Your Ultimate Guide to Sourcing Septic Tanks Companies

Introduction: Navigating the Global Market for septic tanks companies

In today’s rapidly evolving global landscape, the demand for efficient waste management solutions has never been more critical. Septic tanks play a pivotal role in ensuring sanitary conditions, especially in areas where centralized sewage systems are not available. For B2B buyers across Africa, South America, the Middle East, and Europe—including key markets like Spain and Germany—understanding the dynamics of septic tanks companies is essential for making informed procurement decisions.

This comprehensive guide serves as your roadmap to navigating the intricate world of septic tank solutions. It delves into various types of septic systems, the materials used in their construction, and the rigorous manufacturing and quality control processes that ensure longevity and compliance with local regulations. Additionally, we will highlight reputable suppliers, cost considerations, and the current market trends that influence pricing and availability.

By equipping yourself with this vital information, you empower your organization to make strategic sourcing decisions that align with both operational needs and budgetary constraints. Whether you are a contractor seeking reliable suppliers or an investor exploring market opportunities, this guide is designed to provide actionable insights that will enhance your decision-making process in the septic tank industry. Prepare to navigate the global market with confidence and clarity as you explore the essential elements that underpin successful septic tank procurement.

Understanding septic tanks companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Septic Tanks | Standard design, gravity-fed system | Residential and small commercial use | Pros: Low maintenance, cost-effective. Cons: Space-intensive, potential for odor issues. |

| Aerobic Treatment Units | Utilizes oxygen to enhance breakdown of waste | Larger residential, commercial, and industrial applications | Pros: More efficient waste treatment, smaller footprint. Cons: Higher operational costs, requires electricity. |

| Mound Systems | Elevated design for areas with high water tables | Rural areas with poor drainage | Pros: Effective in challenging soil conditions. Cons: Installation complexity, higher initial costs. |

| Constructed Wetlands | Natural filtration system using plants and soil | Environmental applications, eco-friendly projects | Pros: Sustainable, low maintenance. Cons: Space requirements, slower processing times. |

| Advanced Treatment Systems | High-tech solutions with multiple treatment stages | Industrial and large-scale applications | Pros: Highly efficient, customizable. Cons: High initial investment, complex maintenance. |

