Your Ultimate Guide to Sourcing Photochemical Machining

Introduction: Navigating the Global Market for photochemical machining

In today’s fast-paced manufacturing landscape, photochemical machining (PCM) stands out as a transformative technology that bridges precision and efficiency. This non-conventional machining process utilizes chemical etching via photoresist stencils, enabling the production of intricate components with exceptional accuracy. As the global market for PCM continues to flourish, reaching an estimated value of $6 billion annually, it presents an invaluable opportunity for international B2B buyers seeking innovative solutions.

This comprehensive guide delves into the multifaceted world of photochemical machining, offering insights into various types of processes, materials used, and the critical aspects of manufacturing and quality control. Buyers will find detailed information on suppliers, an analysis of cost factors, and an overview of the current market dynamics. Furthermore, a dedicated FAQ section addresses common queries, empowering decision-makers with the knowledge needed to navigate this complex landscape confidently.

For businesses in Africa, South America, the Middle East, and Europe, understanding PCM is essential for informed sourcing decisions. This guide equips buyers with actionable insights and strategic considerations to leverage photochemical machining effectively, ensuring they remain competitive in a rapidly evolving market. By harnessing the power of PCM, companies can optimize their manufacturing processes, reduce costs, and enhance product quality, ultimately driving growth and innovation in their respective industries.

Understanding photochemical machining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Photochemical Machining | Uses a photoresist to etch metals and other materials; ideal for complex geometries. | Aerospace, electronics, medical devices | Pros: High precision, versatile; Cons: Limited to thin materials. |

| Micro Photochemical Machining | Focuses on producing micro-scale components; utilizes advanced photoresist techniques. | Microfluidics, MEMS, sensors | Pros: Extremely precise, suitable for small parts; Cons: Higher costs, requires specialized equipment. |

| 3D Photochemical Machining | Combines traditional etching with 3D printing methods; allows for complex structures. | Aerospace, automotive, custom tooling | Pros: Greater design flexibility; Cons: Longer lead times, potentially higher costs. |

| Laser-Assisted Photochemical Machining | Integrates laser technology for improved material removal and surface finish. | Automotive, electronics, defense | Pros: Enhanced precision, faster processing; Cons: Requires advanced machinery, potentially higher operational costs. |

| Batch Photochemical Machining | Processes multiple parts simultaneously; cost-effective for high-volume production. | Consumer electronics, automotive parts | Pros: Economies of scale, reduced per-unit cost; Cons: Less flexibility in design changes. |

Standard Photochemical Machining

Standard photochemical machining (PCM) is widely recognized for its ability to create intricate designs in thin materials. This method employs a photoresist layer that is selectively exposed to light, allowing for precise etching of metals such as stainless steel and copper. B2B buyers should consider this technique for applications in industries like aerospace and medical devices, where precision and accuracy are paramount. However, it is essential to note that this method is generally limited to thin materials, which may not suit all project requirements.

Micro Photochemical Machining

Micro photochemical machining specializes in producing components at the micro-scale, making it ideal for applications in microfluidics and MEMS (Micro-Electro-Mechanical Systems). This variation utilizes advanced photoresist materials and techniques to achieve extremely high precision. B2B buyers looking to innovate in sectors such as medical diagnostics or sensor technology should consider this method, as it allows for the creation of complex, miniature parts. However, the costs can be higher due to the specialized nature of the equipment and materials involved.

3D Photochemical Machining

3D photochemical machining merges traditional etching techniques with 3D printing capabilities, enabling the production of complex geometries that were previously difficult to achieve. This method is particularly beneficial for industries like aerospace and automotive, where custom tooling and intricate designs are often required. Buyers should weigh the benefits of design flexibility against longer lead times and potentially increased costs, which can arise from the need for specialized machinery and processes.

Laser-Assisted Photochemical Machining

This variation incorporates laser technology to enhance the photochemical machining process, resulting in improved material removal rates and superior surface finishes. It is particularly useful in industries such as automotive and defense, where high precision is critical. B2B buyers should consider this method for applications demanding fast processing and high accuracy. However, the need for advanced machinery can lead to higher operational costs, which must be factored into budgeting decisions.

