Your Ultimate Guide to Sourcing Ss Hardware Cloth

Introduction: Navigating the Global Market for ss hardware cloth

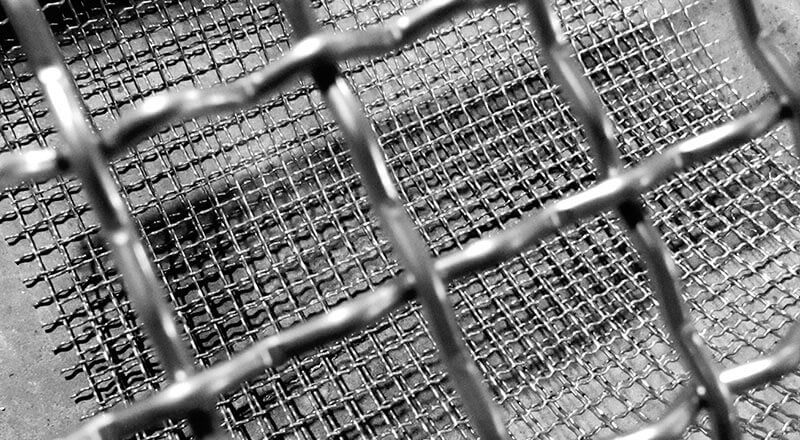

Navigating the global market for stainless steel (ss) hardware cloth is essential for international B2B buyers looking to enhance their supply chain efficiency and product quality. As a versatile material, ss hardware cloth serves a multitude of applications, from construction and agriculture to industrial filtration and home improvement projects. Its durability, resistance to corrosion, and ability to be fabricated into various mesh sizes make it a critical component in numerous sectors.

This guide provides an in-depth exploration of ss hardware cloth, addressing key aspects that empower informed sourcing decisions. Buyers will gain insights into the different types of ss hardware cloth, the materials used in its production, and the manufacturing and quality control processes that ensure product reliability. Additionally, we will cover supplier selection strategies, cost considerations, and an analysis of current market trends across regions, including Africa, South America, the Middle East, and Europe.

By equipping B2B buyers with actionable knowledge and a comprehensive understanding of ss hardware cloth, this guide aims to facilitate smarter procurement strategies. Whether you’re sourcing for construction projects in Kenya or filtration solutions in Colombia, having the right information at your fingertips will enable you to make confident, strategic decisions that enhance operational efficiency and drive competitive advantage.

Understanding ss hardware cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Welded Wire Cloth | Made from welding wires at intersections; uniform openings | Construction, agriculture, and industrial applications | Pros: Strong and durable; Cons: Limited flexibility in shape. |

| Stainless Steel Mesh | Features fine openings for filtration; corrosion-resistant | Food processing, pharmaceuticals, and water treatment | Pros: High durability; Cons: Higher cost compared to other materials. |

| Expanded Metal Mesh | Created by stretching metal sheets; diamond-shaped openings | Security fencing, ventilation, and architectural applications | Pros: Lightweight and strong; Cons: Less effective for fine filtration. |

| Hardware Cloth | Generally made from galvanized steel; hexagonal openings | Animal enclosures, gardening, and fencing | Pros: Economical and versatile; Cons: Less durable than stainless steel options. |

| Perforated Metal Sheets | Contains holes punched into flat metal sheets; customizable hole patterns | Industrial applications, architectural features, and soundproofing | Pros: Customizable; Cons: Can be less robust than welded options. |

Welded Wire Cloth

Welded wire cloth is constructed by welding wires together at their intersections, creating a grid-like pattern with uniform openings. This type is highly suitable for applications requiring strength, such as in construction, agriculture, and industrial settings. When purchasing, buyers should consider the gauge of the wire and the spacing of the openings, as these factors will influence the cloth’s strength and suitability for specific applications.

Stainless Steel Mesh

Stainless steel mesh is characterized by its fine openings and excellent corrosion resistance. It is commonly used in environments where hygiene and durability are paramount, such as in food processing, pharmaceuticals, and water treatment facilities. Buyers should evaluate the mesh’s weave type and wire diameter, as these will affect its filtration efficiency and strength. While it is more expensive, its longevity often justifies the investment.

