Your Ultimate Guide to Sourcing Toroidal Inductors And

Introduction: Navigating the Global Market for toroidal inductors and transformers

In today’s rapidly evolving technological landscape, toroidal inductors and transformers stand out as crucial components for a wide array of applications, from power supply systems to high-frequency electronic devices. These devices, characterized by their unique toroidal shapes, offer distinct advantages such as reduced electromagnetic interference, enhanced efficiency, and compact design. For international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of these components is vital for making informed sourcing decisions.

This comprehensive guide delves into the essential aspects of toroidal inductors and transformers. It covers various types and materials, manufacturing processes, quality control measures, and supplier insights. Additionally, the guide addresses cost considerations, market trends, and frequently asked questions, ensuring a holistic view of the market landscape.

By equipping buyers with actionable insights and practical knowledge, this guide empowers businesses to navigate the complexities of sourcing toroidal inductors and transformers effectively. Whether you are in Mexico or Poland, making informed choices can lead to improved product performance and reduced operational costs. Prepare to enhance your procurement strategy and strengthen your supply chain with the insights provided in this essential resource.

Understanding toroidal inductors and transformers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Toroidal Transformers | Donut-shaped core with windings encircling it | Power supplies, audio equipment, control systems | Pros: High efficiency, low noise, compact size. Cons: Higher initial cost compared to traditional transformers. |

| Toroidal Inductors | Insulated coil on a ferrite core | High-frequency circuits, RF applications | Pros: Low electromagnetic interference, high inductance. Cons: Limited performance at low frequencies. |

| Custom Toroidal Designs | Tailored specifications for specific applications | Specialized electronic devices, custom power supplies | Pros: Optimized for unique needs, enhanced performance. Cons: Longer lead times and potentially higher costs. |

| Ferrite Toroidal Inductors | Ferrite core for high-frequency applications | Switching power supplies, signal processing | Pros: Minimal eddy current loss, ideal for high frequencies. Cons: Susceptible to saturation at low frequencies. |

| Powdered Iron Toroidal Inductors | Core made from powdered iron for broader frequency range | Audio applications, power electronics | Pros: Good performance across a range of frequencies. Cons: Higher core losses compared to ferrite at high frequencies. |

Toroidal Transformers

Toroidal transformers are characterized by their circular core that minimizes magnetic flux leakage, making them highly efficient in power delivery. They are often used in sensitive applications such as audio equipment and control systems, where noise reduction is critical. When purchasing, buyers should consider the transformer’s voltage ratings, efficiency levels, and physical size, as these factors can significantly impact performance in compact electronic designs.

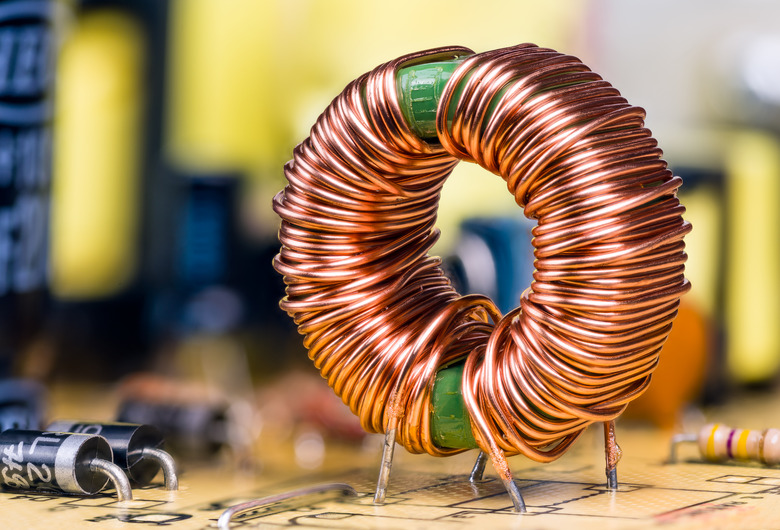

Toroidal Inductors

Toroidal inductors consist of an insulated copper wire wound around a ferrite core, designed for high-frequency applications. Their unique shape and core material result in low electromagnetic interference, making them ideal for RF applications and switching power supplies. Buyers should evaluate the inductor’s inductance value, current ratings, and frequency response to ensure they meet the specific requirements of their applications.