Batch Photochemical Machining

Batch photochemical machining allows for the simultaneous processing of multiple parts, making it a cost-effective choice for high-volume production runs. This method is commonly used in consumer electronics and automotive parts manufacturing. Buyers can benefit from economies of scale, significantly reducing per-unit costs. However, this approach may offer less flexibility for design changes during production, which could be a drawback for companies needing rapid adaptability in their manufacturing processes.

Related Video: Photo Chemical Machining Process – Northwest Etch

Key Industrial Applications of photochemical machining

| Industry/Sector | Specific Application of photochemical machining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of complex aerospace components | High precision and lightweight parts reduce fuel costs | Supplier certifications (AS9100), material traceability, lead times |

| Medical Devices | Production of intricate surgical instruments | Enhanced accuracy improves patient outcomes | Compliance with medical standards (ISO 13485), biocompatibility |

| Electronics | Creation of microelectronic components | Miniaturization enables advanced technology applications | Cleanroom capabilities, rapid prototyping, and testing services |

| Automotive | Fabrication of intricate parts for vehicles | Cost-effective production of lightweight components | Understanding of industry standards (IATF 16949), material sourcing |

| Defense | Development of precision components for systems | Reliability and performance are critical for mission success | Security clearances, long-term partnerships, and quality assurance |

Aerospace Applications

In the aerospace industry, photochemical machining is pivotal for producing complex components such as brackets, housings, and other lightweight structures. The ability to create intricate designs while maintaining high precision significantly reduces the overall weight of parts, leading to lower fuel consumption. International buyers in this sector should ensure that suppliers hold necessary certifications like AS9100 and can provide material traceability, which is crucial for meeting stringent aerospace regulations.

Medical Devices Applications

Photochemical machining is extensively used to manufacture surgical instruments and implants, where precision is non-negotiable. The process allows for the creation of fine features that enhance the functionality and effectiveness of medical devices. Buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers that comply with medical industry standards such as ISO 13485, ensuring that products are not only accurate but also biocompatible and safe for patient use.

Electronics Applications

In electronics, photochemical machining is essential for fabricating microelectronic components like circuit boards and sensors. This technology enables the miniaturization of parts, which is critical for modern electronic devices. B2B buyers should focus on suppliers that can operate in cleanroom environments and offer rapid prototyping and testing services. These capabilities are vital for maintaining the high standards of quality and reliability expected in the electronics sector.

Illustrative Image (Source: Google Search)

Automotive Applications

The automotive industry benefits from photochemical machining through the production of lightweight, intricate parts such as brackets and heat exchangers. This method allows manufacturers to reduce costs while improving fuel efficiency through weight reduction. Buyers should consider suppliers with a solid understanding of automotive standards like IATF 16949, as well as their ability to source materials that meet industry requirements.

Defense Applications

In defense, photochemical machining is used to develop precision components critical for various systems, including weaponry and communication devices. The reliability and performance of these parts can significantly impact mission success. International buyers must ensure that their suppliers have the necessary security clearances and can maintain long-term partnerships while adhering to rigorous quality assurance processes.

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for photochemical machining

When selecting materials for photochemical machining (PCM), it is essential to consider the specific properties and performance characteristics that will influence the effectiveness of the manufacturing process. Below, we analyze four common materials used in PCM, focusing on their key properties, advantages and disadvantages, application impacts, and considerations for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures. It typically exhibits a temperature rating of up to 870°C (1600°F) and can handle pressures exceeding 2000 psi, depending on the grade.

Pros & Cons:

The durability of stainless steel makes it suitable for a wide range of applications, particularly in industries such as automotive and aerospace. However, it can be more expensive than other metals, and its machining can be complex due to work-hardening properties, which may increase production time.

Impact on Application:

Stainless steel is highly compatible with various media, including corrosive substances, making it ideal for components in chemical processing and food industries.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel grades. It is also crucial to consider local availability and import regulations, especially in regions like Africa and South America, where sourcing may vary.

Copper

Key Properties:

Copper has excellent thermal and electrical conductivity, with a melting point around 1085°C (1985°F). It also offers good corrosion resistance, although it is less resistant than stainless steel.

Pros & Cons:

Copper is relatively easy to machine and provides excellent performance in electrical applications. However, it is softer than stainless steel, which can lead to wear and deformation under stress, making it less suitable for high-pressure applications.

Impact on Application:

Copper is particularly effective for applications requiring high electrical conductivity, such as connectors and circuit boards. Its compatibility with various environments is generally good, but it may not perform well in highly corrosive settings.