Expanded Metal Mesh

Expanded metal mesh is produced by stretching metal sheets, resulting in a lightweight material with diamond-shaped openings. This type is ideal for applications such as security fencing, ventilation systems, and architectural features. Buyers should assess the thickness and pattern of the mesh to ensure it meets specific strength and aesthetic requirements. While it is strong, it may not be suitable for applications requiring fine filtration.

Hardware Cloth

Hardware cloth, typically made from galvanized steel, features hexagonal openings and is widely used for various applications, including animal enclosures and gardening. It is economical and versatile, making it a popular choice for many buyers. However, it is less durable than stainless steel options, which should be considered when evaluating long-term usage and exposure to the elements.

Perforated Metal Sheets

Perforated metal sheets are created by punching holes into flat sheets of metal, allowing for customizable hole patterns. This type is suitable for industrial applications, architectural features, and soundproofing solutions. Buyers should consider the hole size, pattern, and thickness of the sheet to ensure it meets their specific needs. While perforated sheets offer flexibility, they may not be as robust as welded options, so application requirements should guide purchasing decisions.

Related Video: Multilevel Models: Introducing multilevel modelling | Ian Brunton-Smith

Key Industrial Applications of ss hardware cloth

| Industry/Sector | Specific Application of ss hardware cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop protection and pest control | Enhances crop yield by preventing pest damage | Ensure corrosion resistance; consider local climate factors |

| Construction | Reinforcement in concrete and masonry | Increases structural integrity and longevity of buildings | Verify mesh size and gauge; assess local building codes |

| Food Processing | Filtration and sieving in food production | Maintains hygiene and quality of food products | Compliance with health regulations; specify mesh openings |

| Mining | Safety barriers and equipment protection | Reduces accidents and improves operational safety | Assess durability and resistance to abrasion; local sourcing |

| Manufacturing | Screens for machinery and equipment | Protects machinery from foreign objects, reducing downtime | Evaluate compatibility with machinery; consider weight and size |

Agriculture

In the agricultural sector, ss hardware cloth is utilized for crop protection and pest control. By creating physical barriers, it prevents pests and wildlife from damaging crops, leading to higher yields. International buyers, particularly in Africa and South America, must consider the corrosion resistance of the material to ensure longevity in various climates. Additionally, understanding local pest challenges can inform the specific mesh size required for effective protection.

Construction

Within the construction industry, ss hardware cloth serves as a reinforcement material in concrete and masonry applications. It enhances structural integrity by providing additional support, which is crucial for long-lasting buildings. Buyers should verify the mesh size and gauge to meet specific project requirements and ensure compliance with local building codes, especially in regions like Europe and the Middle East where regulations can be stringent.

Food Processing

In food processing, ss hardware cloth is employed for filtration and sieving processes, ensuring the hygiene and quality of food products. Its non-corrosive properties make it suitable for contact with food, which is vital for compliance with health regulations. International buyers must specify the appropriate mesh openings based on the type of food being processed and ensure that the material meets local health and safety standards.

Mining

The mining industry uses ss hardware cloth for safety barriers and equipment protection. This application reduces the risk of accidents by preventing unauthorized access to hazardous areas and protecting machinery from debris. Buyers should assess the durability and resistance to abrasion of the cloth to ensure it can withstand the harsh conditions often found in mining operations. Local sourcing may also be beneficial to reduce lead times and shipping costs.

Manufacturing

In the manufacturing sector, ss hardware cloth is used as screens for machinery and equipment. It protects against foreign objects, thereby minimizing downtime due to maintenance and repairs. When sourcing, buyers should evaluate the compatibility of the cloth with existing machinery, considering factors such as weight and size to optimize performance. Understanding the specific operational requirements of the manufacturing process is critical for selecting the right type of hardware cloth.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for ss hardware cloth

When selecting materials for stainless steel (ss) hardware cloth, international B2B buyers must consider various factors that influence product performance, cost, and suitability for specific applications. Below is an analysis of four common materials used in ss hardware cloth, providing insights into their properties, advantages, disadvantages, and important considerations for buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

1. 304 Stainless Steel

Key Properties:

304 stainless steel is known for its excellent corrosion resistance and good formability. It can withstand temperatures up to 870°C (1600°F) in intermittent service and is suitable for a wide range of environments.

Pros & Cons:

– Advantages: It is durable, cost-effective, and widely available. 304 stainless steel is easy to fabricate, making it suitable for various applications, including food processing and architectural uses.

