Your Ultimate Guide to Sourcing Tungsten Carbide Vs

Introduction: Navigating the Global Market for tungsten carbide vs titanium carbide

Navigating the global market for tungsten carbide and titanium carbide is crucial for international B2B buyers seeking high-performance materials for various industrial applications. Both tungsten carbide (WC) and titanium carbide (TiC) are renowned for their exceptional hardness, wear resistance, and thermal stability, making them essential in sectors such as aerospace, mining, and manufacturing. Understanding the nuanced differences between these materials can significantly impact operational efficiency, product durability, and overall cost-effectiveness.

This comprehensive guide delves into the critical aspects of tungsten carbide and titanium carbide, providing insights on their properties, manufacturing processes, quality control measures, and supplier considerations. Buyers will gain a clear understanding of cost implications and market trends, equipping them to make informed sourcing decisions that align with their specific industry needs.

For stakeholders from Africa, South America, the Middle East, and Europe, including key markets like Germany and the UAE, this guide serves as an authoritative resource. It addresses frequently asked questions and highlights best practices for evaluating and selecting the right material for your applications. By leveraging the insights offered, international B2B buyers can enhance their procurement strategies, ensuring they choose the most suitable materials for their unique operational challenges.

Understanding tungsten carbide vs titanium carbide Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cemented Tungsten Carbide | High density, exceptional hardness, and impact resistance. | Cutting tools, mining equipment | Pros: Superior wear resistance; Cons: Brittle under extreme impact. |

| Titanium Carbide Coatings | Lightweight, high hardness, and thermal stability. | Aerospace components, wear-resistant coatings | Pros: Excellent oxidation resistance; Cons: Lower thermal conductivity. |

| Titanium Carbide Composites | Mixture of TiC with metal binders for enhanced toughness. | Industrial dies, cutting tools | Pros: Improved toughness; Cons: Higher cost compared to pure materials. |

| Cobalt-Bonded Tungsten Carbide | Tungsten carbide combined with cobalt for enhanced toughness. | Heavy-duty industrial machinery | Pros: Better fracture toughness; Cons: Susceptible to oxidation at high temperatures. |

| Titanium Carbide Nanocomposites | Nano-sized particles for increased surface area and hardness. | Advanced manufacturing, electronics | Pros: Exceptional wear resistance; Cons: More complex manufacturing process. |

Cemented Tungsten Carbide

Cemented tungsten carbide is one of the most common forms of tungsten carbide, characterized by its high density and exceptional hardness. It is often used in cutting tools and mining equipment due to its ability to withstand wear and tear in abrasive environments. When considering this material, buyers should note its brittleness under extreme impact, which could lead to fractures if not used appropriately. The investment in this material can yield long-term cost savings in high-performance applications.

Titanium Carbide Coatings

Titanium carbide coatings are lightweight yet provide a significant hardness advantage, making them suitable for aerospace components and wear-resistant coatings. These coatings are beneficial in high-temperature environments due to their oxidation resistance, which can prolong the life of the underlying materials. Buyers must consider the lower thermal conductivity of TiC coatings, which may lead to localized heat buildup in certain applications, potentially affecting performance.

Titanium Carbide Composites

Titanium carbide composites combine TiC with metal binders to enhance toughness, making them ideal for industrial dies and cutting tools. This variation offers a balance between hardness and durability, allowing for effective performance in diverse manufacturing settings. However, the cost of titanium carbide composites can be higher than that of pure materials, necessitating careful evaluation of the application requirements and budget constraints.

Cobalt-Bonded Tungsten Carbide

Cobalt-bonded tungsten carbide is a variation that incorporates cobalt as a binder, providing enhanced toughness and impact resistance. This material is widely used in heavy-duty industrial machinery, where durability is paramount. While it offers better fracture toughness than pure tungsten carbide, buyers should be aware of its susceptibility to oxidation at high temperatures, which could limit its use in certain applications.