Considerations for International Buyers:

Buyers in Europe and the Middle East should be aware of standards like EN 1976 for copper and copper alloys. Additionally, considerations around recycling and sustainability are increasingly important in these regions.

Aluminum

Key Properties:

Aluminum is lightweight with a melting point of about 660°C (1220°F) and is known for its good corrosion resistance when treated with anodization. It is also relatively strong for its weight, making it a popular choice in many industries.

Pros & Cons:

The low density and ease of machining make aluminum an attractive option for various applications, especially in the aerospace and automotive sectors. However, its lower strength compared to steel can limit its use in high-stress applications.

Impact on Application:

Aluminum is compatible with a wide range of media but may oxidize in highly acidic or alkaline environments. Its lightweight nature makes it ideal for applications where weight reduction is critical.

Considerations for International Buyers:

Compliance with standards such as ASTM B211 for aluminum alloys is necessary. Buyers should also consider the local market’s preference for aluminum, especially in regions like Australia and Europe, where lightweight materials are favored.

Titanium

Key Properties:

Titanium boasts a high strength-to-weight ratio and excellent corrosion resistance, with a melting point of approximately 1668°C (3034°F). It can withstand extreme temperatures and harsh environments.

Pros & Cons:

While titanium is highly durable and suitable for aerospace and medical applications, it is one of the more expensive materials and can be challenging to machine due to its toughness.

Impact on Application:

Titanium is ideal for applications in the aerospace and medical fields, where high strength and corrosion resistance are critical. However, its cost can be a limiting factor for broader applications.

Considerations for International Buyers:

Buyers should be aware of standards like ASTM F136 for titanium used in medical applications. Understanding the supply chain dynamics in Africa and South America is crucial, as sourcing titanium can be more complex compared to other metals.

| Material | Typical Use Case for photochemical machining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Automotive and aerospace components | Excellent corrosion resistance | Higher cost and complex machining | High |

| Copper | Electrical connectors and circuit boards | Excellent conductivity | Softer, less suitable for high-stress | Medium |

| Aluminum | Aerospace and automotive lightweight parts | Lightweight and easy to machine | Lower strength compared to steel | Medium |

| Titanium | Aerospace and medical applications | High strength-to-weight ratio | Expensive and challenging to machine | High |

In-depth Look: Manufacturing Processes and Quality Assurance for photochemical machining

The manufacturing processes for photochemical machining (PCM) are distinct and highly specialized, catering to a variety of industries that require precision parts. Understanding these processes and the associated quality assurance measures is critical for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe. Here, we delve into the key stages of PCM manufacturing and the quality control standards that ensure product reliability and safety.

Manufacturing Processes

1. Material Preparation

The first step in PCM is selecting the appropriate substrate material, which often includes metals like stainless steel, copper, brass, and aluminum. The chosen material must be compatible with the chemical etching processes.

- Surface Cleaning: The materials undergo rigorous cleaning to remove any contaminants that might affect adhesion and etching quality. This is typically done using ultrasonic cleaning or chemical baths.

- Material Thickness: Buyers should specify the required thickness as PCM is particularly effective for thin sheets (0.1 mm to 6 mm).

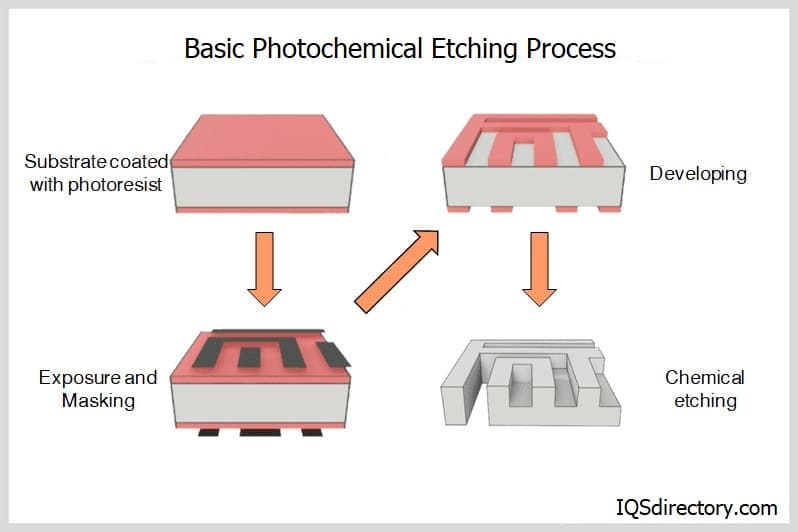

2. Forming

This stage involves applying a photoresist layer to the cleaned substrate.

