Your Ultimate Guide to Sourcing Spring Door Latch

Introduction: Navigating the Global Market for spring door latch

In today’s competitive global marketplace, the spring door latch stands out as a crucial component across various industries, including construction, automotive, and manufacturing. These devices not only enhance security but also ensure seamless functionality in doors, gates, and cabinets, making them indispensable in both residential and commercial applications. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing spring door latches can significantly impact operational efficiency and product quality.

This comprehensive guide delves into the various types of spring door latches, including their materials, manufacturing processes, and quality control standards. It provides insights into sourcing strategies, highlighting reputable suppliers and cost considerations that align with different market demands. Additionally, the guide addresses common FAQs to equip buyers with the knowledge needed to make informed decisions.

By navigating the complexities of the global market for spring door latches, buyers can effectively mitigate sourcing risks and optimize their supply chains. This resource empowers businesses to balance cost with quality, ensuring they select the right products that meet their specific requirements while fostering long-term supplier relationships. In a landscape marked by geopolitical shifts and supply chain disruptions, this guide serves as an essential tool for international B2B buyers seeking reliable solutions.

Understanding spring door latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Spring Latch | Simple design; spring-loaded mechanism | Residential doors, internal doors | Pros: Cost-effective, easy to install. Cons: May lack durability under heavy use. |

| Deadlatch | Automatic locking mechanism with a spring | Commercial buildings, security doors | Pros: Enhanced security, self-locking feature. Cons: More complex installation, higher cost. |

| Sliding Door Latch | Designed for sliding doors; often has a hook | Warehouses, industrial sites | Pros: Space-saving, smooth operation. Cons: Limited to specific door types. |

| Adjustable Latch | Customizable length for various door thicknesses | Custom installations, renovations | Pros: Versatile, adaptable to different applications. Cons: May require additional tools for adjustments. |

| Electronic Spring Latch | Integrates with electronic access control systems | High-security facilities, hotels | Pros: Remote access, advanced security features. Cons: Higher upfront cost, requires power source. |