Custom Toroidal Designs

Custom toroidal designs allow manufacturers to tailor inductors and transformers to meet specific operational requirements. This option is particularly beneficial for specialized electronic devices that demand unique specifications. While these designs can enhance performance and efficiency, buyers must be prepared for longer lead times and potentially higher costs, making it essential to assess the trade-off between customization and budget constraints.

Ferrite Toroidal Inductors

Ferrite toroidal inductors are specifically designed for high-frequency operations, leveraging the properties of ferrite to reduce eddy current losses. They are commonly found in applications such as switching power supplies and signal processing. Buyers should consider the inductor’s saturation characteristics and operational frequency range, as these factors will influence overall performance and reliability in specific applications.

Powdered Iron Toroidal Inductors

Powdered iron toroidal inductors offer versatility across various frequency ranges, making them suitable for audio applications and power electronics. While they perform well at both low and high frequencies, they may exhibit higher core losses at elevated frequencies compared to ferrite cores. When selecting powdered iron inductors, buyers should focus on the inductor’s resistance, inductance values, and thermal performance to ensure optimal application fit.

Related Video: Transformers, explained: Understand the model behind GPT, BERT, and T5

Key Industrial Applications of toroidal inductors and transformers

| Industry/Sector | Specific Application of toroidal inductors and transformers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics | Power supply units for consumer electronics | High efficiency and low electromagnetic interference | Certification standards, size constraints, and lead time |

| Renewable Energy | Inverters in solar energy systems | Enhanced energy conversion and lower losses | Material quality, environmental compliance, and pricing |

| Telecommunications | Signal processing in RF applications | Improved signal integrity and reduced noise | Frequency range, custom designs, and reliability |

| Industrial Automation | Control systems in manufacturing equipment | Increased operational efficiency and reduced downtime | Compatibility with existing systems and technical support |

| Medical Devices | Power conditioning in diagnostic equipment | Safety and precision in sensitive applications | Regulatory compliance, sourcing from certified vendors, and warranty terms |

Electronics

In the electronics sector, toroidal inductors and transformers are extensively utilized in power supply units for consumer electronics. Their design minimizes electromagnetic interference, making them ideal for sensitive devices. Businesses must consider certification standards, size constraints, and lead time when sourcing these components, especially as consumer demand for compact and efficient electronic devices continues to rise globally.

Renewable Energy

In the renewable energy sector, particularly in solar energy systems, toroidal transformers are integral to inverters that convert DC to AC power. Their high energy efficiency and reduced losses are vital for maximizing energy output. Buyers should prioritize material quality, ensure environmental compliance, and evaluate pricing to remain competitive in this rapidly growing market, particularly in regions like Africa and South America, where solar energy adoption is increasing.

Illustrative Image (Source: Google Search)

Telecommunications

The telecommunications industry leverages toroidal inductors and transformers for signal processing in RF applications. These components enhance signal integrity and reduce noise, crucial for maintaining high-quality communication. B2B buyers must focus on the frequency range, consider custom designs to meet specific needs, and ensure reliability under varying operational conditions, especially in regions with diverse technological infrastructures.

Industrial Automation

In industrial automation, toroidal transformers are used in control systems for manufacturing equipment. Their efficiency contributes to increased operational efficiency and reduced downtime, which are critical for maintaining productivity. Buyers should assess compatibility with existing systems and seek suppliers who can provide robust technical support to ensure seamless integration and optimal performance in automated environments.

Medical Devices

In the medical devices sector, toroidal inductors and transformers play a vital role in power conditioning for diagnostic equipment. Their ability to provide stable and precise power is essential for the safety and accuracy of sensitive medical applications. When sourcing these components, businesses should ensure regulatory compliance, prioritize sourcing from certified vendors, and consider warranty terms to mitigate risks associated with high-stakes medical environments.

Related Video: Understanding Inductors: The Basics, Types, and Applications

Strategic Material Selection Guide for toroidal inductors and transformers

When selecting materials for toroidal inductors and transformers, it is essential to consider the specific properties, advantages, disadvantages, and application impacts of various materials. This guide analyzes four common materials used in the construction of these components, providing actionable insights for international B2B buyers.

1. Ferrite

Key Properties: Ferrite cores are made from ferrimagnetic materials, which exhibit high resistivity and low eddy current losses, making them ideal for high-frequency applications. They can operate effectively at temperatures up to 150°C, depending on the specific formulation.

