Your Ultimate Guide to Sourcing Screw Conveyor Components

Introduction: Navigating the Global Market for screw conveyor components

In today’s competitive landscape, screw conveyor components play a vital role in ensuring efficient bulk material handling across various industries, including agriculture, mining, and food processing. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of these components is essential for optimizing operations and enhancing productivity.

This comprehensive guide delves into the various types of screw conveyor components, including standard and customized solutions tailored to specific industry needs. It covers critical aspects such as materials used—ranging from carbon steel to stainless steel—and the importance of manufacturing and quality control processes to ensure reliability and durability. Buyers will also gain insights into sourcing strategies, evaluating suppliers, and understanding cost implications, which are crucial for making informed purchasing decisions.

Moreover, the guide addresses common FAQs, empowering buyers with the knowledge required to navigate the complexities of the global market. By equipping you with actionable insights and expert guidance, this resource aims to enhance your procurement strategy and ensure you select the right screw conveyor components for your operational needs. Whether you are looking to streamline your supply chain or enhance equipment performance, this guide serves as a valuable tool in your sourcing journey.

Understanding screw conveyor components Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Shafted Screw Conveyors | Features a central shaft with helical screw blades. | Agriculture, mining, and food processing. | Pros: High efficiency; suitable for various materials. Cons: Requires more maintenance due to wear on the shaft. |

| Shaftless Screw Conveyors | No central shaft; uses a spiral blade for material handling. | Waste management and recycling industries. | Pros: Reduced maintenance; allows for more flexibility in layout. Cons: Lower capacity compared to shafted types. |

| Vertical Screw Conveyors | Designed for vertical transport; compact and space-saving. | Bulk material handling in limited spaces. | Pros: Efficient use of vertical space; minimizes footprint. Cons: Can be more expensive to install. |

| Screw Feeders | Controls the flow of materials with variable speed options. | Food, chemical, and plastic industries. | Pros: Precise material control; adaptable to different materials. Cons: May require more sophisticated controls. |

| Auger Conveyors | Similar to screw conveyors but typically used for granular materials. | Agriculture (grain handling) and construction. | Pros: Effective for bulk materials; simple design. Cons: Limited to certain material types; may clog with moist materials. |

Shafted Screw Conveyors

Shafted screw conveyors are characterized by their central shaft, which supports helical blades that move materials along the conveyor. These systems are highly efficient and versatile, making them ideal for applications across agriculture, mining, and food processing. Buyers should consider the maintenance needs, as the shaft can wear over time, impacting performance. However, their ability to handle a variety of materials makes them a popular choice for many industries.

Shaftless Screw Conveyors

Unlike traditional screw conveyors, shaftless screw conveyors utilize a spiral blade without a central shaft, allowing for more flexibility in design and layout. They are particularly effective in waste management and recycling applications, where materials can vary widely. Buyers benefit from reduced maintenance requirements, as there are fewer components that can wear out. However, the capacity may be lower than that of shafted models, which is an important consideration for high-volume operations.

Vertical Screw Conveyors

Vertical screw conveyors are designed to transport materials vertically, making them ideal for operations with limited space. Their compact design allows for efficient use of vertical space in facilities. Common applications include bulk material handling in food and chemical industries. While they offer significant space-saving benefits, potential buyers should be aware that installation costs may be higher compared to traditional conveyors.

Screw Feeders

Screw feeders are specialized for controlling the flow of materials, often equipped with variable speed options to adjust feed rates. These systems are widely used in food, chemical, and plastic industries where precise material control is essential. They offer adaptability for different materials, but buyers should consider the need for sophisticated control systems to optimize performance.

Auger Conveyors

Auger conveyors are similar to screw conveyors but are primarily used for granular materials, such as grains in agricultural applications. Their straightforward design makes them effective for bulk material handling. However, buyers should keep in mind that auger conveyors may struggle with moist materials, leading to clogging issues. Understanding the specific material characteristics is crucial when considering this option.

