Your Ultimate Guide to Sourcing Shaft Coupling

Introduction: Navigating the Global Market for shaft coupling

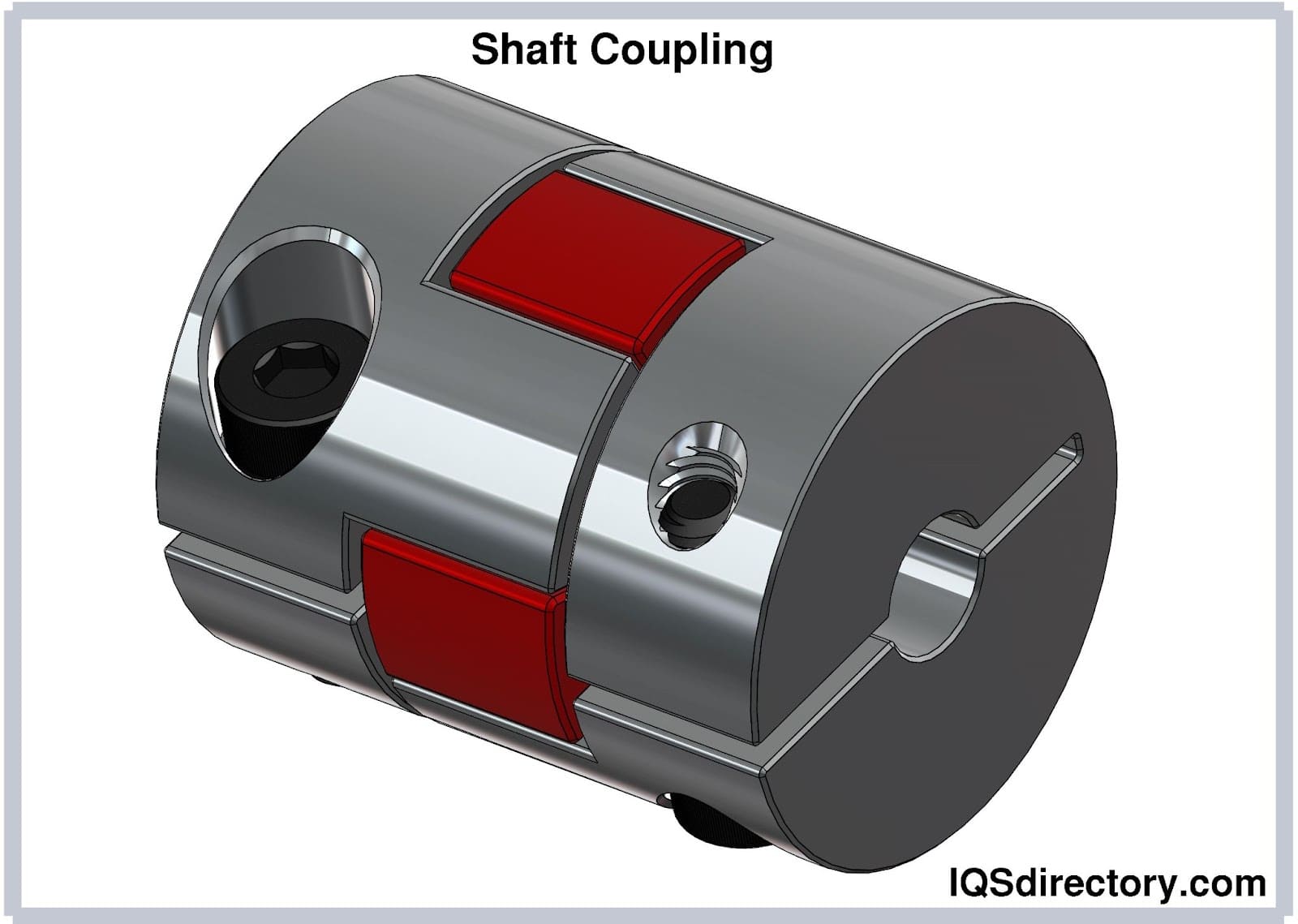

Navigating the global market for shaft coupling is essential for businesses aiming to enhance operational efficiency and ensure machinery reliability. As a critical component in various industrial applications, shaft couplings facilitate the connection between shafts, allowing for effective power transmission while compensating for misalignment and reducing vibration. The increasing demand for high-performance machinery across sectors such as manufacturing, automotive, and energy makes understanding the nuances of shaft couplings vital for B2B buyers.