Pros & Cons: Ferrite cores are lightweight and compact, offering high inductance values with minimal magnetic leakage. However, they are brittle and can be prone to cracking under mechanical stress, which may complicate manufacturing and handling processes. Additionally, ferrites can be more expensive than other materials.

Impact on Application: Ferrite cores are particularly suited for high-frequency circuits, such as in switching power supplies and RF applications. Their low eddy current losses make them highly efficient for these uses.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and JIS. Given the brittle nature of ferrite, shipping and handling logistics must be carefully managed, especially in regions with high humidity or temperature fluctuations.

2. Silicon Steel

Key Properties: Silicon steel is a ferromagnetic material known for its excellent magnetic properties and relatively high saturation point. It can withstand temperatures up to 300°C and is often used in low-frequency applications.

Pros & Cons: Silicon steel is durable and cost-effective, making it a popular choice for many industrial applications. However, it has higher hysteresis losses compared to ferrite, which can lead to inefficiencies in high-frequency applications. Additionally, the manufacturing process can be more complex due to the need for lamination to reduce eddy currents.

Impact on Application: This material is commonly used in power transformers and inductors designed for low-frequency operations, such as in power distribution systems.

Considerations for International Buyers: Buyers should be aware of the specific grades of silicon steel that meet local standards, such as DIN in Europe. The availability of silicon steel may vary by region, impacting lead times and costs.

3. Amorphous Steel

Key Properties: Amorphous steel, or metallic glass, has a non-crystalline structure that significantly reduces energy losses due to its unique magnetic properties. It can operate efficiently at temperatures up to 200°C and offers lower hysteresis losses than traditional silicon steel.

Pros & Cons: The primary advantage of amorphous steel is its high efficiency, particularly in low-frequency applications. However, it is more expensive and requires specialized manufacturing processes, which can increase production costs and lead times.

Impact on Application: Amorphous steel is ideal for transformers and inductors that require high efficiency and low energy losses, making it suitable for renewable energy applications and advanced power systems.

Considerations for International Buyers: Buyers should investigate the availability of amorphous steel and its compliance with local standards. It may also be beneficial to evaluate the supply chain for sourcing this material, as it may not be as widely available in some regions.

4. Copper Wire

Key Properties: Copper wire is the most common conductor used in toroidal inductors and transformers due to its excellent electrical conductivity and thermal properties. It can operate effectively at high temperatures, typically up to 200°C.

Pros & Cons: Copper is highly conductive and offers good durability. However, it is susceptible to corrosion, which may necessitate additional protective coatings. The cost of copper can also fluctuate significantly based on market conditions.

Impact on Application: Copper wire is crucial for ensuring efficient energy transfer in both inductors and transformers, making it suitable for a wide range of applications, from consumer electronics to industrial machinery.

Considerations for International Buyers: Buyers should consider the impact of local regulations on copper sourcing and environmental compliance. Additionally, fluctuations in copper prices should be monitored to ensure budget adherence.

Summary Table

| Material | Typical Use Case for toroidal inductors and transformers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ferrite | High-frequency applications (e.g., RF circuits) | High efficiency, low losses | Brittle, expensive | High |

| Silicon Steel | Low-frequency applications (e.g., power transformers) | Cost-effective, durable | Higher hysteresis losses | Medium |

| Amorphous Steel | High-efficiency transformers (e.g., renewable energy) | Very low energy losses | Expensive, complex manufacturing | High |

| Copper Wire | General use in inductors and transformers | Excellent conductivity | Susceptible to corrosion | Medium |

This guide provides a strategic overview of material selection for toroidal inductors and transformers, aiding international B2B buyers in making informed decisions tailored to their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for toroidal inductors and transformers

Manufacturing Processes for Toroidal Inductors and Transformers

The manufacturing of toroidal inductors and transformers is a meticulous process that involves several stages, each critical to ensuring the final product meets quality and performance standards. Understanding these processes allows B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, to make informed decisions when selecting suppliers.

Main Stages of Manufacturing

-

Material Preparation

– Core Materials: The choice of core material is pivotal. Ferrite cores are commonly used for their high magnetic permeability and low eddy current losses, particularly in high-frequency applications. Manufacturers often source high-grade ferrite materials that meet specific electrical and thermal properties.