Related Video: Screw Conveyor vs. Screw Feeder

Key Industrial Applications of screw conveyor components

| Industry/Sector | Specific Application of screw conveyor components | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Transporting grain and feed | Enhances operational efficiency and minimizes waste | Material durability, resistance to corrosion, and maintenance ease |

| Chemicals | Moving bulk chemicals in processing plants | Ensures safe and efficient handling of hazardous materials | Compliance with safety standards, material compatibility |

| Food Products | Conveying ingredients in food manufacturing | Maintains hygiene and prevents contamination | Food-grade materials, ease of cleaning, and compliance certifications |

| Mining | Handling ores and minerals during extraction and processing | Increases productivity and reduces manual handling risks | Strength and durability, resistance to abrasion, and custom designs |

| Recycling | Transporting recyclable materials in waste management | Supports environmental sustainability and operational efficiency | Flexibility in design, adaptability to various materials, and cost-effectiveness |

Agriculture

In the agricultural sector, screw conveyor components are crucial for transporting grain, feed, and other bulk materials. They facilitate continuous movement, which enhances efficiency and reduces waste during loading and unloading processes. For buyers in regions like Africa and South America, where agriculture is a significant economic driver, sourcing durable and corrosion-resistant materials is essential. Additionally, considering the local climate and potential exposure to harsh conditions can influence material choices and design specifications.

Chemicals

Screw conveyors are extensively used in the chemical industry for moving bulk chemicals safely and efficiently within processing plants. These components help manage hazardous materials, ensuring that operations comply with strict safety regulations. International buyers, particularly from the Middle East and Europe, should prioritize sourcing equipment that meets regional safety standards and is compatible with various chemical compositions. This includes evaluating the material of construction to ensure resistance to corrosive substances.

Food Products

In food manufacturing, screw conveyor components play a vital role in conveying ingredients while maintaining hygiene standards. These conveyors are designed to prevent contamination and ensure that the materials are handled safely throughout the production process. For B2B buyers from Europe, especially Spain, it is critical to select food-grade materials that comply with health regulations. Additionally, ease of cleaning and maintenance is a significant consideration to meet operational efficiency.

Mining

In the mining industry, screw conveyor components are essential for handling ores and minerals during extraction and processing. They provide a reliable means of transporting heavy materials, significantly increasing productivity while minimizing manual handling risks. Buyers from regions with active mining operations, such as Africa, should focus on sourcing components that are robust and resistant to abrasion. Custom designs may also be necessary to accommodate specific material characteristics and operational challenges.

Recycling

The recycling industry utilizes screw conveyor components to transport various recyclable materials effectively. These conveyors support environmental sustainability by streamlining the recycling process and reducing manual labor. For international buyers, especially in developing regions, sourcing flexible and adaptable designs is crucial to accommodate a wide range of materials. Cost-effectiveness and durability are also key factors to consider, ensuring that the equipment can withstand the demands of a busy recycling facility.

Related Video: Belt conveyor | Tutorial | Types | Applications | Grades | Splicing | Joining | Steel cord | Safety

Strategic Material Selection Guide for screw conveyor components

When selecting materials for screw conveyor components, it is crucial to consider the specific properties, advantages, and limitations of each material. This decision impacts not only the performance of the equipment but also its longevity, maintenance needs, and overall cost-effectiveness. Below, we analyze four common materials used in screw conveyor components, providing insights tailored for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and ability to withstand moderate temperatures and pressures. It is generally less resistant to corrosion compared to other materials unless treated with a protective coating.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness and durability, making it suitable for a wide range of applications. However, its susceptibility to corrosion can be a significant drawback, especially in humid or corrosive environments. Maintenance costs can rise due to the need for protective coatings or replacements.

Impact on Application:

Carbon steel is ideal for handling dry, non-corrosive materials. In applications involving wet or corrosive media, its longevity may be compromised.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM or DIN for quality assurance. Additionally, understanding the local environmental conditions is crucial for selecting the right protective coatings.

Stainless Steel (304 and 316)

Key Properties:

Stainless steel, particularly grades 304 and 316, offers excellent corrosion resistance, high-temperature tolerance, and good mechanical properties. Grade 316 is particularly suited for harsher environments due to its added molybdenum content.

Pros & Cons:

The key advantage of stainless steel is its durability and resistance to corrosion, making it suitable for food, chemical, and pharmaceutical applications. However, the higher cost and more complex manufacturing processes can be significant disadvantages.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive substances. It is often required in industries where hygiene and contamination are critical, such as food processing.