This comprehensive guide provides international buyers from Africa, South America, the Middle East, and Europe with actionable insights into the shaft coupling market. It covers a wide array of topics, including the different types of shaft couplings, the materials used in their construction, and the manufacturing and quality control processes that ensure product reliability. Additionally, we will explore the supplier landscape, helping you identify reputable manufacturers and distributors, while also addressing cost considerations and the latest market trends that can influence pricing strategies.

By answering frequently asked questions and offering strategic sourcing tips, this guide empowers B2B buyers to make informed decisions tailored to their specific needs. Whether you are sourcing for a large-scale industrial project or a niche application, understanding the complexities of shaft couplings will significantly enhance your procurement strategy and strengthen your supply chain management.

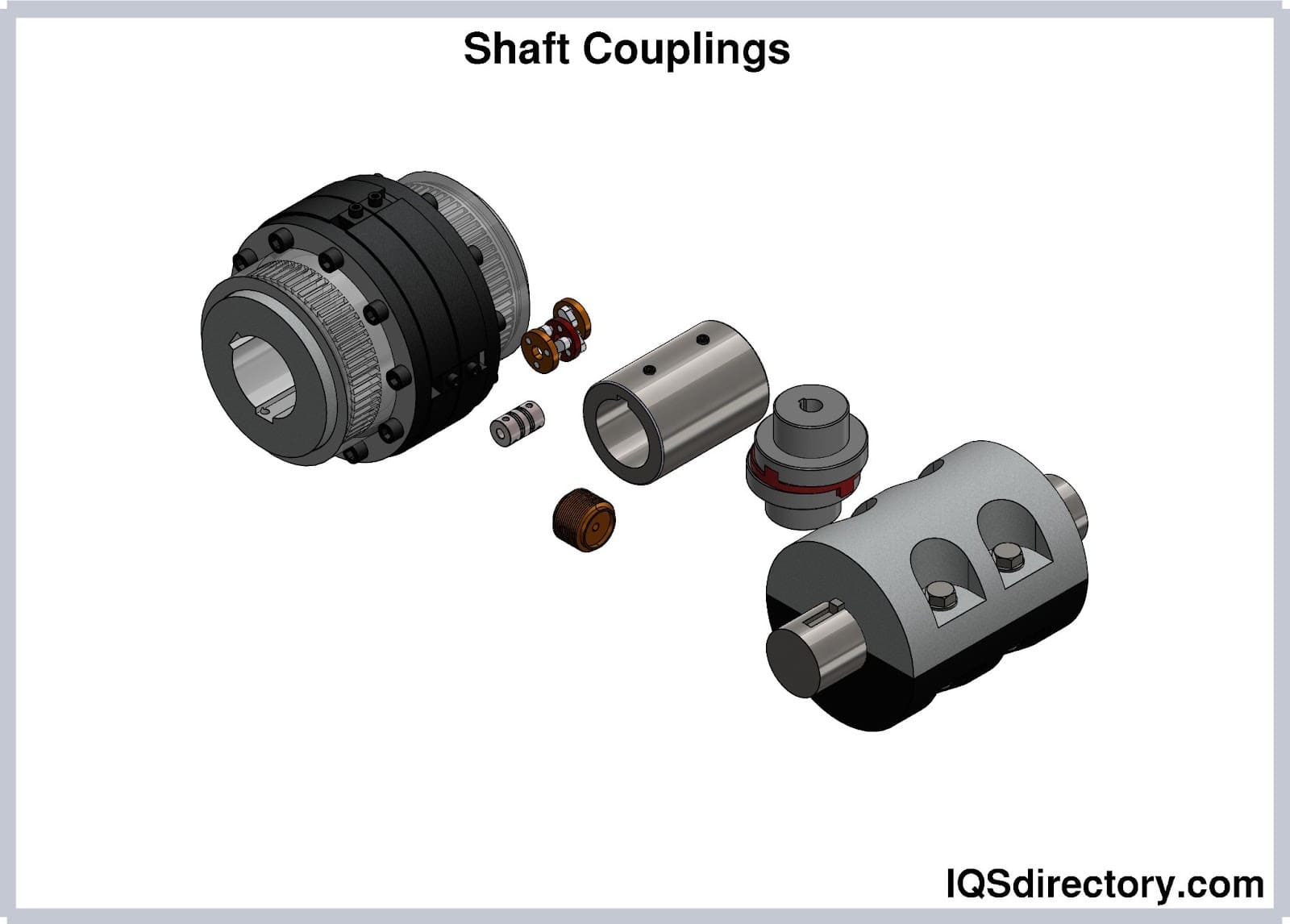

Understanding shaft coupling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigid Couplings | Solid construction, no flexibility | Precision machinery, automotive | Pros: High torque transmission; Cons: No misalignment compensation. |