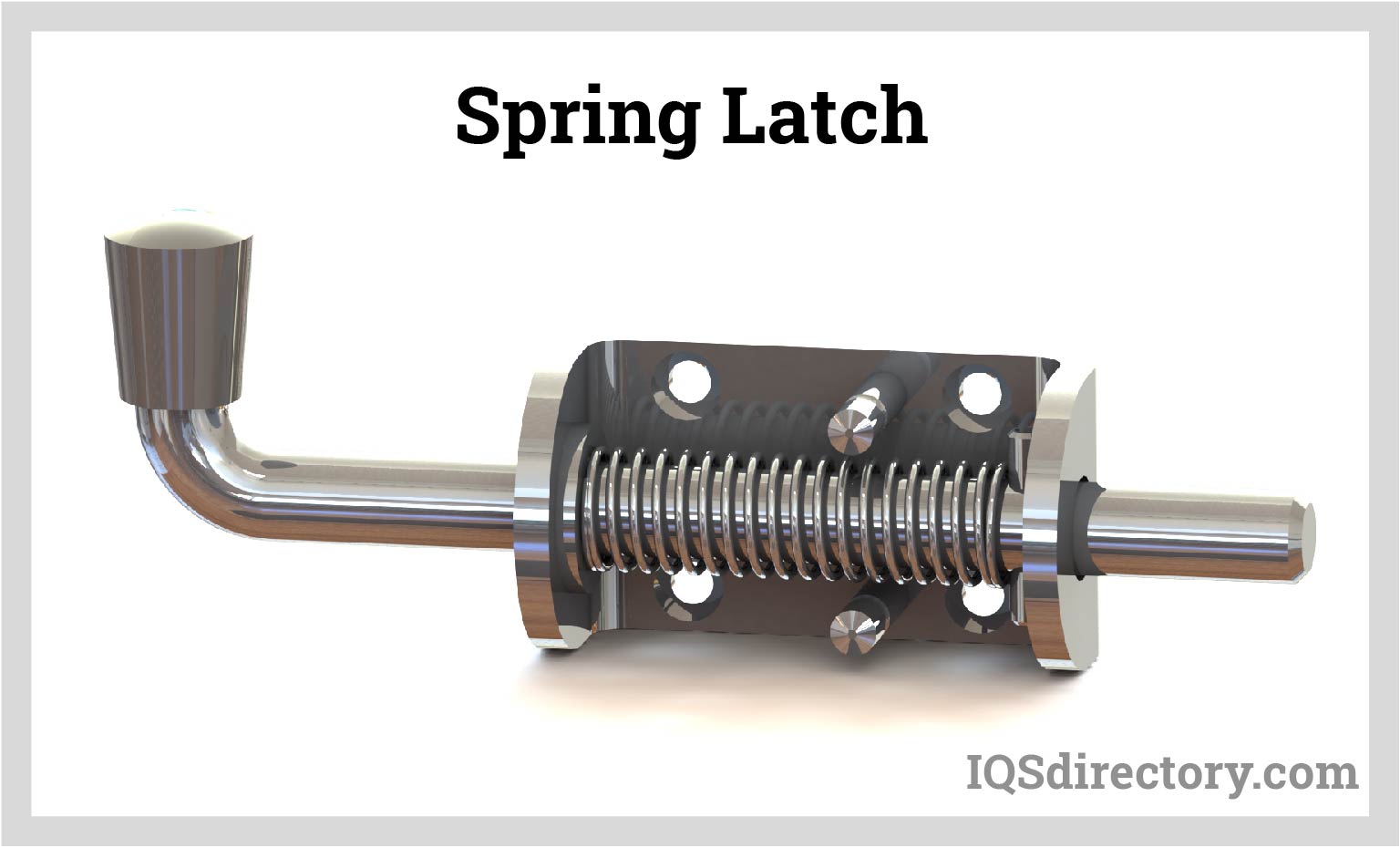

Standard Spring Latch

The standard spring latch is the most common type, characterized by its straightforward design and spring-loaded mechanism. It is widely used in residential settings for internal doors, offering a cost-effective solution for everyday locking needs. When purchasing, B2B buyers should consider the latch’s durability, particularly in high-traffic areas, as it may not withstand heavy use over time.

Deadlatch

A deadlatch features an automatic locking mechanism that engages when the door is closed, providing an added layer of security. It is ideal for commercial applications, particularly in buildings requiring enhanced safety measures. Buyers should evaluate the complexity of installation and the total cost, as deadlatches can be more expensive than standard latches but offer significant security benefits.

Sliding Door Latch

Designed specifically for sliding doors, this latch typically incorporates a hook mechanism to secure the door in place. Its primary applications include warehouses and industrial sites where space is limited. B2B buyers should ensure compatibility with their sliding door systems, as these latches are not suitable for conventional hinged doors, and consider their ease of use in daily operations.

Adjustable Latch

The adjustable latch is a versatile option that can be customized to fit various door thicknesses, making it particularly useful for renovations or custom installations. This adaptability allows for greater flexibility in applications across different industries. Buyers should assess the necessary tools for adjustment and installation, as this may add to the overall project cost and complexity.

Electronic Spring Latch

The electronic spring latch integrates with electronic access control systems, making it an ideal choice for high-security facilities and hotels. This type of latch offers remote access capabilities and advanced security features, appealing to businesses that prioritize safety. However, B2B buyers should consider the higher upfront costs and the need for a reliable power source, which may complicate installation in certain environments.

Related Video: 2-way Gate Latch & how to install it!

Key Industrial Applications of spring door latch

| Industry/Sector | Specific Application of spring door latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Door locking mechanisms in vehicles | Enhances vehicle security and user convenience | Quality standards, compliance with automotive regulations, durability under extreme conditions |

| Construction | Entry and exit doors in commercial buildings | Improves safety and accessibility | Material specifications, weather resistance, and ease of installation |

| Manufacturing | Access control in factories and warehouses | Streamlines operations and secures inventory | Supplier reliability, lead times, and compatibility with existing systems |

| Aerospace | Cabin doors and compartments in aircraft | Ensures safety during flight and ease of access | Compliance with aviation standards, weight considerations, and corrosion resistance |

| Home Appliances | Latches for refrigerators and washing machines | Increases energy efficiency and appliance reliability | Energy efficiency ratings, material quality, and ease of assembly |

Automotive Applications

In the automotive industry, spring door latches are integral to vehicle locking mechanisms. They ensure that doors remain securely closed while also allowing for easy access. By utilizing these latches, manufacturers can enhance vehicle security and user convenience, addressing common issues such as accidental door openings while driving. International buyers should focus on sourcing latches that meet stringent automotive quality standards and are durable enough to withstand extreme weather conditions.