Titanium Carbide Nanocomposites

Titanium carbide nanocomposites utilize nano-sized TiC particles to increase surface area and hardness, making them suitable for advanced manufacturing and electronics. These nanocomposites exhibit exceptional wear resistance, which can be advantageous in high-tech applications. However, the complexity of the manufacturing process can lead to increased costs, prompting buyers to assess the specific performance benefits against their investment.

Key Industrial Applications of tungsten carbide vs titanium carbide

| Industry/Sector | Specific Application of Tungsten Carbide vs Titanium Carbide | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Tungsten Carbide for drill bits and cutting tools | Exceptional wear resistance and durability reduce downtime and costs | Consider local suppliers with access to high-quality WC |

| Aerospace | Titanium Carbide for thermal barrier coatings | Enhances performance in high-temperature environments | Ensure compliance with aerospace standards and certifications |

| Manufacturing | Tungsten Carbide for industrial dies and molds | Increased lifespan of tools leads to lower replacement costs | Evaluate suppliers based on precision and customization capabilities |

| Oil & Gas | Titanium Carbide for wear-resistant components | Reduces maintenance costs and improves operational efficiency | Source from manufacturers experienced in harsh environmental applications |

| Automotive | Tungsten Carbide for engine components | Enhances performance and longevity of critical engine parts | Look for suppliers with proven track records in automotive applications |

Mining

In the mining industry, tungsten carbide is predominantly used in drill bits and cutting tools due to its exceptional wear resistance and durability. These tools face intense friction and pressure, making tungsten carbide an ideal choice for enhancing operational efficiency. By minimizing downtime associated with tool replacements, businesses can significantly reduce costs. International buyers should consider sourcing from local suppliers who can guarantee the quality and availability of tungsten carbide products, ensuring timely delivery and support.

Aerospace

Titanium carbide finds its application in aerospace as a thermal barrier coating, which protects components from extreme temperatures. This is crucial for parts exposed to high thermal stress, as it enhances their performance and extends their lifespan. The aerospace sector demands materials that comply with stringent safety and performance standards, so international buyers must ensure that their suppliers meet these certifications. Additionally, understanding the specific thermal requirements of components can guide sourcing decisions effectively.

Manufacturing

In manufacturing, tungsten carbide is widely used for industrial dies and molds, where its hardness and durability are critical. The longevity of these tools translates into lower replacement costs, making tungsten carbide a cost-effective choice for manufacturers. Buyers should evaluate potential suppliers based on their ability to provide precision-engineered products that meet specific application requirements. Customization capabilities can also be a significant factor in selecting the right supplier.

Oil & Gas

The oil and gas industry utilizes titanium carbide in wear-resistant components that are subjected to extreme conditions, including high pressure and corrosive environments. By reducing maintenance costs and improving operational efficiency, titanium carbide components can significantly enhance productivity in this sector. International buyers should prioritize sourcing from manufacturers experienced in producing high-performance materials that can withstand harsh environmental conditions, ensuring reliability and performance.

Automotive

In the automotive sector, tungsten carbide is commonly used for critical engine components due to its ability to enhance performance and longevity. The high hardness of tungsten carbide ensures that engine parts can withstand the stresses of operation, thus reducing the likelihood of failure. Buyers in this sector should focus on sourcing from suppliers with a proven track record in automotive applications, as this ensures that the materials meet the demanding specifications required for reliability and safety.