Conventional Septic Tanks

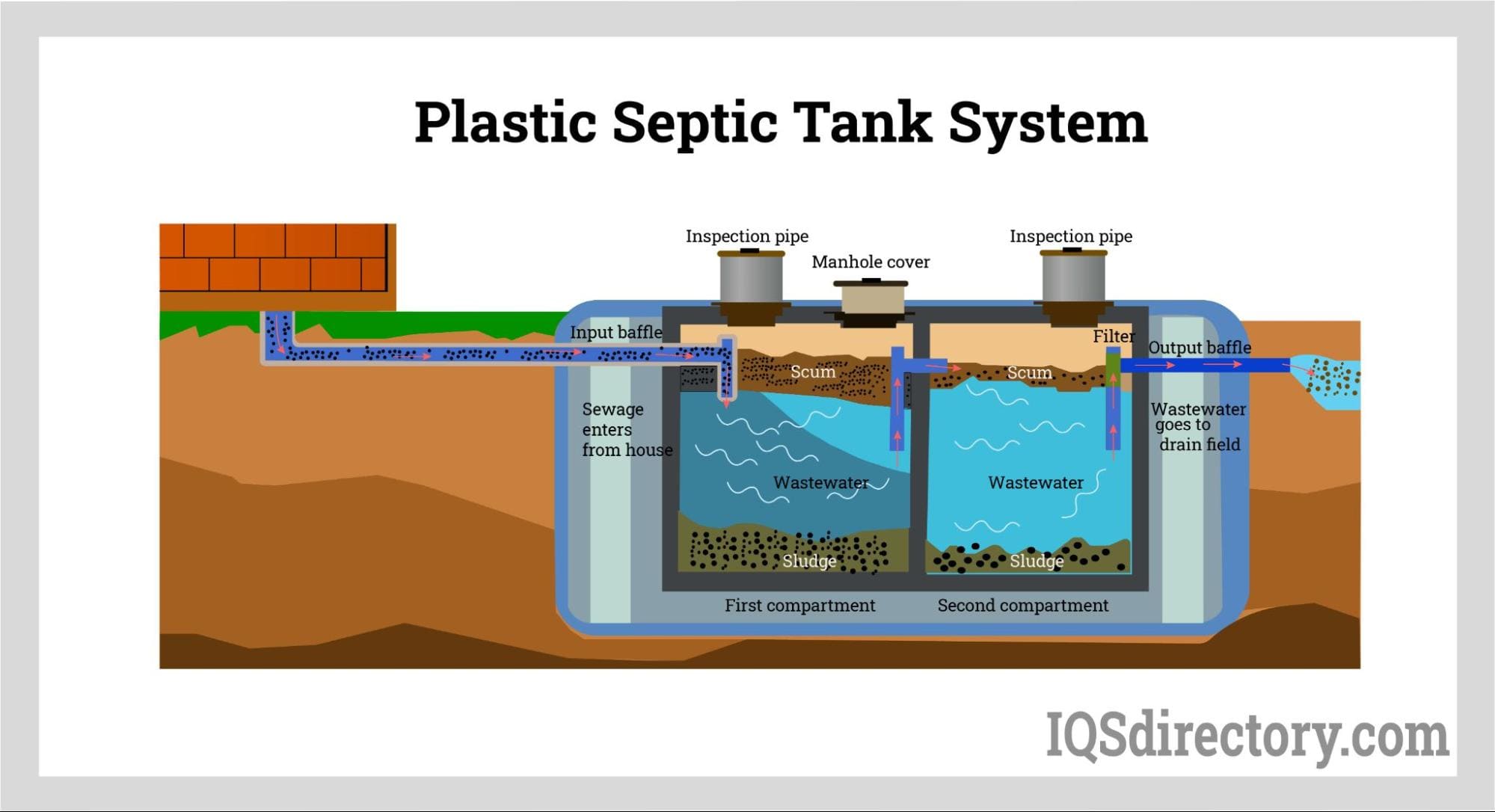

Conventional septic tanks are the most common type, designed for gravity-fed systems. They typically consist of a two-chamber tank that allows solids to settle and effluent to flow into a drain field. This type is suitable for residential and small commercial applications, particularly in areas with adequate land. When considering a conventional septic tank, buyers should evaluate local soil conditions, zoning regulations, and the available space for installation. While they are generally cost-effective and require low maintenance, they can pose challenges in terms of odors and space requirements.

Aerobic Treatment Units

Aerobic Treatment Units (ATUs) enhance waste breakdown by introducing oxygen into the treatment process. This results in more efficient waste treatment compared to conventional systems. ATUs are particularly well-suited for larger residential, commercial, and industrial applications where space is limited. Buyers should consider the operational costs associated with electricity and maintenance, as these systems require regular monitoring to ensure efficiency. The advantages include a smaller footprint and improved treatment efficacy, making them a compelling option for B2B buyers focused on optimizing space and performance.

Mound Systems

Mound systems are specially designed for areas with high water tables or poor soil drainage. They consist of a mound of sand and gravel that acts as a drain field above the natural ground level. This type is particularly useful in rural areas where traditional septic systems may fail. When evaluating mound systems, buyers should account for the complexity of installation and the higher initial costs. However, their ability to function effectively in challenging conditions makes them an attractive option for buyers in regions with specific environmental challenges.

Constructed Wetlands

Constructed wetlands utilize natural processes involving plants and soil to filter wastewater. This eco-friendly approach is suitable for environmental applications and projects aiming for sustainability. Buyers should consider the space requirements and slower processing times associated with these systems. The pros include low maintenance and a reduced environmental footprint, making them ideal for businesses committed to sustainable practices. However, they may not be suitable for all applications, particularly those requiring quick processing or in areas with limited land.

Advanced Treatment Systems

Advanced treatment systems employ high-tech solutions that incorporate multiple treatment stages, providing comprehensive waste management. These systems are best suited for industrial and large-scale applications where efficiency is paramount. Buyers should weigh the high initial investment and complex maintenance requirements against the benefits of superior treatment efficacy and customization options. For businesses operating in sectors with strict environmental regulations, advanced treatment systems can offer significant advantages, making them a valuable consideration in the B2B purchasing process.