Construction Applications

In construction, spring door latches are commonly used for entry and exit doors in commercial buildings. These latches improve safety by providing reliable locking mechanisms that prevent unauthorized access while also facilitating smooth entry for occupants. Buyers in this sector must consider material specifications to ensure durability, as well as weather resistance, particularly in regions with extreme climates. Additionally, ease of installation can significantly impact project timelines and labor costs.

Manufacturing Applications

Within the manufacturing sector, spring door latches are crucial for access control in factories and warehouses. They help streamline operations by ensuring that doors remain securely closed, thus protecting inventory and sensitive areas. For international B2B buyers, sourcing reliable suppliers who can meet lead times and provide latches compatible with existing systems is essential. This focus on compatibility can reduce downtime during installation and enhance operational efficiency.

Aerospace Applications

In the aerospace industry, spring door latches are vital for securing cabin doors and compartments within aircraft. These latches must meet strict aviation safety standards, ensuring they function correctly during flight. Buyers in this sector should prioritize sourcing latches that are lightweight yet durable, and resistant to corrosion, as these factors significantly affect aircraft performance and safety. Ensuring compliance with aviation regulations is also critical for international procurement.

Home Appliance Applications

Spring door latches are widely used in home appliances, such as refrigerators and washing machines, to secure doors and improve energy efficiency. By ensuring that doors remain tightly closed, these latches help maintain optimal internal temperatures and reduce energy consumption. B2B buyers in this sector should focus on sourcing latches with high energy efficiency ratings and superior material quality to enhance the reliability of their products. Additionally, ease of assembly is a key consideration that can influence manufacturing processes and costs.

Related Video: Door Latch

Strategic Material Selection Guide for spring door latch

When selecting materials for spring door latches, international B2B buyers must consider various properties, advantages, and limitations of common materials. The choice of material impacts not only the performance and durability of the latch but also its compliance with regional standards and suitability for specific applications.

Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and performs well under pressure.

Pros & Cons:

Stainless steel latches are durable and resistant to rust, making them ideal for outdoor applications. However, they can be more expensive than other materials and may require more complex manufacturing processes, which can increase lead times.

Impact on Application:

Stainless steel is compatible with a wide range of environments, including those exposed to moisture and chemicals. This makes it suitable for industrial and marine applications.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel. Additionally, understanding local sourcing capabilities and potential tariffs is crucial, especially in regions like Africa and South America where material costs can vary significantly.

Zinc-Plated Steel

Key Properties:

Zinc-plated steel offers moderate corrosion resistance due to its protective zinc coating. It can withstand temperatures up to 500°F (260°C) and is typically less expensive than stainless steel.

Pros & Cons:

The primary advantage of zinc-plated steel is its cost-effectiveness and ease of manufacturing. However, it is less durable than stainless steel, particularly in harsh environments, as the zinc coating can wear off over time.

Impact on Application:

Zinc-plated steel is suitable for indoor applications where moisture is minimal. It is often used in residential settings but may not be ideal for outdoor or industrial environments.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding zinc coatings and ensure that products meet standards such as ISO 1461 for hot-dip galvanizing. Understanding regional preferences for material durability is also essential.

Plastic (Polymer)

Key Properties:

Plastics, particularly high-performance polymers like nylon or polycarbonate, offer good resistance to corrosion and can operate effectively at temperatures ranging from -40°F to 200°F (-40°C to 93°C).

Pros & Cons:

Plastic latches are lightweight and resistant to rust, which makes them suitable for a variety of applications. However, they may not be as durable under mechanical stress compared to metals and can be affected by UV exposure.

Impact on Application:

Plastic latches are ideal for lightweight applications and environments where corrosion is a concern, such as in food processing or medical equipment.

Considerations for International Buyers:

Buyers should verify the material’s compliance with safety standards relevant to their industry, such as FDA regulations for food-grade applications. Additionally, understanding the impact of temperature variations in different regions is important for performance reliability.