– Disadvantages: While it offers good corrosion resistance, it is not as effective against chlorides, which can lead to pitting in coastal areas.

Impact on Application:

304 stainless steel hardware cloth is ideal for applications where exposure to moisture is limited but may not be suitable in highly corrosive environments.

Considerations for International Buyers:

Buyers should ensure compliance with local standards (e.g., ASTM A240) and consider the availability of 304 stainless steel in their region. In markets like Kenya and Colombia, sourcing from local suppliers can reduce shipping costs and lead times.

2. 316 Stainless Steel

Key Properties:

316 stainless steel offers superior corrosion resistance compared to 304, particularly in chloride environments. It can handle temperatures up to 870°C (1600°F) and is often used in marine applications.

Pros & Cons:

– Advantages: Its enhanced durability and resistance to pitting make it suitable for harsh environments, including coastal areas and chemical processing facilities.

– Disadvantages: The higher nickel content makes it more expensive than 304 stainless steel, which may impact budget-sensitive projects.

Impact on Application:

316 stainless steel hardware cloth is ideal for applications in marine environments, chemical processing, and any area exposed to saltwater or harsh chemicals.

Considerations for International Buyers:

Buyers must verify compliance with international standards such as ASTM A240. In regions like the Middle East, where salt exposure is common, 316 stainless steel is often preferred despite the higher cost.

3. Galvanized Steel

Key Properties:

Galvanized steel is coated with zinc to provide corrosion resistance. It is suitable for moderate temperatures and is often used in outdoor applications.

Pros & Cons:

– Advantages: It is less expensive than stainless steel options and provides decent protection against rust. Its availability and ease of fabrication make it a popular choice for various applications.

– Disadvantages: The zinc coating can wear off over time, especially in harsh environments, leading to rusting. It also has a lower temperature tolerance compared to stainless steel.

Impact on Application:

Galvanized steel hardware cloth is suitable for applications like fencing and gardening but may not be ideal for environments with high moisture or chemical exposure.

Considerations for International Buyers:

Buyers should ensure that the galvanization meets local standards (e.g., ASTM A653). In regions like South America, where cost is a significant factor, galvanized steel may be a preferred option.

4. Aluminum

Key Properties:

Aluminum hardware cloth is lightweight and resistant to corrosion. It can handle moderate temperatures and is often used in applications where weight is a concern.

Pros & Cons:

– Advantages: Its lightweight nature makes it easy to handle and install. It is also resistant to rust, making it suitable for outdoor applications.

– Disadvantages: Aluminum is less durable than stainless steel and may not withstand heavy loads or impacts.

Impact on Application:

Aluminum hardware cloth is commonly used for insect screens, ventilation, and lightweight barriers, making it suitable for residential and light commercial applications.

Considerations for International Buyers:

Buyers should confirm that aluminum products comply with local standards (e.g., ASTM B221). In European markets, where lightweight and corrosion-resistant materials are valued, aluminum may be a preferred choice.

Summary Table

| Material | Typical Use Case for ss hardware cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 Stainless Steel | Food processing, architectural uses | Cost-effective, good corrosion resistance | Limited in highly corrosive environments | Medium |

| 316 Stainless Steel | Marine applications, chemical processing | Superior corrosion resistance | Higher cost than 304 stainless steel | High |

| Galvanized Steel | Fencing, gardening | Economical, decent rust protection | Zinc coating can wear off, lower durability | Low |

| Aluminum | Insect screens, ventilation | Lightweight, rust-resistant | Less durable, not suitable for heavy loads | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the performance and suitability of various materials for ss hardware cloth, helping them make informed purchasing decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for ss hardware cloth

The manufacturing processes and quality assurance for stainless steel (ss) hardware cloth are critical for ensuring product reliability and performance in various applications. This section provides an in-depth look at the typical stages of manufacturing, key techniques employed, and the quality control measures that B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider when sourcing these materials.

Manufacturing Processes for Stainless Steel Hardware Cloth

Material Preparation

The initial stage in the manufacturing of ss hardware cloth involves the careful selection and preparation of raw materials. Stainless steel wire is typically chosen for its corrosion resistance, strength, and durability. The wire is often available in various grades, such as 304 and 316, which offer different levels of resistance to rust and chemical exposure.