– Wire Selection: Copper wire is typically used for winding due to its excellent conductivity. The wire gauge is selected based on the application’s current requirements. -

Forming

– Core Shaping: The core is shaped into a toroidal form, often through molding or sintering processes. Precision in this step is crucial to minimize air gaps and ensure optimal magnetic performance.

– Winding: The insulated copper wire is wound around the toroidal core. This process can be automated for consistency, but skilled operators are essential to maintain tight tolerances and proper winding techniques to avoid issues like uneven inductance.

Illustrative Image (Source: Google Search)

-

Assembly

– Insulation and Layering: Depending on the design, multiple layers of winding may be required. Insulating materials are applied between layers to prevent short circuits and ensure safety.

– Connecting Leads: After winding, leads are attached to the inductor or transformer. This step often includes soldering or crimping to ensure reliable electrical connections. -

Finishing

– Encapsulation: Many manufacturers encapsulate the finished product in resin or other materials to protect against environmental factors and mechanical stress.

– Labeling and Packaging: Proper labeling with specifications and packing for shipment are conducted to ensure the integrity of the products during transit.

Key Techniques Employed

- Automated Winding Machines: These machines enhance precision and efficiency in the winding process, reducing human error and increasing production rates.

- Vacuum Impregnation: This technique is used to enhance insulation and reduce the risk of moisture ingress, particularly important in humid environments.

- Thermal Treatment: Some manufacturers apply heat treatments to the cores to relieve stress and improve magnetic properties.

Quality Assurance in Manufacturing

Quality assurance is critical in the production of toroidal inductors and transformers, ensuring that products meet both international and industry-specific standards.

Relevant International Standards

- ISO 9001: This standard outlines a framework for quality management systems, ensuring consistent quality in manufacturing processes. Suppliers adhering to ISO 9001 are more likely to provide reliable products.

- CE Marking: For products sold in the European market, compliance with CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For applications in the petroleum and natural gas industry, adherence to API standards ensures that products meet rigorous performance and safety requirements.

QC Checkpoints

-

Incoming Quality Control (IQC)

– Inspection of raw materials and components upon arrival to ensure they meet specified criteria.

– Verification of certificates of compliance from suppliers. -

In-Process Quality Control (IPQC)

– Continuous monitoring during manufacturing stages, including visual inspections and measurements of winding consistency.

– Use of statistical process control (SPC) techniques to identify variations in the manufacturing process. -

Final Quality Control (FQC)

– Comprehensive testing of the finished product, including electrical testing (e.g., inductance, resistance), thermal cycling tests, and dielectric strength tests.

– Visual inspections for physical defects and compliance with design specifications.

Common Testing Methods

- Electrical Testing: Measurement of inductance, resistance, and current handling capacity to ensure performance specifications are met.

- Thermal Testing: Evaluating the thermal behavior of the inductor or transformer under operational conditions to prevent overheating.

- Mechanical Testing: Assessing the physical robustness of the product, including vibration and shock tests.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to ensure the quality of their suppliers:

- Audits: Conducting on-site audits of manufacturing facilities can provide insights into processes, compliance with standards, and overall quality management practices.

- Quality Reports: Requesting detailed quality reports can help assess a supplier’s commitment to quality assurance and any corrective actions taken on past issues.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased review of manufacturing processes and product quality, ensuring compliance with both local and international standards.

QC and Certification Nuances for International Buyers

When sourcing from different regions, international buyers must consider the following:

- Cultural Differences: Understanding local manufacturing practices and quality expectations can help in establishing effective communication with suppliers.

- Regulatory Compliance: Familiarize yourself with the regulatory environment of the supplier’s country, as this can affect product certification and compliance requirements.

- Logistics and Supply Chain Risks: Consider potential risks related to logistics, including delays in shipping and customs clearance, which may impact the timely delivery of quality products.

By gaining a comprehensive understanding of the manufacturing processes and quality assurance measures for toroidal inductors and transformers, international B2B buyers can make informed decisions that align with their operational needs and standards.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for toroidal inductors and transformers Sourcing

Understanding the cost structure and pricing dynamics of toroidal inductors and transformers is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Below, we delve into the various components that contribute to the pricing of these essential electrical components, alongside actionable insights for effective sourcing.

Cost Components

-

Materials:

– Core Material: The cost of ferrite or other magnetic materials significantly impacts pricing. High-quality ferrite cores, while more expensive, reduce losses and improve efficiency, making them a preferred choice for high-frequency applications.