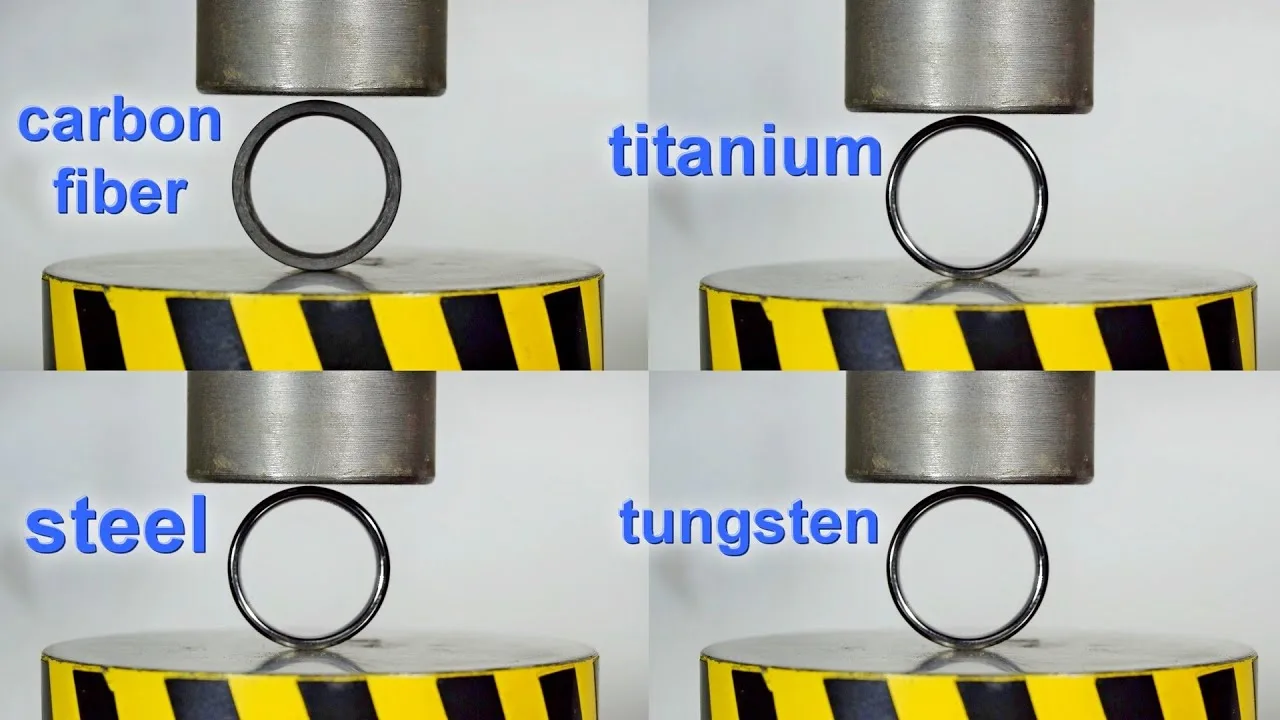

Related Video: What is Cemented Tungsten Carbide?

Strategic Material Selection Guide for tungsten carbide vs titanium carbide

When selecting between tungsten carbide and titanium carbide for industrial applications, it is essential to understand their unique properties, advantages, and limitations. This analysis will focus on these two materials, along with their implications for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Tungsten Carbide (WC)

Key Properties:

Tungsten carbide is renowned for its exceptional hardness (1800-2400 HV) and density (15 g/cm³). It has a melting point of approximately 2870°C and exhibits high thermal and wear resistance, making it suitable for high-stress applications. However, it is less resistant to oxidation at temperatures above 500°C.

Pros & Cons:

The primary advantage of tungsten carbide lies in its durability and wear resistance, making it ideal for cutting tools, mining equipment, and industrial machinery. However, its brittleness under impact can be a disadvantage, particularly in applications requiring high toughness. Additionally, the cost of tungsten carbide is relatively high due to the complexity of its manufacturing process.

Impact on Application:

Tungsten carbide is widely used in environments that demand high wear resistance, such as drilling and cutting operations. Its compatibility with abrasive materials makes it a preferred choice in mining and manufacturing industries.

Considerations for International Buyers:

Buyers should be aware of compliance with international standards such as ASTM and DIN, especially in regions like Germany and the UAE. The cost implications of sourcing tungsten carbide can vary significantly based on local availability and market conditions.

Titanium Carbide (TiC)

Key Properties:

Titanium carbide boasts superior hardness (2800-3200 HV) and a higher melting point of 3160°C, along with excellent thermal stability and oxidation resistance up to 800°C. Its lower density (4.9 g/cm³) compared to tungsten carbide makes it advantageous in lightweight applications.

