranging shipping, but it’s essential to discuss who bears the cost and responsibility for damages during transit. Confirm shipping methods, estimated delivery times, and tracking options. Be aware of any import duties or taxes applicable to your country, as these can affect the overall cost. -

What should I do if there is a dispute with the supplier?

In case of a dispute, begin by communicating directly with the supplier to resolve the issue amicably. Document all correspondence and agreements for reference. If a resolution isn’t reached, consult the terms of your purchase agreement, which may outline dispute resolution processes. Consider mediation or arbitration as a next step before pursuing legal action, as these methods can be less costly and time-consuming. -

Are there specific certifications I should look for when sourcing optical comparators?

Yes, when sourcing optical comparators, look for certifications such as ISO 9001 for quality management systems, CE marking for compliance with European safety standards, and any industry-specific certifications relevant to your sector. These certifications indicate that the supplier adheres to recognized quality standards and practices. Request documentation of these certifications during your supplier evaluation process to ensure compliance and reliability in the products you purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for optical comparitor

As the demand for precision measurement tools continues to grow globally, the optical comparator remains a critical asset across various manufacturing sectors. Key takeaways for international B2B buyers include understanding the importance of selecting the right type of optical comparator—be it traditional or digital—based on specific application needs. The ongoing advancements in digital technologies offer enhanced accuracy and efficiency, crucial for meeting the stringent quality standards expected in today’s competitive market.

Strategic sourcing of optical comparators not only ensures access to superior measurement solutions but also fosters long-term partnerships with reputable suppliers. This can significantly enhance quality control processes, reduce operational costs, and improve production output. Buyers from Africa, South America, the Middle East, and Europe should prioritize sourcing from manufacturers that provide comprehensive support, including calibration and maintenance services.

Looking ahead, the integration of smart technologies and automation in optical comparators presents exciting opportunities for increased precision and efficiency. Now is the time for international buyers to explore these innovations and position themselves as leaders in their respective industries. Engage with trusted suppliers today to secure the best optical comparator solutions that will drive your business forward.