Your Ultimate Guide to Sourcing Pvc Extrusion Companies

Introduction: Navigating the Global Market for pvc extrusion companies

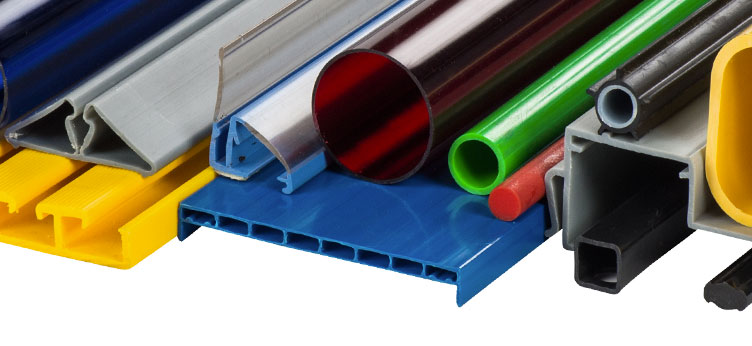

Navigating the global landscape of PVC extrusion companies is essential for B2B buyers seeking reliable and high-quality plastic solutions. As industries across Africa, South America, the Middle East, and Europe (including the UK and Spain) increasingly adopt PVC materials for their versatility and durability, understanding the intricacies of this market becomes critical. PVC extrusion companies play a pivotal role in producing essential components for various applications, including plumbing, construction, and electrical systems.

This guide offers a comprehensive exploration of the PVC extrusion sector, covering a wide range of topics that empower buyers to make informed sourcing decisions. Key areas of focus include the types of PVC products available, the materials used in production, manufacturing processes, quality control standards, and supplier evaluations. Additionally, we will delve into cost considerations and market trends, providing insights that are particularly relevant to international buyers navigating diverse regulatory environments and sourcing challenges.

By equipping B2B buyers with actionable insights and a robust understanding of the PVC extrusion industry, this guide aims to enhance procurement strategies and foster successful partnerships. Whether you are looking to optimize your supply chain or ensure compliance with local standards, the information provided herein will serve as a valuable resource in your quest for quality and reliability in PVC products.

Understanding pvc extrusion companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PVC Extrusion | Focus on producing common profiles and pipes; high-volume output. | Plumbing, construction, electrical conduits. | Pros: Cost-effective, widely available. Cons: Limited customization. |

| Custom PVC Extrusion | Tailored designs to meet specific requirements; flexibility in shapes and sizes. | Specialty applications, custom fittings, signage. | Pros: High customization, unique solutions. Cons: Higher costs, longer lead times. |

| Multi-Layer PVC Extrusion | Combines different materials for enhanced properties; complex production process. | Automotive, industrial applications, packaging. | Pros: Improved performance, durability. Cons: More expensive, requires specialized equipment. |

| Foamed PVC Extrusion | Produces lightweight, insulating materials; lower density. | Signage, construction, decorative applications. | Pros: Lightweight, cost-efficient. Cons: Less structural strength compared to solid PVC. |

| Specialty PVC Extrusion | Focus on niche markets; uses advanced techniques for unique applications. | Medical devices, aerospace components. | Pros: Targeted solutions, high performance. Cons: Limited production volume, higher costs. |

Standard PVC Extrusion

Standard PVC extrusion companies specialize in producing high-volume, commonly used profiles and pipes. These manufacturers often utilize automated machinery to ensure efficiency and consistency in production. This type is ideal for B2B buyers looking for cost-effective solutions in plumbing, construction, and electrical conduits. When purchasing, buyers should consider the reliability of supply and the ability to meet regulatory standards, as these factors can significantly impact project timelines.

Custom PVC Extrusion

Custom PVC extrusion companies offer tailored solutions, allowing for unique designs and specifications that standard products cannot meet. These manufacturers work closely with clients to create specialized fittings, profiles, and signage. This type is particularly suitable for businesses needing bespoke applications. B2B buyers should weigh the benefits of customization against potential higher costs and longer lead times, ensuring that the supplier can deliver on specifications without compromising quality.