Considerations for International Buyers:

Buyers should verify compliance with international standards, especially in food-related applications (e.g., FDA regulations). Understanding the specific grade requirements based on local industry standards is also essential.

Plastic (Polymer)

Key Properties:

Plastics, such as polyethylene or polypropylene, are lightweight, corrosion-resistant, and can operate effectively at lower temperatures. They are generally not suitable for high-pressure applications.

Pros & Cons:

The primary advantage of plastic is its resistance to corrosion and low weight, which can lead to lower shipping and installation costs. However, its lower strength and thermal resistance compared to metals can limit its applications.

Impact on Application:

Plastics are ideal for handling granular materials and are often used in agricultural applications. However, they are not suitable for applications involving high temperatures or heavy loads.

Considerations for International Buyers:

Buyers should consider the specific environmental conditions and ensure that the selected plastic can withstand local temperatures and humidity levels. Compliance with local safety standards is also necessary.

Alloy Steel

Key Properties:

Alloy steel is designed to enhance specific properties, such as toughness, wear resistance, and strength. It can withstand higher stresses and is often used in heavy-duty applications.

Pros & Cons:

The key advantage of alloy steel is its enhanced durability and performance in demanding applications. However, the higher cost and potential for brittleness in certain grades can be limitations.

Impact on Application:

Alloy steel is suitable for abrasive materials and high-stress applications, such as mining and construction. It offers superior performance in challenging environments.

Considerations for International Buyers:

Buyers must ensure that the alloy specifications meet local and international standards for performance and safety. Understanding the specific application requirements is crucial for selecting the right alloy grade.

Summary Table

| Material | Typical Use Case for screw conveyor components | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General bulk material handling | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Food, chemical, and pharmaceutical industries | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Agricultural applications | Lightweight and corrosion-resistant | Lower strength and thermal resistance | Medium |

| Alloy Steel | Heavy-duty applications | Enhanced durability and performance | Higher cost and potential brittleness | High |

This guide serves as a strategic resource for international B2B buyers, enabling informed decisions on material selection based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for screw conveyor components

When evaluating screw conveyor components, understanding the manufacturing processes and quality assurance measures is critical for international B2B buyers. This section outlines the typical stages involved in manufacturing these components, the quality control (QC) measures in place, and how buyers can verify these standards.

Manufacturing Processes

The manufacturing of screw conveyor components involves several key stages, each contributing to the overall quality and performance of the final product.

1. Material Preparation

The first step in the manufacturing process is material preparation. This involves selecting the appropriate materials based on the intended application of the screw conveyor. Common materials include:

- Carbon Steel: Ideal for general use due to its strength and cost-effectiveness.

- Stainless Steel (304, 316): Preferred for environments that require corrosion resistance, such as food processing and chemical handling.

- Specialty Alloys: Used for high-temperature or highly abrasive applications.

Once the materials are selected, they undergo cutting and shaping to meet specific dimensions and tolerances. This ensures that the components will fit together seamlessly during assembly.

2. Forming

The forming stage includes various techniques such as:

- Cold Forming: Often used for creating helical flights and other complex shapes without heating the material, preserving its mechanical properties.

- Welding: Critical for joining components such as the screw shaft and flights. Various welding methods (MIG, TIG) are employed depending on the material and thickness.

- Casting: Used for producing custom parts that are difficult to machine or shape from solid stock.

Advanced technologies such as CNC (Computer Numerical Control) machining ensure precision during this stage, reducing waste and enhancing the quality of the components.

3. Assembly

Once the individual components are formed, they are assembled into the final product. This process can include:

- Pre-assembly Inspection: Checking each part for defects before final assembly.

- Alignment: Ensuring that all components fit together correctly, which is crucial for the efficient operation of the screw conveyor.

- Final Assembly Techniques: Utilizing bolts, screws, or welding to secure the components together, depending on the design requirements.

4. Finishing

The finishing stage involves surface treatments to enhance durability and performance. Common finishing techniques include:

- Painting or Powder Coating: Provides corrosion resistance and improves aesthetics.