Pros & Cons:

The key advantage of titanium carbide is its hardness and thermal stability, making it suitable for high-performance coatings and cutting tools. However, its lower toughness and higher manufacturing complexity can limit its use in certain applications. Additionally, titanium carbide is generally more expensive than tungsten carbide.

Impact on Application:

TiC is particularly effective in applications requiring thermal barrier coatings and high-stress environments. Its ability to withstand high temperatures and resist oxidation makes it suitable for aerospace and high-performance industrial applications.

Considerations for International Buyers:

For international buyers, understanding the specific requirements of their applications is crucial. Compliance with standards like JIS and ASTM is essential, especially in markets like South America and Europe, where regulatory frameworks are stringent.

Summary Table

| Material | Typical Use Case for tungsten carbide vs titanium carbide | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tungsten Carbide | Cutting tools, mining equipment, industrial machinery | Exceptional wear resistance | Brittle under impact | High |

| Titanium Carbide | High-performance coatings, aerospace components | Superior hardness and thermal stability | Lower toughness and higher manufacturing cost | High |

This guide provides a comprehensive overview of tungsten carbide and titanium carbide, highlighting their distinct properties and implications for B2B buyers. Understanding these factors will enable international buyers to make informed decisions tailored to their specific industrial needs.

In-depth Look: Manufacturing Processes and Quality Assurance for tungsten carbide vs titanium carbide

Manufacturing Processes for Tungsten Carbide and Titanium Carbide

The manufacturing processes for tungsten carbide (WC) and titanium carbide (TiC) involve several key stages, each critical to ensuring the performance and quality of the final products. Understanding these processes can help international B2B buyers make informed decisions when sourcing materials or components.

1. Material Preparation

Tungsten Carbide:

– Raw Material Selection: The primary raw materials for tungsten carbide production are tungsten powder and carbon black. The quality of these materials directly impacts the hardness and durability of the final product.

– Powder Metallurgy: The tungsten powder is often mixed with a binder, typically cobalt or nickel, to improve toughness. This mixture is then subjected to a milling process to achieve the desired particle size.

Titanium Carbide:

– Titanium Source: Titanium carbide production usually starts with titanium dioxide or titanium sponge, which is reduced using carbon sources like petroleum coke.

– Synthesis: The titanium and carbon are reacted at high temperatures in a controlled environment to form titanium carbide powder. This process requires precise control of temperature and atmosphere to prevent contamination.

2. Forming

Tungsten Carbide:

– Pressing: The powder mixture is compacted into molds using uniaxial or isostatic pressing techniques. This step determines the density and shape of the final product.

– Sintering: The pressed parts are sintered at high temperatures (around 1400-1600°C) in a vacuum or inert gas atmosphere. This process fuses the particles together, enhancing the hardness and wear resistance of the material.

Titanium Carbide:

– Cold Pressing: Similar to tungsten carbide, titanium carbide powder is cold-pressed into desired shapes.

– Sintering: The cold-pressed parts undergo sintering at high temperatures, typically ranging from 1400-1700°C. This process is crucial for achieving the desired mechanical properties.

3. Assembly

For both materials, assembly may involve combining different components or layers, particularly in applications where TiC or WC is used as a coating or in composite materials. This can include:

– Coating: Applying titanium carbide or tungsten carbide coatings onto tools or components using techniques such as chemical vapor deposition (CVD) or physical vapor deposition (PVD) to enhance wear resistance.

– Joining: Techniques like laser welding or brazing may be employed to join tungsten carbide parts in complex assemblies.

4. Finishing

Tungsten Carbide:

– Grinding and Polishing: The final product often undergoes grinding and polishing to achieve precise dimensions and surface finishes.

– Surface Treatment: Additional treatments, such as heat treatment or surface hardening, can further enhance performance characteristics.

Titanium Carbide:

– Machining: TiC components may require machining to meet tight tolerances and surface finish requirements.

– Coating: In some cases, TiC parts are coated with other materials for enhanced properties, such as corrosion resistance.

Quality Assurance for Tungsten Carbide and Titanium Carbide

Quality assurance (QA) is a critical aspect of the manufacturing process for both tungsten carbide and titanium carbide. It ensures that the materials meet international standards and are suitable for their intended applications.

