Your Ultimate Guide to Sourcing Pneumatic Cylinder Parts

Introduction: Navigating the Global Market for pneumatic cylinder parts

In today’s global industrial landscape, pneumatic cylinder parts play a pivotal role in driving automation and efficiency across various sectors. These components are essential for converting compressed air into mechanical motion, making them indispensable in manufacturing, transportation, and robotics. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—including key markets like Spain and Saudi Arabia—understanding the nuances of pneumatic cylinder parts is crucial for optimizing procurement strategies.

This comprehensive guide offers an in-depth exploration of pneumatic cylinder parts, covering a wide array of topics. From the various types of cylinders available, including ISO 15552 standards, to the materials used in their construction, each section is designed to equip buyers with the knowledge needed to make informed decisions. We delve into manufacturing processes and quality control measures, ensuring that buyers understand the standards that govern these critical components.

Additionally, the guide addresses supplier options, pricing structures, and market trends, enabling buyers to navigate the complexities of international sourcing. With a dedicated FAQ section, we aim to clarify common queries, enhancing the overall buying experience. By leveraging this guide, B2B buyers will be empowered to select the right pneumatic cylinder parts that meet their operational needs, ultimately driving productivity and reducing costs in their businesses.

Understanding pneumatic cylinder parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| ISO 15552 Cylinders | Standardized dimensions, robust design, wide range of sizes | Automation, material handling, packaging | Pros: High reliability, ease of maintenance. Cons: Slightly higher initial costs. |

| Double-Acting Cylinders | Operates with air pressure on both sides of the piston | Robotics, assembly lines, automotive | Pros: Greater control and force in both directions. Cons: More complex installation. |

| Single-Acting Cylinders | Uses air pressure on one side only, spring return mechanism | Lifting applications, clamping, fixtures | Pros: Simpler design, cost-effective. Cons: Limited motion range. |

| Rodless Cylinders | Piston travels inside the cylinder without an external rod | Tight spaces, conveyor systems, packaging | Pros: Space-saving design, versatile. Cons: More expensive and complex. |

| Compact Cylinders | Smaller footprint, lightweight materials | Limited space applications, mobile machinery | Pros: Easy integration in tight areas. Cons: May have lower force output. |

ISO 15552 Cylinders

ISO 15552 cylinders are known for their standardization, which ensures compatibility across various manufacturers. They are designed to withstand mechanical and environmental stresses, making them suitable for diverse industrial applications such as automation and material handling. When purchasing, buyers should consider the specific size and stroke length required for their application, as well as the quality of materials used, which can affect durability and performance.

Double-Acting Cylinders

Double-acting cylinders provide power in both extension and retraction, utilizing air pressure on both sides of the piston. This makes them ideal for applications requiring precise control, such as robotics and assembly lines. Buyers should evaluate the installation complexity and the required air pressure specifications, ensuring compatibility with their existing systems. While they offer enhanced performance, they may come at a higher cost and require more maintenance.

Single-Acting Cylinders

Single-acting cylinders utilize air pressure on one side of the piston and rely on a spring mechanism for retraction. This design is simpler and often more cost-effective, making it suitable for lifting and clamping applications. B2B buyers should assess the specific motion range needed, as single-acting cylinders offer limited motion capabilities compared to their double-acting counterparts. They are generally easier to install, which can save time and labor costs.

Rodless Cylinders

Rodless cylinders feature a piston that moves within the cylinder without an external rod, making them ideal for tight spaces. They are versatile and can be used in conveyor systems and packaging applications. However, buyers should be aware that rodless cylinders tend to be more expensive and complex in design. It’s crucial to consider the specific application requirements and whether the benefits of space-saving outweigh the higher costs.

Compact Cylinders

Compact cylinders are designed for applications where space is limited. They are lightweight and easy to integrate into smaller machines or systems. While they excel in tight areas, buyers should be cautious about their force output, which may be lower than larger cylinders. When purchasing compact cylinders, it’s important to evaluate the force requirements of the application to ensure adequate performance without compromising on efficiency.