| Flexible Couplings | Allow for some misalignment; made from elastic materials | Pumps, compressors, and conveyors | Pros: Compensates for misalignment; Cons: Limited torque capacity. |

| Oldham Couplings | Features a sliding block mechanism for alignment | Robotics, precision equipment | Pros: Good for angular misalignment; Cons: Wear over time can lead to failure. |

| Chain Couplings | Utilizes chains and sprockets for power transmission | Heavy machinery, industrial motors | Pros: High load capacity; Cons: Requires regular maintenance. |

| Gear Couplings | Interlocking gears for torque transmission | High-torque applications | Pros: High efficiency; Cons: More expensive; complex installation. |

Rigid Couplings

Rigid couplings are designed to connect two shafts without any allowance for misalignment. They provide a solid connection, making them ideal for applications requiring precise alignment, such as in precision machinery and automotive systems. When purchasing rigid couplings, buyers should consider the material quality, torque ratings, and compatibility with existing systems. The primary drawback is their inability to accommodate any misalignment, which can lead to increased wear or failure in misaligned setups.

Flexible Couplings

Flexible couplings are engineered to accommodate some degree of misalignment between shafts. Made from elastic materials, they are commonly used in applications such as pumps, compressors, and conveyors. These couplings are particularly valuable for reducing vibrations and shocks in machinery. Buyers should evaluate the coupling’s flexibility range, torque capacity, and material durability to ensure it meets operational requirements. However, they may have limitations in high-torque applications due to their construction.

Oldham Couplings

Oldham couplings feature a unique sliding block mechanism that allows for angular misalignment, making them suitable for robotics and precision equipment. Their design minimizes backlash and enhances the precision of motion transmission. When sourcing Oldham couplings, buyers should assess the material used for the sliding block, as wear can affect performance over time. While they excel in applications requiring angular compensation, their longevity may be a concern if not monitored.

Chain Couplings

Chain couplings employ chains and sprockets to facilitate power transmission, making them ideal for heavy machinery and industrial motors. They offer high load capacity and are particularly effective in high-torque environments. Buyers should consider the maintenance requirements, as regular inspection and lubrication are necessary to ensure optimal performance. The primary downside is the need for consistent upkeep to prevent wear and potential failure.

Gear Couplings

Gear couplings utilize interlocking gears to transmit torque efficiently, making them suitable for high-torque applications. They are known for their high efficiency and ability to handle significant loads. Buyers should focus on the coupling’s design complexity, installation requirements, and overall cost. While they offer superior performance, gear couplings can be more expensive and may require specialized installation, which could be a consideration for budget-conscious buyers.

Related Video: Shaft Coupling | Types of Coupling | Rigid Coupling & Flexible Coupling | Flange, Muff, Universal

Key Industrial Applications of shaft coupling

| Industry/Sector | Specific Application of shaft coupling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Connecting motors to pumps and compressors | Ensures smooth power transmission, reducing downtime | Material quality, compatibility with existing equipment, supplier reliability |

| Oil & Gas | Coupling in drilling rigs and pipelines | Enhances operational efficiency and safety | Compliance with industry standards, durability against harsh conditions |

| Mining | Drive systems for conveyors and crushers | Increases productivity and minimizes maintenance | Availability of specialized designs, local support services |

| Agriculture | Linkages in tractors and harvesting machines | Improves machinery performance and reliability | Access to spare parts, adaptability to various machinery types |

| Renewable Energy | Wind turbine rotor connections | Maximizes energy efficiency and operational uptime | Supplier certifications, technology compatibility, and warranty terms |

Manufacturing Applications

In the manufacturing sector, shaft couplings are critical for connecting motors to pumps and compressors. They facilitate smooth power transmission, which is essential for maintaining operational efficiency and minimizing downtime. International buyers should prioritize sourcing couplings that meet specific material and compatibility standards, ensuring they can seamlessly integrate with existing equipment. Additionally, reliable suppliers who can provide consistent quality are crucial, especially in regions where access to high-quality components may be limited.

Oil & Gas Sector

In the oil and gas industry, shaft couplings are vital components in drilling rigs and pipeline systems. They help to enhance operational efficiency and safety by ensuring robust connections between rotating elements. Buyers in this sector need to focus on sourcing couplings that comply with stringent industry standards, particularly regarding durability and performance under extreme conditions. It’s essential to partner with suppliers who have a proven track record in the industry, as this can significantly impact safety and operational continuity.