Related Video: Septics101 (Full Course): A Guide to Septic System Maintenance

Key Industrial Applications of septic tanks companies

| Industry/Sector | Specific Application of septic tanks companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Wastewater management for residential and commercial sites | Ensures compliance with environmental regulations, reduces project delays | Local regulations, tank capacity, material durability |

| Agriculture | Treatment of farm wastewater and effluent from livestock | Protects soil and water quality, enhances farm productivity | Size of tank, maintenance requirements, local soil conditions |

| Hospitality | Wastewater treatment for hotels and resorts | Improves guest experience, minimizes environmental impact | Installation space, service frequency, local permits |

| Manufacturing | Industrial wastewater treatment for factories | Reduces operational costs, complies with discharge standards | Technology compatibility, waste composition, service support |

| Real Estate Development | On-site sewage treatment for new developments | Increases property value, meets local health codes | Site assessment, long-term maintenance plans, local regulations |

Construction

In the construction sector, septic tanks are essential for managing wastewater at both residential and commercial sites. These systems ensure that builders comply with local environmental regulations, preventing project delays caused by inadequate waste management solutions. International buyers, particularly in developing regions, should consider local regulations and the required tank capacity to accommodate varying project sizes. Additionally, the durability of materials used in the septic tanks is crucial to ensure long-term performance and reduce replacement costs.

Agriculture

Septic tanks play a vital role in the agricultural industry by treating wastewater and effluent generated from livestock operations. Effective wastewater management helps protect soil and water quality, which is essential for maintaining farm productivity. Buyers in this sector should assess the size of the tank necessary for their specific operations and consider maintenance requirements to ensure compliance with environmental standards. Understanding local soil conditions is also critical, as it influences the design and installation of the septic system.

Hospitality

In the hospitality industry, septic tanks are used for wastewater treatment in hotels and resorts, where maintaining a clean and pleasant environment is paramount. Proper wastewater management enhances the guest experience while minimizing the establishment’s environmental footprint. B2B buyers should evaluate installation space, the frequency of necessary service, and any local permits required for installation. Ensuring that the septic system can handle peak loads during high occupancy periods is also essential for operational efficiency.

Manufacturing

Manufacturing facilities generate significant amounts of industrial wastewater, making septic tanks an important component of their waste management strategy. These systems help factories reduce operational costs by allowing them to treat wastewater on-site, thus complying with local discharge standards. When sourcing septic tanks, businesses must consider technology compatibility with their existing systems, the composition of their waste, and the availability of service support for maintenance and repairs. Ensuring the system’s efficiency can lead to substantial cost savings over time.

Real Estate Development

For real estate developers, on-site sewage treatment solutions like septic tanks are critical in new developments, especially in areas without centralized sewer systems. These systems not only meet local health codes but also enhance property values by ensuring reliable wastewater management. Buyers in this sector should conduct thorough site assessments to determine the best septic tank solution for their projects. Long-term maintenance plans and adherence to local regulations are also essential to ensure the sustainability of the development.

Related Video: How It’s Made: Septic Tanks

Strategic Material Selection Guide for septic tanks companies

When selecting materials for septic tanks, companies must consider various factors that influence performance, durability, and compliance with regional regulations. Here, we analyze four common materials used in septic tank construction: concrete, polyethylene, fiberglass, and steel. Each material has unique properties and implications for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe.

Concrete

Key Properties: Concrete septic tanks are known for their high compressive strength and durability. They can withstand extreme temperatures and pressures, making them suitable for various soil conditions. Concrete also has good resistance to corrosion when properly sealed.

Pros & Cons: The primary advantage of concrete is its longevity and robustness, often lasting several decades with minimal maintenance. However, the initial manufacturing complexity can be high, and transportation costs may increase due to weight. Additionally, if not properly installed, concrete tanks can crack or leak over time.

Impact on Application: Concrete is compatible with a wide range of wastewater media, including those with high organic loads. However, buyers must ensure that the concrete is treated to resist sulfate attack, particularly in regions with high sulfate levels in the soil.