Multi-Layer PVC Extrusion

Multi-layer PVC extrusion involves combining different materials to enhance the properties of the final product, such as strength, flexibility, and thermal insulation. This method is prevalent in industries like automotive and packaging, where performance is critical. Buyers must evaluate the supplier’s capability to handle complex production processes and ensure that the materials used comply with industry standards, as this can affect product longevity and safety.

Foamed PVC Extrusion

Foamed PVC extrusion produces lightweight and insulating materials, making it ideal for signage and decorative applications. This variation is advantageous for projects where weight reduction is essential, such as in transportation or temporary structures. However, buyers should consider the trade-off between cost efficiency and structural integrity, as foamed PVC may not provide the same durability as solid PVC options.

Specialty PVC Extrusion

Specialty PVC extrusion companies focus on niche markets, utilizing advanced techniques to create products for unique applications like medical devices and aerospace components. This type of extrusion often involves stringent quality controls and compliance with specific industry regulations. B2B buyers should assess the supplier’s expertise in their particular field, as well as their ability to deliver high-performance products that meet exacting standards, despite potentially higher costs and limited production capacity.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of pvc extrusion companies

| Industry/Sector | Specific Application of PVC Extrusion Companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | PVC pipes for plumbing and drainage systems | Durable, corrosion-resistant solutions that reduce maintenance costs | Compliance with local building regulations and standards |

| Electrical | Electrical conduit and insulation products | Enhanced safety and protection for wiring systems, reducing fire risks | Availability of customized sizes and specifications |

| Automotive | Interior and exterior trim components | Lightweight materials that improve fuel efficiency and reduce production costs | Expertise in automotive-grade materials and regulations |

| Signage and Displays | Custom extruded profiles for signs | High-quality finishes that enhance brand visibility and appeal | Flexibility in design and color matching capabilities |

| Agriculture | Irrigation systems and fittings | Efficient water management solutions that support sustainable farming practices | Durability under extreme weather conditions and pressure requirements |

Construction

PVC extrusion companies play a critical role in the construction industry by providing PVC pipes for plumbing and drainage systems. These pipes are favored for their durability and resistance to corrosion, which significantly lowers maintenance costs over time. For international buyers, especially in regions like Africa and South America, it’s essential to ensure that the products comply with local building regulations and standards. This compliance not only protects investments but also ensures safety and reliability in construction projects.

Electrical

In the electrical sector, PVC extrusion companies supply conduits and insulation products that safeguard wiring systems. The lightweight nature of PVC contributes to improved safety and protection against environmental factors, reducing the risk of fire hazards. Buyers from the Middle East and Europe should prioritize sourcing from manufacturers who offer customized sizes and specifications, ensuring that products meet specific project requirements and local compliance standards.

Automotive

The automotive industry benefits from PVC extrusion companies by utilizing extruded materials for both interior and exterior trim components. PVC’s lightweight properties enhance fuel efficiency while also lowering production costs. International buyers, particularly in Europe, should seek suppliers with expertise in automotive-grade materials that adhere to stringent safety regulations. This focus on quality and compliance is vital for maintaining brand integrity and customer satisfaction.

Signage and Displays

Custom extruded profiles from PVC extrusion companies are widely used in the signage and displays sector. These products provide high-quality finishes that elevate brand visibility and appeal. For B2B buyers in Europe and South America, sourcing companies that offer flexibility in design and color matching capabilities is crucial. This adaptability allows businesses to create unique signage solutions that resonate with their target audience.

Agriculture

In agriculture, PVC extrusion companies produce irrigation systems and fittings that are essential for efficient water management. These solutions support sustainable farming practices by ensuring optimal water distribution. Buyers from regions with varying climates, such as Africa and the Middle East, should consider the durability of PVC products under extreme weather conditions and high-pressure requirements. This durability is key to maintaining effective agricultural operations and maximizing yield.

Related Video: The Extrusion Process of Making PVC Profiles

Strategic Material Selection Guide for pvc extrusion companies

When selecting materials for PVC extrusion, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of various materials. This knowledge will help in making informed decisions that align with specific application requirements and market standards.