Mining Applications

Shaft couplings are extensively used in mining for drive systems in conveyors and crushers. They play a crucial role in increasing productivity and minimizing maintenance costs by providing reliable connections that withstand harsh operational environments. Buyers should look for specialized designs that cater to the unique demands of mining equipment. Additionally, having access to local support services can be a significant advantage in ensuring timely maintenance and replacement, particularly in remote mining locations.

Agricultural Machinery

In agriculture, shaft couplings are integral to the operation of tractors and harvesting machines, linking various components for efficient performance. They improve machinery reliability, which is vital for maximizing productivity during critical harvesting periods. B2B buyers should ensure they have access to spare parts and consider the adaptability of couplings to different types of machinery. Sourcing from local suppliers who understand the agricultural landscape can also enhance service delivery and support.

Renewable Energy Sector

Shaft couplings are essential in renewable energy applications, particularly in wind turbines where they connect rotor assemblies. They maximize energy efficiency and ensure operational uptime, which is critical for the profitability of renewable energy projects. Buyers should prioritize suppliers with the necessary certifications and experience in renewable technologies. Compatibility with existing systems and robust warranty terms are also key considerations for international B2B buyers looking to invest in this growing sector.

Related Video: Types of Shaft Coupling, Animation, Machine Design | Solidworks

Strategic Material Selection Guide for shaft coupling

When selecting materials for shaft couplings, international B2B buyers must consider various factors that influence performance, durability, and cost. Below is an analysis of four common materials used in shaft coupling applications, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

Steel

Key Properties:

Steel is renowned for its high tensile strength and durability, making it suitable for high-pressure applications. It typically has a temperature rating of up to 300°C and offers good corrosion resistance when treated.

Pros & Cons:

Steel couplings are highly durable and can withstand significant mechanical stress. However, they can be heavier than alternatives, which may affect installation and operational efficiency. Additionally, while the initial cost is moderate, the need for protective coatings to enhance corrosion resistance can increase overall expenses.

Impact on Application:

Steel is compatible with various media, including oil and water, making it versatile for industrial applications. Its robustness makes it ideal for heavy machinery and automotive uses.

Considerations for Buyers:

Buyers should ensure compliance with international standards like ASTM or DIN. In regions with high humidity or corrosive environments, additional protective measures may be necessary.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a typical temperature rating of around 150°C. It is less dense than steel, making it easier to handle and install.

Pros & Cons:

The main advantage of aluminum couplings is their lightweight nature, which reduces the load on connected components. However, they are not as strong as steel, making them less suitable for high-torque applications. Additionally, aluminum can be more expensive than steel, depending on the alloy used.

Impact on Application:

Aluminum is particularly effective in applications where weight reduction is critical, such as in aerospace or automotive sectors. Its corrosion resistance makes it suitable for marine environments.

Considerations for Buyers:

Buyers should verify that aluminum couplings meet relevant standards, especially in regions with stringent regulations. The choice of alloy can significantly impact performance, so understanding local availability and pricing is crucial.

Plastic (Polymer)

Key Properties:

Plastic couplings, often made from materials like nylon or polycarbonate, offer excellent chemical resistance and can handle temperatures up to 100°C. They are non-corrosive and lightweight.

Pros & Cons:

The primary advantage of plastic couplings is their resistance to corrosion and chemicals, making them suitable for harsh environments. However, they have lower mechanical strength compared to metals, limiting their use in high-stress applications. They are also less durable in high-temperature scenarios.

Impact on Application:

Plastic couplings are ideal for applications involving corrosive media or where weight is a significant concern. They are commonly used in food processing and chemical industries.

Considerations for Buyers:

International buyers must ensure that the selected plastic materials comply with food safety regulations (if applicable) and other relevant standards. Understanding the specific chemical compatibility is essential for ensuring long-term performance.

Composite Materials

Key Properties:

Composite couplings, often made from reinforced plastics or fiber-reinforced polymers, combine lightweight properties with enhanced strength and temperature resistance, typically rated up to 200°C.

Pros & Cons:

The main advantage of composite materials is their ability to resist fatigue and wear while being lightweight. However, they can be more expensive to manufacture and may require specialized suppliers, complicating the sourcing process.

Impact on Application:

Composite couplings are suitable for high-performance applications, including aerospace and high-speed machinery, where weight and strength are critical.

Considerations for Buyers:

Buyers should investigate the specific properties of the composite materials used, as these can vary significantly. Ensuring compliance with international standards is crucial, especially in regulated industries.