– Copper Wire: The quality and gauge of copper wire used for windings can influence both performance and cost. Fluctuations in copper prices should be monitored as they can affect overall costs. -

Labor:

– Skilled labor is required for the precision winding of toroidal inductors and transformers. Labor costs vary significantly by region, affecting the final pricing, particularly in countries with higher wage standards. -

Manufacturing Overhead:

– This includes costs related to machinery, facility maintenance, and utilities. Manufacturers with advanced technologies may have higher overheads but can offer better quality and efficiency. -

Tooling:

– Initial tooling costs for custom designs can be substantial. Buyers should consider these costs in their total budget, especially for unique specifications or high-volume orders. -

Quality Control (QC):

– Rigorous testing and quality assurance processes are essential for ensuring product reliability. The costs associated with QC processes should be factored into the final price, particularly for critical applications. -

Logistics:

– Shipping and handling costs can vary widely based on the location of the supplier and the destination. Consideration of Incoterms (International Commercial Terms) is critical for understanding who bears the shipping risk and costs. -

Margin:

– Suppliers typically include a margin to cover their operational costs and profit. This can vary widely depending on the supplier’s market positioning and the competitiveness of the industry.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity):

– Prices often decrease with larger order volumes. Negotiating for bulk purchasing can lead to significant savings. -

Specifications/Customization:

– Custom designs and specifications generally incur higher costs. Standardized products are usually more cost-effective, so buyers should evaluate their needs carefully. -

Materials and Quality Certifications:

– The inclusion of quality certifications (e.g., ISO, CE) can add to the cost but may provide assurance of reliability and performance, which is especially important in regulated markets. -

Supplier Factors:

– The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium but offer better support and quality assurance. -

Incoterms:

– Understanding Incoterms is essential for international transactions as they dictate the responsibilities of buyers and sellers regarding shipping and costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total landed cost.

Buyer Tips

-

Negotiation: Always negotiate prices and terms. Suppliers may have room to adjust pricing based on order size or long-term relationships.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as energy efficiency and lifespan, which can lead to savings over time.

-

Pricing Nuances: Be aware of regional pricing differences. Suppliers in different geographical areas may have varying pricing structures influenced by local economies and labor costs.

-

Market Trends: Stay informed about material price fluctuations, especially for copper and core materials. Timing your purchase can lead to significant savings.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, improved service, and access to new technologies or products.

Disclaimer

Prices for toroidal inductors and transformers can vary widely based on the factors outlined above. It is advisable for buyers to obtain multiple quotes and conduct thorough market research to ensure competitive pricing and quality assurance.

Spotlight on Potential toroidal inductors and transformers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘toroidal inductors and transformers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for toroidal inductors and transformers

Key Technical Properties of Toroidal Inductors and Transformers

When navigating the procurement of toroidal inductors and transformers, understanding essential technical properties is crucial for making informed decisions. Here are several critical specifications that should be considered:

-

Core Material: The choice of core material significantly impacts performance. Common materials include ferrite for high-frequency applications and silicon steel for lower frequencies. Ferrite cores offer high resistivity and low eddy current loss, making them ideal for compact designs in high-frequency circuits. Selecting the right core material ensures optimal efficiency and minimizes energy losses, which is crucial for energy-sensitive applications.

-

Inductance Value: Measured in henries (H), the inductance value indicates the inductor’s ability to store energy in a magnetic field. It is essential for determining how the inductor will perform in various circuit configurations. Buyers should assess the inductance requirements based on their specific applications, as this will influence both the functionality and size of the component.

-

Tolerance: This specification refers to the acceptable deviation from the nominal inductance value. High precision is often required in applications like audio equipment and telecommunications. Understanding tolerance levels is essential for ensuring that the components will perform reliably in the intended application, especially in industries where small discrepancies can lead to significant performance issues.

-

DC Resistance (DCR): The DC resistance of an inductor affects its efficiency and heat generation. Lower resistance values lead to reduced power loss, which is particularly important in power supply circuits. Buyers should evaluate DCR alongside other specifications to ensure the selected component meets their performance and efficiency standards.

-

Operating Temperature Range: This specification indicates the temperatures within which the component can operate effectively. Exceeding the specified range can lead to failure or reduced performance. Understanding the operating temperature is critical, especially for applications in extreme environments or where thermal management is a concern.