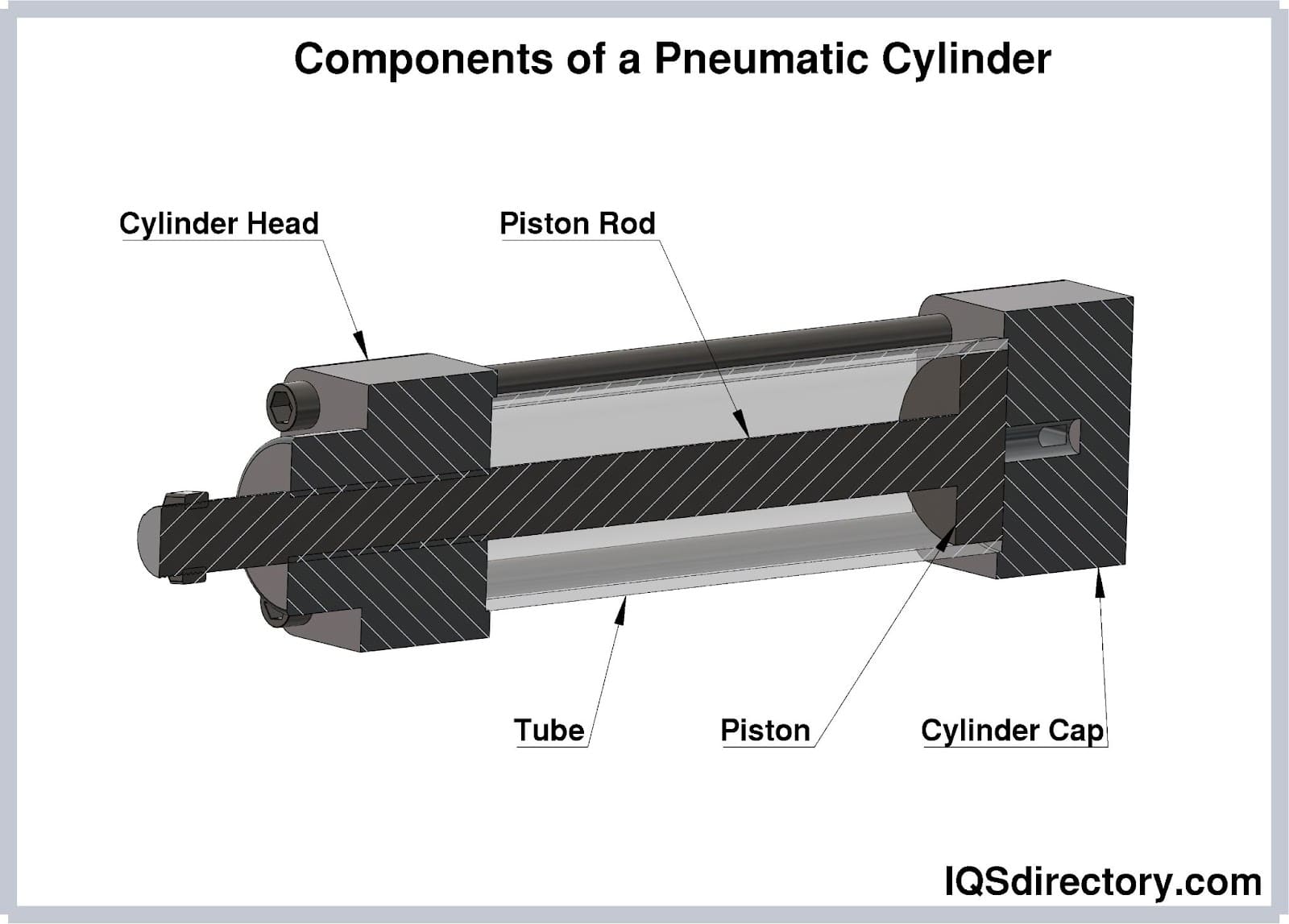

Related Video: PARTS OF PNEUMATIC CYLINDER

Key Industrial Applications of pneumatic cylinder parts

| Industry/Sector | Specific Application of pneumatic cylinder parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated assembly lines | Increases production efficiency and reduces labor costs | Quality of materials, compatibility with existing machinery, lead times |