Summary Table

| Material | Typical Use Case for shaft coupling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive | High durability and strength | Heavier, potential corrosion | Medium |

| Aluminum | Aerospace, automotive | Lightweight, corrosion resistant | Lower strength than steel | High |

| Plastic (Polymer) | Food processing, chemical industry | Corrosion resistant, lightweight | Lower mechanical strength | Medium |

| Composite | Aerospace, high-speed machinery | Lightweight, fatigue resistant | Higher manufacturing cost | High |

This guide provides a comprehensive overview of materials used in shaft couplings, empowering B2B buyers to make informed decisions based on their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for shaft coupling

Manufacturing Processes for Shaft Coupling

Shaft couplings are critical components in machinery, designed to connect two shafts together while allowing for misalignment and movement. The manufacturing of shaft couplings involves several key stages, each of which is vital to producing a reliable and durable product.

1. Material Preparation

The first step in manufacturing shaft couplings is material selection. Common materials include carbon steel, stainless steel, and aluminum, chosen based on the application requirements, such as load capacity, environmental conditions, and corrosion resistance.

- Material Inspection: Before processing, materials undergo rigorous inspection to ensure they meet specified standards. This may include checking for tensile strength, hardness, and chemical composition.

- Cutting: Once the materials are verified, they are cut to the required dimensions using techniques such as sawing, shearing, or laser cutting, depending on the complexity of the design.

2. Forming

The forming stage shapes the raw materials into the desired configuration. This can involve several techniques:

- Machining: This is a common method where the material is shaped using lathes, milling machines, or CNC machines. Precision machining is essential to achieve the exact dimensions and tolerances required for effective coupling.

- Forging: For high-strength applications, forging processes may be utilized. This involves shaping the metal by applying compressive forces, which enhances the material’s mechanical properties.

- Casting: In some cases, casting may be employed, where molten metal is poured into a mold to create complex shapes that would be difficult to achieve through machining alone.

3. Assembly

After the individual components are formed, they are assembled. This stage may include:

- Fitting: Components such as hubs, sleeves, and bolts are fitted together, often requiring precise alignment to ensure the coupling operates effectively.

- Welding or Fastening: Depending on the design, parts may be welded or fastened using screws, bolts, or clamps to secure them in place.

4. Finishing

The finishing stage enhances the surface quality and prepares the couplings for service:

- Surface Treatment: This may include processes like shot blasting, anodizing, or painting to improve corrosion resistance and aesthetics.

- Final Inspection: Each coupling undergoes a final inspection to ensure it meets all specifications and quality standards before packaging.

Quality Assurance in Shaft Coupling Manufacturing

Quality assurance (QA) is crucial in the manufacturing of shaft couplings to ensure reliability and performance. B2B buyers must be aware of international standards and specific quality checkpoints throughout the manufacturing process.

Relevant International Standards

- ISO 9001: This standard outlines a framework for a quality management system, ensuring consistent quality in products and services. Manufacturers certified to this standard demonstrate their commitment to quality processes.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For couplings used in the oil and gas industry, adherence to American Petroleum Institute (API) standards is often required, ensuring the components can withstand extreme operational conditions.

Quality Control Checkpoints

Quality control (QC) is integrated at multiple stages of the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor dimensional accuracy and adherence to manufacturing processes.

- Final Quality Control (FQC): After assembly and finishing, a thorough inspection is performed to ensure the final product meets all quality standards.

Common Testing Methods

B2B buyers should be familiar with various testing methods used in the quality assurance of shaft couplings:

- Dimensional Inspection: Using calipers and gauges to verify that the coupling meets specified dimensions.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle inspection, or dye penetrant testing are used to identify internal flaws without damaging the component.

- Load Testing: Some manufacturers perform load testing to simulate operational conditions and verify the coupling’s performance under stress.

Verifying Supplier Quality Control

B2B buyers, especially those sourcing from international suppliers, must adopt strategies to verify the quality control practices of potential partners:

- Supplier Audits: Conducting on-site audits of suppliers can provide insight into their manufacturing processes and quality assurance systems. This ensures compliance with international standards and best practices.

- Requesting Quality Reports: Buyers should request detailed quality assurance reports that document testing results and compliance with relevant standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control processes. This is particularly important when dealing with suppliers in regions where quality assurance practices may vary.

QC Considerations for International B2B Buyers

For international buyers, particularly from Africa, South America, the Middle East, and Europe, several nuances in quality control should be considered:

- Cultural and Regulatory Differences: Understanding local manufacturing practices and regulatory requirements can affect quality assurance. Buyers should familiarize themselves with the specific standards applicable in the supplier’s country.