Considerations for International Buyers: Compliance with local standards such as ASTM (in the USA) or EN (in Europe) is crucial. Buyers should also consider the environmental impact of concrete production and seek suppliers who adhere to sustainable practices.

Polyethylene

Key Properties: Polyethylene (PE) tanks are lightweight, resistant to corrosion, and have a good temperature tolerance. They are often manufactured using rotational molding, which ensures uniform thickness and strength.

Pros & Cons: The main advantage of polyethylene is its resistance to chemical corrosion, making it ideal for various wastewater types. However, PE tanks can be less durable than concrete and may require additional anchoring in flood-prone areas. The cost of polyethylene tanks tends to be moderate, but they may have a shorter lifespan compared to concrete options.

Impact on Application: Polyethylene tanks are suitable for residential and commercial applications, particularly where weight and installation ease are critical. They are not recommended for areas with extreme temperature fluctuations, as they can become brittle.

Considerations for International Buyers: Buyers should ensure that the polyethylene used meets local regulations regarding chemical resistance and environmental safety. Certification standards like DIN in Europe can provide assurance of quality.

Fiberglass

Key Properties: Fiberglass septic tanks are known for their lightweight nature and excellent resistance to corrosion and chemicals. They are typically molded into shape, allowing for a seamless design that minimizes leaks.

Pros & Cons: The key advantage of fiberglass is its resistance to rust and decay, making it a long-lasting option. However, the manufacturing process can be complex, leading to higher costs. Additionally, fiberglass tanks can be susceptible to damage from extreme impacts.

Impact on Application: Fiberglass tanks are suitable for various wastewater applications, particularly in areas with high groundwater levels. They are also effective in preventing infiltration of groundwater into the tank.

Considerations for International Buyers: Buyers should verify that fiberglass tanks comply with local and international standards, such as JIS in Japan or ASTM in the USA. Awareness of local climate conditions is also essential, as extreme UV exposure can degrade fiberglass over time.

Steel

Key Properties: Steel septic tanks are robust and can handle high pressure and temperature variations. They are often coated with protective materials to enhance corrosion resistance.

Pros & Cons: Steel tanks are durable and can be manufactured to custom specifications. However, they are susceptible to rust if not properly maintained and can be heavy, increasing transportation costs. The overall cost is generally moderate to high, depending on the protective coatings used.

Impact on Application: Steel tanks are suitable for industrial applications where high strength is required. However, they may not be ideal for residential use in corrosive environments unless properly treated.

Considerations for International Buyers: Buyers should ensure that steel tanks comply with relevant standards and consider the long-term maintenance requirements associated with corrosion prevention. Awareness of local environmental regulations is also critical.

Summary Table

| Material | Typical Use Case for septic tanks companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Concrete | Residential and commercial septic systems | Long-lasting and robust | Heavy; potential for cracking | High |

| Polyethylene | Residential systems in light soil areas | Corrosion-resistant and lightweight | Less durable; may require anchoring | Medium |

| Fiberglass | Residential and commercial applications | Excellent chemical resistance | Higher cost; susceptible to impacts | High |

| Steel | Industrial applications | Customizable and strong | Susceptible to rust; heavy | Medium to High |

This guide provides a comprehensive overview of material selection for septic tanks, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for septic tanks companies

The manufacturing of septic tanks involves several key stages, each critical to ensuring the final product meets both functional and regulatory requirements. B2B buyers must understand these processes to make informed purchasing decisions. Here’s a detailed exploration of the typical manufacturing processes and quality assurance measures adopted by septic tank companies.

Illustrative Image (Source: Google Search)

Manufacturing Processes

1. Material Preparation

The initial stage involves selecting and preparing the right materials. Common materials for septic tanks include reinforced concrete, fiberglass, and polyethylene.

- Material Selection: Buyers should prioritize suppliers who utilize durable and corrosion-resistant materials that comply with local environmental regulations.

- Pre-treatment: Materials often undergo pre-treatment to enhance their performance characteristics, such as resistance to chemicals and UV degradation.

2. Forming

The forming stage involves shaping the selected materials into the desired septic tank configurations.