- Photoresist Application: A light-sensitive photoresist film is applied to the substrate. The application can be achieved through methods such as spin coating or lamination.

- Exposure: The coated material is exposed to ultraviolet (UV) light through a mask that defines the desired pattern. This step is crucial as it determines the accuracy and detail of the final part.

3. Etching

Once the photoresist is developed, the actual machining process begins.

- Chemical Etching: The substrate is immersed in an etching solution that removes the exposed areas of the material, leaving behind the desired shape. Common etchants include ferric chloride for metals.

- Precision: PCM allows for intricate designs with tolerances as tight as ±0.025 mm, making it suitable for applications in microengineering and electronics.

4. Finishing

After etching, the parts may require additional treatments to enhance their properties or prepare them for assembly.

- Deburring and Cleaning: The parts are cleaned again to remove any residual chemicals and burrs from the edges.

- Surface Treatments: Depending on the application, surface finishes such as passivation, plating, or anodizing may be applied to improve corrosion resistance and surface quality.

5. Assembly

For components that require assembly, this stage includes fitting parts together, which may involve welding, soldering, or mechanical fastening.

Quality Assurance

Quality control in PCM is vital to ensure that the products meet international standards and customer specifications. Here’s a breakdown of key quality assurance processes:

International Standards

Adhering to recognized standards is crucial for ensuring product quality and safety.

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization. It emphasizes continuous improvement and customer satisfaction.

- Industry-Specific Certifications: Depending on the application, additional certifications may be required, such as CE marking for products sold in Europe or API standards for oil and gas applications.

Quality Control Checkpoints

Implementing a structured quality assurance process involves several checkpoints throughout the manufacturing cycle:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to ensure adherence to process parameters and to identify any deviations early on.

- Final Quality Control (FQC): The finished products undergo rigorous testing, including dimensional checks and surface quality assessments, to confirm they meet specifications.

Common Testing Methods

Various testing methods are employed to validate the quality of the machined parts:

- Dimensional Measurement: Using calipers, micrometers, or coordinate measuring machines (CMM) to ensure precise dimensions.

- Surface Roughness Testing: Assessing the surface finish to meet application requirements.

- Functional Testing: Conducting tests specific to the component’s application, such as pressure tests for fluidic components.

Verification of Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks.

- Supplier Audits: Conducting on-site audits to assess the supplier’s quality management systems and processes.

- Quality Reports: Requesting detailed quality control reports, including test results and certifications, can provide insights into the supplier’s reliability.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance practices.

Considerations for International Buyers

B2B buyers from diverse regions must consider specific nuances in quality assurance when sourcing PCM components:

- Cultural Differences: Understanding local manufacturing practices and standards can aid in establishing effective communication with suppliers.

- Regulatory Compliance: Ensure that the supplier adheres to local and international regulations pertinent to the industry.

- Logistical Challenges: Consider the impact of logistics on quality, such as transportation conditions that may affect product integrity.

In conclusion, a comprehensive understanding of manufacturing processes and quality assurance in photochemical machining is indispensable for international B2B buyers. By focusing on these areas, buyers can make informed decisions, ensuring that they source high-quality components that meet their specific needs.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for photochemical machining Sourcing

The cost structure of photochemical machining (PCM) is multifaceted and varies based on several factors. Understanding these components is essential for international B2B buyers seeking to optimize their sourcing strategies. Below is a detailed analysis of the cost components, pricing influencers, and actionable buyer tips.

Cost Components

-

Materials: The primary materials used in PCM include metals such as stainless steel, aluminum, copper, and various alloys. The cost of these materials can fluctuate based on market conditions, availability, and sourcing location. Buyers should consider sourcing from regions with lower raw material costs to enhance overall savings.

-

Labor: Labor costs in PCM are generally lower than traditional machining due to the automation of processes. However, skilled labor is still essential for setup, monitoring, and quality control. Understanding local labor rates is crucial, especially when sourcing from different regions, as this can significantly affect total costs.

