Your Ultimate Guide to Sourcing Sewing Technology

Introduction: Navigating the Global Market for sewing technology

Across the dynamic landscape of the global textile and apparel industry, sewing technology serves as the backbone of efficient production and quality output. For international B2B buyers—from established garment manufacturers in Turkey to emerging fashion startups in Kenya—understanding and sourcing the right sewing components is essential. The intricacies of sewing machine parts and their performance directly impact production efficiency, cost management, and ultimately, the bottom line.

This guide is designed to navigate the complexities of sourcing sewing technology, providing actionable insights tailored for buyers in Africa, South America, the Middle East, and Europe. It encompasses a comprehensive overview of component types and their specific functions, offering clarity on essential and specialized parts. Insights into material selection will empower buyers to make informed choices, enhancing durability and performance tailored to local production needs.

Moreover, the guide delves into manufacturing and quality control processes, spotlighting leading production hubs and supplier reliability. It outlines effective sourcing strategies to assess global vendors and navigate cost dynamics, including price trends and total cost of ownership.

By leveraging this guide, B2B buyers can confidently identify premium suppliers, mitigate risks, and optimize procurement strategies. With a focus on practical solutions, this resource equips businesses to thrive in diverse markets, ensuring they remain competitive in an ever-evolving industry landscape.

Understanding sewing technology Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Sewing Machines | Simplicity, manual operation, basic stitching options | Small-scale garment production, DIY crafts | Low initial cost; limited functionality for advanced tasks |

| Electronic Sewing Machines | Variety of settings, greater versatility | Intermediate garment construction | Offers flexibility; may require more maintenance |

| Computerized Sewing Machines | Built-in computers, customizable settings | High-precision sewing, fashion design | High precision and automation; higher upfront investment |

| Heavy-Duty Sewing Machines | Stronger motors, designed for thick materials | Upholstery, leather goods manufacturing | Durable and powerful; may be overkill for lighter fabrics |

| Embroidery Sewing Machines | Specialized for embroidery, detailed designs | Custom apparel, promotional items | Ideal for small businesses; limited to embroidery tasks only |

Mechanical Sewing Machines

Mechanical sewing machines are known for their simplicity and reliability, making them a popular choice for beginners and small-scale operations. They typically operate manually and offer basic stitching options like straight and zig-zag stitches. For B2B buyers, these machines are cost-effective and require minimal maintenance. However, their limited functionality may hinder more advanced sewing tasks, which could be a consideration for businesses looking to expand their capabilities.

Electronic Sewing Machines

Electronic sewing machines provide a range of settings and features that enhance versatility compared to mechanical machines. They are suitable for intermediate users and can handle a variety of sewing tasks, from garment construction to crafting. Buyers should consider the machine’s ease of use and the availability of spare parts. While these machines offer more flexibility, they may also require more frequent maintenance, which can impact operational efficiency.

Computerized Sewing Machines

Computerized sewing machines are designed for advanced users and professionals who demand high precision and a wide range of options. These machines come equipped with built-in computers that allow users to select from various stitch patterns and save custom settings. For B2B buyers, the investment in computerized machines can significantly enhance productivity and creativity. However, the higher upfront cost and potential need for technical support should be factored into purchasing decisions.

Heavy-Duty Sewing Machines

Heavy-duty sewing machines are built to handle thicker materials, such as leather and canvas, making them ideal for upholstery and leather goods manufacturing. They feature stronger motors and durable components, ensuring longevity even under frequent use. B2B buyers should assess their specific fabric needs and consider the machine’s capabilities to avoid over-investing in unnecessary features for lighter materials. While these machines offer robust performance, they may be more expensive than standard models.

Embroidery Sewing Machines

Embroidery sewing machines are specialized for creating detailed designs and patterns, making them popular among businesses focused on custom apparel and promotional items. These machines are ideal for small businesses and home-based entrepreneurs. When considering an embroidery machine, buyers should evaluate the software compatibility and the range of design features available. However, they are limited to embroidery tasks, which could restrict versatility in broader sewing operations.