- Supply Chain Transparency: Maintain open communication with suppliers regarding their quality control processes and any certifications they hold. Transparency is key to building trust and ensuring product quality.

- Long-Term Relationships: Establishing long-term partnerships with suppliers can lead to improved quality over time, as they become more attuned to the buyer’s specific quality expectations.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing shaft couplings, ensuring they select suppliers that meet their quality and performance requirements.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for shaft coupling Sourcing

Understanding the cost structure and pricing dynamics for sourcing shaft couplings is crucial for international B2B buyers. This analysis delves into the various cost components, price influencers, and actionable insights to enhance sourcing strategies, particularly for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary material used in shaft couplings is often steel or aluminum, with variations based on specific applications. The choice of material significantly impacts the overall cost. Specialty materials may be required for high-stress applications, leading to higher prices.

-

Labor: Labor costs can vary significantly based on the region of production. Countries with higher wage standards will generally incur higher labor costs, which can influence the final pricing of couplings.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative costs associated with production. Efficient manufacturing processes can help reduce overhead, thereby lowering overall costs.

-

Tooling: Investment in specialized tooling is necessary for producing high-quality shaft couplings. The initial tooling costs can be substantial, but they are amortized over the production run, impacting unit costs for larger orders.

-

Quality Control (QC): Ensuring that shaft couplings meet industry standards requires rigorous QC processes. These costs are integral to maintaining product reliability and can vary based on the complexity of the QC measures implemented.

-

Logistics: Shipping and handling costs are particularly significant for international buyers. Factors such as distance, mode of transport, and customs duties can greatly affect overall expenses.

-

Margin: Suppliers will add a profit margin to cover their business risks and operational costs. This margin can vary based on competition and supplier reputation.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing, which can significantly lower the unit price. Buyers should assess their needs carefully to take advantage of economies of scale.

-

Specifications/Customization: Custom-designed shaft couplings may incur additional costs. Standard products generally have lower prices due to streamlined manufacturing processes.

-

Materials: The choice of material not only affects the performance but also the cost. Buyers should evaluate material options against application requirements to optimize pricing.

-

Quality/Certifications: Couplings that meet specific quality standards or certifications may command higher prices. However, investing in certified products can reduce risks and enhance product performance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service.

-

Incoterms: The agreed-upon shipping terms can also impact pricing. Buyers should be aware of their responsibilities in terms of freight costs, insurance, and customs clearance.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating terms with suppliers. Discuss potential discounts for bulk orders or long-term contracts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors like maintenance, reliability, and potential downtime when assessing the value of shaft couplings.

-

Pricing Nuances: Be mindful of currency fluctuations, especially when sourcing from suppliers in different regions. Contracts should include clauses that address potential price changes due to currency shifts.

-

Research Local Suppliers: For buyers in Africa and South America, local suppliers may offer competitive pricing and reduced logistics costs. Assess the quality and reliability of local options before committing to international suppliers.

-

Quality Assurance: Always prioritize quality, as low-cost options may lead to higher long-term costs due to failures or replacements. Establish clear quality expectations upfront to avoid discrepancies later.

Disclaimer

Prices for shaft couplings can vary widely based on the aforementioned factors. Buyers should conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential shaft coupling Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘shaft coupling’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for shaft coupling

Key Technical Properties of Shaft Couplings

Understanding the technical properties of shaft couplings is vital for B2B buyers to ensure compatibility, reliability, and efficiency in their applications. Here are several critical specifications:

-

Material Grade: Shaft couplings can be made from various materials, including steel, aluminum, and composite materials. The choice of material affects strength, weight, and resistance to corrosion or wear. For instance, high-grade steel is often preferred for heavy-duty applications due to its durability.

-

Tolerance: This refers to the permissible limit of variation in a physical dimension. Tight tolerances are crucial in precision applications where misalignment can lead to failure. Buyers should ensure that the couplings meet the required tolerances for their specific machinery to avoid operational issues.

-

Torque Rating: This specification indicates the maximum torque a coupling can transmit without failure. Understanding the torque requirements of your machinery is essential to prevent damage and ensure optimal performance. Selecting a coupling with an adequate torque rating is critical, especially in high-load applications.

-

Misalignment Capability: Couplings are designed to accommodate various types of misalignment (angular, parallel, and axial). Knowing the misalignment tolerance can help buyers choose the right coupling for their application, ensuring better performance and extended service life.