- Wire Drawing: The stainless steel is drawn through a series of dies to achieve the desired diameter. This process enhances the tensile strength of the wire.

- Annealing: After drawing, the wire undergoes annealing, a heat treatment process that relieves internal stresses and improves ductility. This step is crucial for ensuring that the wire can be manipulated without breaking.

Forming

Once the material is prepared, the next step is forming the wire into the desired mesh pattern. This is accomplished through several techniques:

- Weaving: The wires are woven together using either a plain weave or a twill weave method, depending on the required mesh specifications. This process is typically done on specialized weaving machines that ensure uniformity and precision.

- Welding: In some cases, the wires are welded at the intersections instead of woven. This method can enhance the strength of the mesh and is often used for heavier gauge wire.

Assembly

After forming the mesh, the assembly process may involve cutting the hardware cloth to specific dimensions or shapes as per client requirements. Additional components, such as frames or borders, may also be added during this stage to provide structural integrity.

Finishing

The final manufacturing stage involves applying surface treatments to enhance the durability and aesthetic appeal of the hardware cloth. Common finishing techniques include:

- Electropolishing: This process removes surface imperfections and enhances corrosion resistance.

- Coating: Depending on the application, the cloth may be coated with additional protective layers to improve its performance in harsh environments.

Quality Assurance in Manufacturing

Quality assurance (QA) is a vital aspect of the manufacturing process for ss hardware cloth, ensuring that the final product meets both international standards and specific customer requirements. The following sections detail the relevant standards, checkpoints, testing methods, and verification processes.

International Standards

Adhering to recognized international quality standards is crucial for ensuring product quality and reliability:

- ISO 9001: This standard outlines the criteria for a quality management system. Companies that adhere to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Required for products sold in the European Economic Area (EEA), CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, adherence to American Petroleum Institute (API) standards is essential for ensuring the safety and reliability of the hardware cloth.

Quality Control Checkpoints

Quality control involves several critical checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival at the manufacturing facility. Tests may include verifying material specifications and conducting initial dimensional checks.

- In-Process Quality Control (IPQC): During the manufacturing process, inspections are conducted at various stages to ensure that production parameters are met. This may involve monitoring wire tension during weaving or checking for weld quality.

- Final Quality Control (FQC): Once manufacturing is complete, the finished product undergoes comprehensive testing. This may include dimensional checks, tensile strength tests, and corrosion resistance evaluations.

Common Testing Methods

Several testing methods are employed to ensure the quality of ss hardware cloth:

- Tensile Testing: This method assesses the strength of the wire and its ability to withstand stress.

- Corrosion Testing: Evaluating the resistance of the stainless steel to corrosive environments is crucial for applications in harsh conditions.

- Microscopic Inspection: This involves examining the wire and welds under a microscope to detect any imperfections or inconsistencies.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, it is essential to verify the quality control measures of potential suppliers. Here are actionable steps to ensure supplier compliance with quality standards:

- Conduct Audits: Regular audits of suppliers can help ensure adherence to quality standards and manufacturing practices. Auditors should evaluate both the processes and the final products.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certificates.

- Engage Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly important for large orders or when sourcing from new suppliers.

Conclusion

Understanding the manufacturing processes and quality assurance measures for stainless steel hardware cloth is vital for B2B buyers looking to make informed purchasing decisions. By focusing on reputable suppliers who adhere to international standards and maintain rigorous quality control practices, buyers can ensure that they receive high-quality products that meet their specific application needs. This proactive approach not only mitigates risks associated with sourcing but also enhances the overall supply chain resilience for businesses operating in diverse markets.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for ss hardware cloth Sourcing

When sourcing stainless steel (ss) hardware cloth, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will break down the key cost components, price influencers, and provide actionable tips for effective negotiations and cost management.

Cost Components

-

Materials: The primary cost driver in ss hardware cloth sourcing is the raw material itself. Stainless steel prices fluctuate based on global demand, tariffs, and mining costs. Buyers should monitor commodity markets and consider sourcing from suppliers that provide price stability through long-term contracts.

-

Labor: Labor costs vary significantly by region. In countries with lower wage standards, manufacturing costs may be reduced, but this can come at the expense of quality. Understanding local labor laws and workforce availability is essential for accurate cost assessment.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, equipment maintenance, and administrative expenses. Buyers should inquire about the supplier’s efficiency and production capacity, as these factors can impact overhead costs.