Related Video: 4 Basic Sewing Machine SEAMS and SEAM ALLOWANCES

Key Industrial Applications of sewing technology

| Industry/Sector | Specific Application of Sewing Technology | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel & Fashion | Garment Manufacturing | High-speed production, custom designs, and reduced labor costs | Compatibility with fabric types and machine models |

| Upholstery & Furniture | Upholstery Production | Durable finishes, aesthetic appeal, and customization options | Sourcing quality materials and specialized sewing machines |

| Automotive | Automotive Interiors | Enhanced comfort, durability, and compliance with safety standards | Supplier reliability and material specifications |

| Technical Textiles | Manufacturing of Protective Gear | Improved safety and performance in hazardous conditions | Compliance with industry standards and material sourcing |

| Medical Textiles | Production of Surgical and Healthcare Textiles | High hygiene standards, comfort, and durability | Quality control and certification of materials |

Apparel & Fashion

Sewing technology plays a pivotal role in the apparel and fashion industry, where it is employed for mass garment production. This application allows manufacturers to produce high volumes of clothing with intricate designs efficiently. International B2B buyers must ensure that the sewing machines and parts they source are compatible with various fabric types to maintain quality standards. Additionally, considering the speed of production and labor costs is essential, especially for buyers in competitive markets like Africa and South America, where rapid turnaround times can significantly impact profitability.

Upholstery & Furniture

In the upholstery and furniture sector, sewing technology is utilized to create durable and aesthetically pleasing products. This involves the stitching of various materials, including leather and heavy fabrics, to produce furniture coverings, cushions, and other decorative elements. B2B buyers should focus on sourcing quality materials and specialized sewing machines capable of handling robust textiles. As this industry often requires custom solutions, understanding the specific needs of clients and the potential for customization is crucial for maintaining a competitive edge.

Illustrative Image (Source: Google Search)

Automotive

The automotive industry leverages sewing technology primarily for the production of vehicle interiors, including seats, dashboards, and upholstery. This application is vital for enhancing comfort and ensuring compliance with safety standards. B2B buyers in this sector must prioritize supplier reliability and the sourcing of materials that meet rigorous industry specifications. Given the increasing demand for customized interiors, suppliers should be prepared to offer innovative solutions that align with evolving consumer preferences in Europe and the Middle East.

Technical Textiles

Sewing technology is essential in the production of technical textiles, particularly for protective gear used in various industries, including construction and manufacturing. These textiles are engineered to provide safety and performance in hazardous conditions. Buyers must ensure that their sourcing strategies comply with industry standards and regulations, focusing on materials that offer durability and protection. This is especially relevant for buyers in regions with stringent safety requirements, such as Europe and the Middle East.

Medical Textiles

In the medical sector, sewing technology is utilized to manufacture surgical gowns, drapes, and other healthcare textiles that require high hygiene standards. The precision and quality of the stitching are critical to ensure durability and comfort for patients and healthcare professionals alike. B2B buyers in this field must emphasize quality control and the certification of materials to ensure compliance with health regulations. This is particularly important in regions where healthcare standards are closely monitored, such as Europe and South America.

Related Video: How To: Use an Industrial Sewing Machine

Strategic Material Selection Guide for sewing technology

In the realm of sewing technology, the selection of materials is crucial for ensuring optimal performance and durability of sewing components. This analysis focuses on four common materials used in sewing technology, providing insights into their properties, advantages, disadvantages, and implications for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe.

1. Steel

Key Properties: Steel is renowned for its high tensile strength and durability, making it suitable for heavy-duty applications. It exhibits excellent resistance to wear and can withstand high temperatures, which is essential for industrial sewing operations.

Pros & Cons:

– Advantages: Steel components, such as needles and presser feet, offer longevity and reliability. They are less prone to bending or breaking under stress, which enhances production efficiency.

– Disadvantages: The primary drawback is susceptibility to corrosion if not properly treated or coated. Additionally, steel can be more expensive than alternative materials like plastic, impacting overall cost.

Impact on Application: Steel is compatible with a wide range of fabrics, including heavy materials like denim and leather. Its strength ensures consistent performance across various sewing tasks.

Considerations for International Buyers: Buyers should ensure compliance with local and international standards, such as ASTM for material properties. Corrosion-resistant coatings may be necessary in humid climates, prevalent in many regions of Africa and South America.

2. Aluminum

Key Properties: Aluminum is lightweight yet strong, offering good corrosion resistance and thermal conductivity. It is often used in machine frames and components that require a balance of strength and weight.