Relevant International Standards

- ISO 9001: This quality management standard is applicable to all manufacturing sectors, ensuring that companies consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For industries like oil and gas, the American Petroleum Institute (API) sets standards that ensure the reliability and safety of materials used in critical applications.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): This involves continuous monitoring during manufacturing processes to detect and correct deviations in real-time.

- Final Quality Control (FQC): Finished products undergo rigorous testing and inspection to verify their performance and compliance with specifications.

Common Testing Methods

- Hardness Testing: Techniques such as Vickers or Rockwell hardness tests are used to measure the hardness of the materials.

- Microstructure Analysis: Scanning electron microscopy (SEM) and X-ray diffraction (XRD) are employed to analyze the microstructure and phase composition.

- Density Measurement: Techniques like Archimedes’ principle are used to ensure that the density meets specified standards.

Verifying Supplier Quality Control

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are actionable strategies:

- Supplier Audits: Conduct regular audits of suppliers to evaluate their manufacturing processes and quality assurance systems. This can be done through on-site visits or third-party inspection services.

- Request Quality Reports: Ask suppliers for detailed quality control reports, including IQC, IPQC, and FQC data, to assess their compliance with international standards.

- Third-Party Certifications: Look for suppliers who have third-party certifications that validate their adherence to international quality standards, such as ISO 9001 or industry-specific certifications.

Quality Control and Certification Nuances for International Buyers

When sourcing tungsten carbide and titanium carbide, B2B buyers must consider the following nuances:

- Cultural Differences: Understanding the cultural context of suppliers in different regions can influence communication and expectations regarding quality.

- Logistics and Compliance: Ensure that suppliers comply with local regulations in their respective countries, as this can affect the quality and certification of materials.

- Traceability: Verify that suppliers can provide traceability for their materials, ensuring that they can track the origin and processing history of their products.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can make well-informed decisions that enhance their supply chain efficiency and product reliability.

Related Video: BMW 5 Series (2024) PRODUCTION 🇩🇪 Car Manufacturing Process

Comprehensive Cost and Pricing Analysis for tungsten carbide vs titanium carbide Sourcing

Cost Components for Tungsten Carbide vs Titanium Carbide Sourcing

When evaluating the cost structure for tungsten carbide (WC) and titanium carbide (TiC), several critical components come into play. Understanding these elements can significantly impact decision-making for international B2B buyers.

-

Materials: The primary cost driver in sourcing either material is the raw material cost. Tungsten, being rarer and more expensive than titanium, typically results in higher material costs for WC. Current market prices fluctuate, but TiC may still present a more economical option depending on the application and required properties.

-

Labor: Labor costs associated with manufacturing can vary based on location and the complexity of the production process. Generally, TiC may require less intensive labor due to its simpler manufacturing processes compared to WC, which often necessitates more skilled labor for handling its dense and tough structure.

-

Manufacturing Overhead: Overhead costs, which include utilities, equipment maintenance, and facility expenses, are usually higher for tungsten carbide due to the energy-intensive processes involved in its production. Both materials require stringent quality controls that can add to overhead costs.

-

Tooling: The initial tooling investment for producing WC is often higher, given its hardness and the need for specialized equipment. For TiC, while tooling costs can be lower, customization for specific applications can increase expenses.

-

Quality Control (QC): The QC process for both materials is crucial, especially for industries like aerospace and mining where failures can have severe consequences. Maintaining certifications and compliance with international standards can add to the cost, particularly for TiC, which might be scrutinized more due to its unique properties.

-

Logistics: Shipping costs can be a significant factor, particularly for international buyers. The dense nature of tungsten carbide can lead to higher transportation costs compared to the lighter titanium carbide. Furthermore, customs duties and import tariffs should be factored into the total logistics costs.

-

Margin: Suppliers often build their margins based on the material’s performance and market demand. Tungsten carbide suppliers might charge a premium due to its superior hardness and wear resistance, while TiC may be priced competitively to attract buyers looking for a balance between performance and cost.