-

Tooling: Custom tooling for specific hardware cloth configurations can add to initial costs. If buyers require specialized designs, they should factor in these tooling expenses into their total cost calculations.

-

Quality Control (QC): Ensuring the quality of ss hardware cloth is paramount. This involves inspections and testing, which can be an additional cost. Buyers should consider suppliers with robust QC processes, as this may reduce long-term costs associated with defective products.

-

Logistics: Shipping costs, including freight and insurance, can significantly affect the overall price. Understanding Incoterms is essential for clarifying responsibilities and costs related to shipping. Buyers should also consider the proximity of suppliers to reduce logistics expenses.

-

Margin: Suppliers will typically add a profit margin to their costs, which varies based on market competition, supplier reputation, and the complexity of the order. Negotiating favorable terms can help reduce this margin.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Higher volumes typically lead to lower per-unit costs. Buyers should assess their needs and negotiate MOQs that align with their purchasing capabilities.

-

Specifications/Customization: Custom specifications can increase costs. Buyers should clearly communicate their requirements to avoid unexpected expenses and delays.

-

Quality/Certifications: Higher quality standards or certifications (e.g., ISO) may come at a premium but can lead to lower total costs through reduced failures and warranty claims. Buyers should weigh the benefits of certification against the added costs.

-

Supplier Factors: The supplier’s market position, reliability, and production capabilities influence pricing. Building long-term relationships with suppliers can yield better pricing and favorable terms.

-

Incoterms: Understanding the implications of different Incoterms (like FOB, CIF, EXW) is vital for determining who bears shipping costs and risks, directly impacting the final price.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing and terms. Leverage volume commitments for better rates and explore opportunities for long-term contracts that can stabilize prices.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, logistics, and potential quality costs. A lower initial price may not always translate to lower overall costs.

-

Pricing Nuances: Be aware of regional pricing variations due to economic factors, tariffs, and transportation costs. Conduct market research to understand these nuances and strengthen your bargaining position.

-

Local Insights: For buyers in regions like Africa and South America, local suppliers may offer competitive pricing due to lower logistics costs. However, they may lack certain certifications or quality assurances, so balance cost with quality expectations.

Disclaimer

Prices for ss hardware cloth can vary widely based on numerous factors, including market conditions and supplier negotiations. It is advisable for buyers to conduct their own market research and obtain multiple quotes to ensure they are receiving competitive pricing.

Spotlight on Potential ss hardware cloth Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ss hardware cloth’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ss hardware cloth

Key Technical Properties of SS Hardware Cloth

When engaging in the procurement of stainless steel (SS) hardware cloth, understanding its critical technical properties is vital for ensuring that the material meets specific project requirements. Here are some essential specifications:

- Material Grade

Stainless steel hardware cloth is available in various grades, with 304 and 316 being the most common. Grade 304 is general-purpose and offers good corrosion resistance, while Grade 316 contains molybdenum for enhanced resistance against chlorides and other corrosive elements. The choice of grade directly affects durability and longevity, impacting maintenance costs and overall project lifecycle.

Illustrative Image (Source: Google Search)

-

Wire Diameter

The wire diameter is crucial as it affects the strength and flexibility of the hardware cloth. Common diameters range from 0.5 mm to 1.6 mm. Thicker wires provide increased strength, making them suitable for applications in high-stress environments, such as fencing or industrial filters. Understanding the required wire diameter helps buyers select the right product for their specific needs. -

Mesh Count

Mesh count refers to the number of openings per linear inch. A higher mesh count means smaller openings, which is essential for applications requiring filtration or pest control. This specification is critical for B2B buyers as it dictates the cloth’s application, from construction to agriculture, influencing performance and compliance with industry standards. -

Tolerance

Tolerance defines the allowable variation in wire diameter and mesh size during manufacturing. It is expressed in terms of percentage and is essential for ensuring that the hardware cloth fits precisely in its intended application. Understanding tolerances helps buyers avoid costly errors in installation and ensures that their products meet regulatory and safety standards. -

Finish

The surface finish of stainless steel hardware cloth can vary from mill finish to polished. A polished finish can enhance corrosion resistance and aesthetic appeal, which may be particularly important for visible installations. Buyers should consider the finish based on environmental conditions and aesthetic requirements. -

Coating Options

Some hardware cloth may come with additional coatings, such as PVC or vinyl, which provide extra protection against rust and corrosion. This is especially relevant for outdoor applications or environments with high moisture levels. Buyers need to assess the cost versus the added longevity and protection offered by coatings.