Pros & Cons:

– Advantages: The lightweight nature of aluminum reduces the overall weight of sewing machines, making them easier to handle and transport. Its resistance to rust makes it suitable for various environments.

– Disadvantages: While aluminum is durable, it is softer than steel, making it more prone to deformation under excessive stress. This can lead to reduced precision over time.

Impact on Application: Aluminum components are ideal for applications requiring mobility and ease of use, such as portable sewing machines. However, they may not be suitable for heavy-duty industrial applications where strength is paramount.

Considerations for International Buyers: Buyers should look for aluminum alloys that meet specific strength requirements and ensure that suppliers adhere to relevant manufacturing standards. In regions with high humidity, the choice of anodized aluminum can enhance corrosion resistance.

3. Plastic

Key Properties: Plastics are versatile materials used in various sewing machine components, including bobbins and presser feet. They are lightweight, resistant to corrosion, and can be molded into complex shapes.

Pros & Cons:

– Advantages: The primary benefit of plastic is its cost-effectiveness and ease of manufacturing. It allows for intricate designs and can be produced in large quantities at a lower price.

– Disadvantages: Plastics may not withstand high temperatures or heavy loads as effectively as metals, leading to potential wear and tear over time. Additionally, they can be less durable in rigorous industrial settings.

Impact on Application: Plastic components are suitable for lightweight and medium-duty applications, such as home sewing machines. However, they may not be ideal for heavy-duty industrial sewing tasks.

Considerations for International Buyers: Buyers should verify the type of plastic used, ensuring it meets industry standards for durability and heat resistance. Compliance with environmental regulations regarding plastic use is also crucial in many regions.

4. Composite Materials

Key Properties: Composite materials, often made from a combination of plastics and fibers, offer enhanced strength and flexibility. They are increasingly used in advanced sewing machine components.

Pros & Cons:

– Advantages: Composites provide a good balance of weight, strength, and resistance to environmental factors. They can be engineered to meet specific performance criteria, making them suitable for various applications.

– Disadvantages: The complexity of manufacturing composite materials can lead to higher costs. Additionally, not all composites are equally durable, so careful selection is necessary.

Impact on Application: Composites are ideal for applications requiring lightweight yet strong components, such as in high-speed sewing machines. They can also provide better shock absorption.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant standards for strength and durability. Understanding the specific composition and manufacturing processes is essential to avoid quality issues.

Summary Table

| Material | Typical Use Case for sewing technology | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Needles, presser feet | High durability and strength | Prone to corrosion without treatment | High |

| Aluminum | Machine frames, lightweight components | Lightweight and corrosion-resistant | Softer and prone to deformation | Medium |

| Plastic | Bobbins, presser feet | Cost-effective and easy to manufacture | Less durable under heavy loads | Low |

| Composite Materials | Advanced machine components | Good balance of strength and weight | Higher manufacturing complexity | Medium |

By understanding these materials and their implications, international B2B buyers can make informed decisions that enhance their sourcing strategies and optimize their manufacturing processes.

In-depth Look: Manufacturing Processes and Quality Assurance for sewing technology

The manufacturing processes and quality assurance (QA) practices for sewing technology are critical to ensuring that sewing machines and their parts meet the high standards demanded by international B2B buyers. Understanding these processes can help buyers from Africa, South America, the Middle East, and Europe make informed sourcing decisions. This section provides a comprehensive overview of the key manufacturing stages, quality control measures, and actionable insights for verifying supplier capabilities.

Manufacturing Processes

The manufacturing of sewing machines and their components typically involves several key stages, each crucial for ensuring the final product’s quality and performance.

1. Material Preparation

The first stage involves sourcing and preparing the materials required for production. Common materials include metals (for frames and components), plastics (for covers and certain parts), and textiles (for testing).

- Material Selection: B2B buyers should prioritize suppliers that use high-quality materials, as this directly affects durability and performance.

- Supplier Transparency: Request information about material origins and certifications to ensure compliance with international standards.

2. Forming

In this stage, raw materials are shaped into components using various techniques, including:

- Casting: Used for producing complex shapes in metal parts.

- Machining: Involves cutting, drilling, or milling metal to achieve precise dimensions.

- Injection Molding: Common for plastic parts, where molten plastic is injected into molds to create specific shapes.