- Molding Techniques:

- Concrete Casting: For concrete tanks, molds are created, and concrete is poured into these forms. This process may involve the use of vibrators to ensure uniform density.

-

Rotational Molding: Used primarily for polyethylene tanks, this method provides consistent wall thickness and structural integrity.

-

Quality Checks: During this stage, dimensional accuracy is critical. Buyers should inquire about the technology used to ensure precise mold dimensions, as inaccuracies can lead to installation issues.

3. Assembly

Once the components are formed, they are assembled into complete units.

- Joint Sealing: Proper sealing of joints is essential to prevent leaks. B2B buyers should ensure that suppliers use high-quality sealing materials and techniques, such as solvent welding or gasket systems.

- Integration of Components: This may include baffles, outlet pipes, and access ports, which must be carefully installed to ensure functionality.

4. Finishing

Finishing processes improve the aesthetic and functional qualities of the septic tanks.

- Surface Treatment: This may involve coating the tank with protective finishes to enhance resistance to environmental factors.

- Inspection: A thorough inspection for surface defects or imperfections is crucial. Buyers should look for suppliers who implement rigorous finishing checks.

Quality Assurance

Quality assurance is paramount in the manufacturing of septic tanks, ensuring that products meet international standards and buyer expectations.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Suppliers certified under ISO 9001 demonstrate a commitment to quality through consistent processes and continual improvement.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. Buyers in Europe, particularly in countries like Germany and Spain, should prioritize suppliers with CE certification.

- API Standards: For tanks used in certain applications, adherence to American Petroleum Institute (API) standards can also be relevant, particularly for tanks involved in wastewater management.

Quality Control Checkpoints

Quality control should be integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This involves checking raw materials upon receipt to ensure they meet specifications. Buyers can request IQC reports to verify material quality.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the forming and assembly processes. Buyers should ask about the frequency and methods of IPQC checks.

- Final Quality Control (FQC): This final inspection ensures that the completed tanks meet all specifications and standards before shipment. It often includes pressure testing and structural integrity assessments.

Common Testing Methods

To verify the quality of septic tanks, several testing methods are employed:

- Hydraulic Testing: This assesses the tank’s ability to hold water without leaks.

- Load Testing: Evaluates the structural integrity under expected loads.

- Visual Inspections: A thorough visual examination for surface defects, weld integrity, and component assembly.

Verification of Supplier Quality Control

B2B buyers should take proactive steps to verify a supplier’s quality control measures:

- Audits: Conducting periodic audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. Buyers should look for suppliers who are open to third-party audits.

- Quality Reports: Requesting access to quality assurance documentation, including inspection and testing reports, can help verify a supplier’s quality practices.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the manufacturing and quality control processes.

QC and Certification Nuances for International Buyers

When dealing with international suppliers, particularly from regions like Africa and the Middle East, understanding the nuances of quality certification is vital:

- Local Regulations: Buyers should familiarize themselves with local regulations that may differ from international standards. This includes understanding any specific certifications required for septic tanks in the target market.

- Cultural Considerations: Engage in discussions about quality expectations, as different regions may have varying perceptions of quality assurance.

- Language Barriers: Ensure clear communication regarding quality requirements and standards, possibly involving local intermediaries or translators if necessary.

In conclusion, understanding the manufacturing processes and quality assurance protocols of septic tank companies is essential for B2B buyers. By focusing on material selection, manufacturing techniques, and rigorous quality control measures, buyers can ensure they procure reliable and compliant septic tanks suited to their needs.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for septic tanks companies Sourcing

When sourcing septic tanks from international suppliers, understanding the comprehensive cost structure is essential for making informed purchasing decisions. This analysis will break down the key cost components and pricing influencers while providing actionable tips for B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver in septic tank manufacturing is the raw materials. Common materials include concrete, polyethylene, and fiberglass. The choice of material significantly impacts durability, weight, and installation complexity. Buyers should assess local availability and price fluctuations of these materials to optimize costs.

-

Labor: Labor costs vary significantly across regions. Countries with lower wage standards may offer lower labor costs, but buyers should consider the trade-off with quality and expertise. Skilled labor is crucial for ensuring that septic tanks are manufactured to the required specifications and standards.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and indirect labor. Overhead costs can vary by location, influenced by local regulations, taxes, and operational efficiencies. Buyers should inquire about these costs to better understand the overall pricing structure.