| Food and Beverage | Packaging and bottling processes | Ensures hygiene and compliance with safety standards | Corrosion resistance, ease of cleaning, certification standards |

| Automotive | Paint spraying and finishing | Enhances precision and quality of finishes | Reliability under varying conditions, availability of spare parts |

| Pharmaceuticals | Filling and capping of vials | Ensures accuracy and sterility in production | Compliance with industry regulations, customization options |

| Material Handling | Conveying systems for transporting goods | Improves workflow and reduces manual handling | Load capacity, durability, and maintenance requirements |

Manufacturing

In manufacturing, pneumatic cylinder parts are crucial for automated assembly lines. They enable the precise movement of components, facilitating tasks such as part placement, fastening, and quality inspections. By automating these processes, businesses can significantly increase production efficiency while reducing labor costs. For international buyers, sourcing high-quality pneumatic cylinders that are compatible with existing machinery is essential to ensure seamless integration and minimal downtime.

Food and Beverage

In the food and beverage industry, pneumatic cylinder parts are widely used in packaging and bottling processes. These cylinders ensure that products are filled and sealed with precision, maintaining hygiene and compliance with safety standards. Buyers must prioritize materials that are corrosion-resistant and easy to clean, as well as suppliers who can provide certifications that meet industry regulations. This is particularly vital for businesses in regions like Europe and the Middle East, where food safety standards are stringent.

Automotive

Pneumatic cylinder parts play a significant role in the automotive sector, especially in paint spraying and finishing applications. These cylinders provide the necessary control for consistent spray patterns, enhancing the quality of finishes while minimizing waste. For buyers, reliability under varying conditions is a key consideration, along with the availability of spare parts to ensure continuous operation. Sourcing from reputable manufacturers with a track record in the automotive industry can help mitigate risks.

Pharmaceuticals

In pharmaceutical manufacturing, pneumatic cylinder parts are essential for filling and capping vials. These applications require high precision to ensure the correct dosage and maintain sterility. International buyers should focus on suppliers that comply with industry regulations and offer customization options to cater to specific production needs. Additionally, understanding the sourcing of materials that meet stringent safety standards is crucial for maintaining product integrity.

Material Handling

Pneumatic cylinder parts are integral to material handling systems that transport goods within warehouses and production facilities. They improve workflow by automating the movement of items, thereby reducing manual handling and the risk of injury. Buyers need to consider the load capacity and durability of these cylinders, as well as their maintenance requirements, to ensure long-term reliability. Sourcing from local suppliers can also help in reducing shipping costs and lead times, particularly for companies in Africa and South America.

Related Video: Pneumatic Cylinder: How Does It Work?

Strategic Material Selection Guide for pneumatic cylinder parts

When selecting materials for pneumatic cylinder parts, it is crucial to understand the properties, advantages, disadvantages, and implications for specific applications. Below is an analysis of four common materials used in pneumatic cylinder manufacturing, tailored for international B2B buyers.

Aluminum

Key Properties: Aluminum is lightweight and has a good strength-to-weight ratio. It typically withstands moderate pressures and has excellent corrosion resistance, making it suitable for various environments.

Pros & Cons: Aluminum is durable and relatively easy to machine, which lowers manufacturing complexity. However, its cost can be higher than some alternatives, and it may not perform well under extreme temperatures or pressures.

Impact on Application: Aluminum is compatible with many media, including air and non-corrosive gases. However, its use in applications involving aggressive chemicals should be carefully evaluated.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM and ISO for quality assurance. In regions like Europe and the Middle East, preferences may lean towards aluminum due to its lightweight nature, which can reduce shipping costs.