Key Techniques:

- CNC Machining: This computer-controlled process ensures high precision in manufacturing components, essential for sewing machine parts that require exact fitting.

- Stamping and Forging: These methods are often used for creating durable metal components, ensuring strength and longevity.

3. Assembly

Once components are formed, they are assembled into the final product. This stage may involve:

- Manual Assembly: Skilled technicians assemble machines, ensuring that each part fits correctly.

- Automated Assembly Lines: Increasingly common, these lines enhance efficiency and consistency.

Considerations for B2B Buyers:

- Assembly Quality: Verify if the assembly process includes checks for alignment and functionality.

- Customization Options: Buyers should inquire about the ability to customize machines according to specific needs.

4. Finishing

The final manufacturing stage involves finishing processes that enhance the product’s appearance and functionality, including:

- Surface Treatment: Coating or painting to prevent corrosion and improve aesthetics.

- Quality Check: Final inspections for defects and overall functionality.

Actionable Insights:

- Certifications: Look for suppliers that adhere to environmental and safety standards, such as ISO 14001, which demonstrates commitment to sustainable practices.

Quality Assurance (QA)

Quality assurance is critical in the sewing technology manufacturing process, ensuring that products meet defined standards and specifications.

International Standards

To ensure quality, manufacturers often comply with international standards, including:

- ISO 9001: A widely recognized standard for quality management systems, ensuring consistent product quality and customer satisfaction.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards, essential for products sold in Europe.

Industry-Specific Standards:

- API: Relevant for manufacturers producing components for specialized applications, ensuring they meet industry-specific requirements.

Quality Control Checkpoints

Quality control is implemented at various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during production to identify and rectify issues early.

- Final Quality Control (FQC): Comprehensive testing and inspection of finished products before shipment.

Common Testing Methods:

- Functional Testing: Ensures machines operate correctly under expected conditions.

- Durability Testing: Assesses longevity and performance under stress.

- Safety Testing: Confirms that products meet safety standards, minimizing risks for end-users.

Verifying Supplier Quality Control

International B2B buyers should take proactive steps to verify the quality control measures of potential suppliers:

- Supplier Audits: Conduct on-site audits to evaluate manufacturing processes, quality control systems, and overall operational integrity.

- Quality Reports: Request detailed QC reports, including results from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Engage independent inspection agencies to conduct evaluations and ensure compliance with agreed standards.

QC and Certification Nuances for International Buyers

When sourcing sewing technology from global suppliers, buyers must be aware of specific QC and certification nuances:

- Regional Regulations: Understand the regulatory requirements of the target market, as they can differ significantly across regions (e.g., CE for Europe versus local standards in Africa or South America).

- Documentation: Ensure that suppliers provide adequate documentation of certifications and quality processes, facilitating smoother customs clearance and compliance.

Strategic Recommendations:

- Build Relationships: Establish strong relationships with suppliers to foster transparency and collaboration on quality issues.

- Leverage Technology: Utilize digital platforms for real-time tracking of production status and quality metrics, enhancing communication and oversight.

By understanding the manufacturing processes and quality assurance measures in sewing technology, international B2B buyers can make informed sourcing decisions, ensuring they procure high-quality products that meet their operational needs.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for sewing technology Sourcing

Navigating the cost structure and pricing dynamics in the sewing technology sector is essential for international B2B buyers. Understanding the various components that contribute to the total cost of ownership (TCO) will empower buyers to make informed decisions, particularly in diverse regions like Africa, South America, the Middle East, and Europe.

Cost Components of Sewing Technology

-

Materials: The type of materials used for sewing machines and parts, such as metals, plastics, and textiles, significantly affects pricing. High-quality materials typically lead to higher costs but also enhance durability and performance.

-

Labor: Labor costs vary across regions, impacting the overall manufacturing expenses. Regions with higher wages will see increased costs, while those with lower labor costs can offer more competitive pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these overheads, affecting the final price.

-

Tooling: The cost of tooling, which includes molds and machines used for production, is a significant upfront investment. Custom tooling can lead to higher initial costs but may provide cost savings in the long run through increased production efficiency.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specified standards, which can add to the overall cost. However, investing in quality reduces the risk of defects, returns, and customer dissatisfaction.