Illustrative Image (Source: Google Search)

Price Influencers

Several factors can influence pricing when sourcing these materials:

-

Volume/MOQ: Purchasing in bulk or meeting minimum order quantities (MOQ) can lead to significant cost reductions. Suppliers often provide discounts for larger orders, making it advantageous for buyers to consolidate their purchases.

-

Specifications/Customization: Custom specifications may increase costs due to additional processing and material requirements. Buyers should clearly define their needs to avoid unexpected expenses.

-

Quality/Certifications: Materials that meet specific industry standards often come at a premium. Ensure that suppliers provide necessary certifications to avoid compromising quality.

-

Supplier Factors: The reputation and reliability of suppliers play a critical role. Established suppliers with proven track records may charge higher prices but can offer better quality assurance and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the final cost due to variations in shipping and insurance responsibilities.

Buyer Tips

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiation: Always negotiate pricing and terms with suppliers. Leverage volume purchases and long-term contracts to secure better rates.

-

Total Cost of Ownership (TCO): Consider not just the upfront costs but the TCO, which includes maintenance, operational efficiency, and lifespan. Often, investing in higher-quality materials can lead to lower TCO in the long run.

-

Pricing Nuances: Be aware of regional pricing differences and market fluctuations. Prices for raw materials can vary significantly by region, affecting overall sourcing costs.

-

Research and Comparison: Conduct thorough research and compare multiple suppliers. Understanding the market landscape can provide leverage during negotiations and help identify the best value.

Disclaimer

The prices and cost estimates provided in this analysis are indicative and may vary based on market conditions, supplier relationships, and specific project requirements. Buyers should conduct their own due diligence to obtain accurate and up-to-date pricing information.

Spotlight on Potential tungsten carbide vs titanium carbide Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘tungsten carbide vs titanium carbide’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for tungsten carbide vs titanium carbide

Understanding the technical properties and trade terminology related to tungsten carbide (WC) and titanium carbide (TiC) is essential for B2B buyers seeking to make informed purchasing decisions. Here, we outline the critical specifications and common jargon that can influence your procurement process.

Key Technical Properties

-

Hardness

– Definition: Hardness is a measure of a material’s resistance to deformation, typically quantified using the Vickers hardness test (HV).

– B2B Importance: For applications requiring high wear resistance, tungsten carbide (1800-2400 HV) is ideal for cutting tools and mining equipment, while titanium carbide (2800-3200 HV) excels in extreme wear environments, such as thermal barrier coatings. -

Density

– Definition: Density is the mass per unit volume of a material, expressed in grams per cubic centimeter (g/cm³).

– B2B Importance: Tungsten carbide has a high density (15 g/cm³), making it suitable for applications where weight aids energy transfer. Conversely, titanium carbide’s lower density (4.9 g/cm³) is advantageous in lightweight applications, such as aerospace components. -

Compressive Strength

– Definition: Compressive strength is the capacity of a material to withstand axial loads without failure, measured in megapascals (MPa).

– B2B Importance: Tungsten carbide can endure crushing forces up to 6000 MPa, making it suitable for heavy-duty applications. Titanium carbide, with a compressive strength of 4000-5000 MPa, is better suited for applications requiring high hardness with less weight. -

Thermal Conductivity

– Definition: Thermal conductivity measures a material’s ability to conduct heat, expressed in watts per meter per kelvin (W/m·K).

– B2B Importance: Tungsten carbide has higher thermal conductivity (84-100 W/m·K), beneficial in high-temperature applications. In contrast, titanium carbide’s lower conductivity (21-25 W/m·K) is advantageous for thermal barrier coatings, preventing heat transfer. -

Oxidation Resistance

– Definition: Oxidation resistance refers to a material’s ability to withstand degradation in the presence of oxygen at elevated temperatures.

– B2B Importance: Titanium carbide can resist oxidation up to 800°C, making it suitable for high-temperature environments. Tungsten carbide, however, is prone to oxidation above 500°C, limiting its use without protective coatings.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships can help buyers identify reliable suppliers for tungsten carbide and titanium carbide products, ensuring quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ is crucial for budgeting and inventory management, especially for B2B buyers who may need large quantities of carbide materials for production. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting price quotes for specific products or services.