Stainless Steel

Key Properties: Stainless steel offers high strength and excellent corrosion resistance, especially in harsh environments. It can handle high pressures and extreme temperatures, making it versatile for various applications.

Pros & Cons: Its durability and longevity are significant advantages, but stainless steel is heavier and more expensive than aluminum. Machining can also be more complex, leading to higher manufacturing costs.

Impact on Application: Stainless steel is ideal for applications involving corrosive media or high-pressure environments, such as in food processing or chemical industries.

Considerations for International Buyers: Buyers in regions like South America and Africa should consider local availability and compliance with DIN or JIS standards. The higher cost may be justified in applications requiring long-term reliability and safety.

Brass

Key Properties: Brass is known for its good machinability and moderate strength. It has decent corrosion resistance, particularly in non-oxidizing environments, and can withstand moderate pressures.

Pros & Cons: Brass components are often less expensive than stainless steel and aluminum, making them a cost-effective option. However, they are not suitable for high-pressure applications and may corrode in certain environments.

Impact on Application: Brass is commonly used in pneumatic systems that handle air or non-corrosive gases. Its limitations in high-pressure scenarios should be a key consideration.

Considerations for International Buyers: Buyers should verify compliance with local standards and consider the availability of brass components. In regions like Europe, where regulatory compliance is stringent, ensuring that brass meets the required specifications is vital.

Composite Materials

Key Properties: Composite materials, such as reinforced plastics, are lightweight and resistant to corrosion. They can be engineered to meet specific temperature and pressure requirements.

Pros & Cons: Composites can be tailored for specific applications, offering flexibility in design. However, they may not be as durable as metals and can be more expensive due to specialized manufacturing processes.

Impact on Application: Composites are suitable for applications requiring lightweight components with good corrosion resistance, such as in automotive or aerospace industries.

Considerations for International Buyers: Buyers should assess the availability of composite materials in their regions and ensure compliance with international standards. In markets like the Middle East, where extreme temperatures are common, ensuring the material can withstand local conditions is crucial.

Summary Table

| Material | Typical Use Case for pneumatic cylinder parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General industrial applications | Lightweight and corrosion-resistant | Limited performance under extreme conditions | Medium |

| Stainless Steel | Food processing, chemical industries | High strength and excellent durability | Higher cost and complexity in machining | High |

| Brass | Low-pressure pneumatic systems | Cost-effective and good machinability | Not suitable for high-pressure applications | Low |

| Composite | Automotive and aerospace applications | Tailored properties for specific needs | Less durability compared to metals | Medium to High |

This guide provides a comprehensive overview of material selection for pneumatic cylinder parts, aiding international B2B buyers in making informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pneumatic cylinder parts

Manufacturing Processes for Pneumatic Cylinder Parts

The production of pneumatic cylinder parts involves a series of well-defined stages, each critical for ensuring the reliability and performance of the final product. Understanding these processes can help B2B buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions when sourcing pneumatic cylinders.

Main Stages of Manufacturing

-

Material Preparation

– Selection: High-quality materials, such as aluminum or stainless steel, are selected based on the application requirements, such as pressure tolerance and environmental conditions.

– Machining: Raw materials are cut to size using CNC machines. Precision is crucial in this stage to ensure that the dimensions meet specifications for further processing. -

Forming

– Shaping: Techniques such as extrusion and forging are employed to shape the cylinder bodies. The choice of technique can influence the strength and durability of the parts.

– Drilling and Tapping: After forming, holes for mounting and other functionalities are drilled. Tapping is also done to create threads for screws or bolts.

Illustrative Image (Source: Google Search)

-

Assembly

– Component Assembly: Parts like pistons, seals, and end caps are assembled. This stage often requires skilled labor to ensure precision and proper fitting.

– Adhesives and Sealing: Some components may require adhesives or sealants to ensure air-tightness and prevent leakage. -

Finishing

– Surface Treatment: Processes such as anodizing or powder coating are used to enhance corrosion resistance and improve aesthetics.