Common Trade Terminology

Familiarizing oneself with industry jargon can significantly streamline the procurement process. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term helps buyers identify suppliers who can provide custom solutions tailored to specific needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget planning, as purchasing below the MOQ may lead to higher per-unit costs or inability to fulfill orders. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for price quotes on specific products or services. Buyers should prepare detailed RFQs to ensure that they receive accurate and competitive pricing. -

Incoterms

International Commercial Terms (Incoterms) are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). These terms clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Knowledge of Incoterms is essential for minimizing risk and ensuring smooth logistics. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is critical for project planning and inventory management, as it affects scheduling and overall supply chain efficiency. -

Certification Standards

These standards indicate that the product meets specific safety, quality, or environmental criteria. Buyers should inquire about relevant certifications (e.g., ISO, ASTM) to ensure compliance with industry regulations and enhance product credibility.

By grasping these technical properties and trade terms, B2B buyers can make informed purchasing decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ss hardware cloth Sector

Market Overview & Key Trends

The stainless steel (ss) hardware cloth sector is experiencing significant growth driven by increased demand across various industries, including construction, agriculture, and manufacturing. Key factors influencing this market include the rising focus on quality and durability, as ss hardware cloth offers superior resistance to corrosion and wear compared to traditional materials. In regions such as Africa and South America, the construction boom and urbanization are propelling the need for robust fencing and filtration solutions. Meanwhile, European markets are increasingly leaning towards sustainable and high-quality materials, thus driving demand for ss hardware cloth.

Emerging technologies are reshaping sourcing trends within this sector. The adoption of advanced analytics and machine learning for demand forecasting is becoming prevalent, enabling manufacturers to optimize production and inventory management. This is particularly relevant for international buyers, as accurate forecasting mitigates risks associated with demand volatility. Additionally, the rise of digital platforms facilitates easier sourcing and supplier engagement, allowing buyers from diverse regions to access global markets and compare prices effectively.

Supply chain dynamics are also evolving, with a shift towards local sourcing to enhance resilience against global disruptions. The recent geopolitical events and supply chain challenges have made companies reconsider their sourcing strategies, leading to a greater emphasis on regional suppliers who can deliver more reliably. Buyers in Africa, South America, the Middle East, and Europe should be aware of these trends to leverage opportunities and mitigate risks effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone in the procurement of ss hardware cloth. The environmental impact of production processes, particularly regarding energy consumption and waste generation, is under scrutiny. As a result, many manufacturers are adopting greener practices, such as using recycled materials and implementing energy-efficient technologies. For B2B buyers, choosing suppliers who prioritize sustainability can lead to enhanced brand reputation and compliance with increasingly stringent regulations.

Illustrative Image (Source: Google Search)

Ethical sourcing is equally important. Buyers are encouraged to assess their suppliers not only on product quality but also on their labor practices and environmental policies. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to ethical practices. Furthermore, utilizing ‘green’ materials in the production of ss hardware cloth, such as recycled stainless steel, can significantly reduce the environmental footprint, appealing to eco-conscious customers and aligning with global sustainability goals.

Investing in ethically sourced materials can also foster long-term partnerships with suppliers who share similar values, enhancing supply chain stability. International buyers should consider these factors when evaluating suppliers to ensure a responsible and sustainable procurement process.

Brief Evolution/History

The use of stainless steel hardware cloth dates back to the early 20th century when advancements in metallurgy allowed for the production of durable and corrosion-resistant materials. Initially employed in industrial applications, the versatility of ss hardware cloth soon saw its adoption in agriculture, residential fencing, and filtration systems. Over the decades, improvements in manufacturing techniques and the introduction of various wire mesh designs have expanded its applications, making it a staple in both commercial and residential settings.