Brass

Key Properties:

Brass is known for its excellent machinability and corrosion resistance, particularly in marine environments. It can withstand temperatures up to 400°F (204°C) and offers good strength.

Pros & Cons:

Brass latches provide a classic aesthetic and are resistant to tarnishing. However, they can be more expensive than steel options and may require additional maintenance to preserve their appearance.

Impact on Application:

Brass is often used in decorative applications and environments where aesthetics are important, such as in residential or commercial buildings.

Considerations for International Buyers:

Buyers should consider the availability of brass in their region and any import duties that may apply. Compliance with standards such as ASTM B16 for brass alloys is also necessary.

Summary Table

| Material | Typical Use Case for spring door latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor and industrial applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Zinc-Plated Steel | Indoor residential applications | Cost-effective and easy to manufacture | Limited durability in harsh environments | Medium |

| Plastic (Polymer) | Lightweight and food processing | Lightweight and corrosion-resistant | Less durable under mechanical stress | Low |

| Brass | Decorative residential applications | Aesthetic appeal and tarnish resistance | Higher cost and maintenance required | Medium |

This guide provides a comprehensive overview of material selection for spring door latches, ensuring that international B2B buyers make informed decisions that align with their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for spring door latch

Manufacturing Processes for Spring Door Latch

The manufacturing of spring door latches involves several critical stages, each designed to ensure that the final product meets the necessary performance and safety standards. Understanding these processes is vital for B2B buyers, particularly those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used in spring door latches include:

- Stainless Steel: Known for its corrosion resistance and strength.

- Zinc Alloy: Offers good strength and is cost-effective.

- Plastic Composites: Used in lighter applications, these materials provide durability and resistance to environmental factors.

Once the materials are selected, they undergo various treatments such as annealing or hardening to enhance their mechanical properties. Material testing is also crucial at this stage to ensure compliance with international standards and specifications.

2. Forming

The forming stage involves shaping the prepared materials into the required components of the door latch. Key techniques used include:

- Stamping: This involves using a die to cut and shape metal sheets into specific forms.

- Machining: Precision tools are employed to create intricate designs and ensure tight tolerances.

- Injection Molding: For plastic components, this method allows for high-volume production with complex shapes.

Each of these techniques plays a vital role in ensuring that the parts fit together correctly and function as intended.

3. Assembly

After the individual components are formed, they are assembled into a complete latch. This stage may involve:

- Mechanical Assembly: Using screws, rivets, or clips to join parts together.

- Welding: For metal components, welding provides a strong bond.

- Spring Installation: Springs are inserted, ensuring they function effectively within the latch mechanism.

During assembly, manufacturers often utilize jigs and fixtures to maintain precision and repeatability.

4. Finishing

Finishing processes enhance the aesthetic appeal and functional performance of the latch. Common techniques include:

- Surface Treatment: Processes such as galvanizing, powder coating, or anodizing protect against corrosion and wear.

- Polishing: Provides a smooth finish, improving appearance and reducing friction.

- Quality Cleaning: Removes any residues from manufacturing processes.

Finishing is essential not just for looks but also for the longevity and reliability of the latch.

Quality Assurance

Quality assurance is a critical component of the manufacturing process, ensuring that the final product meets both customer expectations and regulatory requirements.

International Standards

B2B buyers must be aware of relevant international standards that govern the quality of spring door latches, including:

- ISO 9001: This standard focuses on quality management systems and is applicable to all organizations, ensuring consistent quality in products and services.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Specifications: For latches used in specific industrial applications, adherence to American Petroleum Institute standards may be necessary.

Understanding these standards helps buyers select suppliers who are compliant and committed to quality.

Quality Control Checkpoints

Quality control (QC) is typically segmented into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Regular inspections during manufacturing help identify defects early in the process.

- Final Quality Control (FQC): The completed latches undergo thorough testing to confirm they meet all performance criteria and specifications.

Common testing methods include:

- Functional Testing: Ensuring the latch operates correctly under various conditions.

- Durability Testing: Simulating long-term use to assess wear and tear.

- Environmental Testing: Subjecting the latch to extreme conditions to verify resistance to corrosion, temperature, and humidity.

Verification of Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers can implement several verification strategies:

- Supplier Audits: Conducting regular audits helps assess compliance with quality standards and manufacturing practices.