1. Polyvinyl Chloride (PVC)

Key Properties: PVC is known for its excellent chemical resistance, durability, and versatility. It can withstand temperatures ranging from -15°C to 60°C, making it suitable for various environmental conditions.

Pros & Cons: The durability of PVC makes it a preferred choice for applications like plumbing and electrical conduits. However, it can become brittle at low temperatures and may require additives to improve impact resistance. The cost of PVC is generally moderate, but manufacturing complexity can increase if custom formulations are needed.

Impact on Application: PVC is compatible with a wide range of media, including water, chemicals, and gases, making it ideal for plumbing and irrigation systems. Its rigidity and strength contribute to the reliability of the end product.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 and EN 1452 is essential. Buyers in regions like Africa and South America should also consider local regulations regarding environmental impact and safety.

2. Chlorinated Polyvinyl Chloride (CPVC)

Key Properties: CPVC offers enhanced temperature and pressure ratings compared to standard PVC, withstanding temperatures up to 93°C. It also has excellent corrosion resistance.

Pros & Cons: CPVC is highly durable and can handle hot water applications, making it suitable for industrial and residential plumbing. However, it is more expensive than standard PVC and may require specialized fittings and installation techniques.

Impact on Application: CPVC is particularly effective in hot water distribution systems and chemical processing, where higher temperatures and corrosive substances are present.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM F441 and ISO 15877. In Europe, adherence to EN 1452 is also necessary. Understanding local market preferences can help in selecting the right CPVC grades.

3. Polypropylene (PP)

Key Properties: PP is known for its high melting point (up to 160°C) and excellent chemical resistance. It is lightweight and has a lower density than PVC.

Pros & Cons: The main advantage of PP is its ability to withstand higher temperatures and aggressive chemicals. However, it is less rigid than PVC and may not be suitable for applications requiring high structural integrity. The manufacturing process for PP can also be more complex, leading to higher costs.

Impact on Application: PP is ideal for applications in the automotive and chemical industries, where resistance to high temperatures and corrosive environments is critical.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM D638 and ISO 1873. In regions like the Middle East, understanding the local chemical compatibility standards is vital for successful applications.

4. Thermoplastic Elastomers (TPE)

Key Properties: TPE combines the properties of rubber and plastic, offering flexibility and durability. It has a temperature range of -40°C to 120°C, making it suitable for various applications.

Pros & Cons: TPE provides excellent impact resistance and flexibility, making it ideal for applications requiring a soft touch or cushioning. However, it can be more expensive than traditional PVC and may require specialized processing techniques.

Impact on Application: TPE is often used in consumer goods, automotive parts, and seals where flexibility and durability are essential.

Considerations for International Buyers: Compliance with industry standards such as ASTM D624 and ISO 179 is important. Buyers should also consider the availability of TPE grades that meet specific performance requirements in their regions.

| Material | Typical Use Case for pvc extrusion companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Plumbing and electrical conduits | Excellent chemical resistance | Brittle at low temperatures | Medium |

| CPVC | Hot water distribution systems | Higher temperature resistance | More expensive than PVC | High |

| Polypropylene (PP) | Automotive and chemical applications | High melting point | Less rigid than PVC | Medium |

| Thermoplastic Elastomers (TPE) | Consumer goods and seals | Flexibility and impact resistance | Higher cost and processing complexity | High |

This guide serves as a comprehensive overview for international B2B buyers, helping them navigate the complexities of material selection in PVC extrusion. Understanding these factors will lead to better product performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc extrusion companies

The manufacturing of PVC extrusions involves a series of well-defined stages, each critical to producing high-quality products that meet international standards. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding these processes, as well as the associated quality assurance measures, is vital for making informed purchasing decisions.

Manufacturing Processes

1. Material Preparation

The first stage in PVC extrusion manufacturing involves the selection and preparation of raw materials. PVC resin is typically combined with various additives to achieve desired properties such as flexibility, color, and UV resistance.

- Compounding: This process involves mixing PVC with additives (e.g., stabilizers, lubricants, and fillers) in a controlled environment. This ensures uniform distribution of materials, which is essential for consistent product quality.