Today, the industry continues to evolve with a focus on sustainable practices and innovative production methods, responding to the demands of a global market that increasingly values quality, resilience, and ethical sourcing. Understanding this historical context allows B2B buyers to appreciate the ongoing advancements and make informed sourcing decisions in the ss hardware cloth sector.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of ss hardware cloth

-

What criteria should I use to vet suppliers of stainless steel hardware cloth?

When vetting suppliers, consider their experience and reputation in the industry. Look for certifications such as ISO 9001, which indicates quality management systems. Check references and customer reviews to gauge reliability and customer service. Additionally, assess their production capacity and delivery timelines to ensure they can meet your demands. A site visit may also be beneficial to verify operational capabilities. -

Can I customize stainless steel hardware cloth according to my specifications?

Yes, many suppliers offer customization options for stainless steel hardware cloth. This can include variations in mesh size, wire diameter, and roll dimensions. Ensure you communicate your specific requirements clearly to the supplier. Request samples of custom products to evaluate quality before placing a larger order. Discuss any potential impacts on pricing and lead times for customized orders. -

What are typical minimum order quantities (MOQ) and lead times for stainless steel hardware cloth?

Minimum order quantities can vary by supplier but often range from 100 to 500 square feet. Lead times typically depend on the supplier’s inventory levels and production capabilities, ranging from a few days to several weeks. For international buyers, factor in additional time for customs clearance and shipping. Always confirm these details upfront to avoid unexpected delays in your supply chain. -

What payment terms are commonly accepted by suppliers?

Payment terms can vary widely, but many suppliers accept options such as wire transfers, letters of credit, or PayPal. For first-time purchases, some suppliers may require full payment upfront, while others might offer net 30 or net 60 terms after establishing a relationship. Always clarify payment terms and conditions in advance to ensure a smooth transaction process. -

How can I ensure quality assurance and certifications from my supplier?

Request documentation that outlines the supplier’s quality control processes, including any relevant certifications (e.g., ASTM, ISO). Inquire about their testing procedures for material strength and durability. Some suppliers may offer third-party inspection reports as part of their quality assurance. Establishing a formal agreement that includes quality expectations can further safeguard your interests. -

What logistics considerations should I keep in mind when sourcing stainless steel hardware cloth internationally?

When sourcing internationally, consider shipping methods (air vs. sea), costs, and delivery timelines. Review the supplier’s experience with export processes, including customs documentation. Factor in local regulations that may affect shipping and import duties. Establish a clear communication channel for tracking shipments and addressing any logistical issues that may arise. -

How should I handle disputes with my supplier regarding product quality or delivery?

Establish a clear communication protocol with your supplier for resolving disputes. Document all agreements and communications to support your case. If issues arise, address them promptly and professionally, aiming for an amicable resolution. In cases where resolution is not possible, refer to the terms of your contract, which should outline dispute resolution mechanisms, such as mediation or arbitration. -

What are the risks associated with sourcing stainless steel hardware cloth from international suppliers?

Risks include quality discrepancies, delivery delays, and potential communication barriers. Variations in manufacturing standards and practices can also pose challenges. To mitigate these risks, thoroughly vet suppliers, request samples, and maintain regular communication throughout the process. Additionally, consider sourcing from suppliers with a proven track record in international trade to enhance reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ss hardware cloth

In summary, strategic sourcing of stainless steel (ss) hardware cloth is a critical component for international B2B buyers navigating today’s complex supply chain landscape. By leveraging data-driven insights and predictive analytics, businesses can enhance their procurement strategies, ensuring optimal inventory levels that align with market demand. The integration of smart manufacturing technologies further empowers firms to boost operational resilience, allowing them to swiftly adapt to disruptions and maintain continuity.

Key Takeaways:

– Demand Forecasting: Utilize advanced analytics to create accurate demand forecasts that inform procurement and inventory decisions.

– Operational Efficiency: Embrace smart manufacturing to enhance productivity and reduce costs, ensuring your sourcing strategies are competitive.

– Supplier Diversification: Build resilient supply chains by diversifying suppliers across regions, which can mitigate risks associated with geopolitical tensions and supply disruptions.

As the global market continues to evolve, international B2B buyers from regions like Africa, South America, the Middle East, and Europe should prioritize strategic sourcing initiatives. By doing so, they can not only secure high-quality ss hardware cloth but also position themselves for sustained growth and innovation. Take the next step today—evaluate your sourcing strategies and engage with suppliers who align with your long-term objectives.