- Galvanizing: Offers enhanced protection against corrosion, especially for components exposed to harsh environments.

- Polishing: Particularly for stainless steel components, this process reduces surface roughness and improves hygiene, which is critical in food and pharmaceutical applications.

Quality Assurance

Quality assurance is paramount in the manufacturing of screw conveyor components, ensuring that they meet international standards and industry-specific requirements.

International Standards

Several international standards guide the quality assurance processes, including:

- ISO 9001: A widely recognized standard for quality management systems. Compliance indicates that the manufacturer has established processes for consistent quality.

- CE Marking: Required for products sold in the European Economic Area, ensuring they meet safety and environmental protection standards.

- API Standards: Important for components used in the oil and gas industry, ensuring they can withstand extreme conditions.

QC Checkpoints

Quality control is conducted at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive inspection of the finished product before shipment. This may include dimensional checks, visual inspections, and functional testing.

Common Testing Methods

Testing methods employed to verify the quality of screw conveyor components include:

- Dimensional Inspection: Verifying that all dimensions meet design specifications.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing to detect internal flaws without damaging the component.

- Functional Testing: Ensuring that the assembled screw conveyor operates correctly under simulated conditions.

Verifying Supplier Quality

For international B2B buyers, verifying the quality assurance processes of suppliers is essential. Here are some actionable steps:

- Supplier Audits: Conduct regular audits to assess the manufacturing processes and quality control measures in place. Look for ISO certifications and other relevant accreditations.

- Request Quality Reports: Ask suppliers for detailed quality assurance reports, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engage independent inspection agencies to evaluate the quality of components before shipment. This adds an additional layer of verification and can provide peace of mind.

QC/CERT Nuances for International Buyers

When sourcing screw conveyor components from different regions, it’s essential to understand the nuances of quality certification:

- Regional Compliance: Ensure that the supplier’s certifications are recognized in your region. For instance, CE certification is critical for buyers in Europe, while API standards are crucial for those in the oil and gas sector.

- Documentation: Maintain thorough documentation of all certifications and quality assurance processes, as this may be required for customs clearance and regulatory compliance in your country.

- Cultural Considerations: Be aware of the cultural differences in quality perceptions and practices. For example, suppliers in Europe might have more stringent quality assurance practices compared to some in Africa or South America.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions and ensure they are sourcing high-quality screw conveyor components that meet their operational needs.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for screw conveyor components Sourcing

Understanding the Cost Structure of Screw Conveyor Components

When sourcing screw conveyor components, understanding the cost structure is vital for international B2B buyers. The total cost typically encompasses several key components:

-

Materials: The choice of materials significantly impacts costs. Carbon steel is generally less expensive than stainless steel, but the latter offers better corrosion resistance and longevity. Custom materials for specific applications can further increase costs.

-

Labor: Labor costs vary by region and can be influenced by local wage rates and the skill level of the workforce. Countries with lower labor costs may provide more competitive pricing, but this should be weighed against quality considerations.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Factories with higher efficiency or better technology might have lower overhead costs, which can translate to more competitive pricing for buyers.

-

Tooling: The cost of specialized tools and dies used in manufacturing can be significant, especially for custom components. Buyers should consider whether the tooling costs will be amortized over a large volume of components or if they will be a one-time expense for a small order.

-

Quality Control (QC): Ensuring that components meet specific standards is crucial, especially for industries like food, pharmaceuticals, or chemicals. Quality assurance processes can add to the overall cost but are necessary to avoid costly failures down the line.

-

Logistics: Shipping costs can vary dramatically based on distance, weight, and the chosen shipping method. Understanding Incoterms (International Commercial Terms) is essential, as they dictate who bears the costs and risks during transit.

-

Margin: Suppliers will add a profit margin to their costs, which can vary based on market conditions, competition, and the perceived value of the components being offered.

Factors Influencing Pricing

Several factors can influence the pricing of screw conveyor components:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their operational needs while benefiting from cost savings.

-

Specifications and Customization: Custom designs or specifications typically incur additional costs. Buyers must balance the need for customization with budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (like ISO or ASTM) can increase costs but are often necessary for regulatory compliance and operational safety.