– Quality Control Checks: After finishing, components undergo initial quality checks before being packaged for shipping.

Key Techniques in Manufacturing

- CNC Machining: Offers high precision and repeatability, essential for producing parts with tight tolerances.

- Hydraulic Pressing: Utilized for forming parts that require significant force, especially in larger cylinders.

- Laser Cutting: Provides clean cuts and intricate designs, minimizing material wastage.

Quality Assurance in Manufacturing

Quality assurance (QA) is vital in the production of pneumatic cylinder parts, as it directly impacts performance and longevity. Adhering to international standards and implementing rigorous quality checks ensures that products meet buyer expectations.

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system, emphasizing customer satisfaction and continuous improvement.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Relevant for manufacturers producing components for oil and gas applications, ensuring safety and reliability.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Raw materials are inspected upon arrival for compliance with specifications. This step is crucial to avoid defects in later stages. -

In-Process Quality Control (IPQC)

– Regular checks are performed during manufacturing to identify and correct any issues early. This includes monitoring machining tolerances and assembly accuracy. -

Final Quality Control (FQC)

– The completed units undergo thorough testing to ensure functionality and performance. This may involve pressure testing and dimensional checks.

Common Testing Methods

- Pressure Testing: Ensures that the cylinder can withstand specified pressure levels without leaking.

- Dimensional Inspection: Uses gauges and calipers to confirm that parts meet required specifications.

- Functional Testing: Assesses the performance of the cylinder in simulated operational conditions.

Verifying Supplier Quality Control

B2B buyers can implement several strategies to ensure that their suppliers adhere to high-quality standards:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes and quality control measures. This can reveal their compliance with international standards.

- Request Quality Reports: Ask suppliers for documentation of their quality control processes, including results from IQC, IPQC, and FQC.

- Third-party Inspections: Engage independent inspection agencies to evaluate supplier facilities and processes, providing an unbiased assessment of quality.

QC and Certification Nuances for International Buyers

For buyers from diverse regions, understanding the nuances of quality control and certification is crucial:

- Cultural and Regulatory Differences: Each region may have different expectations and regulations regarding quality. It’s essential for buyers to familiarize themselves with local standards and how they align with international norms.

- Documentation: Ensure that all quality certifications are documented and valid. This includes checking the expiration dates of certifications and understanding the scope of each certification.

- Language Barriers: Communication can be a barrier. It’s advisable to work with suppliers who can provide documentation in a language that is understandable to the buyer or offer translation services.

Conclusion

Understanding the manufacturing processes and quality assurance practices for pneumatic cylinder parts is essential for international B2B buyers. By focusing on material selection, production techniques, and rigorous quality control, buyers can ensure they procure high-quality products that meet their operational needs. Additionally, leveraging verification strategies helps mitigate risks associated with sourcing from global suppliers, ensuring a reliable supply chain and optimal performance in their applications.

Related Video: How Things Are Made | An Animated Introduction to Manufacturing Processes

Comprehensive Cost and Pricing Analysis for pneumatic cylinder parts Sourcing

Understanding the cost structure and pricing of pneumatic cylinder parts is crucial for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. This analysis will break down the main components of costs, the factors influencing pricing, and practical tips for buyers to optimize their sourcing strategies.

Cost Components

- Materials: The primary driver of costs in pneumatic cylinder manufacturing is the material used. High-quality metals such as aluminum, stainless steel, and brass are commonly utilized, with prices varying significantly based on market conditions and supplier sourcing. The choice of material directly impacts durability, weight, and resistance to environmental factors.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs encompass wages and benefits for workers involved in manufacturing, assembly, and quality control. In regions with lower labor costs, such as certain parts of Africa and South America, buyers may find competitive pricing opportunities. However, this can also vary based on the complexity of the assembly process.

-

Manufacturing Overhead: Overhead costs include rent, utilities, and administrative expenses related to running the manufacturing facility. These costs can fluctuate based on the geographic location of the manufacturer, impacting the final price of pneumatic cylinder parts.