- Pelletizing: Once compounded, the mixture is cooled and cut into pellets for easy handling and feeding into the extruder.

2. Forming

The core of the PVC extrusion process is the forming stage, where the prepared material is shaped into desired profiles.

- Extrusion: The pellets are fed into a heated barrel of the extruder. Here, they are melted and forced through a die that shapes the material into the desired profile, whether it be pipes, sheets, or custom shapes.

- Cooling: The extruded material is then cooled, typically using water baths or air cooling systems, to solidify it into the final form.

3. Assembly

For products that require additional components, such as fittings or connectors, the assembly stage comes into play.

- Joining Techniques: Depending on the product design, various joining techniques such as welding, adhesive bonding, or mechanical fasteners are used to assemble different components.

- In-line Fabrication: Many companies incorporate in-line processes that allow for additional features to be added during extrusion, such as holes or grooves.

4. Finishing

The final stage involves finishing processes that enhance product performance and aesthetics.

- Trimming and Cutting: Excess material is trimmed away, and the extruded items are cut to specified lengths.

- Surface Treatment: Additional treatments such as coating, painting, or polishing may be applied to improve durability or appearance.

Quality Assurance

Quality assurance is a crucial aspect of PVC extrusion manufacturing, ensuring that products meet regulatory standards and customer expectations.

Relevant International Standards

International quality standards such as ISO 9001 set the framework for establishing effective quality management systems. Additionally, industry-specific certifications, such as CE marking for products sold in Europe and API standards for pipes in the oil and gas sector, are essential for compliance and market acceptance.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, involving several key checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards. This includes checking the physical and chemical properties of the PVC resin and additives.

- In-Process Quality Control (IPQC): During production, various parameters such as temperature, pressure, and extrusion speed are monitored. Regular sampling of the extruded product is conducted to check for consistency in dimensions and physical properties.

- Final Quality Control (FQC): Once production is complete, finished products undergo rigorous testing for compliance with quality standards. This includes dimensional checks, mechanical testing, and sometimes environmental testing to ensure durability.

Common Testing Methods

To validate product quality, manufacturers employ various testing methods:

- Mechanical Testing: Includes tensile strength, impact resistance, and elongation tests to assess the physical properties of the PVC products.

- Dimensional Testing: Utilizes calipers and gauges to ensure that products meet specified dimensions and tolerances.

- Thermal Testing: Measures the thermal properties of the material to ensure it can withstand operational conditions.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to ensure that their suppliers adhere to stringent quality standards.

- Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. This includes checking for certifications, reviewing production records, and evaluating compliance with international standards.

- Quality Reports: Requesting quality assurance reports from suppliers can help buyers understand the quality of the materials and products being manufactured. These reports should detail testing results and compliance with relevant standards.

- Third-Party Inspections: Engaging independent third-party inspectors can add an additional layer of assurance. These inspectors can evaluate the supplier’s processes, conduct random sampling, and provide unbiased reports on product quality.

Quality Control and Certification Nuances

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential:

- Regional Standards: Different regions may have specific quality requirements. For instance, products sold in Europe must comply with CE marking, whereas products in the Middle East might require local certifications.

- Documentation: Ensure that suppliers can provide all necessary documentation, including certificates of conformity, test reports, and compliance declarations. This documentation is often required for customs clearance and market entry.

- Cultural Considerations: Engage in clear communication with suppliers regarding quality expectations, as cultural differences may influence manufacturing practices and standards adherence.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for PVC extrusion is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control practices, buyers can ensure they partner with suppliers who deliver high-quality products that meet global standards.

Related Video: Cable extrusion production process – TANO

Comprehensive Cost and Pricing Analysis for pvc extrusion companies Sourcing

Understanding the cost structure and pricing dynamics is crucial for international B2B buyers in the PVC extrusion sector. This analysis will cover the primary cost components, key influencers on pricing, and actionable tips for buyers, particularly those from Africa, South America, the Middle East, and Europe.

Cost Components

- Materials

The choice of PVC resin and additives directly impacts costs. High-quality materials may come at a premium but can result in better product performance and durability. Buyers should consider the long-term benefits of investing in superior materials versus cheaper alternatives.