- Requesting Quality Reports: Suppliers should provide documentation detailing their QC processes and outcomes.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s quality measures.

Quality Control Nuances for International Buyers

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC can be critical. These include:

- Cultural Differences: Recognizing that quality perceptions may vary across cultures, buyers should establish clear communication regarding quality expectations.

- Regulatory Compliance: Ensuring that the supplier understands and complies with both local and international regulations is vital.

- Logistical Considerations: The complexity of international shipping and customs can impact quality; thus, buyers should discuss how suppliers handle these challenges.

By focusing on these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing spring door latches, ensuring they select suppliers capable of delivering high-quality products that meet their specific needs.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for spring door latch Sourcing

When sourcing spring door latches, a comprehensive understanding of the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis encompasses various cost components, price influencers, and actionable tips that can enhance your sourcing strategy.

Cost Components

-

Materials: The primary cost driver in manufacturing spring door latches is the raw materials, which typically include steel, aluminum, or plastic. The choice of material directly impacts durability, functionality, and, consequently, the price. Buyers should consider sourcing materials locally where possible to reduce costs associated with imports.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs can provide savings but may also come with trade-offs in quality or production speed. Understanding the local labor market is essential for evaluating total production costs.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facilities. Overhead can be a significant portion of the total cost, especially in regions with high energy prices or stringent environmental regulations.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. Investing in high-quality tooling can improve production efficiency and product quality, leading to long-term savings.

-

Quality Control (QC): Implementing stringent QC measures is vital to ensure product reliability. While this may increase upfront costs, it can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs can fluctuate based on distance, freight methods, and local tariffs. Understanding Incoterms can help buyers navigate these costs more effectively and reduce uncertainties in pricing.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can vary based on market demand, supplier reputation, and the competitive landscape.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly influence pricing. Larger orders often lead to reduced per-unit costs. However, buyers must balance this with inventory management capabilities.

-

Specifications/Customization: Custom designs or specific material requirements can lead to higher prices due to increased complexity in production. Clearly defining specifications upfront can help in obtaining accurate quotes.

-

Quality/Certifications: Products that meet international quality standards or certifications (like ISO) may command higher prices. However, these certifications can enhance product reliability and marketability.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Engaging with suppliers who have a proven track record can mitigate risks associated with quality and delivery timelines.

-

Incoterms: Understanding the implications of different Incoterms is critical for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the cost at various stages of transportation.

Buyer Tips

-

Negotiate: Leverage your purchasing power by negotiating better terms based on volume or long-term partnerships. Establishing a good rapport with suppliers can lead to favorable pricing arrangements.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider factors such as durability, maintenance, and potential savings from reduced returns or replacements.

-

Understand Pricing Nuances: Be aware of regional differences in pricing and availability. For instance, sourcing from regions with lower manufacturing costs, like parts of Asia or Eastern Europe, can be beneficial, but also consider the implications of longer lead times.

-

Stay Informed: Keep abreast of market trends, material price fluctuations, and geopolitical factors that could influence costs. This knowledge will empower you to make informed purchasing decisions.

Disclaimer

Prices and costs outlined in this analysis are indicative and may vary based on specific circumstances, supplier negotiations, and market conditions. Always seek multiple quotes and conduct thorough due diligence before finalizing any sourcing agreements.

Spotlight on Potential spring door latch Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘spring door latch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for spring door latch

Key Technical Properties of Spring Door Latches

Understanding the technical specifications of spring door latches is crucial for international B2B buyers to ensure they select the right product for their applications. Here are some essential properties to consider:

-

Material Grade

The material used in manufacturing a spring door latch significantly impacts its durability and performance. Common materials include stainless steel, brass, and zinc alloy. Stainless steel offers corrosion resistance and strength, while brass provides aesthetic appeal and durability. Selecting the appropriate material grade can enhance the longevity of the latch and reduce maintenance costs. -

Spring Tension

This specification defines the force required to operate the latch mechanism. Proper spring tension is vital for ensuring the latch engages and disengages smoothly. B2B buyers should consider the application context; for example, heavier doors may require latches with higher spring tension to ensure secure closure. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions. In spring door latches, tight tolerances are essential for ensuring proper fit and function. High precision in manufacturing leads to enhanced reliability and reduces the risk of mechanical failure, which is crucial in industrial applications. -