-

Size and Dimensions: The outer diameter, length, and bore size are important for ensuring that the coupling fits properly within the existing setup. Accurate size specifications help avoid compatibility issues, which can lead to increased downtime and costs.

-

Operating Temperature Range: This indicates the environmental conditions under which the coupling can operate effectively. Buyers should ensure that the chosen coupling can withstand the temperature extremes of their application, especially in industries like automotive or aerospace.

Common Trade Terminology in Shaft Coupling

Familiarizing yourself with industry-specific jargon can enhance communication and streamline the procurement process. Here are some common terms:

-

OEM (Original Equipment Manufacturer): Refers to companies that produce components that are used in the assembly of a final product. For shaft couplings, buyers should consider OEM parts for guaranteed quality and compatibility with their machinery.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ can help buyers plan their purchases effectively and manage inventory costs.

-

RFQ (Request for Quotation): A formal process where buyers ask suppliers for pricing and terms for specific products. Issuing an RFQ for shaft couplings can help in obtaining competitive bids and ensuring the best value for money.

-

Incoterms: Short for International Commercial Terms, these are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping, insurance, and delivery responsibilities, which is crucial for international sourcing.

-

Lead Time: This refers to the time taken from placing an order to delivery. Knowing the lead times for shaft couplings is essential for managing production schedules and avoiding delays in projects.

-

Certification Standards: Many industries require components to meet specific certification standards (e.g., ISO, ANSI). Buyers should verify that the couplings comply with relevant standards to ensure quality and reliability in their applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right shaft couplings for their specific needs while also facilitating smoother negotiations with suppliers.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shaft coupling Sector

The shaft coupling sector is experiencing significant transformations shaped by various market dynamics and sourcing trends. As industries across Africa, South America, the Middle East, and Europe increasingly invest in infrastructure and machinery, the demand for reliable shaft couplings is on the rise. Key drivers include the expansion of the manufacturing sector, the growth of renewable energy projects, and the need for enhanced operational efficiency in existing machinery.

Current and Emerging B2B Trends

-

Digital Transformation: The adoption of digital tools for procurement and supply chain management is gaining momentum. Platforms that facilitate real-time communication and data sharing are becoming essential for B2B buyers to track supplier performance and manage inventory effectively.

-

Local Sourcing: There is a growing preference for sourcing from local suppliers to reduce lead times and transportation costs. This trend is particularly pronounced in regions like Europe and Africa, where buyers are increasingly prioritizing suppliers within their geographical proximity.

-

Customization: As industries diversify, the demand for customized shaft couplings tailored to specific applications is rising. Suppliers who offer flexible manufacturing capabilities are positioned to capture market share.

-

Collaboration and Partnerships: Strategic alliances between manufacturers and distributors are becoming more common. These partnerships facilitate innovation and allow for shared resources in research and development, particularly in the pursuit of high-performance coupling solutions.

Market Dynamics for International B2B Buyers

International buyers must navigate fluctuating material costs and supply chain disruptions, which have become prevalent due to geopolitical tensions and global economic challenges. Understanding local market conditions and regulatory requirements is crucial for successful sourcing. Buyers should also be aware of the varying standards for shaft couplings across different regions, especially when sourcing from multiple countries.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a core consideration in the shaft coupling sector, driven by increasing regulatory pressure and consumer demand for environmentally friendly products. B2B buyers are encouraged to prioritize suppliers who demonstrate a commitment to sustainable practices, which can include the use of recycled materials and energy-efficient manufacturing processes.

Environmental Impact and Ethical Supply Chains

The production of shaft couplings can have a considerable environmental impact, primarily through energy consumption and waste generation. Thus, ethical sourcing practices are vital for minimizing this impact. Buyers should seek suppliers who adhere to recognized environmental standards, such as ISO 14001, and those who can provide certifications for their materials, ensuring they are sourced responsibly.

Green Certifications and Materials

Buyers should consider suppliers that offer ‘green’ certifications, indicating that their products meet specific environmental criteria. This can encompass certifications related to materials used in manufacturing, such as those that highlight the use of sustainable or recyclable materials. By aligning with such suppliers, B2B buyers can enhance their own sustainability credentials while meeting the growing demand for environmentally responsible products.