-

Logistics: Shipping and transportation costs can vary widely depending on the origin and destination of the goods. Factors like distance, freight method, and the complexity of logistics networks can influence these costs.

Illustrative Image (Source: Google Search)

- Margin: Supplier margins depend on market positioning and competitiveness. Buyers should be aware of the typical margins in their specific market to negotiate effectively.

Price Influencers

Several factors impact the pricing strategy in sewing technology:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk discounts. Buyers should assess their needs against MOQ requirements to optimize costs.

-

Specifications/Customization: Customized products typically incur higher costs due to the complexities involved in production. Buyers should weigh the benefits of customization against the associated costs.

-

Materials: The choice of materials can significantly influence prices. Buyers should evaluate trade-offs between cost and quality.

-

Quality and Certifications: Products that meet international quality standards or certifications may come at a premium. However, these certifications can enhance trust and marketability.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may command higher prices but offer better quality assurance and service.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs and responsibilities. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the overall cost structure.

Buyer Tips for Cost Efficiency

-

Negotiation: Engage in thorough negotiations to secure favorable terms. Understanding the cost structure allows buyers to identify areas for potential savings.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, which includes maintenance, operation, and disposal costs. A lower initial cost may lead to higher long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and trade regulations that can affect pricing. Buyers from Africa, South America, the Middle East, and Europe should factor these variables into their sourcing strategy.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield benefits such as priority service and lower costs.

-

Market Research: Stay informed about market trends and pricing benchmarks. This knowledge can aid in making competitive offers and understanding market dynamics.

Disclaimer

Prices in this analysis are indicative and can vary based on market conditions, supplier policies, and regional factors. Always conduct thorough due diligence and consult multiple sources before finalizing any procurement decisions.

Spotlight on Potential sewing technology Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘sewing technology’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for sewing technology

Understanding the technical properties and trade terminology in sewing technology is essential for international B2B buyers looking to optimize their procurement processes. Here’s an overview of critical specifications and common industry jargon that can enhance decision-making and supplier negotiations.

Key Technical Properties

-

Material Grade

– Definition: Material grade refers to the classification of the materials used in sewing machine components, such as metals and plastics, based on their mechanical and physical properties.

– B2B Importance: Selecting the right material grade ensures durability and functionality. For instance, using high-grade steel for needle manufacturing can significantly reduce breakage rates, enhancing production efficiency. -

Tolerance

– Definition: Tolerance is the allowable variation in dimensions of machine parts. It defines the acceptable limits of size and shape deviations.

– B2B Importance: Precise tolerances are crucial for component compatibility and machine performance. Poor tolerance can lead to misalignment, increased wear, and ultimately, costly machine downtime. -

Stitch Density

– Definition: Stitch density indicates the number of stitches per unit length (e.g., stitches per inch) used in sewing.

– B2B Importance: Higher stitch density typically results in stronger seams, which is vital for the durability of finished products. Buyers need to ensure that suppliers can provide the required stitch density to meet their product specifications. -

Speed Rating

– Definition: Speed rating refers to the maximum sewing speed of a machine, often measured in stitches per minute (SPM).

– B2B Importance: Understanding the speed rating helps buyers select machines that align with production targets. Higher speed ratings can lead to increased output but may require careful consideration of the type of fabric being processed. -

Power Consumption

– Definition: This refers to the amount of electrical energy a sewing machine uses during operation, typically measured in watts.

– B2B Importance: Buyers should consider power consumption for cost management and sustainability. Machines with lower power consumption can lead to significant savings in electricity bills, especially in high-volume production environments.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer under its brand name.

– Relevance: Understanding OEM relationships is crucial for buyers to ensure they are sourcing genuine parts that meet quality standards and are compatible with existing machinery. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is essential for budgeting and inventory management. Buyers must balance the need for stock with the financial implications of ordering in bulk.

-

RFQ (Request for Quotation)

– Definition: An RFQ is a formal document issued by buyers to solicit price bids from suppliers for specific products or services.

– Relevance: Crafting a comprehensive RFQ can lead to better pricing and terms. Buyers should clearly outline specifications to receive accurate quotations. -

Incoterms

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the transportation of goods.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, aiding in smoother international transactions. -

Lead Time

– Definition: Lead time is the period between the initiation of an order and its completion, including manufacturing and shipping.