-

Tooling: Tooling costs are incurred during the initial setup for production, including the creation of molds and dies. Custom tooling for specialized parts can significantly increase initial costs but may lead to reduced costs per unit in large-volume orders.

-

Quality Control (QC): Investing in rigorous quality control processes ensures that the final products meet specified standards. While this adds to the cost, it is essential for maintaining reliability and compliance with international certifications, which is particularly important for buyers in regulated industries.

-

Logistics: Transportation costs, including shipping and handling, play a significant role in the total cost of pneumatic cylinders. The choice of shipping method (air vs. sea) and the distance from the manufacturer can lead to considerable variations in logistics expenses.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. This margin can vary based on the supplier’s reputation, the demand for their products, and the level of service provided.

Price Influencers

- Volume/MOQ: Purchasing in bulk can lead to significant discounts, making it crucial for buyers to understand minimum order quantities (MOQ) and negotiate accordingly.

- Specifications/Customization: Customized parts tailored to specific applications may incur additional costs. Buyers should evaluate the necessity of customization against potential cost increases.

- Materials and Quality/Certifications: Higher quality materials and certifications (ISO, CE, etc.) can lead to increased costs but may also ensure better performance and longevity.

- Supplier Factors: Established suppliers may charge higher prices due to their reputation and reliability. Buyers should weigh the benefits of working with reputable suppliers against potential savings from lesser-known manufacturers.

- Incoterms: Understanding Incoterms (International Commercial Terms) is vital for managing logistics costs and risks. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence the total cost of ownership.

Buyer Tips

- Negotiate: Always negotiate prices, especially for bulk purchases. Suppliers may have flexibility in pricing based on order size and long-term relationships.

- Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational efficiency, and potential downtime costs. Investing in higher-quality components may lead to lower TCO.

- Research Local Suppliers: In regions such as Africa and South America, local suppliers may offer competitive pricing due to lower labor and logistics costs. However, ensure that they meet the required quality standards.

- Be Aware of Pricing Nuances: Understand that prices can fluctuate based on global market trends, exchange rates, and regional economic conditions. Regularly review market conditions to make informed sourcing decisions.

Disclaimer

Prices for pneumatic cylinder parts can vary widely based on the aforementioned factors. The insights provided here are indicative and should be supplemented with direct quotations from suppliers to ensure accuracy in budgeting and sourcing.

Spotlight on Potential pneumatic cylinder parts Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘pneumatic cylinder parts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for pneumatic cylinder parts

Understanding the essential technical properties and trade terminology related to pneumatic cylinder parts is crucial for international B2B buyers. This knowledge can help in making informed decisions and optimizing procurement strategies. Below are some critical specifications and industry terms that buyers should be familiar with.

Key Technical Properties

-

Material Grade

The material used for pneumatic cylinder components, such as aluminum, stainless steel, or brass, is pivotal. Each material has specific properties, including weight, strength, and corrosion resistance. Selecting the right material affects the cylinder’s performance, durability, and overall cost. For instance, stainless steel is ideal for corrosive environments, while aluminum is lighter and often more cost-effective. -

Tolerance

Tolerance refers to the permissible limits of variation in a physical dimension. Tight tolerances are essential for ensuring proper fit and function in pneumatic systems, impacting efficiency and reliability. For B2B buyers, understanding tolerance specifications can prevent costly errors in production and maintenance. -

Stroke Length

The stroke length is the distance the piston travels within the cylinder. It influences the application and efficiency of the pneumatic system. Buyers should evaluate the stroke length based on their specific operational needs, as it directly affects the cylinder’s performance and the machinery it operates. -

Operating Pressure

This specification indicates the maximum pressure at which the cylinder can operate safely. It is vital for ensuring the cylinder’s longevity and performance under various working conditions. Buyers must match the operating pressure with their application requirements to avoid premature failure or safety hazards. -