-

Tooling: Initial tooling costs can be substantial, particularly for custom septic tank designs. Buyers should discuss tooling options with suppliers, as some may offer shared tooling arrangements to reduce initial costs.

-

Quality Control (QC): Ensuring compliance with international standards often incurs additional costs. Comprehensive QC processes can add to the overall price but are essential for minimizing future liabilities. Buyers should prioritize suppliers with robust QC measures to ensure product reliability.

-

Logistics: Transportation costs can vary widely based on the origin and destination of the product. Factors such as shipping method, distance, and customs duties all play a role. For international buyers, understanding Incoterms is crucial for determining who is responsible for shipping costs and risks.

-

Margin: Supplier margins can vary based on competition and market demand. Buyers should compare multiple quotes to gauge what constitutes a fair margin within the industry.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts. Buyers should assess their needs and negotiate for better rates based on their purchasing power.

-

Specifications/Customization: Custom designs or specific regulatory requirements can increase costs. Buyers should be clear about their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Products that meet higher quality standards or have specific certifications may carry a premium price. Buyers should evaluate whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of a supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and customs duties, which can significantly affect total costs.

Buyer Tips

-

Negotiation: Approach negotiations with a clear understanding of your needs and the market rates. Being informed about the costs involved can empower you to negotiate better terms.

-

Cost-Efficiency: Look beyond the initial purchase price. Consider the Total Cost of Ownership (TCO), which includes installation, maintenance, and potential operational costs over the lifespan of the septic tank.

-

Pricing Nuances: Be aware of regional price variances. For instance, prices in Europe may differ significantly from those in Africa or South America due to local market conditions and regulations.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Consider establishing partnerships with suppliers who demonstrate reliability and quality.

-

Market Research: Conduct thorough research on local suppliers and market conditions to gain insight into pricing trends and supplier capabilities. This knowledge can help you make better sourcing decisions.

Disclaimer

The prices and cost estimates provided are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Always seek multiple quotes and conduct due diligence when sourcing septic tanks.

Spotlight on Potential septic tanks companies Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘septic tanks companies’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for septic tanks companies

Key Technical Properties of Septic Tanks

When evaluating septic tanks, understanding the technical properties is crucial for B2B buyers to ensure compliance, durability, and performance. Here are some essential specifications to consider:

-

Material Grade

Septic tanks are typically made from materials such as polyethylene, fiberglass, and concrete. The material grade affects the tank’s strength, longevity, and resistance to chemical corrosion. Buyers should assess the material properties to ensure they meet local regulations and environmental standards. For instance, polyethylene tanks are lightweight and resistant to rust, while concrete tanks offer superior durability but may require additional maintenance. -

Tank Capacity

The capacity of a septic tank is measured in gallons or liters and must be appropriate for the volume of wastewater generated by the household or commercial establishment. Understanding the required capacity is vital to avoid overflows or inadequate treatment. It’s essential for buyers to calculate the expected daily wastewater flow to select a tank that meets their needs. -

Tolerance Levels

Tolerance levels refer to the acceptable variations in dimensions and structural integrity of the tank. Proper tolerances ensure that the tank fits into the designated site without leakage or structural failure. Buyers should verify the manufacturer’s specifications to ensure the product adheres to industry standards, which can significantly impact installation and long-term performance. -

Baffle Design

The baffle is an internal component that separates the tank into compartments, aiding in the separation of solids and liquids. A well-designed baffle system enhances the efficiency of wastewater treatment and minimizes the risk of clogs. Buyers should inquire about baffle configurations and their compliance with local regulations to ensure optimal tank performance. -

Installation Requirements

Understanding the installation specifications, including depth, backfill material, and soil conditions, is critical for ensuring the septic tank functions properly. Buyers should consult with manufacturers about recommended installation practices to avoid costly failures or compliance issues.