-

Manufacturing Overhead: This includes expenses related to utilities, maintenance, and facility management. Overhead costs can vary widely depending on the geographic location and operational efficiency of the supplier. Buyers should inquire about overhead rates when negotiating contracts.

-

Tooling: While PCM typically requires less complex tooling than conventional machining, initial setup for stencils and photoresists can incur costs. Custom tooling designed for specific projects may also add to expenses. Buyers should assess the tooling requirements early in the project to avoid unexpected costs.

-

Quality Control (QC): Implementing stringent QC measures is vital in PCM to ensure product accuracy and compliance with specifications. The costs associated with QC can vary based on the complexity of the parts being produced and the certifications required (e.g., ISO standards). Buyers should prioritize suppliers with established QC processes to minimize defects and rework.

-

Logistics: Transportation and handling costs must be factored into the total cost of ownership (TCO). These costs can vary based on shipping methods, distances, and Incoterms. Understanding the logistics implications of sourcing from different regions can lead to substantial savings.

-

Margin: Suppliers will typically mark up their costs to establish a profit margin. This can vary widely based on the supplier’s market position, competition, and operational efficiencies. Buyers should negotiate pricing based on the overall value provided, including service and support.

Price Influencers

Several key factors can influence the pricing of PCM services:

-

Volume/MOQ: Higher order quantities often lead to lower per-unit costs due to economies of scale. Buyers should consider placing larger orders or establishing long-term contracts to secure better pricing.

-

Specifications/Customization: Complex designs or custom requirements can increase costs. Buyers should clearly define their specifications and assess whether standard options could meet their needs to avoid unnecessary expenses.

-

Quality/Certifications: Higher quality materials and certifications often come at a premium. Buyers should balance quality requirements with budget constraints, ensuring that they meet necessary standards without overspending.

-

Supplier Factors: The reputation, location, and capabilities of suppliers can greatly impact pricing. Engaging with multiple suppliers for quotes can help buyers gauge a fair market price.

-

Incoterms: Understanding the implications of Incoterms on shipping responsibilities and costs is crucial. Buyers should choose terms that align with their logistics capabilities and cost structures.

Buyer Tips

-

Negotiate Effectively: Approach negotiations with a clear understanding of your requirements and market rates. Leverage multiple quotes to strengthen your position.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership, not just the initial price. Consider long-term costs related to quality, maintenance, and logistics.

-

Understand Pricing Nuances: Be aware of regional pricing differences, especially when sourcing from Africa, South America, the Middle East, or Europe. Currency fluctuations and local economic conditions can impact costs.

-

Build Strong Supplier Relationships: Foster relationships with suppliers for better terms, flexibility, and support. Long-term partnerships can lead to improved pricing and service.

Disclaimer: Pricing can fluctuate based on market conditions and specific project requirements. Always request up-to-date quotes from suppliers to ensure accurate budgeting.

Spotlight on Potential photochemical machining Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘photochemical machining’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for photochemical machining

Photochemical machining (PCM) is a sophisticated manufacturing technique that requires a solid understanding of its essential technical properties and trade terminology. This section outlines critical specifications and industry terms that international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be familiar with to make informed purchasing decisions.

Key Technical Properties of Photochemical Machining

-

Material Grade

– The choice of material grade is crucial in PCM, as it determines the machinability and performance characteristics of the final product. Common materials include stainless steel, copper, brass, and aluminum. Understanding the specific properties of each material, such as corrosion resistance and conductivity, helps buyers select the right option for their applications. -

Tolerance

– Tolerance refers to the allowable deviation from a specified dimension. In PCM, tolerances can range from ±0.005 mm to ±0.1 mm, depending on the complexity of the component. High precision is essential for applications in sectors like aerospace and electronics, where even minute variations can lead to significant failures. Buyers should ensure that their suppliers can meet the required tolerances to avoid costly reworks. -

Thickness

– The thickness of the material being processed is another critical specification. PCM can effectively handle materials ranging from 0.1 mm to 6 mm. The thickness directly influences the etching time and the quality of the finish. Buyers should specify their thickness requirements clearly to ensure optimal processing and product quality. -

Etching Depth

– Etching depth is the depth of material removed during the photochemical process. This specification is vital for applications requiring specific features like grooves or channels. Buyers should discuss their etching depth needs with suppliers to ensure compatibility with the intended application and the capabilities of the PCM technology. -