Mounting Style

Mounting style refers to how the cylinder is attached within a system. Different styles, such as tie-rod, square body, or flange-mounted, offer various advantages in terms of space, ease of installation, and alignment. Understanding the mounting requirements can facilitate smoother integration into existing setups.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, sourcing from OEMs can ensure quality and compatibility, especially when replacing parts in existing machinery. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs with suppliers to align with their purchasing needs without incurring excess costs. -

RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to request pricing information from suppliers. It is a critical step in the procurement process, allowing buyers to compare costs and services. Crafting a detailed RFQ can lead to better pricing and terms from suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms can help B2B buyers navigate shipping, insurance, and liability issues, ensuring smoother logistics and cost management. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. For B2B buyers, knowing lead times is crucial for planning production schedules and inventory management. Shorter lead times can enhance operational efficiency and responsiveness to market demands.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make more informed decisions, optimize their procurement strategies, and foster better relationships with suppliers in the pneumatic cylinder parts market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pneumatic cylinder parts Sector

Market Overview & Key Trends

The pneumatic cylinder parts market is witnessing significant growth driven by increased automation across various industries, including manufacturing, automotive, and food processing. Global demand for pneumatic systems is largely influenced by the push for operational efficiency, reduced costs, and enhanced productivity. Emerging markets in Africa and South America are rapidly adopting pneumatic technology, motivated by the need to modernize their manufacturing capabilities and increase competitiveness on a global scale.

Key trends include the rise of Industry 4.0 technologies, integrating smart sensors and IoT devices into pneumatic systems. This digital transformation enhances real-time monitoring and predictive maintenance, allowing businesses to optimize their operations and minimize downtime. Additionally, there is a growing emphasis on customization in pneumatic cylinder design, where suppliers are increasingly offering tailored solutions to meet specific application needs, thus enhancing customer satisfaction and loyalty.

Another important trend is the shift towards local sourcing. As international supply chains face disruptions, particularly post-pandemic, B2B buyers are seeking suppliers closer to home to mitigate risks associated with long lead times and transportation costs. For buyers in Europe, Africa, and the Middle East, this trend presents an opportunity to engage local manufacturers or distributors who can provide timely delivery and support.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers in the pneumatic cylinder parts sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, necessitates a focus on sustainable practices. Buyers should prioritize suppliers that implement eco-friendly manufacturing techniques and utilize recyclable materials, reducing their carbon footprint.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are increasingly interested in the sourcing practices of their suppliers, looking for transparency in how materials are obtained and processed. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for materials can serve as indicators of a supplier’s commitment to sustainability.

Utilizing green materials—such as biodegradable plastics or sustainably sourced metals—can further enhance a company’s sustainability profile. This not only helps in meeting regulatory requirements but also resonates with environmentally conscious consumers and businesses, leading to improved brand loyalty and market competitiveness.

Brief Evolution/History

The history of pneumatic cylinders dates back to the late 19th century when the first applications of compressed air in industrial settings emerged. Initially used for simple tasks, advancements in technology have transformed pneumatic cylinders into sophisticated components integral to modern automation. The introduction of ISO standards in the late 20th century standardized dimensions and specifications, facilitating easier integration across diverse applications and manufacturers.

As industries have evolved, so too have pneumatic technologies, with significant innovations in materials and design that enhance durability, efficiency, and energy savings. The focus on automation, driven by the digital revolution, has further propelled the adoption of pneumatic systems, solidifying their role as essential components in contemporary industrial operations.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of pneumatic cylinder parts

-

What criteria should I use to vet suppliers of pneumatic cylinder parts?

When vetting suppliers, focus on their industry experience, reputation, and compliance with international quality standards such as ISO certifications. Request references from previous clients, check for customer reviews, and evaluate their production capacity and capabilities. It’s also beneficial to assess their financial stability and ability to provide after-sales support. For international buyers, consider suppliers with a proven track record in your region to ensure they understand local market dynamics and regulations. -

Can pneumatic cylinder parts be customized to my specifications?