– Significance: Issuing RFQs allows buyers to compare prices and terms from multiple suppliers, ensuring competitive sourcing of tungsten carbide and titanium carbide. -

Incoterms

– Definition: Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions.

– Significance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost implications when sourcing materials across borders. -

Cermet

– Definition: A cermet is a composite material made of ceramic and metallic materials, often used to enhance toughness and wear resistance.

– Significance: Recognizing the importance of cermets can help buyers evaluate options for tungsten carbide or titanium carbide products, particularly in applications requiring improved durability.

Illustrative Image (Source: Google Search)

By understanding these essential properties and trade terms, international B2B buyers can make more informed decisions, ensuring they select the right material for their specific industrial applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tungsten carbide vs titanium carbide Sector

Market Overview & Key Trends

The tungsten carbide (WC) and titanium carbide (TiC) markets are driven by a combination of global industrial demand and technological advancements. Key sectors such as aerospace, mining, and manufacturing are increasingly adopting these materials due to their superior hardness, wear resistance, and thermal stability. In regions like Africa and South America, the growth of mining operations is a significant factor, with tungsten carbide being favored for cutting tools and drill bits due to its durability. Meanwhile, Europe, particularly Germany, is witnessing a shift towards titanium carbide for applications requiring lightweight materials without compromising strength, especially in high-performance automotive and aerospace components.

Emerging trends include the integration of advanced manufacturing technologies such as additive manufacturing and laser sintering, which are revolutionizing how these materials are processed and applied. Buyers should note the increasing emphasis on local sourcing to mitigate supply chain disruptions caused by geopolitical tensions and the pandemic. Moreover, the rise of digital procurement platforms is enabling international B2B buyers to access a broader range of suppliers, facilitating competitive pricing and improved material traceability.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal concern in the sourcing of tungsten carbide and titanium carbide. The extraction and processing of raw materials for these compounds can have significant environmental impacts, including habitat destruction and pollution. Therefore, international buyers must prioritize suppliers that adhere to sustainable practices, such as responsible mining and recycling initiatives.

Ethical supply chains are increasingly important, particularly for buyers in Europe and the Middle East, where regulatory frameworks are tightening around environmental standards. Certifications such as ISO 14001 for environmental management and adherence to the OECD Guidelines for Multinational Enterprises can serve as indicators of a supplier’s commitment to sustainability. Additionally, the adoption of “green” materials and processes is gaining traction; for instance, manufacturers are exploring the use of recycled tungsten carbide to reduce waste and energy consumption. Buyers should seek partnerships with suppliers who demonstrate transparency in their sourcing practices and sustainability credentials.

Brief Evolution/History

The use of tungsten carbide dates back to the early 20th century, primarily in cutting tools and industrial applications, owing to its unmatched hardness and wear resistance. Titanium carbide, on the other hand, gained traction in the 1960s and 70s, particularly in high-temperature applications and aerospace due to its lightweight properties and thermal stability. Over the decades, both materials have evolved through advancements in metallurgy and manufacturing techniques, leading to enhanced performance characteristics that cater to modern industrial needs. This evolution reflects an ongoing commitment to improving material properties, making them indispensable in high-performance applications across various sectors.

Overall, understanding the market dynamics, sourcing trends, and sustainability challenges in the tungsten carbide vs. titanium carbide sector enables B2B buyers to make informed decisions that align with both operational goals and ethical standards.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of tungsten carbide vs titanium carbide

-

What key factors should I consider when vetting suppliers for tungsten carbide and titanium carbide?

When vetting suppliers, assess their experience and reputation in the industry. Check for certifications like ISO 9001 or equivalent quality assurance standards, which indicate a commitment to quality. Additionally, request samples to evaluate material properties and performance. It’s also prudent to review customer testimonials and case studies to understand their reliability and service quality. Ensure the supplier can provide documentation regarding material specifications and compliance with international standards, especially if you are sourcing from different regions. -

Can tungsten carbide and titanium carbide be customized for specific applications?