Surface Finish

– The surface finish achieved through PCM can vary based on the material and process parameters. Surface finish is critical in industries where aesthetics or performance (such as in medical devices or consumer electronics) are paramount. Buyers should inquire about the expected surface finish and any post-processing options available to meet their standards. -

Production Volume

– Understanding production volume requirements is essential for determining cost-efficiency in PCM. Whether for low-volume custom parts or high-volume production runs, suppliers may have different capabilities and pricing structures. Buyers should be clear about their volume needs to receive accurate quotes and lead times.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers as it impacts sourcing and supply chain strategies. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand, as it affects inventory management and budget planning. Negotiating MOQs can lead to cost savings, especially for smaller companies. -

RFQ (Request for Quotation)

– An RFQ is a document sent by buyers to suppliers asking for pricing information on specific products or services. It is a standard practice in B2B transactions, allowing buyers to compare offers and make informed decisions. -

Incoterms (International Commercial Terms)

– Incoterms are international standards for shipping and freight, defining the responsibilities of buyers and sellers. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, which is vital for effective international trade. -

Lead Time

– Lead time refers to the time taken from placing an order to the delivery of the product. For PCM, lead times can vary based on material availability and production capacity. Buyers should factor in lead times when planning their projects to avoid delays. -

Prototype

– A prototype is an initial sample or model of a product used to test and validate design concepts. In PCM, developing prototypes can significantly reduce risk before full-scale production. Buyers should consider prototyping as a step in their project development to ensure design integrity.

Understanding these essential technical properties and terminology will enable international B2B buyers to navigate the complexities of photochemical machining effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the photochemical machining Sector

Market Overview & Key Trends

The photochemical machining (PCM) sector is experiencing significant growth, driven by advancements in precision manufacturing and the increasing demand for lightweight, complex components across various industries, including aerospace, automotive, and electronics. As of 2023, the global PCM market is valued at approximately $6 billion, with projections indicating a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is fueled by the rise of microfabrication technologies and the need for custom, high-precision parts that traditional machining methods cannot efficiently produce.

International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, should be aware of several emerging trends in sourcing within the PCM sector. Firstly, there is a shift towards digital transformation, with manufacturers increasingly adopting Industry 4.0 technologies such as IoT and AI to enhance production efficiency and precision. Additionally, supply chain diversification is becoming crucial; companies are looking beyond traditional suppliers to mitigate risks associated with geopolitical tensions and disruptions, ensuring a more resilient supply chain.

Moreover, sustainability is emerging as a key consideration, as firms seek suppliers that align with their environmental goals. The integration of advanced materials, such as eco-friendly photoresists and recyclable substrates, is gaining traction, presenting new opportunities for collaboration and innovation among international buyers.

Sustainability & Ethical Sourcing in B2B

Sustainability in the photochemical machining industry is not just a regulatory requirement but a competitive advantage. The environmental impact of PCM processes, particularly concerning waste management and chemical usage, necessitates a strong commitment to sustainable practices. B2B buyers should prioritize suppliers who actively minimize their ecological footprint through the use of green materials and the implementation of closed-loop water systems in their manufacturing processes.

Ethical sourcing is equally important. Buyers should look for suppliers who demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices meet international standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability. Additionally, seeking out suppliers who utilize biodegradable or recyclable materials can significantly enhance a company’s sustainability profile.

Engaging with suppliers who prioritize sustainable practices not only fosters goodwill but also aligns with the growing consumer demand for environmentally responsible products, enhancing brand reputation and market competitiveness.

Brief Evolution/History

Photochemical machining has evolved significantly since its inception in the 1960s as a niche manufacturing process. Initially regarded as a “best-kept secret” within the industry, it has transformed into a vital technology for producing intricate components with high precision and minimal material waste. Over the decades, PCM has expanded its applications across various sectors, including telecommunications, medical devices, and automotive parts.

The process relies on chemical etching techniques that enable the creation of complex geometries, making it an attractive option for modern manufacturing challenges. As industries increasingly demand lightweight and compact solutions, PCM’s relevance continues to grow, positioning it as a critical technology in the landscape of contemporary manufacturing. Understanding this historical context can help international B2B buyers appreciate the potential and reliability of PCM as a sourcing option for their specific needs.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of photochemical machining

-

What criteria should I use to vet suppliers of photochemical machining?