-

Supplier Factors: The reliability, reputation, and location of the supplier can significantly affect pricing. Local suppliers may reduce shipping costs and lead times but might have different pricing structures than international suppliers.

Buyer Tips for Cost-Efficiency

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, consider the following tips for achieving better pricing and cost efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, payment terms, and lead times. Suppliers may be willing to offer discounts for early payments or larger orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost of ownership, including maintenance, operational costs, and potential downtime. Sometimes, a higher upfront cost can lead to lower overall costs.

-

Understand Pricing Nuances: Be aware of regional pricing trends and how currency fluctuations can affect costs. This understanding can help in making timely purchasing decisions.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and insights into future pricing trends.

Disclaimer

Prices for screw conveyor components can vary significantly based on the factors mentioned above. It is advisable to obtain quotes from multiple suppliers and conduct thorough due diligence to ensure competitive pricing and quality standards.

Spotlight on Potential screw conveyor components Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘screw conveyor components’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for screw conveyor components

Key Technical Properties of Screw Conveyor Components

Understanding the essential technical properties of screw conveyor components is critical for international B2B buyers. Here are some of the most important specifications:

-

Material Grade

– The material used in screw conveyor components significantly affects durability and performance. Common materials include carbon steel, stainless steel (e.g., 304 and 316 grades), and specialized alloys. Each material has unique properties such as resistance to corrosion, wear, and heat. Selecting the right material grade ensures longevity and reliability in various operating environments. -

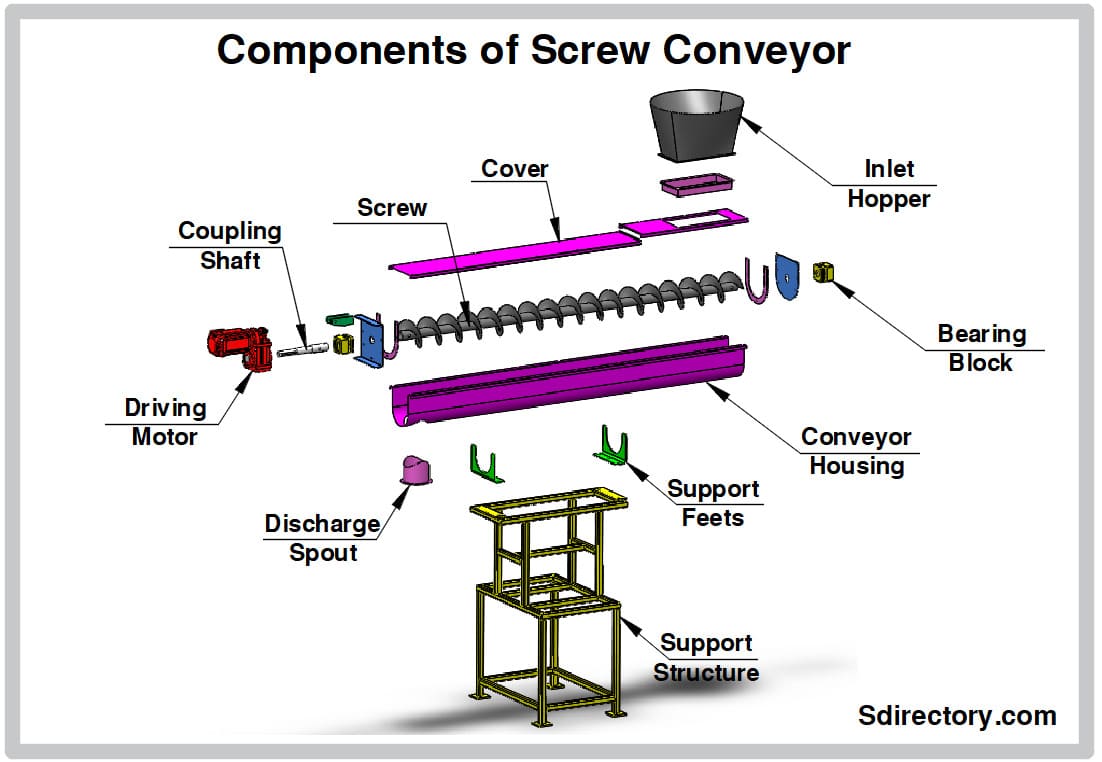

Diameter and Pitch

– The diameter of the screw and the pitch (distance between the screw threads) are vital for determining the capacity and efficiency of the conveyor. A larger diameter typically increases capacity, while pitch affects the material flow rate. Buyers should choose dimensions based on the specific application to optimize performance. -