– Relevance: Buyers must be aware of lead times to plan their production schedules effectively and avoid disruptions in supply chains.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, streamline their sourcing processes, and enhance their competitive edge in the global sewing technology market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the sewing technology Sector

In the ever-evolving landscape of sewing technology, understanding market dynamics and sourcing trends is crucial for international B2B buyers. The global market for sewing machines and accessories is primarily driven by the booming textile and apparel industries, with a notable shift toward automation and digitalization. As of 2023, the industrial segment holds approximately 70% of the market share, showcasing the increasing demand for efficient production capabilities. Buyers from Africa, South America, the Middle East, and Europe must stay attuned to several key trends shaping the industry.

Market Overview & Key Trends

-

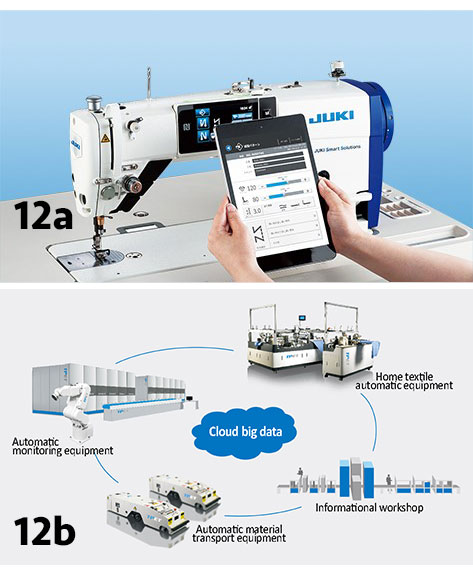

Automation and Smart Technologies: The integration of IoT technology and automation in sewing machines is gaining momentum. Smart machines equipped with sensors can optimize stitching processes, reducing errors and maintenance downtime. This trend is particularly beneficial for manufacturers looking to enhance productivity while minimizing labor costs.

-

Sustainability Focus: There is a growing emphasis on sustainable practices across the textile supply chain. B2B buyers are increasingly seeking suppliers who prioritize eco-friendly materials and manufacturing processes. This shift is driven by consumer demand for sustainable products and regulatory pressures in various regions.

-

Global Supply Chain Diversification: Recent disruptions have prompted buyers to diversify their supplier networks. Establishing relationships with multiple suppliers across different regions can mitigate risks associated with geopolitical tensions and logistical challenges. Buyers from emerging markets should consider local suppliers to reduce lead times and costs.

-

Customization and Flexibility: The demand for customized sewing solutions is on the rise, particularly in niche markets. Buyers should look for suppliers who offer modular and flexible manufacturing capabilities, allowing for quick adjustments to meet changing market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere trend; it has become a fundamental expectation in the sewing technology sector. The environmental impact of textile production is significant, with water usage, energy consumption, and waste generation at the forefront of concerns. International B2B buyers should prioritize partnerships with suppliers who demonstrate a commitment to sustainability through ethical sourcing practices.

-

Eco-friendly Certifications: Look for suppliers with recognized certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which signify compliance with environmental and social standards. These certifications help ensure that materials used in sewing technology are sourced sustainably.

-

Innovative Materials: The adoption of recycled and biodegradable materials is gaining traction. Buyers should explore options like recycled polyester and organic cotton, which can significantly reduce the carbon footprint of production.

-

Transparency in Supply Chains: Engaging with suppliers who provide transparent supply chains allows B2B buyers to assess the environmental and social impacts of their sourcing decisions. This transparency fosters trust and aligns with the growing consumer demand for ethical practices.

Brief Evolution/History

The sewing technology sector has undergone significant transformations since its inception. Initially dominated by manual techniques, the industry saw the advent of the sewing machine in the 19th century, revolutionizing garment production. The introduction of electric machines in the 20th century further enhanced efficiency, paving the way for the industrialization of textile manufacturing. In recent years, technological advancements such as computerized sewing machines and automated production lines have reshaped the landscape, allowing for greater precision and scalability. Understanding this evolution is essential for B2B buyers as they navigate the complexities of sourcing and production in today’s market.

By leveraging these insights, international buyers can make informed decisions that not only enhance their operational efficiency but also align with the growing demand for sustainability and ethical practices in the sewing technology sector.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of sewing technology

-

How can I effectively vet suppliers for sewing technology?