-

Shielding Options: Some toroidal inductors and transformers come with shielding to reduce electromagnetic interference (EMI). This can be vital for sensitive electronic applications. Evaluating the need for shielding based on the application can enhance product reliability and performance.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are several important terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers looking to source components that meet specific quality and compatibility standards.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory planning, especially for smaller businesses or projects with limited funding.

-

RFQ (Request for Quote): An RFQ is a formal document requesting pricing and terms from suppliers. For B2B buyers, crafting a detailed RFQ can lead to more accurate quotes and better negotiation outcomes.

-

Incoterms (International Commercial Terms): These are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers mitigate risks and clarify obligations during international transactions.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning and inventory management, ensuring that production schedules are met without delays.

-

Testing Standards: This refers to the criteria used to evaluate the performance and safety of inductors and transformers. Familiarity with relevant testing standards, such as those from IEC or UL, is crucial for ensuring that components meet regulatory requirements and industry benchmarks.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of sourcing toroidal inductors and transformers with greater confidence and strategic insight.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the toroidal inductors and transformers Sector

Market Overview & Key Trends

The global market for toroidal inductors and transformers is witnessing significant growth, driven by increasing demand for energy-efficient and compact electrical components across various industries, including telecommunications, automotive, and renewable energy. Key trends influencing this market include the rising adoption of high-frequency applications, which leverage the low electromagnetic interference (EMI) and superior performance characteristics of toroidal designs. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing advanced technology solutions that not only enhance operational efficiency but also comply with regional regulatory standards.

Emerging technologies, such as electric vehicles and renewable energy systems, are propelling the need for innovative inductors and transformers. Manufacturers are responding by investing in R&D to develop products that support higher frequencies and improved thermal performance. Additionally, the integration of smart technologies in power management systems is creating new sourcing opportunities for buyers looking to enhance their product offerings with intelligent design features.

Furthermore, buyers should be aware of the regional disparities in production capabilities and supply chain logistics. For instance, European manufacturers often lead in technology and quality standards, while suppliers from South America and Africa may offer cost-effective solutions. Understanding these dynamics will help international buyers make informed sourcing decisions that align with their operational needs and market expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a crucial factor in the sourcing of toroidal inductors and transformers. The environmental impact of manufacturing processes, particularly in the context of material sourcing and waste management, is under scrutiny. B2B buyers are encouraged to prioritize suppliers who demonstrate a commitment to sustainable practices, such as minimizing energy consumption during production and utilizing recyclable materials.

Ethical sourcing is equally important, as companies are expected to maintain transparency in their supply chains. Buyers should seek out manufacturers who adhere to recognized sustainability certifications, such as ISO 14001, which focuses on effective environmental management systems. Moreover, materials like ferrite, which are commonly used in toroidal designs, should be sourced from suppliers that ensure responsible mining and processing practices.

Incorporating ‘green’ certifications and materials into procurement strategies not only enhances a company’s corporate social responsibility profile but also meets the growing consumer demand for environmentally friendly products. By aligning purchasing decisions with sustainability goals, international B2B buyers can contribute to a more sustainable future while also potentially accessing new markets and customer segments that prioritize eco-friendly solutions.

Brief Evolution/History

The evolution of toroidal inductors and transformers can be traced back to the early 20th century, where advancements in magnetic materials and manufacturing techniques paved the way for their adoption in electrical engineering. Initially, these components were primarily used in specialized applications due to their complex design and manufacturing processes.

Over the decades, technological innovations, such as the development of ferrite cores in the 1960s, greatly enhanced the performance characteristics of toroidal inductors and transformers. This shift allowed for greater efficiency and reduced size, making them suitable for a wider range of applications. As industries evolved and the demand for energy efficiency and compact designs increased, toroidal components gained prominence, leading to their widespread use in modern electronics and power systems.

Today, the market continues to evolve, with a focus on integrating smart technologies and sustainable practices, further solidifying the role of toroidal inductors and transformers in the future of electrical systems.

Related Video: Globalization- trade and transnational corporations | Society and Culture | MCAT | Khan Academy

Frequently Asked Questions (FAQs) for B2B Buyers of toroidal inductors and transformers

-

What should I consider when vetting suppliers of toroidal inductors and transformers?