Brief Evolution/History

The shaft coupling industry has evolved significantly since its inception. Initially designed for basic mechanical transmission, modern couplings are engineered for high performance and precision, accommodating a wide range of applications from automotive to industrial machinery. The introduction of advanced materials and manufacturing techniques has allowed for lighter, stronger, and more efficient couplings, essential for meeting the demands of today’s fast-paced industrial landscape. As industries continue to advance, the evolution of shaft couplings is expected to align with broader technological innovations, particularly in automation and digitalization.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of shaft coupling

-

What criteria should I use to vet suppliers of shaft couplings?

When vetting suppliers for shaft couplings, consider their industry reputation, years of experience, and certifications (such as ISO 9001). Request references from previous clients and assess their production capacity and technology used. Evaluate their financial stability to ensure they can fulfill orders over the long term. Additionally, check their compliance with international standards relevant to your region, as this can affect product reliability and legal compliance. -

Can shaft couplings be customized to meet specific application needs?

Yes, many manufacturers offer customization options for shaft couplings to suit specific applications. This can include alterations in size, material, or design features such as additional torque capacity or vibration dampening. When requesting customization, provide detailed specifications and discuss your requirements with the supplier. Ensure that the supplier has experience in producing tailored solutions and inquire about the implications for lead times and costs. -

What are the typical minimum order quantities (MOQs) for shaft couplings?

Minimum order quantities for shaft couplings can vary significantly by supplier and product type. Generally, MOQs can range from a few units for standard products to several hundred for custom designs. When negotiating with suppliers, be clear about your needs and potential future orders. Some suppliers may offer flexibility on MOQs for first-time buyers or larger contracts, so it’s worth discussing your purchasing strategy upfront.

Illustrative Image (Source: Google Search)

-

How long do lead times typically take for orders of shaft couplings?

Lead times for shaft couplings can vary based on factors such as the complexity of the order, customization requirements, and the supplier’s production capacity. Standard lead times can range from 2 to 6 weeks, while customized orders may take longer, sometimes extending to 12 weeks or more. To mitigate delays, maintain open communication with your supplier, confirm production schedules, and consider placing orders well in advance of your operational needs. -

What quality assurance measures should I look for in shaft coupling suppliers?

Quality assurance is critical when sourcing shaft couplings. Look for suppliers that implement rigorous QA processes, including material testing, dimensional checks, and performance evaluations. Request certifications that demonstrate adherence to international quality standards, such as ISO or ASTM. Additionally, inquire about their warranty and return policies, which can provide further assurance of product quality and reliability. -

What certifications should shaft couplings have for international trade?

For international trade, look for certifications that indicate compliance with industry standards, such as ISO 9001 for quality management systems and CE marking for European markets. Depending on your region, additional certifications may be required, such as ASTM standards in the U.S. or specific environmental regulations. Confirming these certifications can facilitate smoother customs processes and ensure that the products meet your local regulatory requirements. -

What logistics considerations should I keep in mind when importing shaft couplings?

When importing shaft couplings, consider logistics aspects such as shipping methods, costs, and delivery times. Work with suppliers who have experience in international shipping and can provide guidance on freight options. Be aware of customs duties and taxes that may apply to your imports, as well as the documentation required for smooth clearance. Establish a reliable communication line with your logistics provider to stay updated on shipping statuses and potential delays. -

How can I resolve disputes with suppliers regarding shaft couplings?

To effectively resolve disputes with suppliers, maintain clear documentation of all agreements, communications, and transactions. Establish a dispute resolution process in your contracts, outlining steps for negotiation, mediation, or arbitration. Engage a legal professional if necessary, especially when dealing with international contracts. Building a strong relationship with suppliers can also help mitigate issues; open communication and mutual respect often lead to quicker, amicable resolutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for shaft coupling

The strategic sourcing of shaft couplings is essential for B2B buyers aiming to enhance their operational efficiency and maintain competitive advantage. Key takeaways emphasize the importance of understanding the various types of shaft couplings available, their specific applications, and the critical role of quality assurance in procurement processes. Additionally, forming partnerships with reputable manufacturers can significantly reduce supply chain disruptions and ensure compliance with international standards.

As the demand for reliable mechanical components continues to grow across regions, including Africa, South America, the Middle East, and Europe, buyers must prioritize a strategic approach to sourcing. This involves leveraging data analytics for supplier evaluation, considering total cost of ownership, and maintaining flexibility to adapt to market changes.

Looking ahead, the focus should shift towards innovation and sustainability in sourcing practices. B2B buyers are encouraged to actively seek suppliers who invest in advanced manufacturing technologies and sustainable materials. By doing so, businesses can not only enhance their product offerings but also contribute to a more sustainable future. Engage with your suppliers today to ensure you are equipped for the challenges of tomorrow’s market.