When vetting suppliers, consider their experience in the photochemical machining industry, focusing on their track record and customer reviews. Check their certifications, such as ISO 9001, which indicates adherence to quality management standards. It’s also wise to assess their technological capabilities and whether they invest in modern equipment. Engage in discussions about their production processes and quality assurance measures. Lastly, consider their capacity to meet your specific needs, including customization options and scalability. -

Can I customize photochemical machining products to fit my specifications?

Yes, many suppliers offer customization options tailored to your specifications. When discussing your project, provide detailed drawings and requirements to ensure that the supplier understands your needs. Inquire about their ability to handle unique materials or specific geometries. It’s essential to confirm their experience with similar projects and request samples or prototypes before committing to a full production run. Engaging in early-stage design discussions can also streamline the customization process. -

What are the typical minimum order quantities (MOQs) and lead times for photochemical machining?

MOQs for photochemical machining can vary significantly based on the supplier and the complexity of the parts being produced. Generally, MOQs can range from a few pieces to several hundred, depending on the production scale. Lead times typically range from 2 to 6 weeks, influenced by factors such as material availability, complexity of the design, and the supplier’s current workload. It’s advisable to communicate your timeline requirements upfront to ensure that the supplier can meet your deadlines. -

What payment terms should I expect when sourcing photochemical machining services?

Payment terms can vary among suppliers, but it’s common to encounter options such as upfront deposits (typically 30-50%) followed by balance payments upon delivery or acceptance of goods. Some suppliers may offer credit terms for established clients. It’s crucial to clarify payment methods accepted, such as bank transfers, credit cards, or letters of credit, especially for international transactions. Ensure that the payment terms are documented in the contract to avoid any disputes later. -

How do suppliers ensure quality assurance and what certifications should I look for?

Quality assurance in photochemical machining is typically ensured through rigorous testing and adherence to industry standards. Look for suppliers with certifications such as ISO 9001 or AS9100, which reflect their commitment to quality management systems. Inquire about their internal quality control processes, including inspection and testing methods used during production. Request documentation of quality assurance practices, such as inspection reports or certificates of conformity, to verify compliance with your requirements. -

What logistics considerations should I keep in mind when sourcing internationally?

When sourcing photochemical machining services internationally, consider shipping methods, costs, and delivery times. Engage with suppliers about their logistics partners and their experience with customs clearance, particularly if you are importing goods into Africa, South America, or the Middle East. It’s essential to clarify who bears responsibility for shipping costs and customs duties. Additionally, ensure that the supplier can provide tracking information and support during the shipping process to mitigate potential delays. -

How can I handle disputes with suppliers in the photochemical machining industry?

To effectively handle disputes, ensure that your contract includes clear terms regarding quality expectations, delivery schedules, and payment conditions. Maintain open communication with your supplier to address issues as they arise. If a dispute occurs, document all communications and relevant evidence, such as photos or quality reports. Consider mediation as a first step before escalating to legal proceedings. It’s also beneficial to choose suppliers with established reputations for reliability to minimize the risk of disputes. -

What are the common challenges faced in international B2B photochemical machining transactions?

Common challenges include language barriers, cultural differences, and varying quality standards across regions. Additionally, navigating customs regulations and international shipping logistics can complicate the procurement process. It’s essential to conduct thorough research and establish clear communication channels with suppliers. Building strong relationships and understanding local market practices can also facilitate smoother transactions. Consider working with local intermediaries or consultants who understand the regional landscape to mitigate these challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for photochemical machining

In conclusion, the strategic sourcing of photochemical machining (PCM) represents a pivotal opportunity for international B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. By leveraging PCM’s unique advantages—such as precision, reduced material waste, and rapid prototyping—companies can significantly enhance their manufacturing capabilities while optimizing costs.

The value of strategic sourcing in this context cannot be overstated. It not only allows buyers to access high-quality components tailored to their specific needs but also fosters long-term partnerships with manufacturers who understand the complexities of global supply chains. As the PCM market continues to expand, estimated to reach $6 billion annually, aligning with the right suppliers will be crucial for gaining a competitive edge.

Looking ahead, it is essential for B2B buyers to actively seek partnerships with PCM specialists who can deliver innovative solutions and reliable service. Engaging in strategic sourcing today will position your business favorably in an increasingly interconnected market. Embrace this opportunity to enhance your manufacturing processes and drive growth in your organization.