To vet suppliers, start by researching their background, including years in business, reputation, and customer reviews. Utilize platforms such as Alibaba or Global Sources for verified supplier lists. Request references from other buyers and check for industry certifications (like ISO 9001). Conduct factory visits, if possible, to assess operational capabilities and quality control processes. Engaging a local agent familiar with the region can also provide valuable insights into supplier reliability. -

What customization options should I consider when sourcing sewing machines?

When sourcing sewing machines, inquire about customization options such as machine specifications, additional features, and branding. Determine if the supplier can accommodate your specific requirements, including stitch patterns or attachments suited to your production needs. Discuss lead times for customized orders and ensure that the supplier has a history of delivering tailored solutions. Understanding their capacity to adapt to your needs can enhance operational efficiency. -

What are typical minimum order quantities (MOQs) and lead times in the sewing technology sector?

MOQs can vary significantly based on the supplier and the type of sewing technology. For industrial machines, MOQs typically range from 10 to 50 units. Lead times can be influenced by customization and supplier location, often ranging from 4 to 12 weeks. Always clarify these terms before proceeding with an order to avoid disruptions in your supply chain. Consider negotiating flexible MOQs or lead times based on your purchasing patterns to optimize inventory management. -

What quality assurance (QA) certifications should I look for when sourcing sewing technology?

Key certifications to look for include ISO 9001 for quality management systems and CE marking, which indicates compliance with EU safety standards. Additionally, specific industry certifications, such as those from the International Organization for Standardization (ISO) related to machinery safety, can be beneficial. Request documentation from suppliers to verify their QA processes and ensure that their products meet international quality standards, thus reducing the risk of defects. -

How should I approach payment terms when sourcing sewing technology internationally?

When negotiating payment terms, consider using secure methods like letters of credit or escrow services to protect your investment. It’s common to pay a deposit (20-30%) upfront, with the balance due upon shipment. Be cautious of suppliers demanding full payment in advance, especially if they are new or unverified. Understanding the currency fluctuations and potential transaction fees is crucial when dealing with international suppliers, so factor these into your overall cost analysis. -

What logistics considerations are important when importing sewing machines?

Logistics plays a critical role in the timely delivery of sewing machines. Assess shipping methods (air vs. sea) based on cost, urgency, and volume. Ensure that your suppliers provide clear shipping terms, including Incoterms, which define responsibilities for shipping, insurance, and tariffs. Additionally, consider working with a freight forwarder who can navigate customs regulations and provide visibility throughout the shipping process, minimizing delays and unexpected costs. -

How can I resolve disputes with suppliers effectively?

To resolve disputes with suppliers, maintain clear communication and document all agreements and correspondence. If issues arise, attempt to discuss them directly with the supplier to seek an amicable solution. If necessary, refer to the terms outlined in your contract, including any arbitration clauses. Engaging a mediator can be helpful for complex disputes. Establishing a strong relationship with your suppliers can also facilitate smoother resolutions and foster long-term partnerships. -

What factors should I consider for after-sales support and service?

After-sales support is crucial for maintaining operational efficiency. Inquire about warranty terms, the availability of spare parts, and the supplier’s response time for service requests. Check if they offer technical support, training, or maintenance services. A reliable supplier will provide comprehensive support to minimize downtime and ensure that your equipment operates at peak efficiency. Assessing these factors upfront can save costs and ensure a smoother operational flow in your production processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for sewing technology

The importance of strategic sourcing in the sewing technology sector cannot be overstated. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing sewing machine parts and accessories is vital for operational success. Key takeaways include prioritizing supplier reliability, ensuring compatibility of components, and evaluating total cost of ownership to mitigate risks associated with procurement.

By leveraging comprehensive sourcing strategies, buyers can enhance production efficiency, minimize downtime, and ultimately improve product quality. The growing trend towards automation, IoT integration, and sustainable practices in the sewing industry further underscores the need for a forward-thinking approach to procurement.

As the market continues to evolve, now is the time for B2B buyers to invest in building strong supplier relationships and staying informed about technological advancements. Embrace the potential of strategic sourcing to not only meet current production demands but also to position your business for future growth. Engage with trusted suppliers, explore innovative technologies, and ensure your operations are resilient and competitive in this dynamic landscape.