Finish and Coating

The surface finish of a spring door latch affects both its aesthetic appeal and its resistance to environmental factors. Common finishes include powder coating and electroplating. A quality finish can prevent rust and corrosion, especially in humid or coastal environments, thereby extending the product’s lifespan. -

Load Capacity

This specification indicates the maximum weight the latch can securely hold. Understanding load capacity is critical for ensuring that the latch is suitable for the intended door type. Buyers should match the load capacity with the expected usage to avoid premature failure. -

Dimensions

The size of the latch, including length, width, and height, must be compatible with the door design. Accurate dimensions ensure that the latch fits properly and operates effectively. B2B buyers should confirm the dimensions during the procurement process to prevent installation issues.

Common Trade Terminology in Spring Door Latch Procurement

Familiarity with industry jargon can facilitate smoother communication and negotiation in B2B transactions. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding whether a supplier is an OEM can impact pricing and quality assurance processes. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for international buyers who may face different economic conditions. -

RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests price quotes from suppliers for specific products. This document often includes detailed specifications and quantities, helping buyers compare offers effectively. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help mitigate risks associated with international shipping logistics.

Illustrative Image (Source: Google Search)

-

Lead Time

This term refers to the time taken from placing an order to the delivery of goods. Understanding lead time is crucial for planning and inventory management, especially in industries where timely delivery is critical. -

Warranty

A warranty is a promise made by the manufacturer regarding the condition of the product and the length of time it will be covered. Knowing the warranty terms can help buyers assess the risk of product failure and the potential costs associated with replacements or repairs.

By mastering these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing spring door latches, ensuring they select products that meet their operational needs while managing costs effectively.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the spring door latch Sector

Market Overview & Key Trends

The global market for spring door latches is experiencing notable growth, primarily driven by increasing construction activities and the rising demand for security solutions across various sectors. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should focus on the following key trends influencing the market dynamics:

-

Technological Advancements: The integration of IoT in locking systems is becoming a game-changer, enabling remote access and monitoring. This trend is particularly relevant for commercial applications where enhanced security and efficiency are paramount.

-

Sourcing Trends: As geopolitical tensions and supply chain disruptions continue, buyers are shifting towards diversifying their supplier bases. Countries like Turkey and Thailand are emerging as viable alternatives for sourcing spring door latches due to their strategic locations and competitive pricing.

-

Customization Demand: There’s an increasing expectation for customized solutions tailored to specific industry needs. Manufacturers are investing in flexible production techniques to accommodate bespoke orders, which is critical for B2B buyers looking for unique specifications.

Illustrative Image (Source: Google Search)

-

Regulatory Compliance: With stricter regulations on safety and quality standards globally, buyers must ensure that their suppliers comply with local and international regulations to avoid penalties and ensure product integrity.

-

Cost Management: The balance between cost, risk, and quality is becoming increasingly important. Buyers should conduct thorough risk assessments of potential sourcing locations to optimize their procurement strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of procurement strategies in the spring door latch sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, necessitates a shift towards more sustainable practices. B2B buyers should prioritize suppliers that demonstrate a commitment to sustainability through the following initiatives:

-

Ethical Supply Chains: Engaging with suppliers who adhere to ethical labor practices is crucial. This not only mitigates risks associated with labor violations but also enhances brand reputation.

-

Green Certifications: Look for suppliers that hold certifications such as ISO 14001 or similar, indicating their commitment to environmental management. These certifications reflect a supplier’s dedication to reducing their ecological footprint.

-

Material Sourcing: The use of recycled and eco-friendly materials in the production of spring door latches is gaining traction. Buyers should seek out suppliers that utilize sustainable materials, thus contributing to a circular economy.

-

Life Cycle Assessments: Understanding the environmental impact of products throughout their life cycle—from production to disposal—can help buyers make informed decisions. Partnering with suppliers who conduct these assessments can lead to more sustainable purchasing choices.

Brief Evolution/History

The spring door latch has evolved significantly since its inception, initially designed for simplicity and functionality. Early models were primarily mechanical, relying on basic spring mechanisms for operation. However, as technological advancements emerged, the design began to incorporate more sophisticated features, such as electronic locking systems and enhanced security mechanisms. Today, the market sees a blend of traditional and innovative designs, catering to a diverse range of applications—from residential to commercial sectors. This evolution reflects broader trends in consumer demand for security, customization, and sustainability, which are critical for B2B buyers navigating the current landscape.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of spring door latch

-

What criteria should I use to vet suppliers for spring door latches?