Tolerance

– Tolerance refers to the allowable variation in dimensions of the components. Precise tolerances are crucial for ensuring compatibility among parts and for maintaining operational efficiency. Tight tolerances minimize wear and enhance performance, which is especially important in high-speed applications. -

Drive Type

– Screw conveyors can be powered by various types of drives, including direct drive, gear drive, or chain drive systems. Each drive type has implications for efficiency, maintenance, and cost. Understanding the advantages and limitations of each option helps buyers select the most suitable drive for their operational needs. -

Length and Configuration

– The length of the conveyor and its configuration (horizontal, inclined, or vertical) play significant roles in determining the system’s effectiveness. Different configurations are suited to different applications, and buyers must assess their specific needs to ensure optimal material handling. -

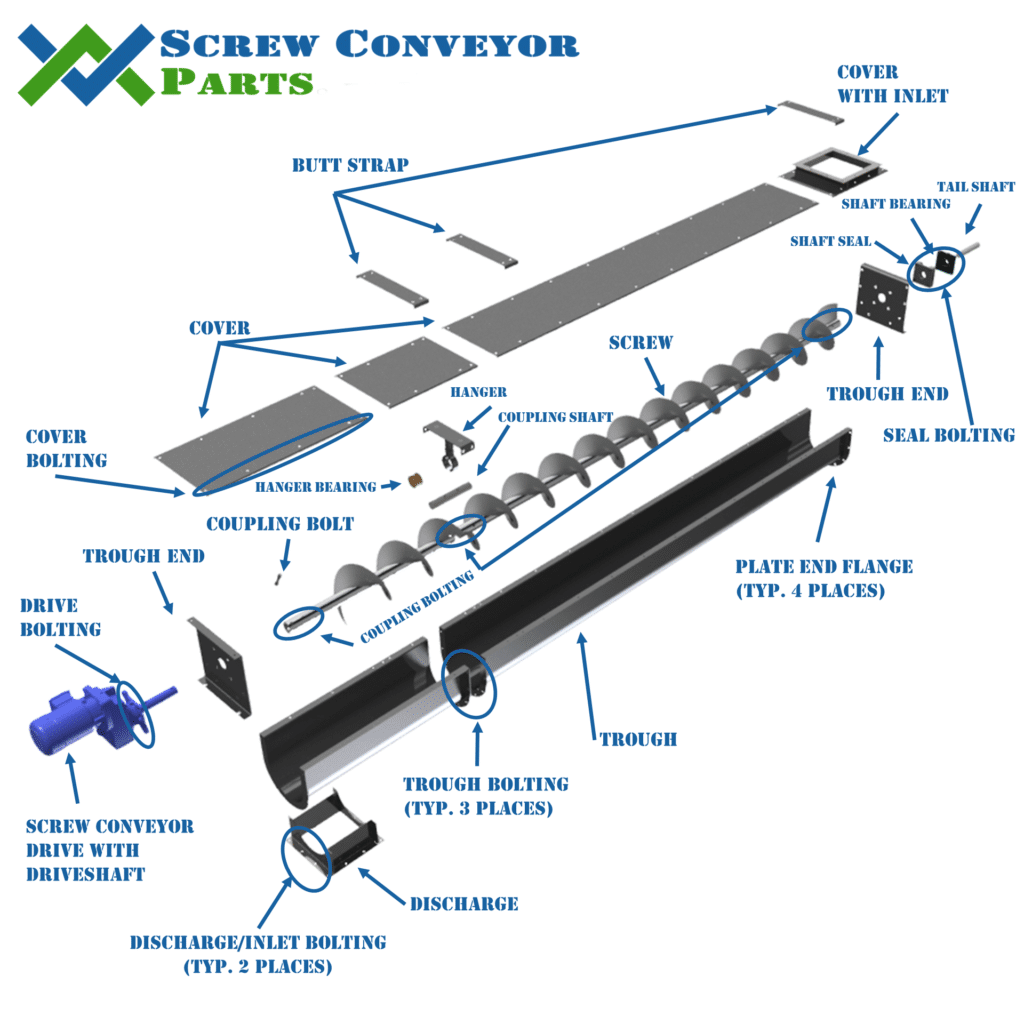

Sealing and Bearing Types

– The choice of seals and bearings impacts the operational efficiency and lifespan of the screw conveyor. Seals prevent material leakage and contamination, while the type of bearings affects friction and wear. Selecting appropriate seals and bearings can reduce maintenance costs and downtime.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiations in the B2B landscape. Here are several key terms:

- OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM specifications ensures that the components purchased are compatible with existing systems and meet quality standards.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units a supplier is willing to sell. This term is crucial for buyers looking to manage inventory effectively and negotiate favorable purchasing terms. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing information for specific products or services. It is an essential step in the procurement process, allowing buyers to compare costs and terms from various suppliers. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for managing shipping costs, risks, and logistics. -

Lead Time

– Lead time refers to the period between placing an order and receiving the goods. For B2B buyers, understanding lead times is essential for planning and ensuring that operations run smoothly without delays.

Illustrative Image (Source: Google Search)

- Aftermarket Support

– Aftermarket support includes services such as maintenance, repairs, and spare parts availability after the initial sale. Buyers should consider the level of aftermarket support offered by suppliers to ensure long-term operational efficiency.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ultimately leading to more successful procurement strategies and enhanced operational performance.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the screw conveyor components Sector

Market Overview & Key Trends

The screw conveyor components sector is experiencing significant growth, driven by increased demand in various industries such as agriculture, mining, and food processing. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note that the growth is fueled by several global drivers:

-

Automation and Industry 4.0: As industries embrace digital transformation, there is a growing trend towards automation. Screw conveyors integrated with IoT technology are gaining traction, enhancing operational efficiency and reducing downtime.

-

Customization and Made-to-Order Solutions: Buyers are increasingly seeking customized screw conveyor components that meet specific operational requirements. Manufacturers offering tailored solutions can capture a larger share of the market.

-

Sourcing Trends: Global sourcing is on the rise, with buyers looking for suppliers that can provide high-quality components at competitive prices. The trend is shifting towards establishing long-term relationships with suppliers who can ensure consistency and reliability.

-

Regional Dynamics: Different regions exhibit unique market dynamics. For instance, Africa is seeing a surge in agricultural applications, while Europe is focusing on high-tech solutions that comply with stringent regulations.

-

Emerging Markets: Countries in South America and Africa are investing heavily in infrastructure, creating opportunities for screw conveyor manufacturers to tap into new markets.

By staying abreast of these trends, international buyers can make informed sourcing decisions that align with their operational needs and market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical focus in the screw conveyor components sector. The environmental impact of manufacturing processes is under scrutiny, leading to a push for more sustainable practices. Key considerations for buyers include:

-

Ethical Supply Chains: B2B buyers must ensure that their suppliers adhere to ethical sourcing practices. This includes evaluating suppliers based on their labor practices, material sourcing, and overall environmental footprint.

-

Green Certifications: Many manufacturers are now offering components that comply with green certifications, such as ISO 14001. These certifications indicate adherence to environmental management standards, providing buyers with confidence in their sustainability claims.

-

Use of Recyclable Materials: There is a growing trend towards using recyclable and eco-friendly materials in the production of screw conveyor components. Buyers should prioritize suppliers who demonstrate a commitment to sustainable materials, such as stainless steel, which is not only durable but also recyclable.

-

Waste Reduction Initiatives: Suppliers are increasingly implementing waste reduction initiatives in their manufacturing processes. Buyers can benefit from partnering with manufacturers that actively seek to minimize waste and improve energy efficiency.

By prioritizing sustainability and ethical sourcing, B2B buyers can enhance their brand reputation and contribute to a more sustainable industrial ecosystem.

Brief Evolution/History

The screw conveyor has evolved significantly since its inception in ancient times, originally designed for agricultural purposes. Over the years, advancements in engineering and materials have led to the development of more efficient and versatile screw conveyor systems.