Common Trade Terminology

Familiarity with industry-specific terminology can facilitate smoother communication and negotiations between buyers and suppliers. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For septic tanks, understanding whether a product is OEM can indicate quality assurance and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. This term is crucial for buyers, as it can affect inventory levels and overall project costs. Understanding MOQ helps buyers negotiate better terms and avoid overstocking. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers. This formal inquiry allows buyers to compare offers and negotiate better deals. Crafting a clear RFQ can ensure that all necessary specifications are covered, leading to accurate quotes.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of sellers and buyers in shipping agreements. Familiarity with these terms helps buyers understand who bears the costs and risks at various stages of transportation, which is vital for budgeting and logistical planning. -

Warranties and Guarantees

Warranties refer to the manufacturer’s commitment to repair or replace defective products within a specified period. Understanding warranty terms is essential for buyers to assess the long-term reliability of septic tanks and safeguard their investment. -

Compliance Standards

Compliance standards refer to the regulations that septic tanks must meet in different regions. Buyers should ensure that the products they are considering adhere to local environmental and safety standards to avoid legal issues and ensure safe operation.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring the septic tanks they procure meet their operational needs while adhering to local regulations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the septic tanks companies Sector

Market Overview & Key Trends

The septic tanks sector is undergoing significant transformations driven by global urbanization, population growth, and increasing regulatory pressures regarding wastewater management. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for efficient and sustainable septic solutions. The market is increasingly influenced by technological advancements, such as IoT-enabled monitoring systems that provide real-time data on tank conditions, leading to improved maintenance and operational efficiency.

Emerging trends include the adoption of modular septic systems that facilitate easier installation and scalability, catering to diverse geographical and regulatory environments. Furthermore, the integration of eco-friendly materials in product design is becoming crucial, aligning with the global shift towards sustainability. In Europe, particularly in countries like Germany and Spain, stringent environmental regulations are propelling the demand for innovative septic solutions that minimize ecological footprints.

Additionally, as emerging economies in Africa and South America advance, there is an escalating need for reliable wastewater treatment solutions. This creates an opportunity for international suppliers to establish partnerships and expand their footprint in these developing markets. B2B buyers should prioritize suppliers who demonstrate agility in adapting to these market dynamics and who leverage technology for enhanced service delivery.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a buzzword; it has become a critical factor in the procurement strategies of septic tanks companies. The environmental impact of wastewater management is significant, prompting buyers to seek solutions that mitigate pollution and promote resource recovery. Ethical sourcing is paramount, as it ensures that materials used in septic tanks are obtained responsibly, reducing harm to both communities and ecosystems.

Buyers should look for suppliers who hold certifications like ISO 14001, which demonstrates a commitment to effective environmental management systems. Furthermore, utilizing recycled materials or bio-based products can enhance the sustainability profile of septic tanks. Companies that invest in ‘green’ certifications not only comply with regulations but also appeal to environmentally conscious customers, providing a competitive edge in the marketplace.

Incorporating sustainability into procurement strategies not only helps in compliance but also fosters long-term relationships with suppliers who share similar values. As buyers from Africa, South America, the Middle East, and Europe increasingly prioritize sustainability, aligning sourcing practices with ethical standards will be essential for market success.

Brief Evolution/History

The septic tank industry has evolved significantly over the past century, transitioning from rudimentary designs to sophisticated systems that integrate advanced materials and technology. Historically, septic tanks were primarily constructed from concrete or steel, leading to issues related to durability and environmental impact. However, advancements in polymer technology and composite materials have revolutionized the market, providing lighter, more durable, and corrosion-resistant options.

In recent decades, the emphasis has shifted towards sustainability, with an increasing number of companies developing systems that not only treat wastewater effectively but also contribute positively to the environment. This evolution reflects broader trends in industrial practices, where environmental considerations are becoming central to product development and business strategy. As the industry continues to innovate, B2B buyers are encouraged to stay informed about historical context to better understand current market dynamics and make informed sourcing decisions.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of septic tanks companies

-

What key factors should I consider when vetting septic tank suppliers?

When vetting septic tank suppliers, consider their industry experience, reputation, and certifications. Look for suppliers with a proven track record of quality and reliability. Check their production capacity and capabilities to ensure they can meet your specific needs. Additionally, inquire about their compliance with local regulations and environmental standards, particularly if you are sourcing from different countries. Engaging with references and reading reviews can provide valuable insights into their performance and customer service. -

Can septic tanks be customized for specific applications or regulations?