When vetting suppliers, prioritize their manufacturing capabilities, quality control processes, and previous experience in producing spring door latches. Request references from other clients, particularly those in your region. It’s advisable to assess their certifications (like ISO 9001) and compliance with international standards. Additionally, consider their financial stability and capacity for scalability to meet your future demands. -

Can I customize spring door latches according to my specifications?

Many suppliers offer customization options for spring door latches, including materials, sizes, and finishes. Discuss your specific requirements with potential suppliers early in the negotiation process. Ensure that you receive prototypes or samples to assess quality before placing larger orders. Customization may affect lead times and pricing, so factor these into your overall budget and timeline. -

What are the typical minimum order quantities (MOQ) and lead times for spring door latches?

MOQs can vary significantly among suppliers, ranging from a few hundred to several thousand units. Lead times depend on factors like the supplier’s production capacity, customization requirements, and logistical considerations. Generally, expect lead times of 4 to 12 weeks. Always clarify these details before finalizing agreements to avoid potential supply chain disruptions. -

What payment terms are commonly offered when sourcing spring door latches?

Payment terms typically vary by supplier and can include options like upfront deposits, letters of credit, or payment upon delivery. For international transactions, consider using secure payment methods to mitigate risks. Negotiate terms that align with your cash flow needs while ensuring the supplier feels secure in the transaction. Always document the terms in a formal contract to prevent misunderstandings. -

How do I ensure quality assurance and compliance with certifications?

Request detailed quality assurance processes from potential suppliers, including information on testing protocols and certifications. Common certifications to look for include ISO standards, CE marking for European markets, and other relevant industry certifications. Implement a quality control plan that includes regular inspections and audits of the supplier’s facilities and processes to ensure compliance with your quality standards. -

What logistics considerations should I keep in mind when sourcing spring door latches?

Logistics play a crucial role in international sourcing. Assess shipping methods, costs, and transit times to ensure they align with your needs. Understand customs regulations and potential tariffs in your country to avoid unexpected expenses. Collaborate with reliable freight forwarders who can help navigate these complexities and ensure timely delivery of your goods. -

How should I handle disputes with suppliers?

Establish clear communication channels and dispute resolution processes in your contracts. If issues arise, address them promptly and professionally, aiming for a mutually beneficial resolution. Consider mediation or arbitration as alternatives to litigation, as these methods can save time and costs. Maintain thorough documentation of all communications and agreements to support your case if disputes escalate. -

What are the risks associated with sourcing spring door latches internationally?

International sourcing carries risks such as geopolitical instability, currency fluctuations, and supply chain disruptions. Conduct a risk assessment of your supplier’s country and industry sector. Diversifying your supplier base can mitigate risks associated with over-reliance on a single source. Additionally, stay informed about global market trends and potential disruptions to proactively manage these challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for spring door latch

As the global marketplace continues to evolve, strategic sourcing for components like spring door latches has never been more critical. Buyers from Africa, South America, the Middle East, and Europe must navigate a landscape marked by geopolitical uncertainties, supply chain disruptions, and varying cost structures. Understanding the trade-offs between cost, risk, and quality will empower businesses to make informed decisions that align with their operational needs.

Key takeaways for B2B buyers include:

-

Assessing Risks: Utilize tools such as risk indexes to evaluate sourcing locations effectively. Countries with higher risks might offer lower costs but can also lead to supply chain vulnerabilities.

-

Supplier Diversification: Avoid over-reliance on single suppliers or regions. Diversifying your supplier base can mitigate risks associated with geopolitical instability or natural disasters.

-

Leveraging Technology: Embrace digital tools for enhanced visibility and communication across the supply chain. This can lead to improved responsiveness and efficiency.

Looking forward, international buyers should engage proactively with suppliers and industry innovations to ensure sustainable sourcing practices. By investing in strategic sourcing now, businesses can position themselves for resilience and growth in an increasingly competitive environment. Take action today to secure your supply chain and drive long-term success in the market for spring door latches.