Illustrative Image (Source: Google Search)

-

Labor

Labor costs vary significantly by region. In countries with lower labor costs, manufacturers may offer competitive pricing. However, this can sometimes compromise quality. Understanding local labor dynamics is essential when evaluating suppliers. -

Manufacturing Overhead

Overhead includes utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which may be passed on to buyers. Look for suppliers who invest in technology to enhance operational efficiency. -

Tooling

Custom tooling for specific product specifications can be a significant upfront cost. However, these costs are often amortized over large production runs. Buyers should assess whether the tooling costs align with their volume needs to ensure cost-effectiveness. -

Quality Control (QC)

Rigorous QC processes ensure product consistency and compliance with industry standards. While this may increase manufacturing costs, it protects buyers from potential liabilities associated with subpar products. -

Logistics

Shipping and handling can add substantial costs, especially for international transactions. Factors such as distance, shipping method, and customs duties should be considered when evaluating total costs. -

Margin

Suppliers typically build a margin into their pricing to cover risks and ensure profitability. Understanding the average margins in the industry can help buyers negotiate better prices.

Price Influencers

-

Volume/MOQ

Minimum order quantities (MOQ) can significantly affect pricing. Higher volumes generally lead to better per-unit prices, making it advantageous for buyers to consolidate orders when possible. -

Specifications/Customization

Custom products often command higher prices due to the additional complexity in production. Buyers should clearly define their specifications to avoid unexpected costs. -

Materials

The type of PVC and additives used can influence pricing. Sustainable or specialty materials typically come at a higher cost but may offer unique benefits. -

Quality/Certifications

Products that meet international quality standards or have specific certifications may carry a premium price. Buyers should weigh the value of these certifications against their specific needs. -

Supplier Factors

A supplier’s reputation, industry experience, and service offerings can influence pricing. Established suppliers with proven track records may charge more but often provide greater reliability and support. -

Incoterms

Understanding Incoterms (International Commercial Terms) is crucial as they dictate the responsibilities of buyers and sellers in shipping. This can impact overall costs, especially in international transactions.

Buyer Tips

-

Negotiate Wisely

Always negotiate based on total costs rather than just unit prices. Highlighting your potential for future orders can leverage better pricing. -

Focus on Cost-Efficiency

Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and disposal. This perspective can lead to better purchasing decisions. -

Understand Pricing Nuances

Recognize that pricing may vary based on regional factors, currency fluctuations, and economic conditions. Buyers from different continents should be prepared to adapt their strategies accordingly. -

Request Indicative Prices

Always ask for indicative pricing to benchmark against competitors. This helps ensure that you are not overpaying for goods.

In summary, a thorough understanding of cost components and price influencers in the PVC extrusion market can empower international B2B buyers to make informed purchasing decisions, ensuring both cost-effectiveness and product quality.

Spotlight on Potential pvc extrusion companies Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘pvc extrusion companies’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for pvc extrusion companies

Key Technical Properties of PVC Extrusion

When selecting PVC extrusion companies, understanding the technical properties of the materials and processes involved is crucial. Here are several key specifications that influence product quality and manufacturing efficiency:

- Material Grade

– Definition: Material grade refers to the specific type of PVC resin used in the extrusion process, which can vary based on intended use (e.g., pressure pipes, electrical conduit).

– Importance: Selecting the appropriate material grade is essential for ensuring that the final product meets industry standards for strength, flexibility, and chemical resistance, thereby reducing the risk of product failure in application.

Illustrative Image (Source: Google Search)

-

Wall Thickness

– Definition: Wall thickness is the measurement of how thick the pipe walls are, which can impact the strength and pressure rating of the finished product.

– Importance: Proper wall thickness is critical for applications requiring specific pressure ratings. Buyers should ensure that the extrusion company can produce pipes that meet the required specifications to avoid safety and regulatory issues. -

Tolerance

– Definition: Tolerance refers to the allowable deviation from specified dimensions during the manufacturing process.

– Importance: High precision in tolerances is vital for ensuring that pipes fit correctly with other components. This is particularly important in applications like plumbing and electrical systems where improper fits can lead to leaks or failures. -

Impact Resistance

– Definition: Impact resistance measures a material’s ability to withstand sudden force or shock.