Yes, many septic tank manufacturers offer customization options to meet specific applications or regional regulations. When discussing your requirements, clearly outline your needs, including capacity, design, and any regulatory compliance. It’s advisable to ask for examples of previous custom projects to gauge the supplier’s expertise in this area. Customization may also involve additional lead times, so ensure you factor this into your project timeline. -

What are the typical minimum order quantities (MOQ) and lead times for septic tanks?

Minimum order quantities (MOQ) for septic tanks can vary significantly based on the supplier and the complexity of your order. Generally, MOQs may range from a single unit for smaller suppliers to larger quantities for industrial manufacturers. Lead times can also differ, typically ranging from a few weeks to several months, depending on the supplier’s production schedule and customization requests. It’s essential to discuss these details upfront to align your expectations and project timelines. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among septic tank suppliers, especially in international trade. Common options include upfront payments, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that protect your interests while maintaining a good relationship with the supplier. Additionally, consider the currency exchange implications and transaction fees associated with international payments. Always ensure that payment terms are clearly outlined in the contract to avoid future disputes. -

How can I ensure quality assurance and certification compliance from suppliers?

To ensure quality assurance, request documentation of certifications and compliance with international standards (such as ISO 9001). A reputable supplier should provide you with quality control processes, testing protocols, and inspection reports. Conducting an audit of the supplier’s facility can also help verify their adherence to quality standards. Additionally, consider third-party inspections for added assurance, especially for large orders or high-value contracts. -

What logistics considerations should I keep in mind when importing septic tanks?

Logistics play a critical role in the successful importation of septic tanks. Consider shipping methods (e.g., sea freight vs. air freight), customs clearance processes, and potential tariffs or taxes that may apply. It’s advisable to work with a logistics partner experienced in handling bulky items like septic tanks to navigate these complexities. Additionally, ensure that the supplier is familiar with international shipping practices and can provide necessary documentation to facilitate smooth delivery. -

How should I handle disputes with suppliers regarding product quality or delivery issues?

Disputes can arise over product quality or delivery issues, so having a clear dispute resolution process in place is essential. Start by addressing the issue directly with the supplier to seek an amicable resolution. Document all communications and keep records of agreements and contracts. If necessary, escalate the issue through formal channels, such as mediation or arbitration, as stipulated in your contract. Establishing clear expectations and communication from the outset can help minimize the likelihood of disputes. -

What are the best practices for maintaining a long-term relationship with septic tank suppliers?

Building a long-term relationship with suppliers is beneficial for ongoing projects and future sourcing needs. Maintain open lines of communication, providing feedback on product performance and service quality. Regularly review contracts and terms to adapt to changing business needs. Consider collaborating on product development or joint marketing efforts to strengthen the partnership. Recognizing and rewarding reliable suppliers can also foster loyalty and encourage better service in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for septic tanks companies

As the global demand for effective wastewater management solutions increases, the strategic sourcing of septic tanks has emerged as a critical focus for international buyers. Key takeaways include the importance of selecting suppliers who not only meet regulatory standards but also demonstrate sustainability in their manufacturing processes. Buyers should prioritize partnerships with companies that offer innovative designs and technologies, as these can enhance efficiency and reduce long-term costs.

Moreover, understanding regional market dynamics in Africa, South America, the Middle East, and Europe is essential. Each region presents unique challenges and opportunities, and leveraging local insights can significantly enhance sourcing strategies. Engaging with suppliers who have a strong local presence can lead to better support and improved logistics, ensuring timely delivery and maintenance services.

Looking ahead, the septic tank industry is poised for growth, driven by increasing environmental awareness and regulatory pressures. B2B buyers are encouraged to take proactive steps in evaluating potential suppliers, emphasizing the importance of quality, reliability, and innovation. By strategically sourcing septic tanks, companies can not only enhance their operational efficiency but also contribute to sustainable development goals in their respective markets. Embrace the opportunity to forge lasting partnerships that drive success in the evolving landscape of wastewater management.