Yes, both tungsten carbide and titanium carbide can be customized based on specific application requirements. Suppliers often offer variations in particle size, composition, and coating options to enhance performance in particular environments. Discuss your application’s unique demands with potential suppliers to determine the best formulations or modifications available. It’s important to ensure that the customization aligns with your production processes and end-use scenarios to maximize efficiency and longevity. -

What are typical minimum order quantities (MOQs) and lead times for tungsten carbide and titanium carbide?

MOQs vary significantly based on the supplier, product type, and customization level. Generally, for standard products, MOQs can range from 100 kg to several tons. Lead times typically range from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production capabilities. For customized solutions, expect longer lead times due to the design and manufacturing process. Always confirm these details upfront to ensure they align with your project timelines and inventory needs. -

What payment terms are commonly offered by suppliers of tungsten carbide and titanium carbide?

Payment terms can vary widely among suppliers. Common arrangements include upfront payments, partial payments upon order confirmation, and balance payments before shipping. For larger orders, you may negotiate more favorable terms, such as payment upon delivery or extended credit terms. It’s advisable to establish clear payment terms in the contract to avoid misunderstandings. Consider using secure payment methods that offer buyer protection, especially when dealing with international suppliers. -

How can I ensure quality assurance and certifications for tungsten carbide and titanium carbide products?

To ensure quality, request certificates of compliance and material test reports from your suppliers. Look for certifications from recognized bodies that validate the quality and performance of the materials, such as ASTM standards. Conducting third-party inspections or audits can further verify the supplier’s adherence to quality standards. Establish a clear quality assurance process, including acceptance criteria, to assess the received products against specified requirements. -

What logistical considerations should I keep in mind when importing tungsten carbide and titanium carbide?

When importing these materials, consider factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner experienced in handling industrial materials to ensure timely and safe delivery. Be aware of the import documentation required, including bills of lading, customs declarations, and safety data sheets. Additionally, factor in the lead times for shipping, which can vary based on the origin and destination countries, particularly when coordinating with suppliers from different regions. -

How should I handle disputes with suppliers regarding tungsten carbide and titanium carbide orders?

To effectively manage disputes, establish clear communication channels with your suppliers from the outset. Include dispute resolution clauses in your contracts, specifying the process for addressing issues such as quality discrepancies, delivery delays, or payment disputes. If a disagreement arises, document all communications and evidence related to the issue. Consider mediation or arbitration as alternatives to litigation, as these methods can be less costly and time-consuming. Always aim for a collaborative approach to maintain a positive business relationship. -

What are the main differences in applications for tungsten carbide versus titanium carbide?

Tungsten carbide is primarily used in applications requiring exceptional hardness and wear resistance, such as cutting tools, mining equipment, and heavy-duty machinery. Its high density and toughness make it ideal for high-stress environments. Conversely, titanium carbide is favored in applications where thermal stability and lightweight properties are essential, such as aerospace components and thermal barrier coatings. Understanding these differences helps in selecting the right material for your specific industrial needs, ensuring optimal performance and longevity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tungsten carbide vs titanium carbide

In conclusion, the strategic sourcing of tungsten carbide and titanium carbide requires a nuanced understanding of their unique properties and applications. Tungsten carbide, with its superior hardness and density, is ideal for high-stress environments such as cutting tools and mining equipment. Conversely, titanium carbide excels in extreme thermal conditions, making it suitable for aerospace applications and thermal barrier coatings.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these distinctions is vital for optimizing procurement strategies. Investing in the right material not only enhances product performance but also reduces long-term costs associated with wear and maintenance.

As industries continue to evolve, the demand for advanced materials will only increase. Buyers should leverage strategic sourcing to not only secure competitive pricing but also ensure access to high-quality materials that meet specific operational needs. Engage with trusted suppliers and industry experts to make informed decisions that drive innovation and efficiency in your operations. The future of high-performance materials is promising, and proactive sourcing will be the cornerstone of success.