– Importance: In regions prone to environmental stresses (like earthquakes or heavy winds), pipes with high impact resistance are essential. Understanding this property helps buyers select products that will perform reliably in their specific conditions. -

Color and Additives

– Definition: Color and additives pertain to any pigments or modifiers included in the PVC to enhance properties such as UV resistance or aesthetics.

– Importance: Buyers may need specific colors for branding or compliance with local regulations. Additionally, additives can enhance durability and lifespan, making them important considerations in the purchasing decision.

Common Trade Terminology in PVC Extrusion

Familiarizing yourself with industry jargon is important when communicating with suppliers and negotiating contracts. Here are some common terms you may encounter:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer.

– Usage: Understanding OEM relationships can help buyers identify whether they are purchasing direct from manufacturers or through third-party vendors, impacting quality assurance and warranty considerations. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Usage: Knowing the MOQ helps buyers plan their purchases and inventory management. It can also influence negotiations, particularly for smaller companies or startups. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting a quote for specific products or services.

– Usage: Submitting an RFQ is a crucial step in procurement, enabling buyers to compare prices, terms, and capabilities across multiple suppliers. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules for the interpretation of the most commonly used trade terms in foreign trade.

– Usage: These terms clarify the responsibilities of buyers and sellers regarding shipping, risk, and costs. Understanding Incoterms helps buyers manage logistics and avoid unexpected expenses. -

Lead Time

– Definition: Lead time refers to the amount of time it takes from placing an order until the product is delivered.

– Usage: Knowing the lead time is essential for project planning and inventory management, especially in industries where timing is critical for operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when engaging with PVC extrusion companies, ensuring they select the right partners and products for their needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pvc extrusion companies Sector

Global drivers of the PVC extrusion market are multifaceted, largely influenced by the increasing demand for lightweight, durable materials across various sectors, such as construction, automotive, and plumbing. The ongoing urbanization in regions like Africa and South America is propelling the need for efficient plumbing and infrastructure solutions, while Europe continues to focus on sustainable building practices. Emerging technologies, including advanced automation and IoT integration, are reshaping the production landscape, enhancing efficiency, and enabling real-time monitoring of manufacturing processes.

International B2B buyers should also be aware of the current trends in sourcing, which favor suppliers who can provide comprehensive production lines that integrate all stages from raw material handling to finished product output. This approach not only streamlines operations but also enhances quality control. Furthermore, buyers are increasingly prioritizing suppliers with a strong track record in regulatory compliance and safety standards, essential for navigating the complexities of different regional markets.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a critical focus for industries worldwide, PVC extrusion companies are under pressure to adopt environmentally friendly practices. The environmental impact of PVC production, including its carbon footprint and the lifecycle of plastic waste, necessitates a shift towards greener alternatives. B2B buyers should seek suppliers who use recycled materials and sustainable additives, which can significantly reduce the ecological footprint of PVC products.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should ensure that their suppliers adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability. By prioritizing these factors, international buyers can not only meet regulatory requirements but also enhance their brand reputation in increasingly eco-conscious markets.

Brief Evolution/History

The PVC extrusion industry has evolved significantly since its inception in the mid-20th century. Initially relying on manual processes, advancements in machinery and automation have revolutionized production capabilities, allowing for greater efficiency and complexity in product designs. The introduction of computer-controlled extruders and sophisticated cooling systems has enabled manufacturers to produce high-quality PVC pipes and profiles that meet stringent industry standards. As market demands shift towards sustainability, the industry is now focusing on innovations that reduce environmental impact while maintaining product integrity. This historical context is essential for B2B buyers as they navigate their sourcing strategies in an ever-evolving market landscape.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of pvc extrusion companies

-

How do I vet a PVC extrusion supplier?

Vetting a PVC extrusion supplier involves several steps. First, assess their industry experience and expertise in PVC manufacturing. Look for certifications such as ISO 9001, which indicate quality management systems. Review customer testimonials and case studies to gauge reliability. Conduct a site visit if possible, or utilize third-party verification services. It’s also wise to inquire about their production capabilities, machinery quality, and adherence to international standards, ensuring they can meet your specific requirements. -

Can I customize the PVC products I order?