Yes, many suppliers offer customization options for pneumatic cylinder parts, including size, material, and specific design features. When discussing customization, provide detailed specifications and any relevant application requirements. Ensure that the supplier has the necessary engineering capabilities and experience to deliver tailored solutions. It’s advisable to request prototypes or samples before committing to large orders, allowing you to assess quality and fit for your applications. -

What are the typical minimum order quantities (MOQs) and lead times for pneumatic cylinder parts?

MOQs for pneumatic cylinder parts can vary significantly based on the supplier and the complexity of the order. Generally, MOQs range from 50 to 200 units. Lead times can also differ, typically ranging from 4 to 12 weeks, depending on customization and production schedules. For urgent needs, discuss potential expedited options with suppliers, but be prepared for higher costs. Always confirm these details before placing an order to avoid delays in your operations. -

What payment terms and options should I expect when sourcing internationally?

International suppliers may offer various payment terms, including letters of credit, bank transfers, or payment platforms like PayPal. Common practices include a deposit upfront (usually 30-50%) with the balance due before shipment. It’s critical to discuss payment terms early in negotiations and ensure they align with your cash flow needs. Additionally, consider securing trade credit insurance to mitigate risks associated with international transactions, especially if you are unfamiliar with the supplier. -

How can I ensure quality assurance and certifications for the parts I purchase?

To ensure quality, request that suppliers provide documentation of their quality assurance processes, including ISO certifications and compliance with industry standards. Conduct inspections either at the supplier’s facility or upon receipt of goods to verify that the parts meet your specifications. Consider engaging third-party inspection services, especially for larger orders, to ensure that the products meet your quality expectations and reduce the risk of defects. -

What logistics considerations should I be aware of when importing pneumatic cylinder parts?

Logistics plays a crucial role in international sourcing. Understand the shipping options available, including air freight for speed or sea freight for cost-effectiveness. Ensure that you are aware of all customs regulations and duties applicable in your country, as these can significantly impact the total landed cost. Collaborate with a reliable freight forwarder who can handle documentation and customs clearance, ensuring smooth transportation of your parts from the supplier to your facility. -

How should I handle disputes with suppliers?

Disputes can arise for various reasons, from quality issues to delivery delays. Establish clear communication channels with your supplier and document all interactions regarding your order. If a dispute occurs, first attempt to resolve it amicably through direct discussions. If that fails, refer to the terms outlined in your contract, particularly regarding arbitration or mediation processes. Consider involving legal counsel if the dispute escalates, especially when significant sums are involved or if contractual obligations are not met. -

What are the key factors affecting the pricing of pneumatic cylinder parts?

The pricing of pneumatic cylinder parts is influenced by several factors, including material costs, manufacturing processes, and supplier brand reputation. High-quality materials like stainless steel or specialized alloys will increase costs, as will complex designs requiring advanced machining. Additionally, consider the supplier’s location and shipping costs, which can vary greatly depending on the distance from the supplier to your location. Lastly, market demand fluctuations can also impact pricing, so staying informed about industry trends is essential for negotiating favorable terms.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pneumatic cylinder parts

Strategic sourcing for pneumatic cylinder parts is essential for international B2B buyers aiming to optimize costs and enhance operational efficiency. By understanding the key components that influence pricing—such as material selection, size, and manufacturing processes—buyers can make informed purchasing decisions that align with their specific operational needs. The benefits of pneumatic cylinders, including speed, precision, and energy efficiency, further underscore the importance of sourcing high-quality parts to maintain competitive advantage in diverse industrial applications.

As the global market evolves, leveraging strategic sourcing will become increasingly vital, particularly for buyers in Africa, South America, the Middle East, and Europe. Establishing relationships with reliable suppliers and staying abreast of industry trends can lead to significant cost savings and improved product performance.

Looking ahead, the demand for innovative and efficient pneumatic solutions will continue to rise. Buyers are encouraged to proactively engage with suppliers, explore new technologies, and consider bulk purchasing strategies to maximize value. Embrace the opportunities that strategic sourcing presents to elevate your operations and drive sustainable growth in your industry.