In the early 20th century, the industrial revolution spurred innovation, resulting in the widespread use of screw conveyors across various sectors, including mining and food processing. Today, these components are integral to bulk material handling systems, designed for durability and adaptability to meet the demands of modern industries.

This evolution has positioned screw conveyors as a critical component in the supply chain, emphasizing the importance for international B2B buyers to understand historical trends and advancements when selecting suppliers and components.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of screw conveyor components

-

How do I vet suppliers for screw conveyor components?

To effectively vet suppliers, conduct thorough research to assess their reputation and reliability. Look for suppliers with a proven track record in the screw conveyor industry, check their certifications (like ISO), and seek customer reviews. You can also request references from previous clients and inquire about their experience with the supplier. Consider visiting the supplier’s facility if possible, or utilize third-party inspection services to evaluate their manufacturing capabilities. -

Can screw conveyor components be customized to meet specific requirements?

Yes, many suppliers offer customization options for screw conveyor components. When engaging with a supplier, clearly communicate your specific needs, including dimensions, materials, and operational requirements. Ensure that the supplier has experience in providing tailored solutions. Request samples or prototypes to validate that the components meet your specifications before placing a bulk order. -

What are the typical minimum order quantities (MOQs) and lead times for screw conveyor components?

MOQs can vary significantly depending on the supplier and the complexity of the components. Generally, you might encounter MOQs ranging from a few units to several dozen. Lead times also differ based on the supplier’s production schedule and your customization requirements, typically ranging from 2 to 12 weeks. Always clarify these details upfront to align with your project timelines and budget. -

What payment options are available when sourcing screw conveyor components?

Payment options can vary by supplier, but common methods include bank transfers, letters of credit, and online payment platforms. For international transactions, consider using secure payment methods that offer buyer protection. Negotiate payment terms that work for both parties, such as partial payments upfront and the balance upon delivery. Establishing a clear payment agreement can help prevent misunderstandings later. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have robust quality assurance processes in place. Expect them to provide documentation of quality control procedures, inspection reports, and certifications for their products. Ask about their testing methods and how they handle defective components. A supplier committed to quality will be willing to share their QA protocols and may offer warranties or guarantees on their products. -

How can I ensure compliance with international shipping and logistics?

When sourcing screw conveyor components internationally, ensure that your supplier understands the logistics requirements for your region. Discuss shipping methods, customs documentation, and potential tariffs or duties. Verify that the supplier has experience with international shipping and can provide reliable tracking. Consider working with logistics partners familiar with your local regulations to streamline the import process. -

What should I do in case of disputes with a supplier?

In the event of a dispute, begin by reviewing your contract and any agreements made regarding the order. Communicate directly with the supplier to express your concerns and seek resolution. If necessary, escalate the issue to a higher level within the supplier’s organization. Should discussions fail, consider mediation or arbitration, and keep all correspondence documented. It’s crucial to have a clear dispute resolution clause in your contracts to guide the process. -

Are there specific certifications I should look for when sourcing screw conveyor components?

Yes, certifications such as ISO 9001 for quality management, CE marking for compliance with European safety standards, and other industry-specific certifications can be important. These certifications indicate that the supplier adheres to recognized quality and safety standards. When sourcing components, request documentation proving these certifications, as they can significantly impact the reliability and performance of the equipment in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for screw conveyor components

In summary, the strategic sourcing of screw conveyor components is pivotal for optimizing operational efficiency and cost-effectiveness in various industries. International B2B buyers should focus on establishing strong relationships with suppliers who can provide high-quality components tailored to specific operational needs. Key considerations include understanding the material specifications, maintenance requirements, and compatibility with existing systems.

By leveraging local suppliers in Africa, South America, the Middle East, and Europe, businesses can enhance supply chain resilience while supporting regional economies. Additionally, engaging in thorough market research and utilizing advanced sourcing strategies can lead to significant long-term savings and improved performance.

As we look toward the future, the demand for innovative and reliable screw conveyor components will only grow. Buyers are encouraged to proactively seek partnerships with manufacturers who prioritize sustainability and technological advancements. Embrace these opportunities to stay ahead in a competitive market, ensuring your operations remain efficient and cost-effective.