Yes, many PVC extrusion companies offer customization options. You can request specific dimensions, colors, and formulations to suit your application needs. When discussing customization, clearly outline your specifications and intended use. Suppliers with strong engineering expertise can provide insights on material compatibility and design feasibility. Ensure that your chosen supplier has a proven track record of delivering custom products, as this can significantly impact your project’s success. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities (MOQ) can vary significantly between suppliers, often depending on the complexity of the product and production capacity. For standard products, MOQs may range from 500 to 1,000 units, while custom items might require larger quantities. Lead times generally range from 2 to 12 weeks, depending on the supplier’s current workload and the specifics of your order. Always discuss these factors upfront to avoid potential delays in your supply chain. -

What payment terms should I expect when sourcing internationally?

Payment terms can vary by supplier and region, but typical arrangements include options such as upfront deposits (often 30-50%) with the balance due upon delivery or before shipping. Some suppliers may also accept letters of credit or payment through escrow services for larger transactions. It’s essential to discuss payment terms early in negotiations and ensure they are documented in your purchase agreement to protect both parties. -

How do I ensure quality assurance and certification compliance?

To ensure quality assurance, request documentation of the supplier’s quality control processes, including any certifications like ISO or compliance with ASTM standards. Ask for samples or trial runs to evaluate product quality before committing to larger orders. Additionally, consider implementing third-party inspections during production to verify compliance with your specifications. Establish clear quality metrics and have these agreed upon in the contract to safeguard your interests. -

What logistics considerations should I be aware of?

When sourcing PVC products internationally, consider logistics aspects such as shipping methods, customs regulations, and potential tariffs. Engage with a logistics provider experienced in international trade to streamline the process. Discuss with your supplier about packaging to minimize damage during transit. Ensure you understand Incoterms to clarify responsibilities for shipping costs and risks. It’s also advisable to plan for potential delays due to customs processing or logistical challenges in the destination country. -

How can I resolve disputes with my PVC supplier?

Dispute resolution can often be mitigated through clear communication and well-documented agreements. Before entering into a contract, establish terms for resolving disputes, such as mediation or arbitration, which can be less costly than litigation. In the event of a dispute, maintain open lines of communication to discuss the issue directly with your supplier. If necessary, involve a third-party mediator to facilitate discussions and find a mutually agreeable solution. -

What are the best practices for maintaining a long-term supplier relationship?

Building a strong, long-term relationship with your PVC supplier involves regular communication and collaboration. Schedule periodic reviews to discuss performance, quality, and any potential areas for improvement. Provide constructive feedback and be open to suggestions from your supplier, as they may have valuable insights into efficiency improvements. Additionally, consider establishing partnership agreements that incentivize both parties to invest in each other’s success, fostering a mutually beneficial relationship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pvc extrusion companies

Strategic sourcing in the PVC extrusion industry is crucial for international buyers aiming to enhance operational efficiency and product quality. By partnering with suppliers that possess deep industry expertise and high-quality machinery, companies can optimize production processes and reduce costs. Understanding the nuances of materials, regulatory compliance, and market trends allows buyers to make informed decisions that align with their long-term business objectives.

Key Takeaways:

– Supplier Selection: Choose suppliers with a proven track record and comprehensive knowledge of PVC materials and extrusion technologies.

– Equipment Quality: Invest in advanced machinery that ensures consistency and durability, ultimately impacting the bottom line.

– Regulatory Awareness: Stay informed about industry standards to avoid compliance issues and ensure product safety.

Looking ahead, the PVC extrusion market is poised for growth, driven by increasing demand across various sectors. International buyers from Africa, South America, the Middle East, and Europe should leverage strategic sourcing to stay competitive. By fostering strong relationships with reliable suppliers and embracing technological advancements, businesses can not only meet current demands but also position themselves for future opportunities. Engage with industry experts and explore innovative solutions that can drive your success in the evolving landscape of PVC extrusion.