When vetting suppliers, prioritize their industry experience, reputation, and product quality. Request references and case studies to assess their reliability. Verify certifications like ISO 9001, which indicates quality management standards. Evaluate their production capabilities and technology used, ensuring they can meet your specific requirements. Additionally, assess their communication responsiveness and willingness to support you throughout the sourcing process, as these factors can impact your overall experience. -

Can toroidal inductors and transformers be customized to meet specific requirements?

Yes, many manufacturers offer customization options for toroidal inductors and transformers. Customization can include variations in size, inductance, winding configurations, and core materials. When discussing customization, clearly outline your specifications, including electrical and mechanical requirements. Be sure to confirm the supplier’s ability to deliver custom products within your desired timeframe, as this can affect project timelines and costs. -

What are the typical minimum order quantities (MOQs) and lead times for these components?

Minimum order quantities (MOQs) for toroidal inductors and transformers can vary widely by supplier and product type. Common MOQs range from 50 to 500 units, depending on customization and material costs. Lead times typically range from 4 to 12 weeks, influenced by factors such as order complexity, supplier location, and current production capacity. Always discuss these details upfront to align expectations and avoid delays in your supply chain. -

What payment terms should I expect when sourcing toroidal inductors and transformers?

Payment terms can vary significantly by supplier and region. Common practices include partial upfront payments (30-50%) with the balance due upon delivery or a letter of credit for larger orders. Ensure you understand the payment methods accepted, such as wire transfers or PayPal, and inquire about any potential discounts for early payments. Establishing clear payment terms in your contract can help prevent disputes and ensure a smoother transaction process. -

How can I ensure quality assurance and certifications for my orders?

To ensure quality assurance, request documentation of the supplier’s quality control processes and relevant certifications, such as ISO 9001 or RoHS compliance. Conducting factory audits, if feasible, can provide insights into their manufacturing practices. Additionally, consider requesting sample products for testing before placing larger orders. Establishing a clear agreement on quality expectations in your contract can also mitigate risks related to product defects. -

What logistical considerations should I keep in mind when sourcing internationally?

International sourcing involves several logistical considerations, including shipping methods, customs regulations, and import duties. Discuss shipping options with your supplier, weighing factors such as cost, delivery speed, and reliability. Ensure you understand the customs clearance process in your country and any potential tariffs that may apply. Engaging a logistics partner or freight forwarder can streamline this process and help avoid unexpected delays or costs. -

How can I handle disputes with suppliers effectively?

To handle disputes effectively, maintain clear communication with your supplier and document all agreements and correspondence. If a dispute arises, attempt to resolve it amicably through negotiation. If necessary, refer to the dispute resolution clause in your contract, which may include mediation or arbitration. In severe cases, legal action may be a last resort. Establishing a strong relationship with your supplier can also help mitigate conflicts before they escalate.

- What are the common applications for toroidal inductors and transformers in various industries?

Toroidal inductors and transformers are widely used in various industries, including electronics, telecommunications, and automotive sectors. Common applications include power supply units, audio equipment, and industrial control systems. Their compact size and high efficiency make them ideal for high-frequency and sensitive electronic circuits. Understanding your specific application requirements can help you select the right components, ensuring optimal performance in your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for toroidal inductors and transformers

In conclusion, the strategic sourcing of toroidal inductors and transformers presents significant advantages for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. By leveraging the unique benefits of toroidal designs—such as reduced magnetic flux leakage, enhanced energy efficiency, and compact form factors—businesses can optimize their electronic applications across various industries.

Key B2B Takeaways:

– Cost Efficiency: Strategic sourcing allows for competitive pricing without compromising quality, enabling businesses to meet budget constraints while enhancing performance.

– Supply Chain Resilience: Establishing relationships with reliable suppliers ensures consistent access to high-quality components, crucial for maintaining production schedules and minimizing downtime.

– Technical Support: Engaging with manufacturers who offer robust technical assistance can streamline integration processes and enhance product performance.

As the demand for high-performance electronic components continues to grow, now is the time for international buyers to evaluate their sourcing strategies. By prioritizing partnerships with reputable suppliers, companies can not only improve their product offerings but also position themselves advantageously in the competitive marketplace. Embrace the future of sourcing today—invest in toroidal inductors and transformers that meet your operational needs and drive innovation.